Treatment method of waste acid, oil shale ash and white mud

A technology for oil shale ash and treatment method, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of huge equipment investment, serious energy consumption, and difficulty in meeting the requirements of continuous production, etc. problems, to achieve continuous and stable production and reduce the effect of generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

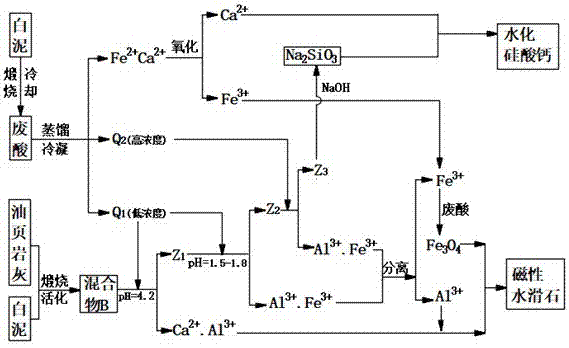

Image

Examples

Embodiment 1

[0067] step 1:

[0068] The white clay is calcined at 940°C for 0.5-6 hours under the condition of flowing air, and after cooling to room temperature, the calcined white clay A is obtained; the ratio of calcium atoms to aluminum atoms is 2:1-3:1 , mixing lime mud and oil shale ash, and calcining the mixture for 3-6 hours at 1260-1270° C. under the condition of flowing air, and cooling to room temperature to obtain mixture B;

[0069] Step 2:

[0070] Under the condition of rapid stirring, add the calcined white mud A to the waste acid with a volume of 5V, until the calcium ion concentration in the acid solution is 0.4 mol / L, distill until the volume is V, and after the distillation gas is condensed, the acid solution is obtained Q1; for the first time, add waste acid with a volume of 3V, continue to distill to 3V, add waste acid with a volume of 2V for the second time, continue to distill to a volume of 4V, and obtain distillation mother liquor Q3; merge the two additional pr...

Embodiment 2

[0088] This embodiment is basically the same as Example 1, the difference is that the ratio of the amount of calcium atoms and aluminum atoms described in step 1 is 2:1-3:1, mixing white mud and oil shale ash , the mixture is calcined for 3-6 hours at 1260-1270° C. under the condition of passing air, preferably: mixing white mud and oil shale ash according to the ratio of the amount of calcium atoms and aluminum atoms to 2.2:1, The mixture was calcined at 1260-1270°C for 6 hours under the condition of flowing air.

[0089] Example 2 Description : For calcium aluminum hydrotalcite, the ratio of the amount of calcium atoms to aluminum atoms is 2:1-3:1 is the preferred condition for the preparation of hydrotalcites, 2:1 is the first choice, because the extraction process may cause the corresponding ion ratio Small fluctuations, so it is more reasonable to choose a ratio of 2.2. At the same time, the relatively low calcium-aluminum ratio can reduce the amount of lime mud that n...

Embodiment 3

[0091] This example is basically the same as Example 1, the difference is that in step 3, add the calcined lime mud A to the distillation mother liquor Q3 until the pH value of the solution is 1-2, preferably add Calcined lime mud A until the pH value of the solution is 1.8.

[0092] Example 3 illustrates: the pH value of the solution is preferably 1.8, which can ensure that the iron ions are fully dissolved and participate in the reaction, and can also increase the processing capacity of the lime mud. If the processing ability for lime mud is further enhanced and the pH value of the solution is further increased, ferric hydroxide precipitation will be produced, which will be mixed with divalent iron, which will lead to incomplete oxidation of divalent iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com