Permeable in-situ leaching uranium mining leaching process for hydrochloric acid modified sand layer

A technology for in-situ leaching of uranium and permeability, which is applied in the fields of mining fluids, earth-moving drilling, wellbore/well components, etc., can solve problems such as the inability to meet mining requirements, and achieve improved pumping and injection capacity, stable control, and compact connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] A uranium leaching process for hydrochloric acid-improved sand layer permeability in-situ leaching mining, specifically comprising the following steps:

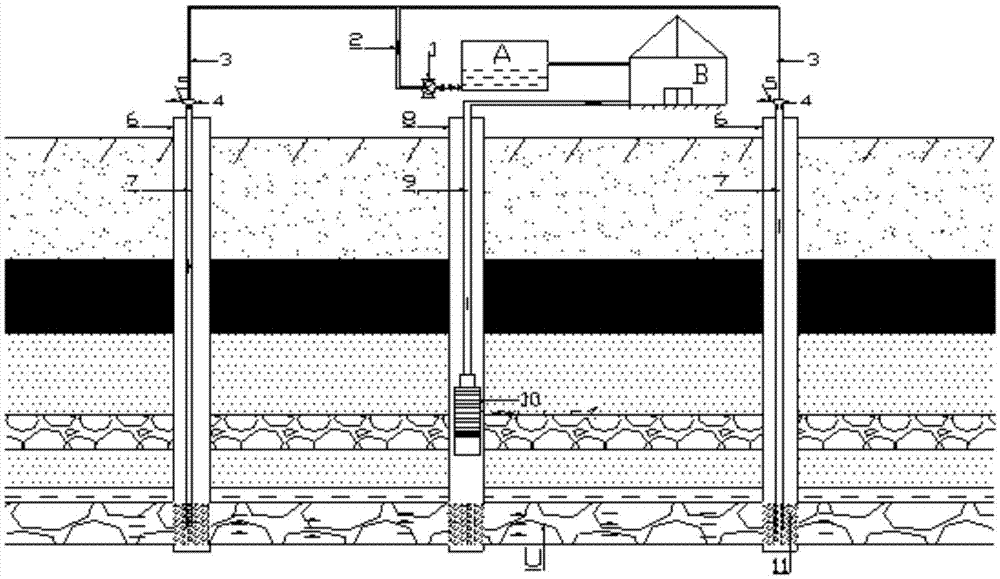

[0023] Step 1: Press figure 1 As shown, after completing the connection of the pipelines on the surface and in the well, an acidic solution with a pH of 4.5 is prepared with industrial hydrochloric acid in the solution preparation tank A. The connection mode of the pipeline is the same as the existing sulfuric acid in-situ leaching process and alkaline in-situ leaching process. The entire leaching process system includes chemical pump 1, solution 2, infusion pipe 3, gas-liquid mixer 4, oxygen inlet 5, injection Liquid well 6, well infusion pipe 7, liquid pumping well 8, liquid pumping pipe 9, submersible pump 10, filter 11, solution configuration tank A, water metallurgy recovery workshop B and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com