A kind of manufacturing method of high energy density pouch battery

A high-energy-density, soft-pack battery technology, applied in the field of high-energy-density soft-pack battery manufacturing, can solve the problems of low initial charge and discharge efficiency, affecting the capacity and energy density of lithium-ion batteries, to compensate for irreversible capacity loss, improve The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

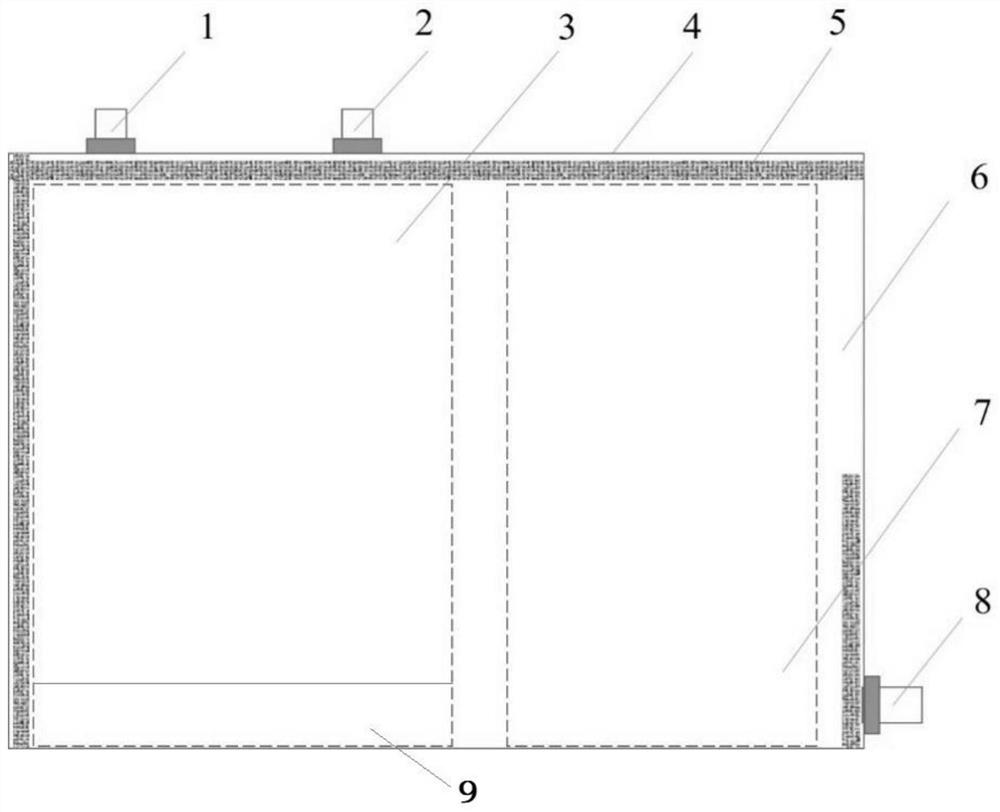

[0029] Such as figure 1 As shown, an in-situ pre-lithiation structure of a high-energy-density soft-pack battery includes a soft-pack battery composed of an aluminum-plastic film 4 and a lithium battery core 3, and the bottom of the lithium battery core 3 is wrapped with an aluminum foil auxiliary electrode 9. The battery core 3 and the aluminum foil auxiliary electrode 9 are separated by a separator.

[0030] The lithium battery roll core 3 includes a positive electrode sheet, a negative electrode sheet and a separator (not shown in the figure), the positive electrode ear 1 of the positive electrode sheet and the negative electrode ear 2 of the negative electrode sheet are located on the top of the pouch battery, and the end of the aluminum foil auxiliary electrode 9 is welded with aluminum plastic The composite tab 8 and the aluminum-plastic composite tab 8 are drawn from the bottom corner of the air bag 7 of the pouch battery.

[0031] One side of the air bag 7 is provided...

Embodiment 2

[0033] A method for manufacturing a high energy density pouch battery, the process is as follows:

[0034] Using lithium cobalt oxide as the positive electrode active material, the positive electrode sheet is prepared according to the traditional process; the nano-silicon / carbon composite material is used as the negative electrode active material, and the negative electrode sheet is prepared according to the traditional process; the positive electrode sheet, the negative electrode sheet, and the diaphragm are wound to obtain the winding core , where the positive tab and the negative tab are located on the top of the core, and a layer of aluminum foil is wrapped at the bottom of the core as an auxiliary electrode. Both surfaces of the auxiliary electrode of the aluminum foil are covered with a separator to insulate the core of the battery. In the aluminum-plastic film, the aluminum-plastic composite tab is connected to the auxiliary electrode of the aluminum foil and drawn out f...

Embodiment 3

[0041] A method for manufacturing a high energy density pouch battery, the process is as follows:

[0042] Using lithium cobalt oxide as the positive electrode active material, the positive electrode sheet is prepared according to the traditional process; the silicon oxide / carbon composite material is used as the negative electrode active material, and the negative electrode sheet is prepared according to the traditional process; the positive electrode sheet, the negative electrode sheet, and the diaphragm are wound to obtain the core , where the positive tab and the negative tab are located on the top of the core, and a layer of aluminum foil is wrapped at the bottom of the core as an auxiliary electrode. Both surfaces of the auxiliary electrode of the aluminum foil are covered with a separator to insulate the core of the battery. In the aluminum-plastic film, the aluminum-plastic composite tab is connected to the auxiliary electrode of the aluminum foil and drawn out from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com