Device and method for producing type II anhydrous gypsum from desulfurized gypsum

Anhydrous gypsum and desulfurized gypsum technology, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium sulfate, etc., can solve problems such as increased processing costs, poor stability, and close temperature, and improve resource utilization The effect of high efficiency, stable performance and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

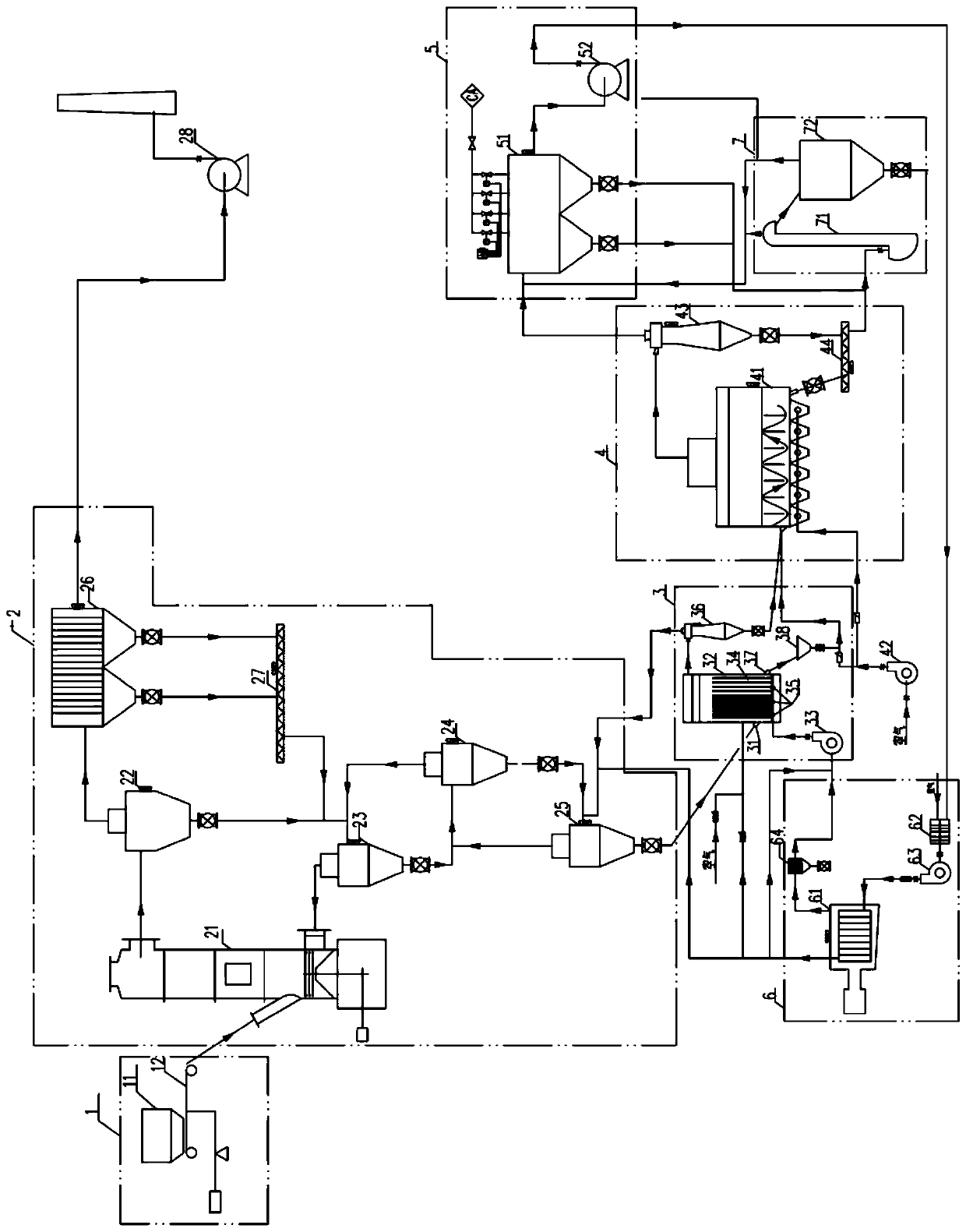

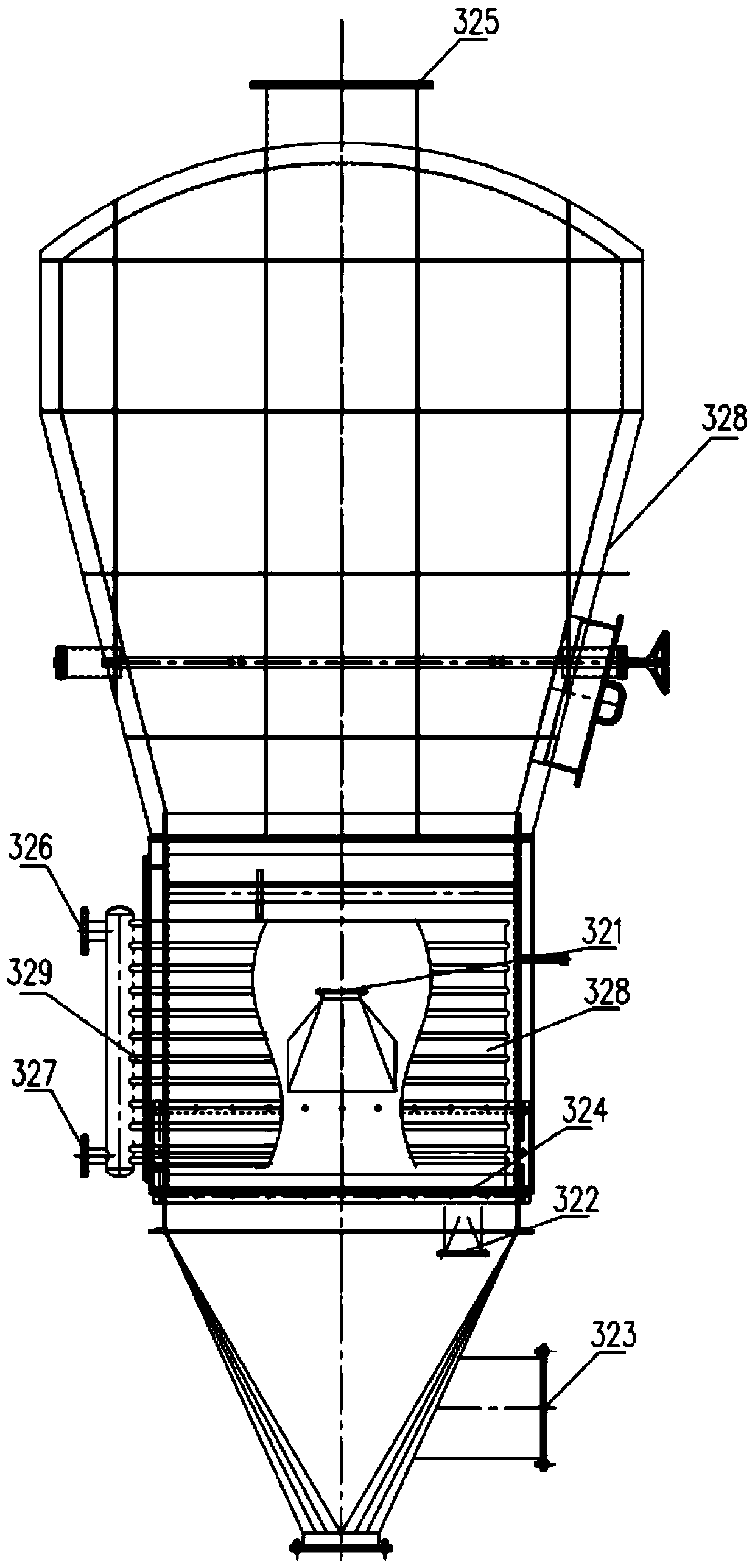

[0078] This embodiment provides a device for producing type II anhydrite from desulfurized gypsum, the structural connection diagram of the device is as follows figure 1 As shown, it includes a drying unit 2 , a calcining unit 3 and a product collection unit 7 connected in sequence, the drying unit 2 includes a crushing device 21 and at least one stage of drying device, and the calcining unit 3 includes a fluidized calcining device 32 .

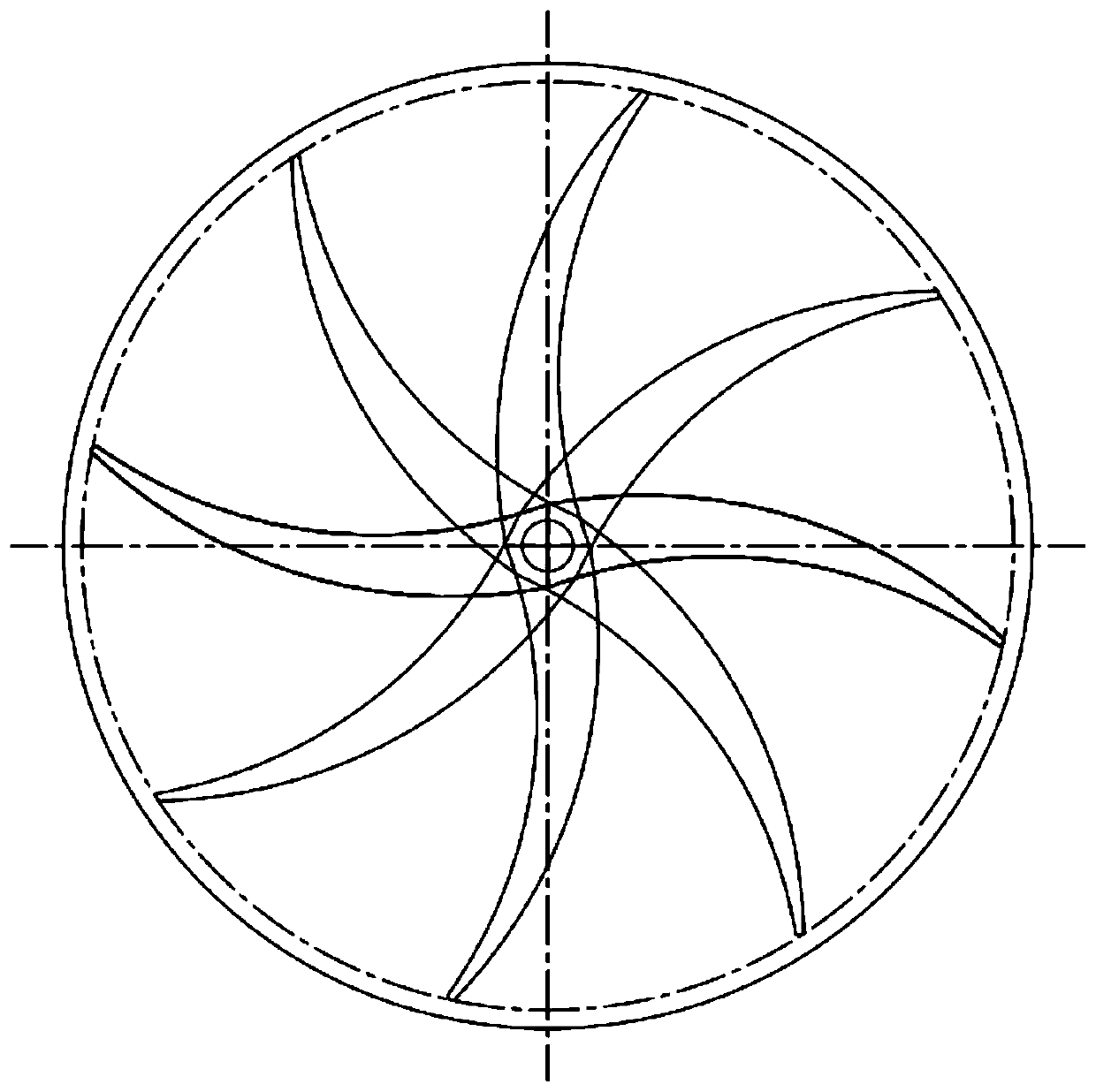

[0079] The crushing device 21 includes a forced air dryer, and a crushing cutter head is arranged below the feed port of the crushing device 21. The structural schematic diagram of the crushing cutter head is as follows: figure 2 As shown, the crushing cutter head is connected with a motor.

[0080] Described drying device comprises cyclone type drier, is divided into 4 stages, wherein first-stage drying device 22, secondary drying device 23, third-stage drying device 24, fourth-stage drying device 25 are connected successively; Solid separ...

Embodiment 2

[0090] This embodiment provides a device for producing type II anhydrite from desulfurized gypsum. The structure of the device refers to the structure in embodiment 1, the difference is that the drying device of the drying unit 2 includes two stages, two stages of drying The solid outlet of the device 33 is connected with the calcining unit 4 .

Embodiment 3

[0094] This embodiment provides a method for producing Type II anhydrite from desulfurized gypsum, said method is carried out using the device in Example 1, comprising the following steps:

[0095] (1) Crushing and drying the desulfurized gypsum by-product of the limestone-gypsum wet desulfurization process, the free water content of the desulfurized gypsum accounts for 12wt% of the total amount of desulfurized gypsum, and the particle size of the crushed raw material is less than 75 μm. 90%, the number of drying stages is 4, the temperature of the next stage of drying is higher than the temperature of the previous stage of drying, and the temperature of the last stage of drying is 350 ° C, to obtain type III anhydrite, the crushing and drying process Into the heat source gas;

[0096] (2) The type III anhydrite obtained in step (1) is subjected to fluidized calcination treatment, the temperature of the calcination treatment is 550° C., and the time of the calcination treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com