Method for optimizing monocrystalline-silicon pyramid-structured textured face

A technology of pyramid structure and optimization method, which is applied in the field of alkali texturing process, can solve the problem of low conversion efficiency improvement, achieve the effect of improving uniformity, conversion efficiency and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

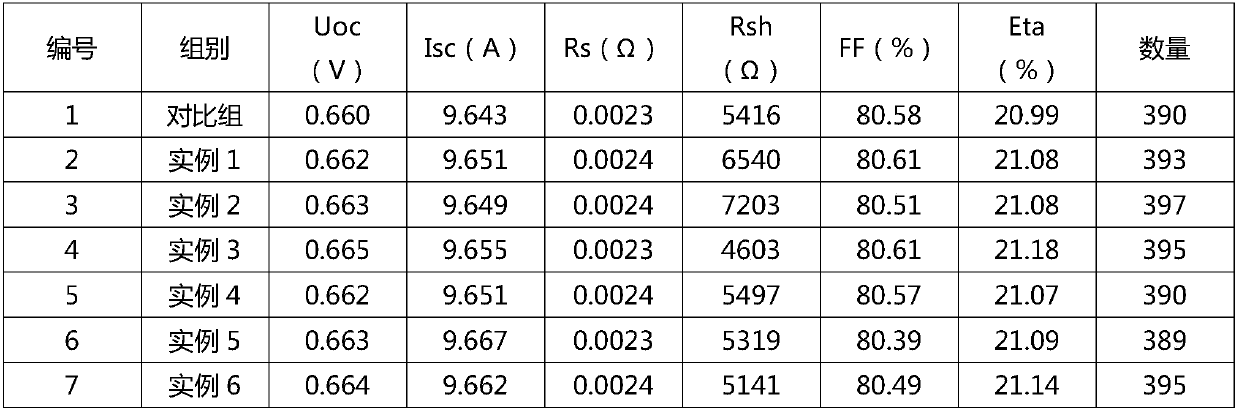

Examples

Embodiment 1

[0025] Embodiment 1, a kind of optimization method of monocrystalline silicon pyramid structure suede, concrete steps are:

[0026] Step (1) Add deionized water, hydrofluoric acid and hydrochloric acid into the pickling tank of the alkali texturing equipment, the weight-to-number ratio of the three is 6:1:3, start bubbling, and mix the solution for 5 minutes;

[0027] Step (2) the ozone produced by the ozone generator is fed into the circulation pump, and then pumped into the pickling tank by the circulation pump;

[0028] Step (3) Put the textured monocrystalline silicon wafer into the pickling tank, start bubbling, and keep it in the tank for 2mins, and complete subsequent washing, hot water slow pulling, and drying;

[0029] Among them, the ozone flow rate was maintained at 50L / min for 15 minutes before the monocrystalline silicon wafer was placed in the pickling tank, and the ozone flow rate was maintained at 15L / min during the process of placing the monocrystalline silico...

Embodiment 2

[0031] Embodiment 2, a kind of optimization method of monocrystalline silicon pyramid structure suede, concrete steps are:

[0032] Step (1) Add deionized water, hydrofluoric acid and hydrochloric acid into the pickling tank of the alkali texturing equipment, the weight-to-number ratio of the three is 6:1:3, start bubbling, and mix the solution for 10 minutes;

[0033] Step (2) the ozone produced by the ozone generator is fed into the circulation pump, and then pumped into the pickling tank by the circulation pump;

[0034] Step (3) Put the monocrystalline silicon wafer that has been textured into the pickling tank, start bubbling, and keep it in the tank for 5mins, and complete the subsequent washing, hot water slow pulling, and drying;

[0035] Among them, the ozone flow rate was maintained at 70L / min for 15 minutes before the monocrystalline silicon wafer was placed in the pickling tank, and the ozone flow rate was maintained at 35L / min during the process of placing the mon...

Embodiment 3

[0037] Embodiment 3, a kind of optimization method of monocrystalline silicon pyramid structure suede, concrete steps are:

[0038] Step (1) Add deionized water, hydrofluoric acid and hydrochloric acid into the pickling tank of the alkali texturing equipment, the weight-to-number ratio of the three is 6:1:3, start bubbling, and mix the solution for 8 minutes;

[0039] Step (2) the ozone produced by the ozone generator is fed into the circulation pump, and then pumped into the pickling tank by the circulation pump;

[0040] Step (3) Put the textured monocrystalline silicon wafer into the pickling tank, start bubbling, and keep it in the tank for 4mins, and complete subsequent washing, hot water slow pulling, and drying;

[0041] Among them, the ozone flow rate was maintained at 60L / min for 15 minutes before the monocrystalline silicon wafer was put into the pickling tank, and the ozone flow rate was kept at 25L / min during the process of putting the monocrystalline silicon wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com