Preparation method of iron phosphate with high tap density

A technology of tap density and iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as low tap density, high energy consumption, and fluctuations in carbon content, and achieve high tap density and specific The effect of small surface area and dense growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

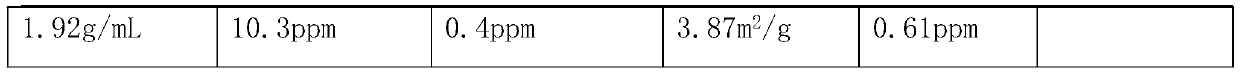

Examples

Embodiment 1

[0035] A method for preparing ferric phosphate with high tap density, which comprises the following steps: mixing red phosphorus and iron powder under an inert atmosphere, then adding alcohol and putting them into a ball mill for ball milling, and then calcining at high temperature in an atmosphere furnace under an inert atmosphere to obtain Phosphorus-iron alloy body; the molar ratio of red phosphorus to iron powder is 1.015:1.

[0036] The inert atmosphere is nitrogen, and the oxygen content in the inert atmosphere is lower than 50ppm.

[0037] In the ball milling process, the mass ratio of the material to the alcohol is 1:0.85. The inner ball of the ball mill is made of zirconia balls. After 3 hours, the calcination temperature is 580°C, and it is taken out after cooling to the temperature <50°C.

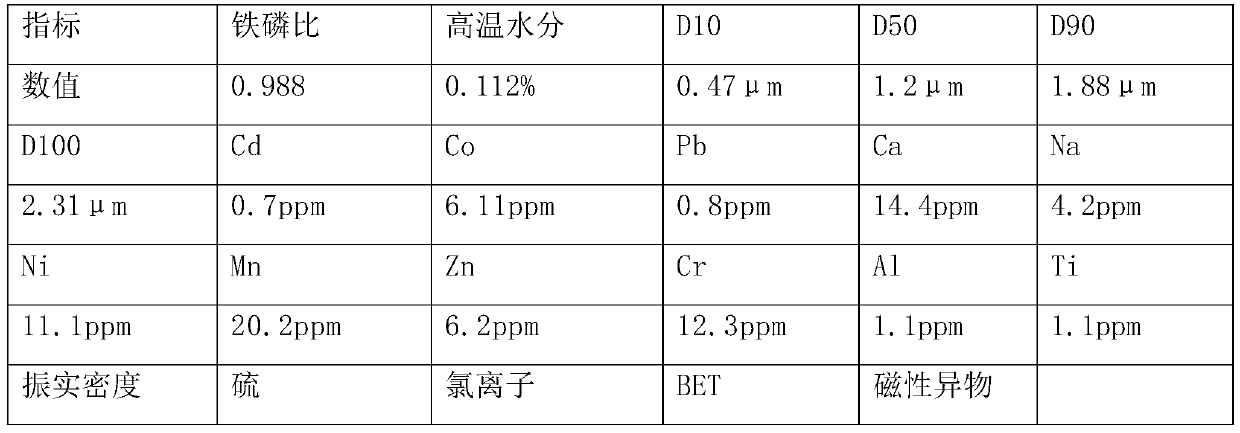

[0038] The detection data of iron powder are as follows:

[0039] project Fe Fsss particle size O C Ni co data 99.64% 1.2μm 0.09% 0.02% 23.1ppm ...

Embodiment 2

[0053] A method for preparing ferric phosphate with high tap density, which comprises the following steps: mixing red phosphorus and iron powder under an inert atmosphere, then adding alcohol and putting them into a ball mill for ball milling, and then calcining at high temperature in an atmosphere furnace under an inert atmosphere to obtain Ferrophosphorus alloy body;

[0054] Put the obtained phosphorus-iron alloy body into a rotary furnace for oxidative calcination through oxygen-enriched gas, the calcination time is 4.8h, and the calcination temperature is 640°C to obtain a calcined powder;

[0055] The calcined powder is pulverized by airflow to obtain a powder with a particle size of 1.2 μm, which is then screened and electromagnetically removed to obtain anhydrous ferric phosphate.

[0056] The purity of the red phosphorus is 99.58%, the purity of the iron powder is 99.61%, the Fsss particle size is 1.7 μm, Ni / Co≤50ppm, Zn / Cd / Pb≤30ppm, Ca / Mg / Na / K≤100ppm.

[0057] The mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com