Composite material for removing arsenic in water and preparation method thereof

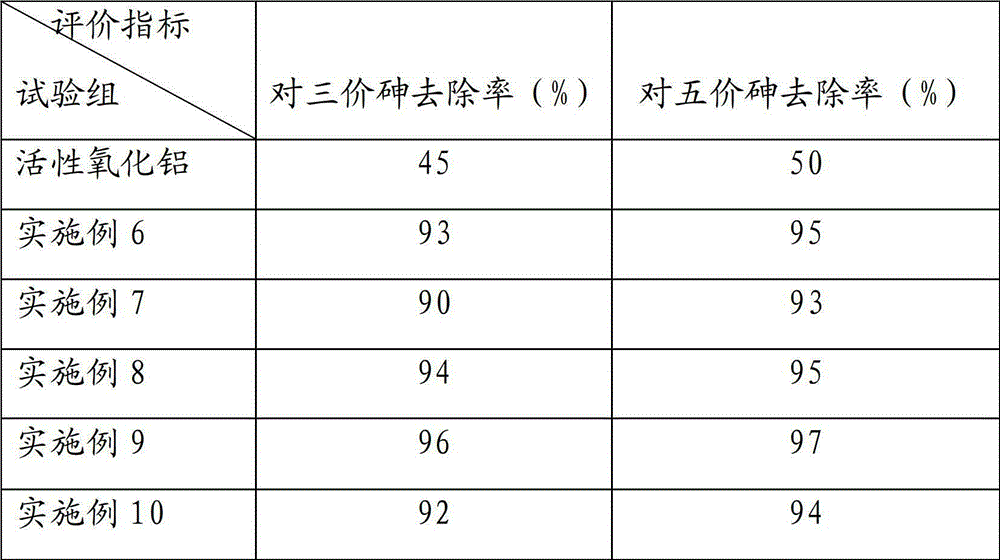

A composite material, water removal technology, applied in chemical instruments and methods, silicon compounds, other chemical processes, etc., can solve the problems of difficult separation and removal, poor removal of trivalent arsenic, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A composite material for removing arsenic in water according to the invention, comprising the following components in parts by weight: 100 parts of bentonite, 1 part of polyferric chloride, and hydrolyzed titanium salt (hydrolyzed titanium salt is the hydrolyzed product of titanium tetrachloride in water) 4.8 parts, the montmorillonite content is 75% in the described bentonite. The amount of the polyferric salt is calculated by the mass of the iron element; the amount of the polyferric chloride is calculated by the mass of the iron element, and the amount of the hydrolyzed titanium salt is calculated by the mass of the titanium element.

Embodiment 2

[0024] A composite material for removing arsenic in water according to the invention comprises the following components in parts by weight: 100 parts of bentonite, 6 parts of polyferric sulfate, and 4.8 parts of hydrolyzed titanium salt, and the content of montmorillonite in the bentonite is 85%. The amount of the polyferric sulfate is calculated by the mass of the iron element; the amount of the hydrolyzed titanium salt is calculated by the mass of the titanium element.

Embodiment 3

[0026] A composite material for removing arsenic in water according to the present invention comprises the following components in parts by weight, 100 parts of bentonite, 1 part of polyferric sulfate, hydrolyzed titanium salt (hydrolyzed titanium salt is titanium tetrachloride in hydrochloric acid and sulfuric acid solution hydrolyzate) 0.8 part, and the montmorillonite content is 80% in the described bentonite. The amount of the polyferric sulfate is calculated by the mass of the iron element; the amount of the hydrolyzed titanium salt is calculated by the mass of the titanium element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com