Magnetic light-enzyme composite catalyst and preparation method thereof

A composite catalyst and magnetic technology, which is applied in the field of new magnetic photoenzyme composite catalysts, can solve the problems of immobilized enzymes and difficult recovery of TiO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (1') The prepared magnetic nano-TiO 2 Nanoparticles dispersed in deionized water to form a suspension, magnetic nano-TiO 2 Fe 3 o 4 The content is 4% (w / w), magnetic nano TiO 2 The concentration is 2% (w / v), and then put it in the refrigerator for later use.

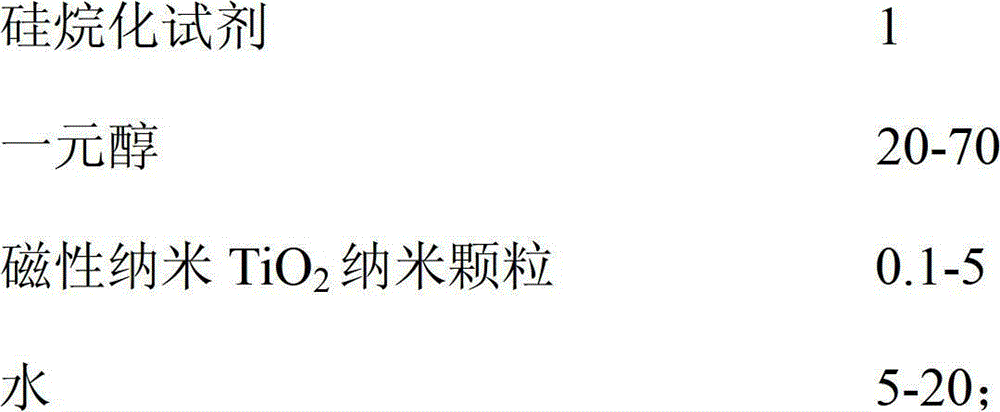

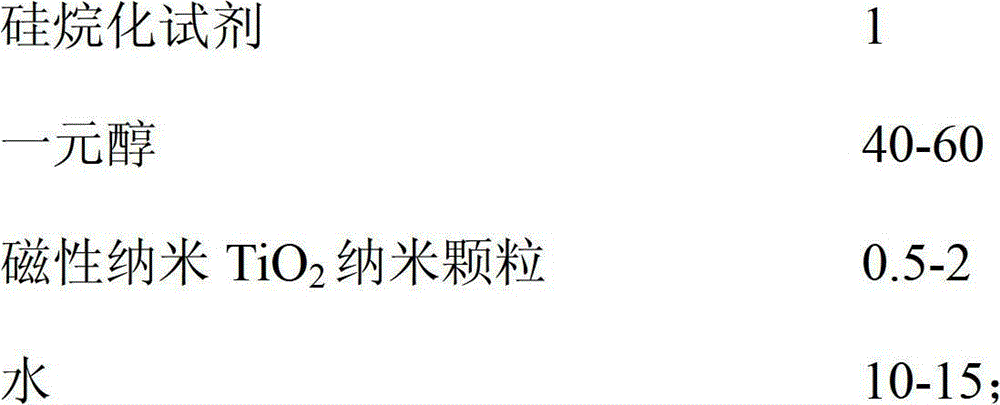

[0079] (1) Add 2 g of silylating reagent, 120 g of monohydric alcohol, and magnetic nano-TiO to the reaction system in sequence at room temperature (25°C) and stirring at 200 rpm. 2 4g of nanoparticles, 30g of water, adjust the pH value to 5, and fully stir for 30min to obtain a silanization reaction solution;

[0080] (2) The silanization reaction solution was reacted for 20 minutes under nitrogen protection, heated in a water bath at 50°C, equipped with a reflux device, and 120W ultrasonic conditions, and the resulting product was magnetically separated to obtain silanized magnetic nano-TiO 2 nanoparticles;

[0081] (3) Silanized magnetic nano-TiO 2 Add nanoparticles to 2% (w / v) sodium iminodiacetic acid ...

Embodiment 2

[0087] (1') The prepared magnetic nano-TiO 2 Nanoparticles dispersed in deionized water to form a suspension, magnetic nano-TiO 2 Fe 3 o 4 The content is 1% (w / w), and its concentration is 10% (w / v), and then put it in the refrigerator for later use;

[0088] (1) Add 2 g of silylating reagent, 80 g of monohydric alcohol, and magnetic nano-TiO 2 1g of nanoparticles, 20g of water, adjust the pH value to 3, and fully stir for 10 minutes to obtain a silanization reaction solution;

[0089] (2) The silanization reaction solution was reacted for 60min under nitrogen protection, heated in a water bath at 30°C, equipped with a reflux device, and 60W ultrasonic conditions, and the obtained silanized magnetic nano-TiO 2 After magnetic separation of nanoparticles, silanized magnetic nano-TiO 2 nanoparticles;

[0090] (3) Silanized magnetic nano-TiO 2 Nanoparticles were added to 0.5% (w / v) sodium iminodiacetic acid solution, the particle concentration was 1% (w / v), the pH was adjus...

Embodiment 3

[0096] (1') The prepared magnetic nano-TiO 2 Nanoparticles dispersed in deionized water to form a suspension, magnetic nano-TiO 2 Fe 3 o 4 The content is 2% (w / w), and its concentration is 5% (w / v), and then put it in the refrigerator for later use;

[0097] (1) Add 2 g of silylating reagent, 100 g of monohydric alcohol, and magnetic nano-TiO to the reaction system in sequence at room temperature (25°C) and stirring at 300 rpm. 2 2.5g of nanoparticles, 25g of water, adjust the pH value to 4, and fully stir for 20 minutes to obtain a silanization reaction solution;

[0098] (2) The silanization reaction solution was reacted for 40 minutes under nitrogen protection, water bath heating at 40°C, reflux device, and 90W ultrasonic conditions to obtain silanized magnetic nano-TiO 2 After magnetic separation of nanoparticles, silanized magnetic nano-TiO 2 nanoparticles;

[0099] (3) Silanized magnetic nano-TiO 2Nanoparticles were added to 1% (w / v) sodium iminodiacetic acid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com