Thermal-insulating, oxidizing and cooling device used in vanadium extraction from stone coal and using method of device

A technology of cooling device and stone coal, which is applied in the fields of cooling device, vanadium extraction and heat preservation of stone coal, and oxidation. The effect of large cooling air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

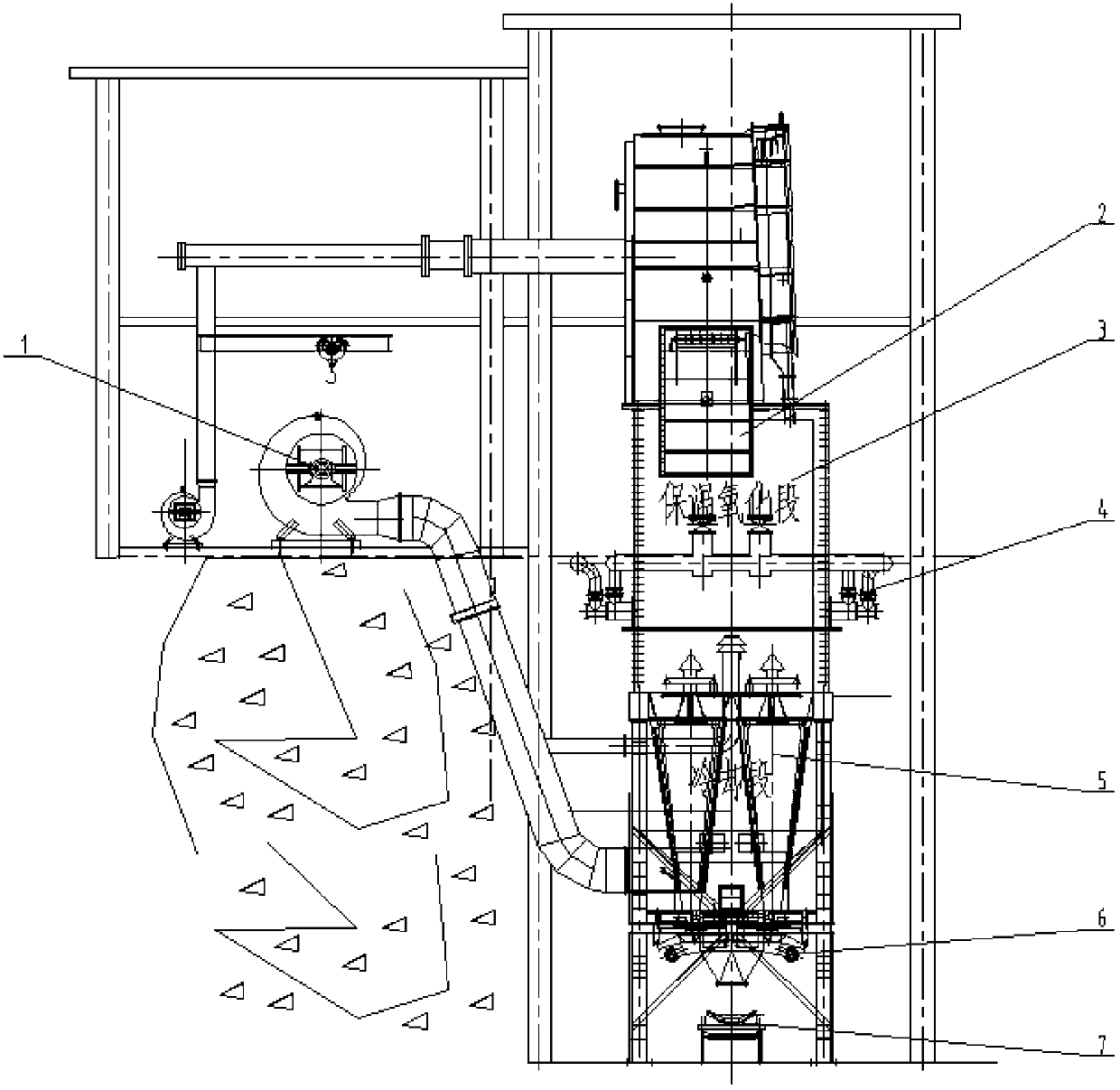

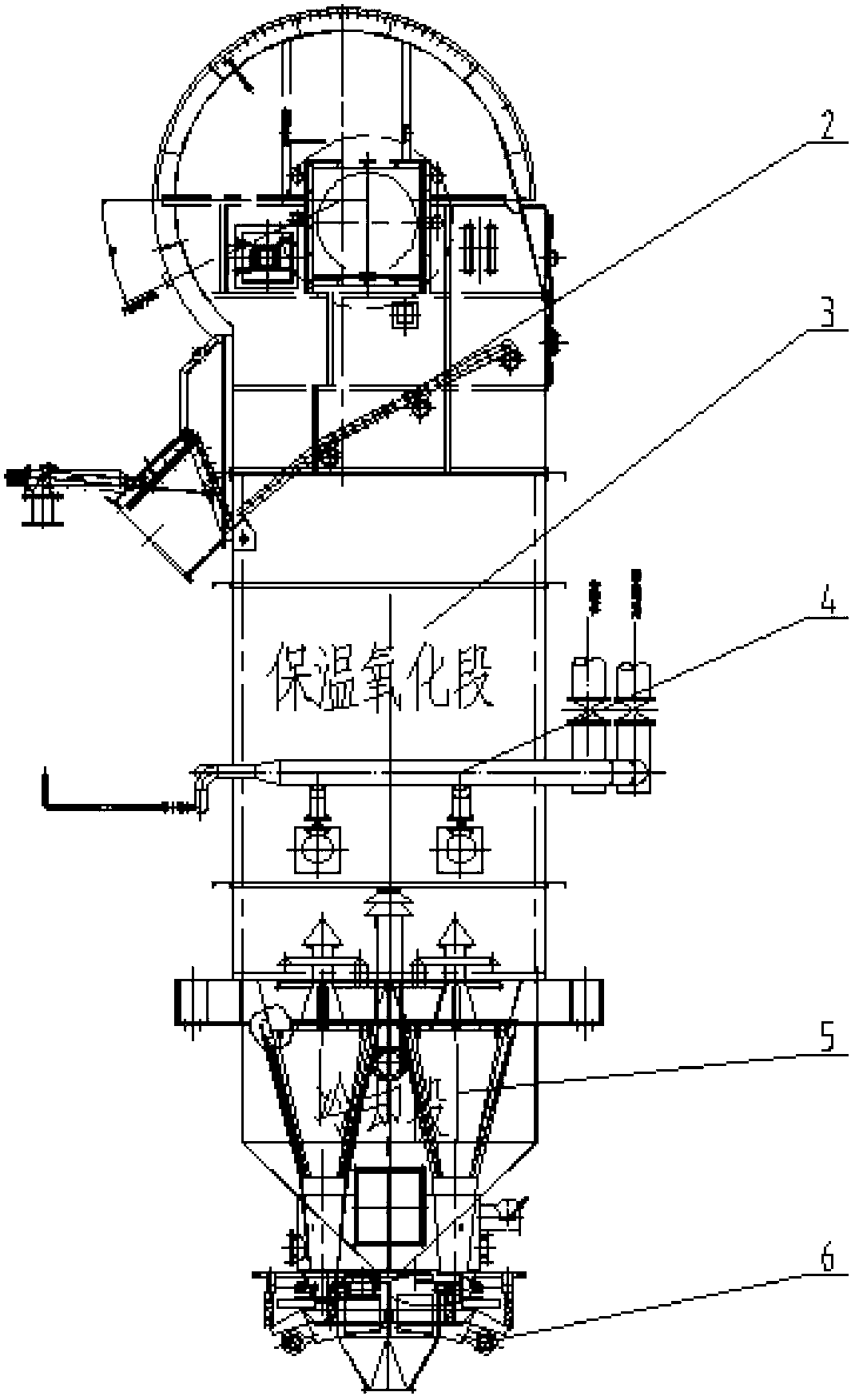

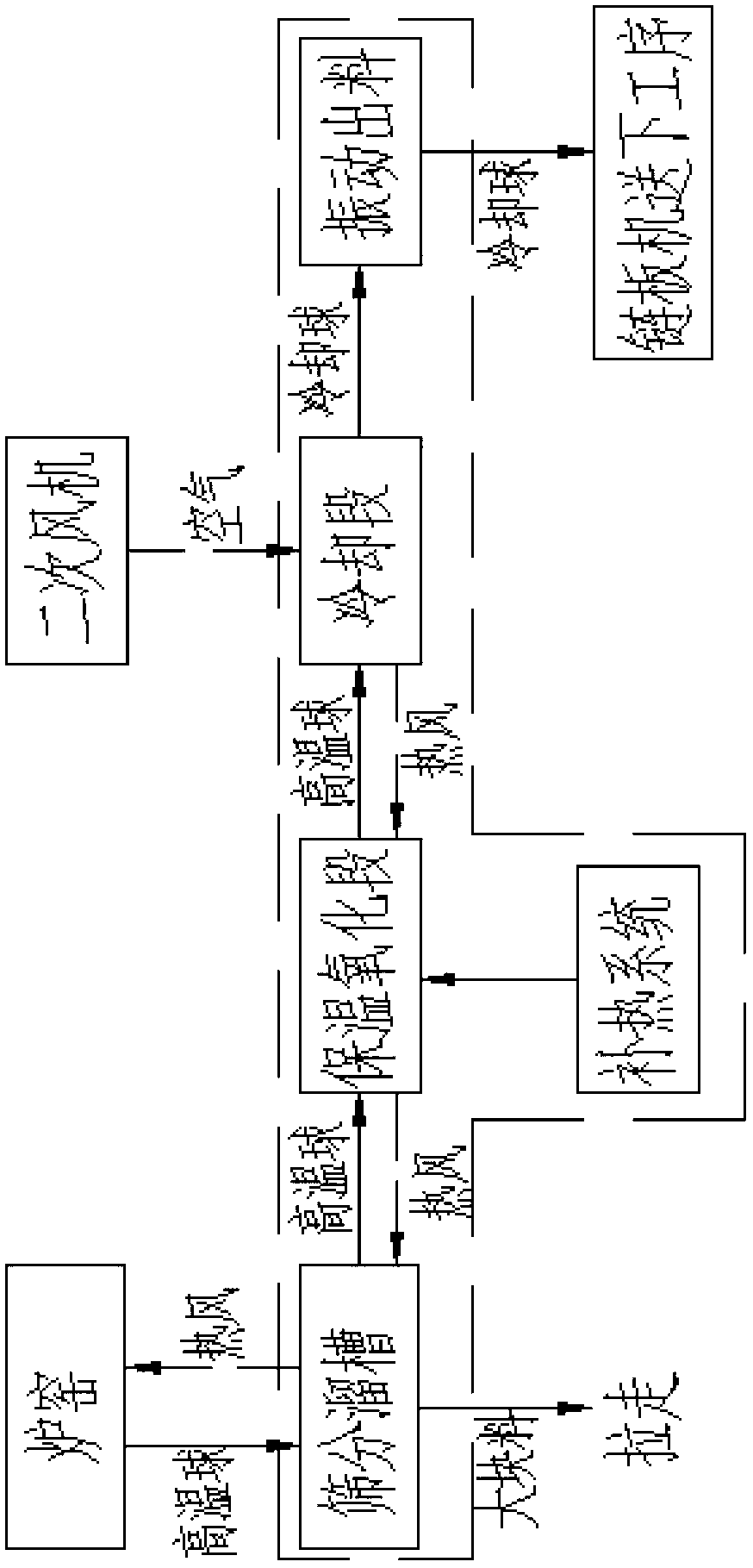

[0021] Figure 1 ~ Figure 3 It is a specific embodiment of the present invention.

[0022] The present invention includes a secondary air blower 1, a screening chute 2, a thermal insulation oxidation section 3, a heat supplement system 4, a cooling section 5, a vibrating discharge device 6, and a chain conveyor 7. The screening chute 2 is inclined at 25° to the plane and supported on the upper beam of the thermal insulation oxidation section 3. Just below the screening chute 2 is the thermal insulation oxidation section 3. The thermal insulation oxidation section is 4 meters high. The structure is an outer steel structure and an inner layer of refractory materials. , the heat preservation oxidation section 3 is the cooling section 5, the cooling section 5 is directly welded to the heat preservation oxidation section 3, the cooling section 5 is 5.6 meters high, the structure is the outer steel structure, the inner layer is refractory material, the lower end of the cooling secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com