Graphene modified material, and preparation method and application thereof

A graphene modification, graphene technology, applied in graphene, chemical instruments and methods, alkali metal oxides/hydroxides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of graphene modified material, comprises the steps:

[0033] (1) Graphene oxide@Fe 3 o 4 Preparation of:

[0034] S1, the graphene and FeCl 3 ·6H 2 O and FeCl 2 4H 2 After O was added to water for ultrasonic blending, FeCl 3 ·6H 2 O and FeCl 2 4H 2 The ratio of the total amount of O to the mass of graphene is 1:100. In a vacuum tube furnace, under an argon atmosphere of 50 sccm, after the temperature rise rate is 5°C / min from room temperature to 750°C, After annealing for 6 hours, cool to room temperature and filter to obtain the intermediate;

[0035] S2. Anneal the intermediate prepared in step S1 under vacuum conditions, raise the temperature from normal temperature to 600°C at a rate of 5°C / min in an argon atmosphere, keep it warm for 3 hours after reaching the highest temperature, and cool to room temperature , washed with deionized water and ethanol in turn, dried in vacuum to constant weight, and prepared graphene oxide@Fe ...

Embodiment 2

[0041] A kind of preparation method of graphene modified material, comprises the steps:

[0042] (1) Graphene oxide@Fe 3 o 4 Preparation of:

[0043] S1, the graphene and FeCl 3 ·6H 2 O and FeCl 2 4H 2 After O was added to water for ultrasonic blending, FeCl 3 ·6H 2 O and FeCl 2 4H 2 The ratio of the total amount of O to the mass of graphene is 1:60. In a vacuum tube furnace, under an argon atmosphere of 45 sccm, after increasing the temperature from room temperature to 700 °C at a rate of 5 °C / min, After annealing for 7 hours, cool to room temperature and filter to obtain the intermediate;

[0044] S2. Anneal the intermediate prepared in step S1 under vacuum conditions, raise the temperature from normal temperature to 625°C at a rate of 5°C / min in an argon atmosphere, keep it warm for 2.5h after reaching the highest temperature, and cool to At room temperature, after washing with deionized water and ethanol in turn, vacuum drying to constant weight, the prepared gr...

Embodiment 3

[0050] A kind of preparation method of graphene modified material, comprises the steps:

[0051] (1) Graphene oxide@Fe 3 o 4 Preparation of:

[0052] S1, the graphene and FeCl 3 ·6H 2 O and FeCl 2 4H 2 After O was added to water for ultrasonic blending, FeCl 3 ·6H 2 O and FeCl 2 4H 2 The ratio of the total amount of O to the mass of graphene is 1:10. In a vacuum tube furnace, under an argon atmosphere of 40 sccm, after increasing the temperature from room temperature to 650 °C at a rate of 5 °C / min, After annealing for 8 hours, cool to room temperature and filter to obtain the intermediate;

[0053] S2. Anneal the intermediate prepared in step S1 under vacuum conditions, raise the temperature from normal temperature to 650°C at a rate of 5°C / min in an argon atmosphere, keep it warm for 2h after reaching the highest temperature, and cool to room temperature , washed with deionized water and ethanol in turn, dried in vacuum to constant weight, and prepared graphene ox...

PUM

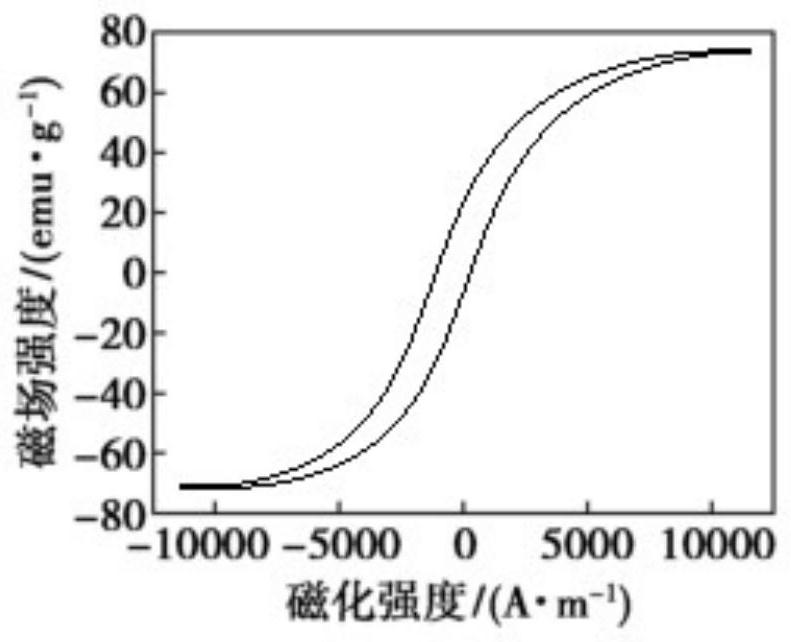

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com