Double-potential anode electrolysis device and method

An anode electrolysis and electrolysis device technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problem of increasing the complexity of the electrolysis device, the inability of the electrolyzer to achieve coordinated oxidation, and the separation of time and space Large and other problems, to achieve significant application value, low energy consumption, high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

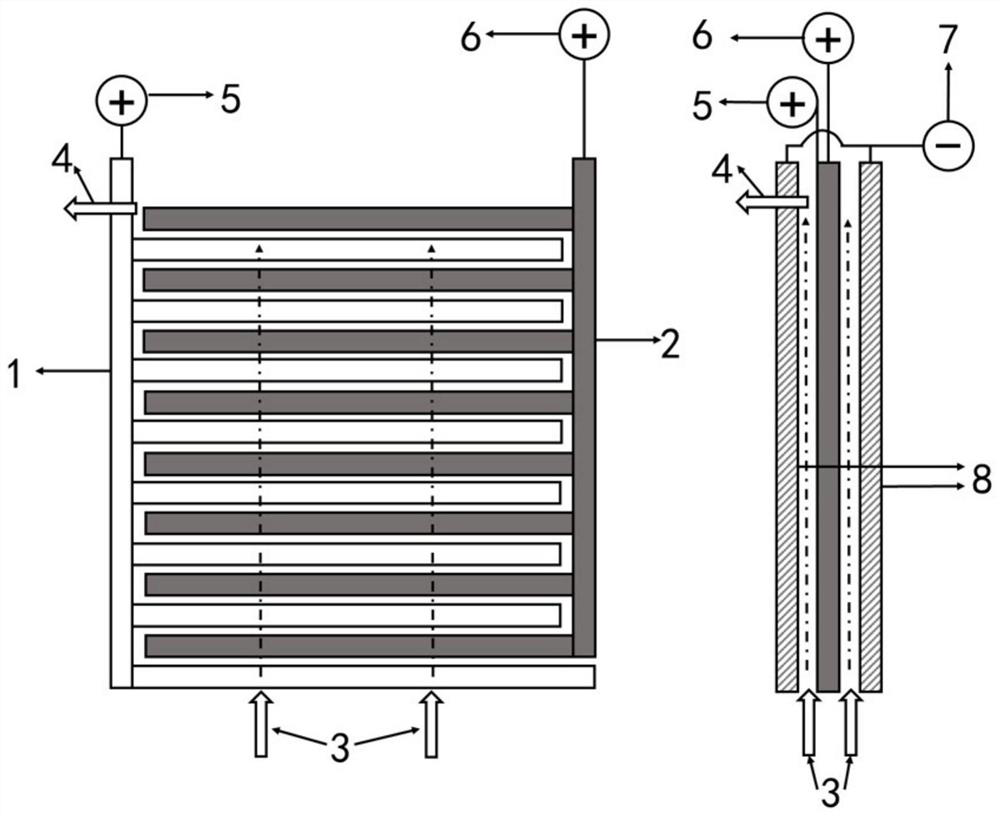

[0024] (1) Process the anode 1, the base of the anode 1 is titanium metal, the coating is ruthenium oxide, and the size of the anode 1 is 100mm*100mm*1mm. Anode 1 The electrode group includes 10 rectangular electrodes with a length, width, and thickness of 100mm*3mm*1mm. The width of a single anode is 3mm, and the distance between each anode is 7mm.

[0025] (2) Process the anode 2, the base of the anode 2 is titanium metal, the coating is titanium black, and the size of the anode 2 is 100mm*100mm*1mm. The anode 2 electrode group includes 10 rectangular electrodes with a length, width, and thickness of 100mm*3mm*1mm. The width of a single anode is 3mm, and the distance between each anode is 7mm.

[0026] (3) In the plate and frame electrolyzer, the anode 1 electrode group and the electrode 2 electrode group are arranged in a staggered manner and fixed in the center, such as figure 1 shown. The single electrode of anode 1 is placed between the two electrodes of anode 2, and t...

Embodiment 2

[0031] (1) Process the anode 1, the base of the anode 1 is titanium metal, the coating is iridium oxide, and the effective size of the anode 1 is about 100mm*90mm*0.5mm. The anode 1 electrode group includes 15 rectangular electrodes with a length, width, and thickness of 100mm*2mm*0.5mm. The width of a single anode is 2mm, and the distance between each anode is 4mm.

[0032] (2) Process the anode 2, the base of the anode 2 is titanium metal, the coating is titanium black, and the effective size of the anode 2 is about 100mm*90mm*0.5mm. The anode 2 electrode group includes 15 rectangular electrodes with a length, width, and thickness of 100mm*2mm*0.5mm. The width of a single anode is 2mm, and the distance between each anode is 4mm.

[0033] (3) In the plate and frame electrolyzer, the anode 1 electrode group and the electrode 2 electrode group are arranged in a staggered manner and fixed in the center, such as figure 1 shown. The single electrode of anode 1 is placed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com