Surface plasmon resonance sensing element and manufacturing method thereof

A surface plasmon, sensing element technology, applied in the field of sensors for biological system detection, can solve the problems of low sensitivity, long film formation time, easy inactivation of biomolecules, etc., and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 The preparation of the surface-formylated magnetic nanoparticles of the present invention.

[0031] Surface aldylated Fe 3 o 4 / SiO 2 The specific preparation process of magnetic nanoparticles is: take 2.6g FeCl 3 ,6H 2 O, 1.0 g FeCl 2 4H 2 O and 0.425mL HCl (12mol L -1 ) was fully dissolved in 15 mL of deionized water, and transferred to the dropping funnel. 125mL concentration 1.5mol L -1 The NaOH solution was added into the three-necked flask, and the dropping funnel was opened under the condition of 80°C, and the mixed solution was added dropwise while fully stirring, and refluxed for 3h. The whole process requires nitrogen protection. After the reaction is completed, the Fe is separated by the action of a magnet. 3 o 4 Particles were thoroughly washed four times with deionized water. Disperse the precipitate into 100 mL of deionized water to obtain Fe 3 o 4 Magnetic Nanoparticle Solution. Take 0.724mL Fe 3 o 4 Add the magnetic nanoparticl...

Embodiment 2

[0037] The characterization of the magnetic nanoparticle of embodiment 2 surface aldylation

[0038] Fe 3 o 4 The magnetic nanoparticles are made of Fe 2+ and Fe 3+ The salt solution is prepared by co-precipitation under alkaline conditions. Its surface morphology can be characterized by transmission electron microscopy. Its spectral properties are detected by infrared spectroscopy and ultraviolet-visible absorption spectroscopy.

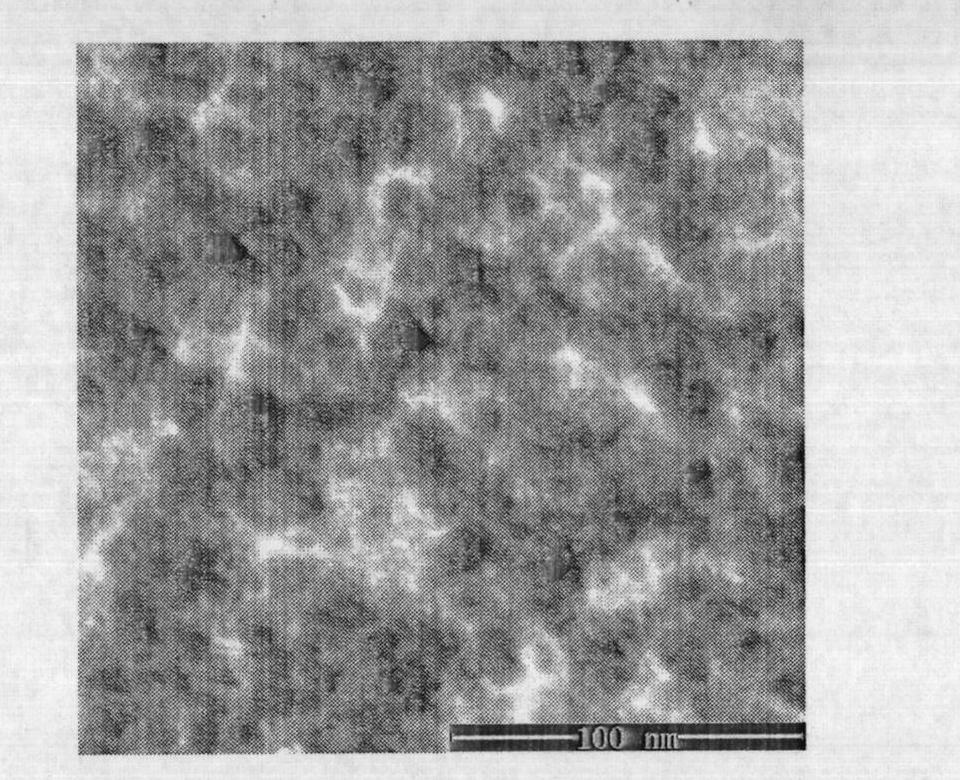

[0039] image 3 , Figure 4 , Figure 5 Respectively Fe 3 o 4 Magnetic nanoparticles, Fe 3 o 4 / SiO 2 Magnetic nanoparticles, Fe 3 o 4 / Ag / SiO 2 Electron microscope image of magnetic nanoparticles. Image 6 is the infrared spectrum of magnetic nanoparticles, (a) Fe 3o 4 Nanoparticles, (b)Fe 3 o 4 / SiO 2 Nanoparticles, (c)Fe 3 o 4 / Ag / SiO 2 Nanoparticles. from Image 6 It can be seen that Fe 3 o 4 Nanoparticles at 590cm -1 There is an obvious absorption peak at , which is because of the Fe-O structure it contains. while ...

Embodiment 3

[0040] Embodiment 3 Fabrication of the sensing element of the present invention.

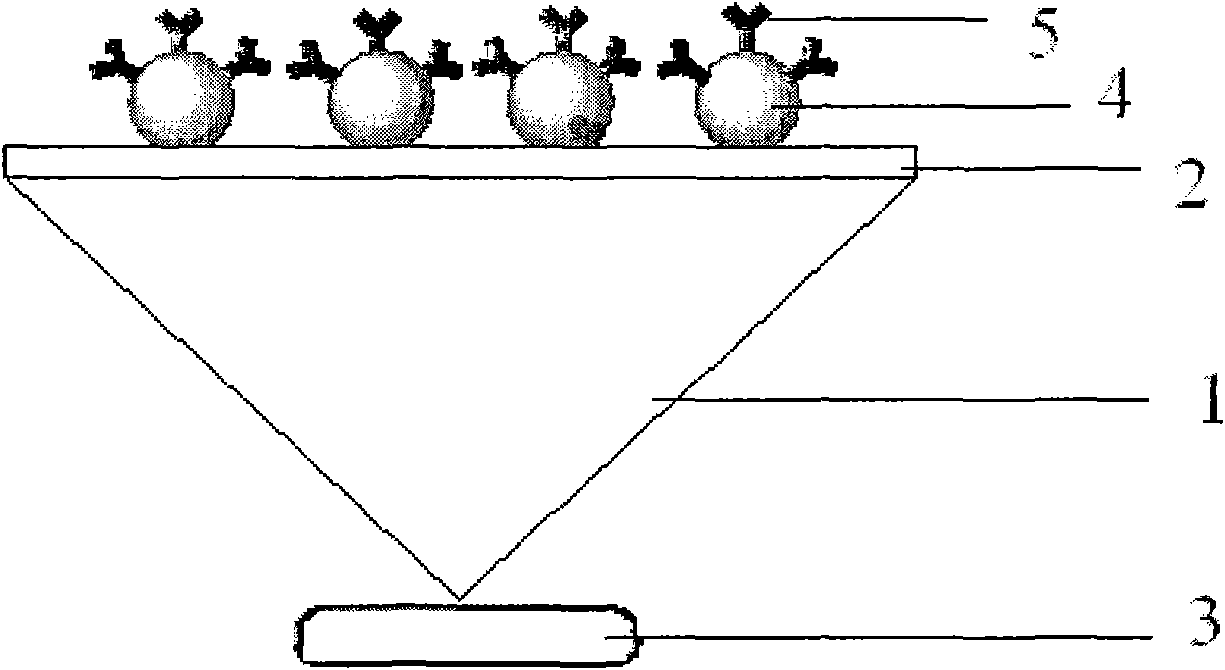

[0041] figure 2 is a schematic diagram of the sensing element based on magnetic nanoparticles of the present invention.

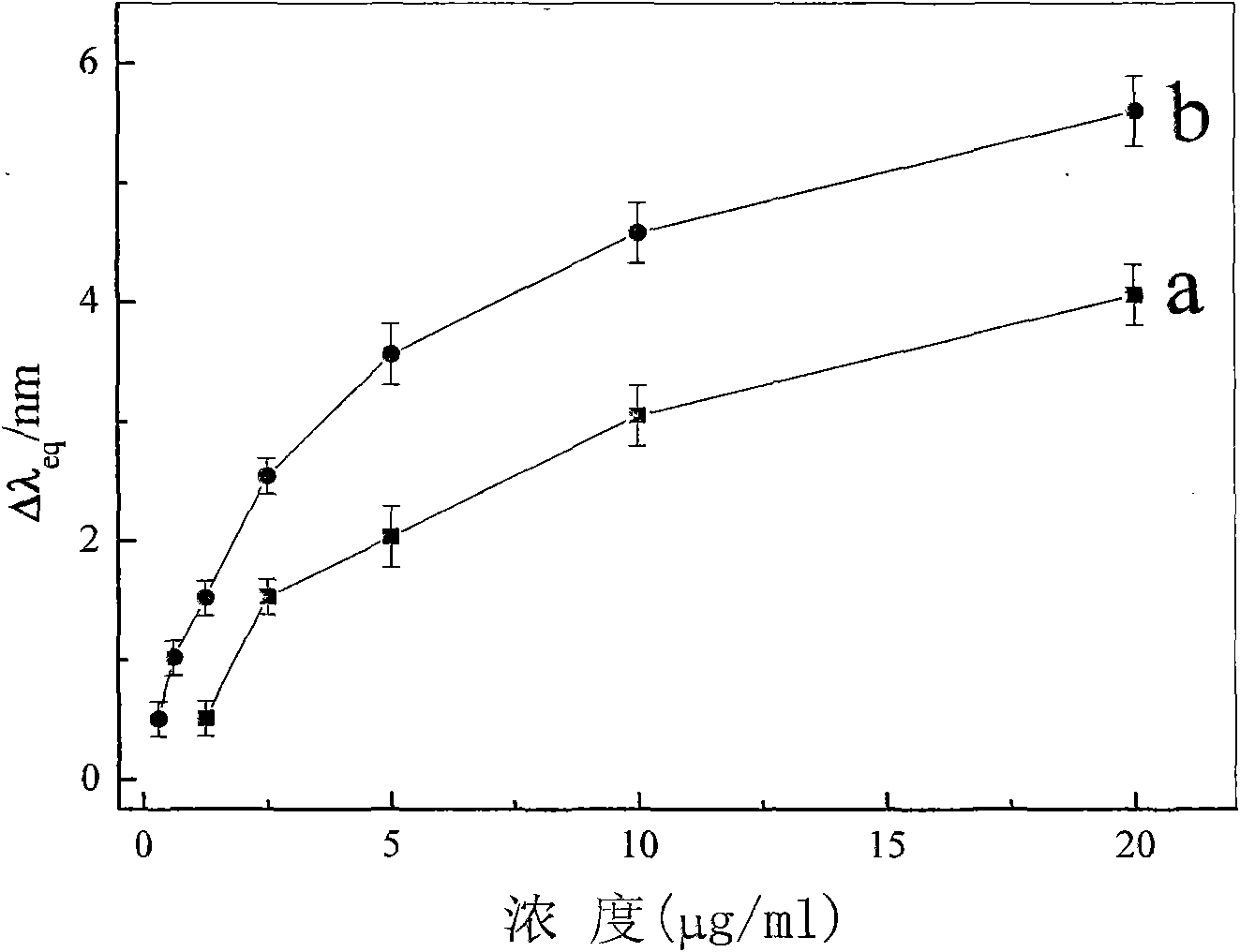

[0042] Two novel sensing elements based on magnetic nanoparticle modification assembled in the present invention. The specific implementation method is that the bottom surface of the glass prism coated with the metal film is placed above, then the flow cell is fixed above the glass prism, and the magnet is fixed below the glass prism. Inject PBS buffer solution into the flow cell as a baseline solution. Then inject surface aldehyde-modified Fe respectively 3 o 4 / SiO 2 Magnetic nanoparticles, Fe 3 o 4 / Ag / SiO 2 The magnetic nanoparticle solution was monitored in real time for 5 hours to observe the shift of its resonance wavelength. Due to the action of the magnet, the magnetic nanoparticles are easily fixed on the gold film, which leads to the change of the refracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com