Hollow structure material as well as preparation method and use thereof

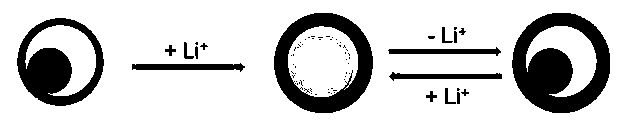

A technology with hollow structure and purpose, applied in the field of electrochemical energy storage, can solve problems such as poor cycle stability, and achieve the effect of easy realization and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

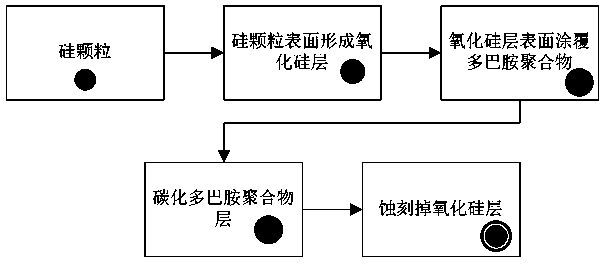

[0045] A method for preparing a hollow structure material, comprising the following steps:

[0046] 1) Using silicon particles as the original material, the surface of silicon particles is oxidized by heating. The silicon particles are placed in a tube-type rotary furnace and heated to 1050 degrees Celsius. During this process, water vapor is continuously introduced to speed up the oxidation rate. The surface of the silicon particles is heated at a high temperature to form an oxide layer (silicon dioxide layer) with a uniform thickness, and the intermediate product A is obtained. Wherein, the thickness of the oxide layer is controlled by adjusting the high temperature heating time.

[0047] 2) Add the intermediate product A obtained in step 1) to tromethamine buffer solution (PH=8, 0.1M) containing dopamine. The mass ratio of product A, dopamine and tromethamine buffer solution is 3:1:60, the above mixed solution is stirred, and after 24 hours of stirring, the surface of pro...

Embodiment 2

[0054] A method for preparing a hollow structure material, comprising the following steps:

[0055] 1) Using silicon particles as the original material, the surface of silicon particles is oxidized by heating. The silicon particles are heated to 1000 degrees Celsius in a tube-type rotary furnace, and water vapor is continuously fed in during the process to speed up the oxidation rate. The surface of the silicon particles is heated at a high temperature to form an oxide layer (silicon dioxide layer) with a uniform thickness, and the intermediate product A is obtained. Wherein, the thickness of the oxide layer is controlled by adjusting the high temperature heating time.

[0056] 2) Add the intermediate product A obtained in step 1) into tromethamine buffer solution containing dopamine, the concentration of tromethamine buffer solution is 0.001M. The mass ratio of product A, dopamine and tromethamine buffer solution is 0.05:1. Stir the above mixed solution. After 24 hours of s...

Embodiment 3

[0060] A method for preparing a hollow structure material, comprising the following steps:

[0061] 1) Using silicon particles as the original material, the surface of silicon particles is oxidized by heating. The silicon particles are heated in a tube-type rotary furnace to 1100 degrees Celsius, and water vapor is continuously fed in during the process to speed up the oxidation rate. The surface of the silicon particles is heated at a high temperature to form an oxide layer (silicon dioxide layer) with a uniform thickness, and the intermediate product A is obtained. Wherein, the thickness of the oxide layer is controlled by adjusting the high temperature heating time.

[0062] 2) Add the intermediate product A obtained in step 1) into tromethamine buffer solution containing dopamine, the concentration of tromethamine buffer solution is 10M. The mass ratio of product A to dopamine is 50:1. Stir the above mixed solution. After 24 hours of stirring, the surface of product A is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com