Heat direct reduced iron conveyor

A technology for conveyors and reduced iron, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve secondary oxidation and other problems, achieve the effects of reducing energy consumption, shortening production cycle, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

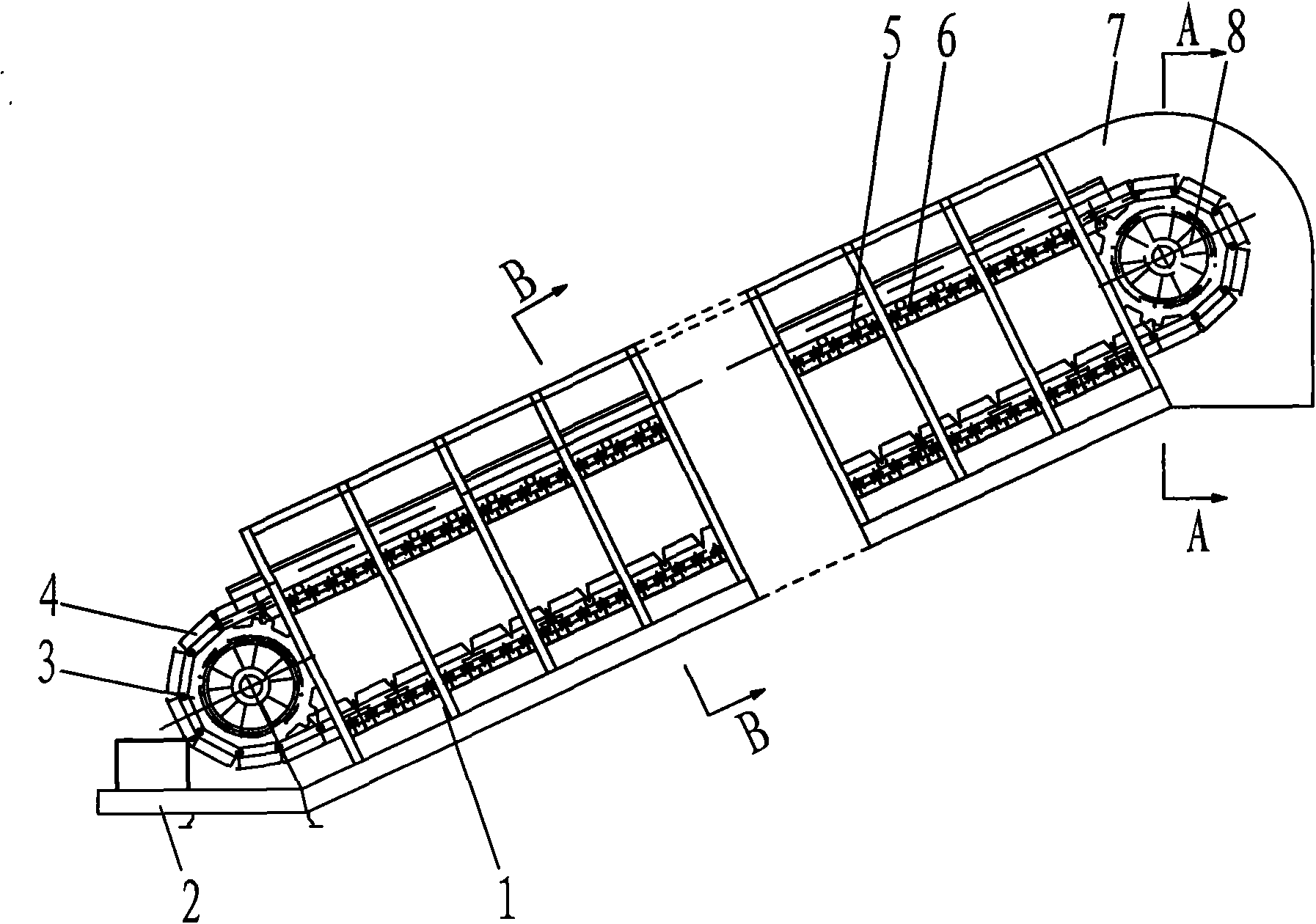

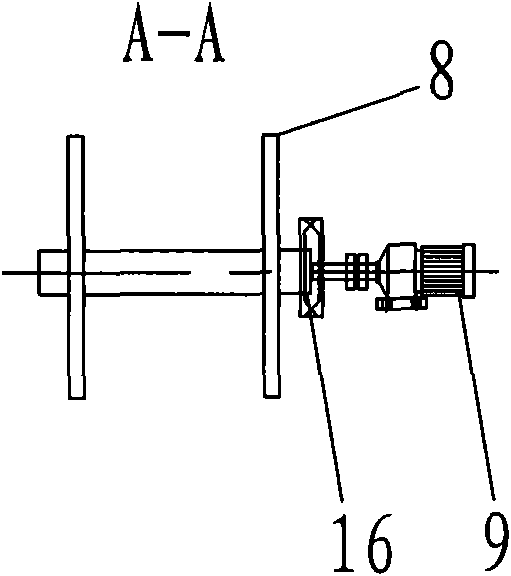

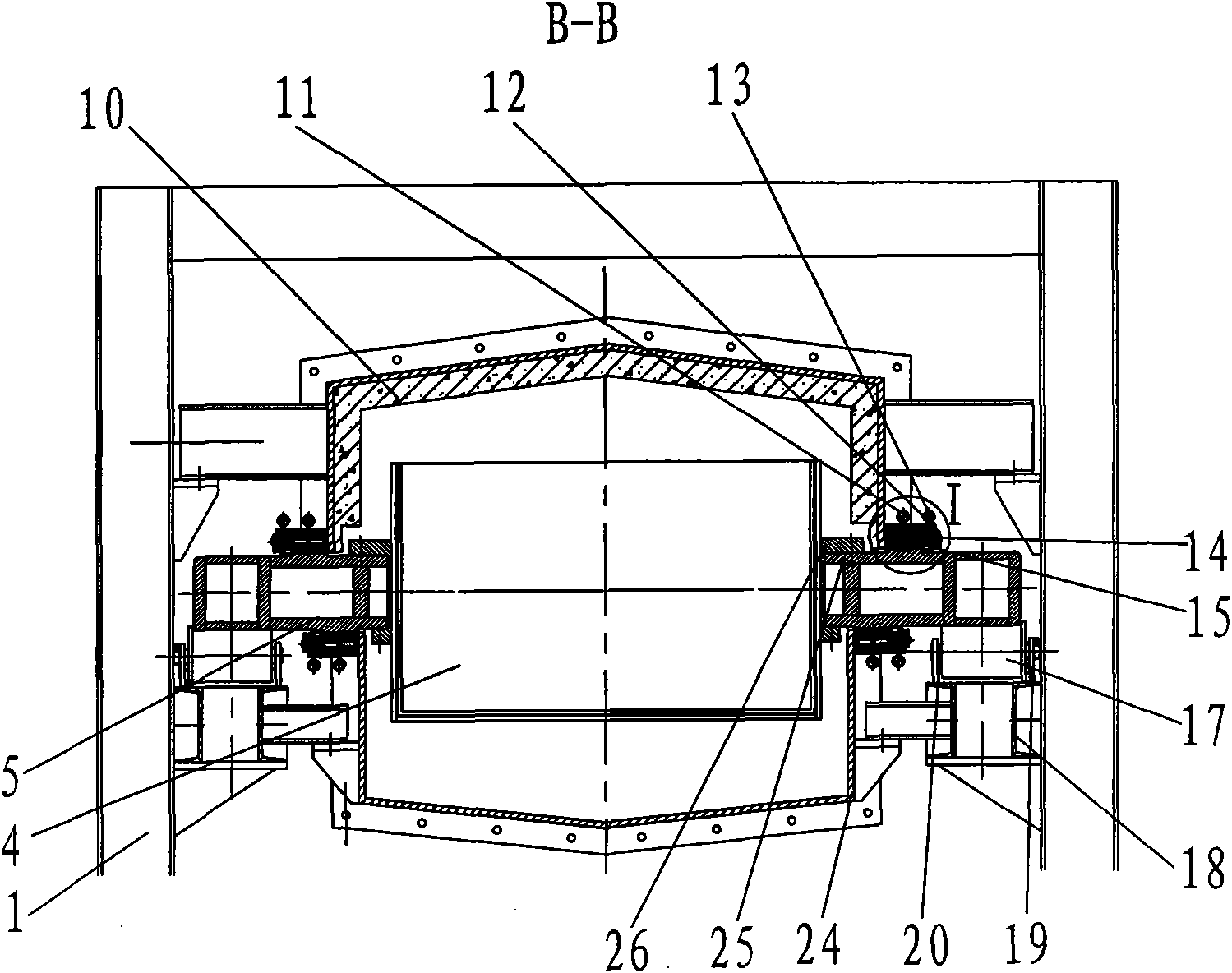

[0026] figure 1 It is an embodiment disclosed by the present invention, the frame 1 of the hot direct reduced iron conveyor is fixed on the platform 2, the unloading bin 7 is installed at the rear of the conveyor, and the driving sprocket 8 is output by the motor 9 Driven by shaft-connected reducer 16, driven sprocket 3 is installed at the front of said frame 1 and driving sprocket 8 is installed at the rear, and roller track 6 is set between driven sprocket 3 and driving sprocket 8. The tooth profiles of driving sprocket 8 and driven sprocket 3 are uniform speed tooth profiles. The two sides of the transport trolley 4 are respectively connected with the chain links 5: the chain link sealing slideway 27 is processed on the chain link upper side plate 25 of the chain link 5, the trolley side ear 26 of the transport trolley 4 is connected with the chain link of the chain link 5 The upper side plate 25 is connected by bolts; another scheme is: the box body of the material transp...

Embodiment 2

[0030] Figure 8 It is another embodiment disclosed by the present invention. The structure of the hot direct reduced iron conveyor is basically the same as that of Embodiment 1, the difference is that only the upper sealing cover is set on the upper part of the transport trolley 4 in advance of meeting the requirements of sealing and heat preservation 10, and the lower sealing cover 24 is not provided.

[0031] In Embodiment 1 and Embodiment 2, the transport trolley 4 with the chain link sealing slideway 27 processed on the upper side plate 25 of the chain link can be used, or the trolley sealing slideway 29 processed on the side ear 28 at the upper end of the trolley can be used. Material delivery trolley 4, its structure is relatively compact on the material delivery trolley 4 of trolley sealing slideway 29 on the upper end side ear 28 of the trolley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com