Patents

Literature

52results about How to "Increase cooling air volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

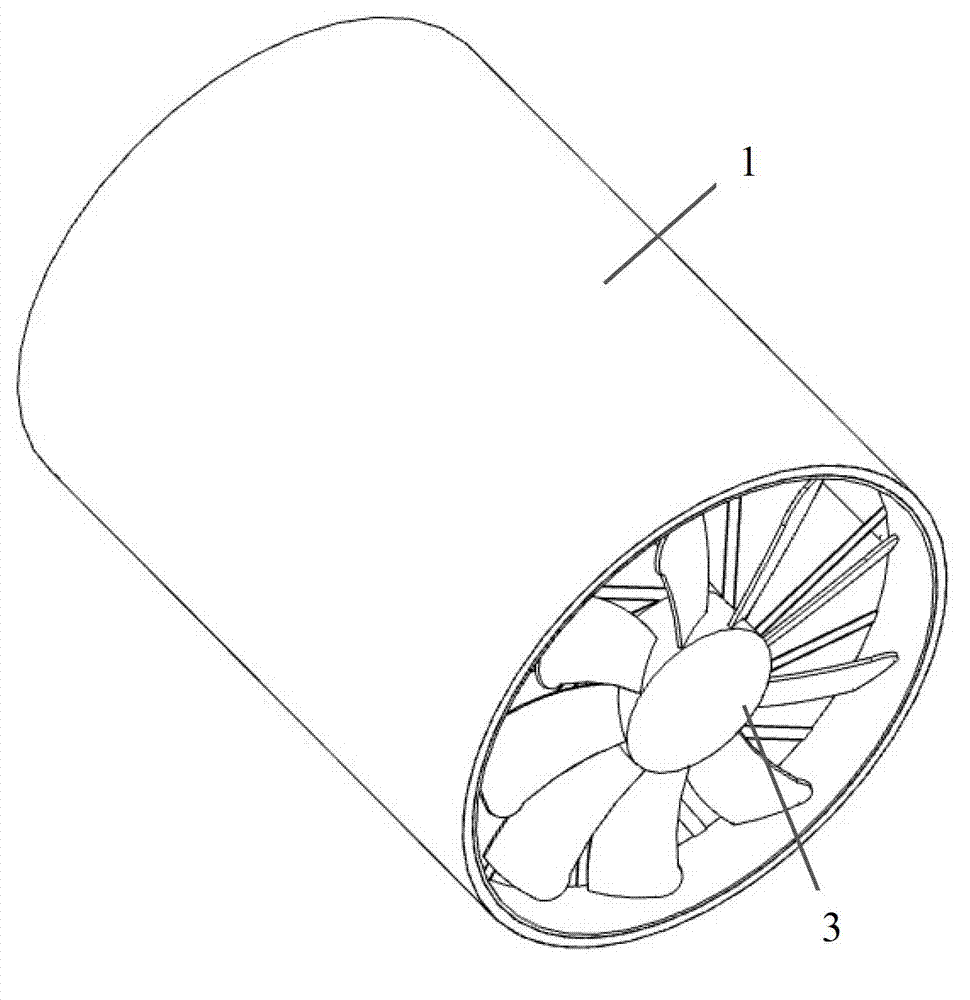

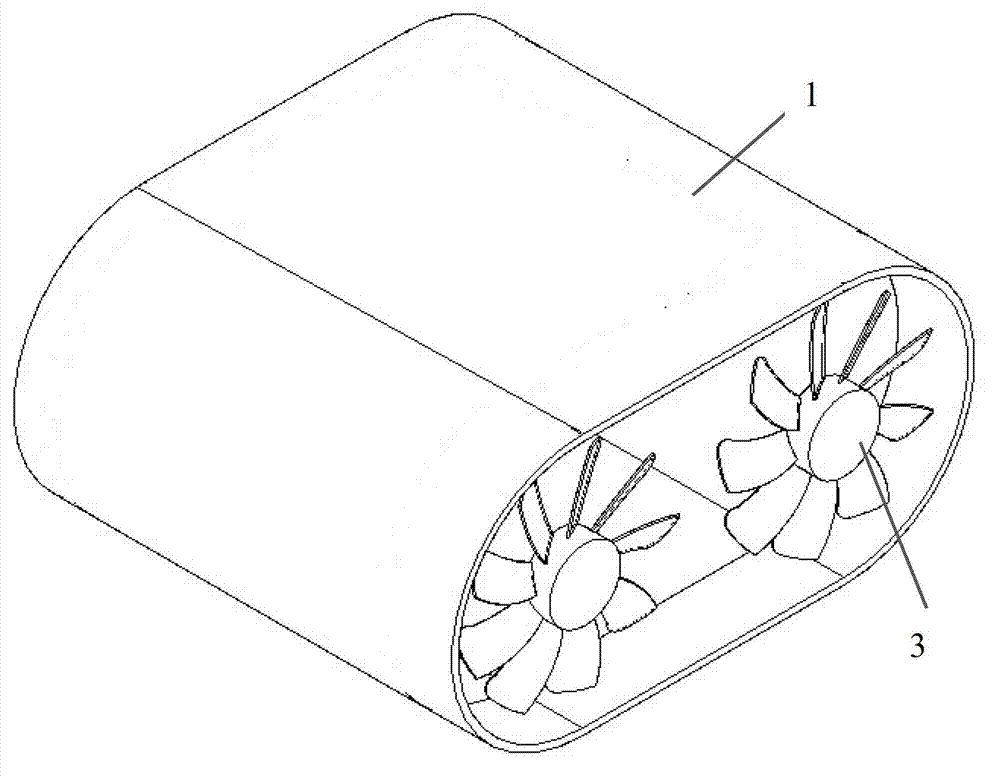

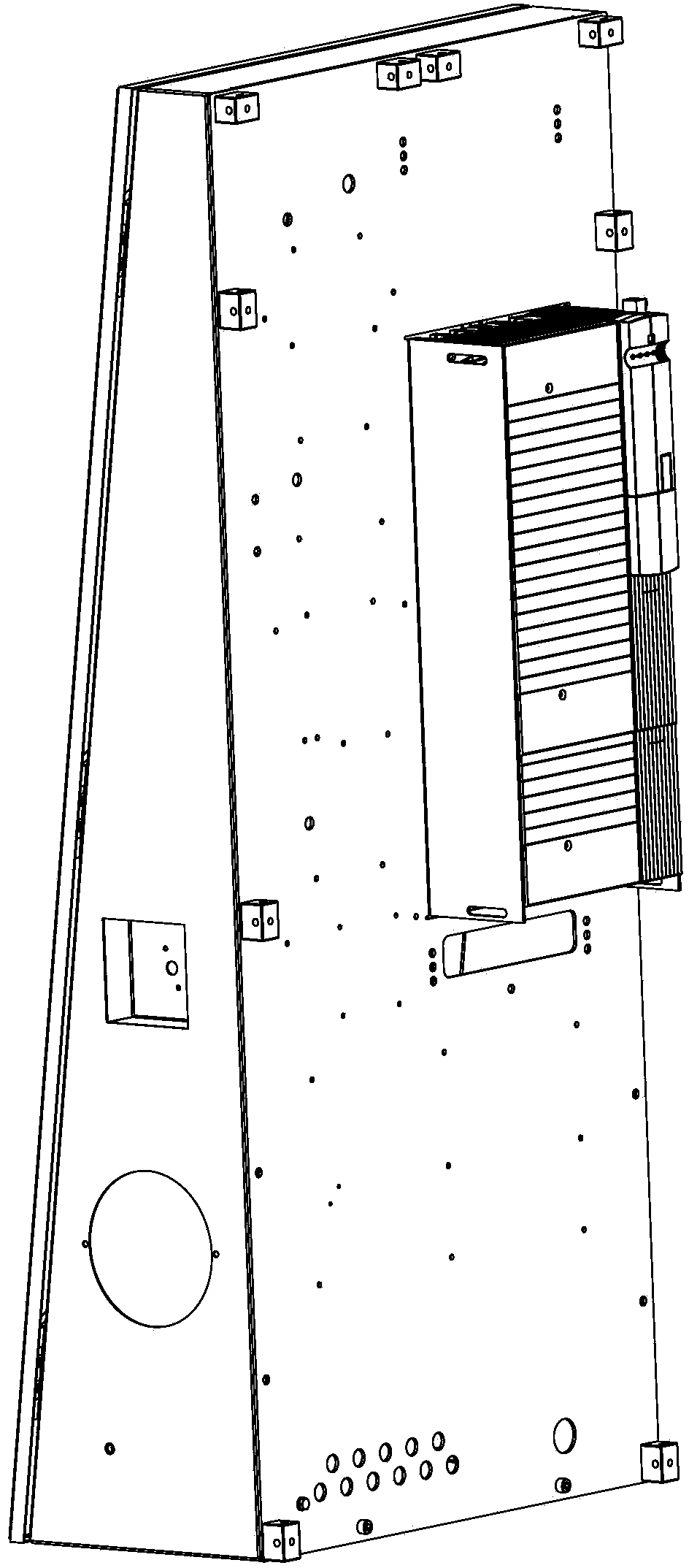

Computer case

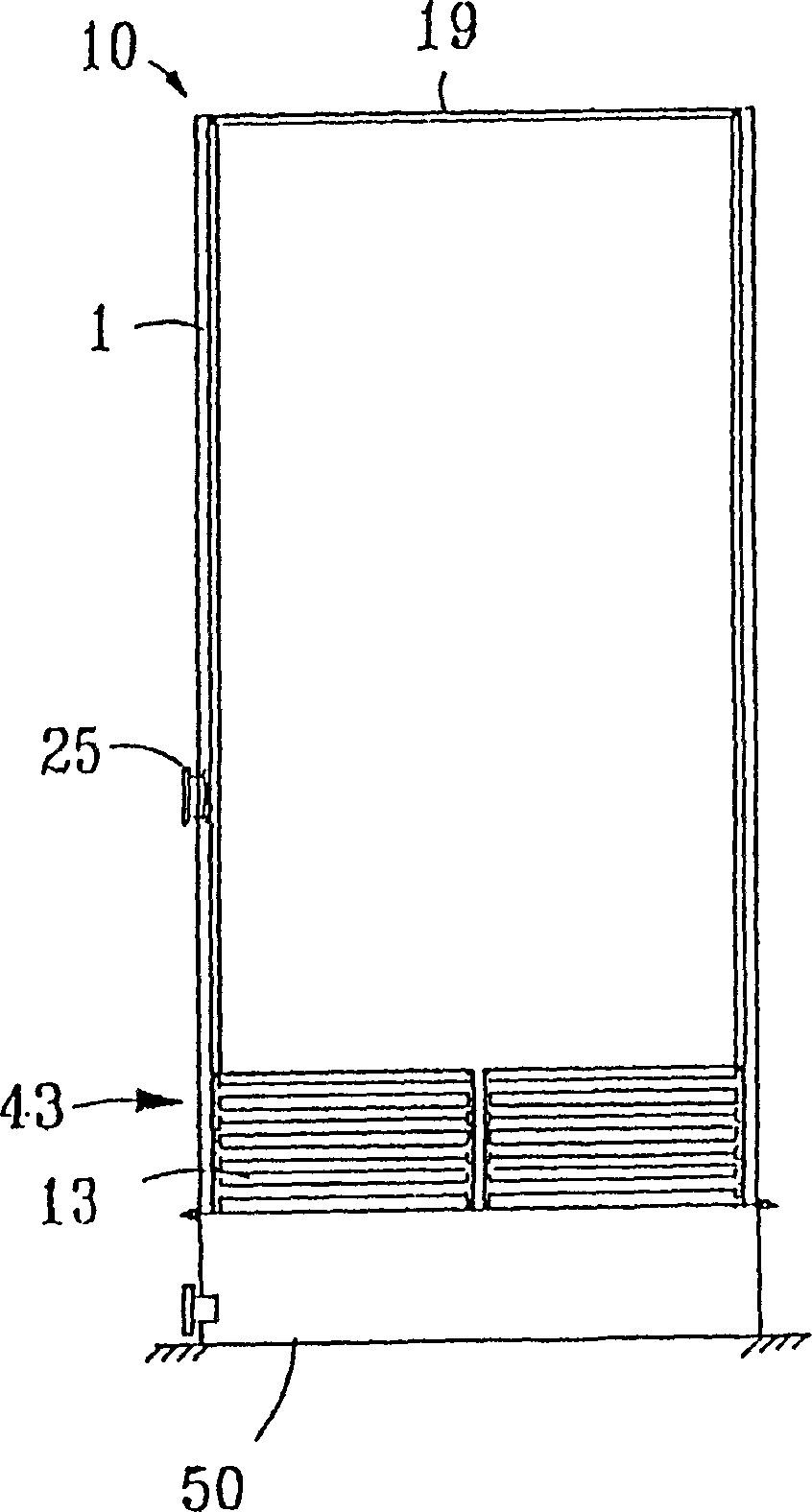

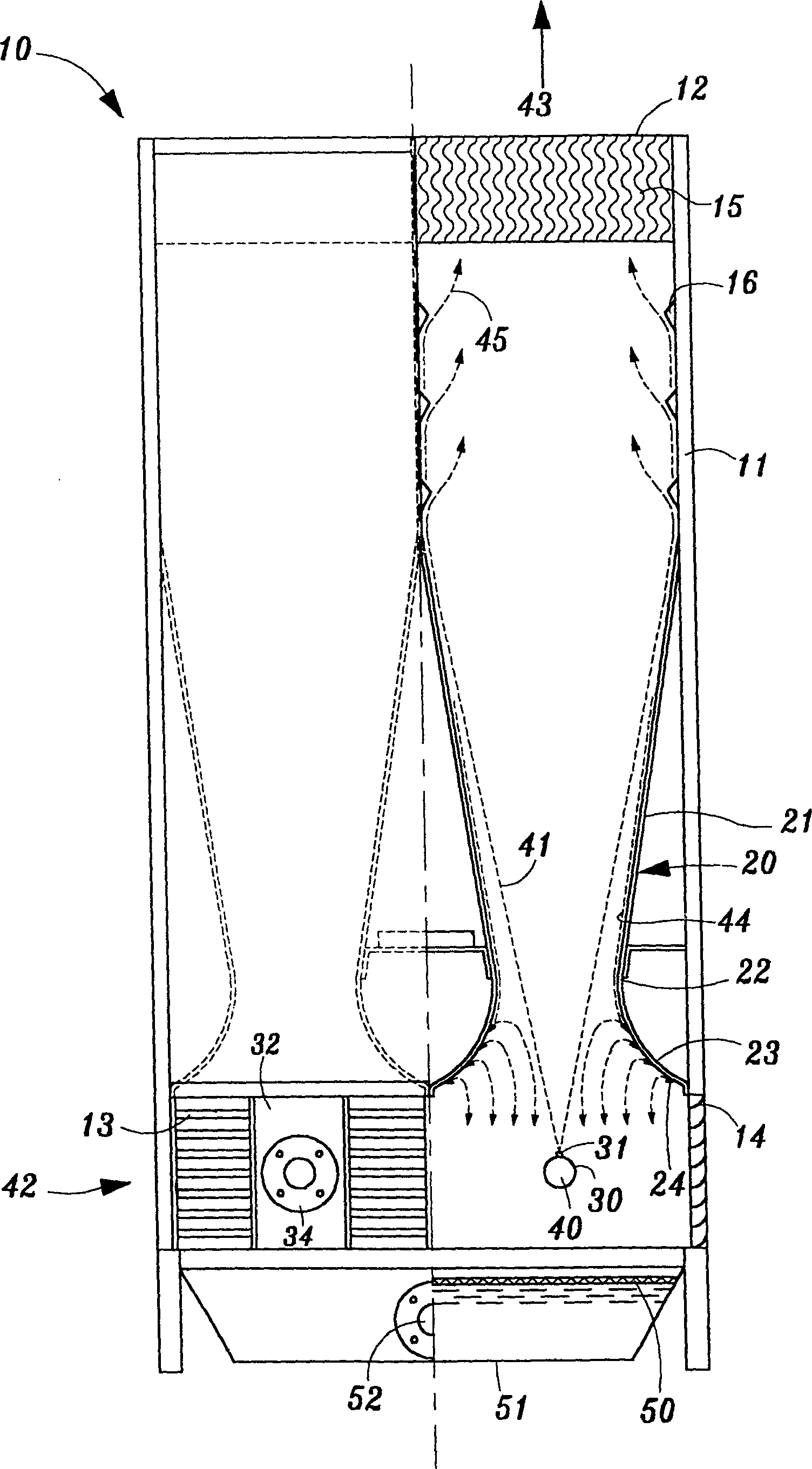

ActiveCN102968163AImprove cooling efficiencyIncrease cooling air volumeDigital processing power distributionComputer engineeringComputer case

The invention discloses a computer case. The computer case comprises a case body, wherein the case body is of a straight cylindrical structure extending along the axis, an air inlet is formed at one end of the case body, and an air-out fan set used for supplying air is formed at the other end of the case body; when the air-out fan set comprises a fan, the cross section contour of the case body is same as the outer contour of the air-out fan set in shape; and when the air-out fan set comprises a plurality of fans, the cross section contour of the case body is same as the outer contour of a region jointly defined by the contours of the fans and the common tangent of the contours of two adjacent fans in shape. Therefore, electronic elements in the computer case are arranged in an air duct, and the heat radiating efficiency is accordingly improved.

Owner:TIANJIN HUARUIYUAN TECH

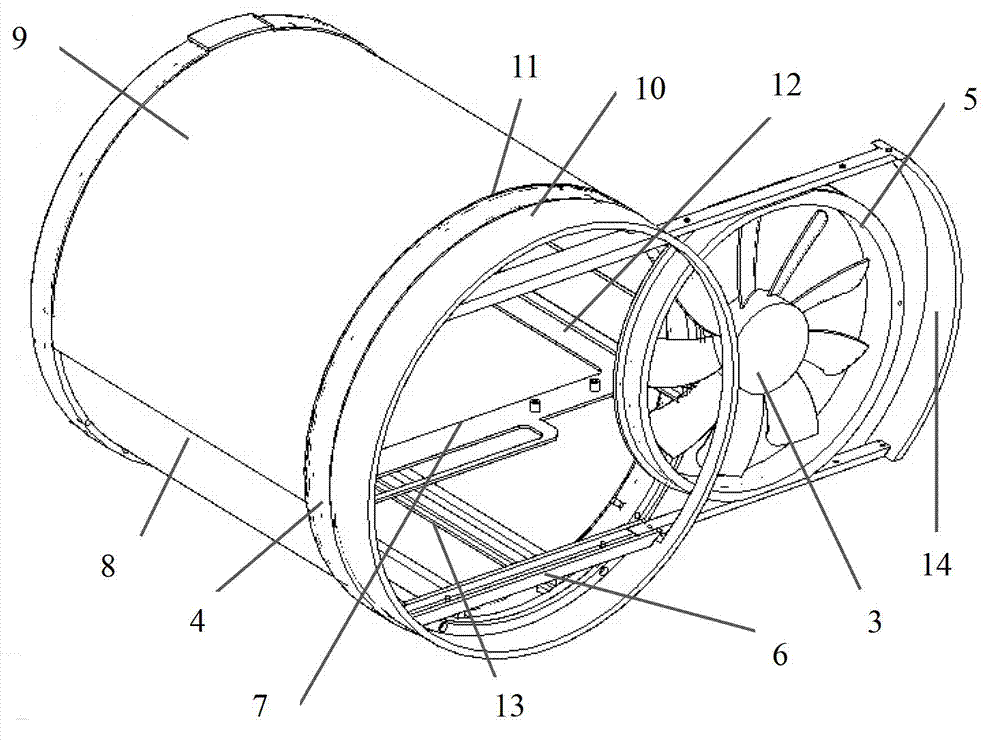

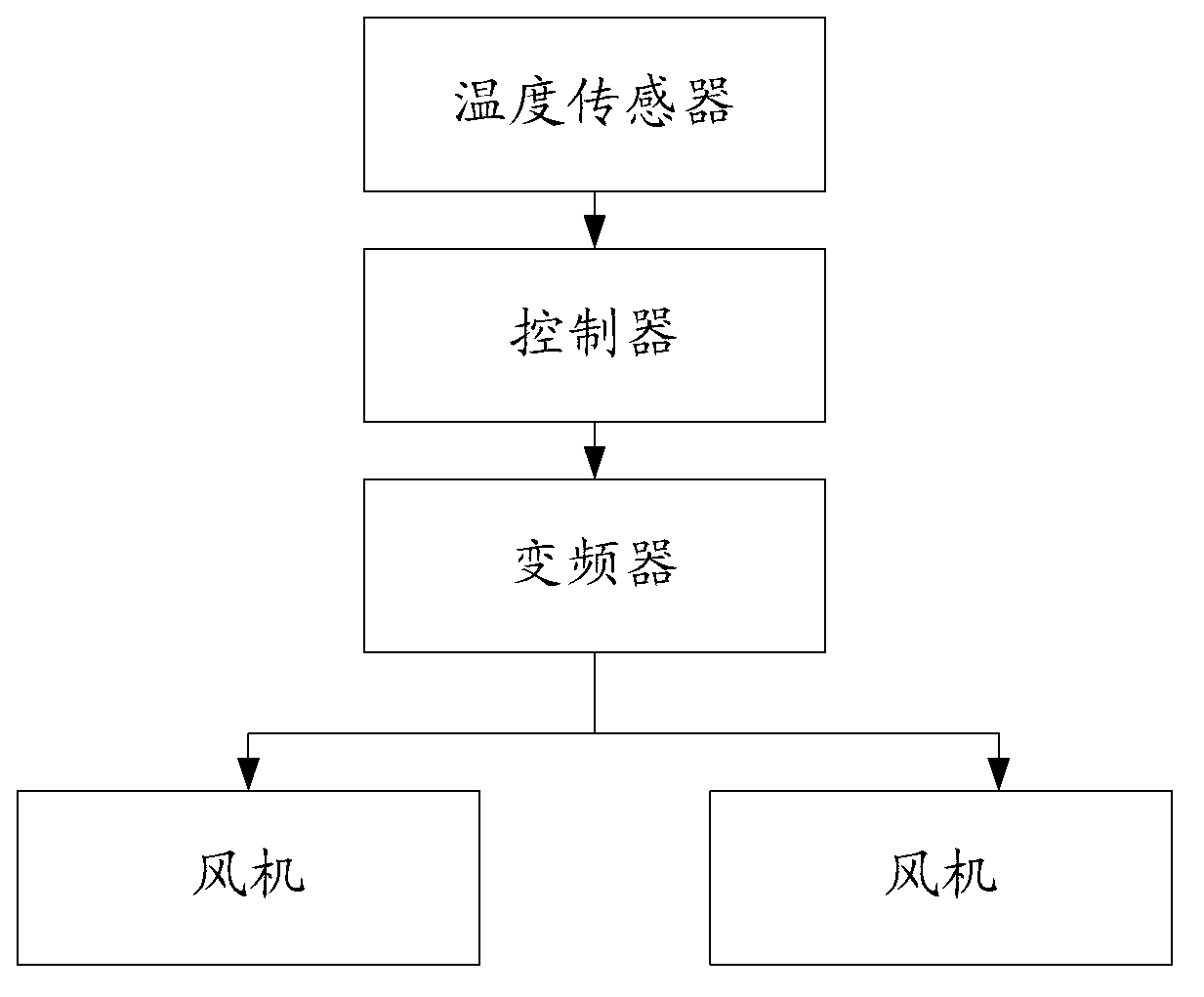

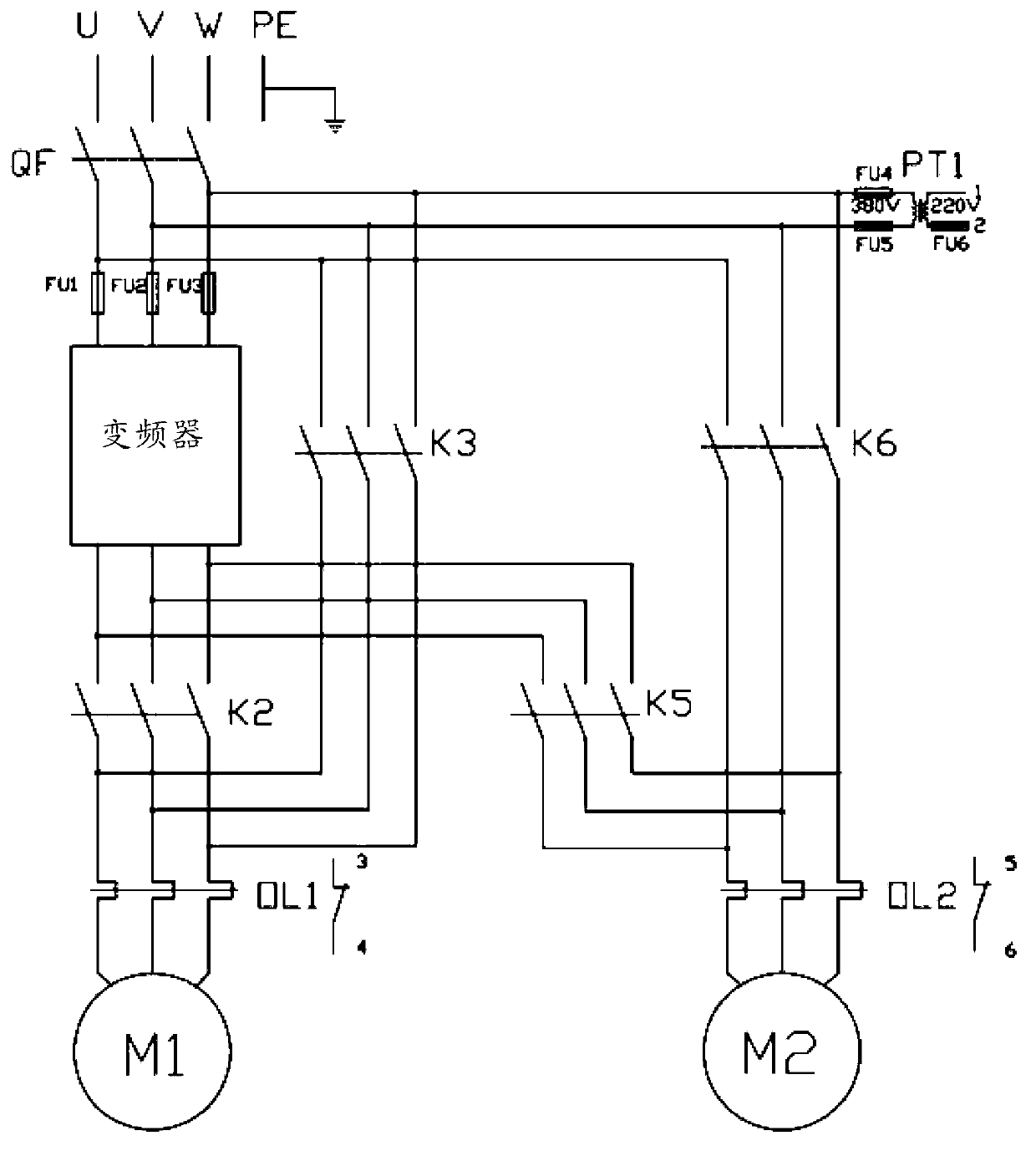

Cooling device and cooling method

ActiveCN102996481AIncrease powerRealize miniaturizationPositive displacement pump componentsPump controlFrequency changerAir volume

The invention discloses a cooling device used for cooling an air compressor. The cooling device comprises at least one fan, a temperature sensor, a controller and a frequency converter, wherein the temperature sensor is used for detecting exhaust temperature of the air compressor; the controller is connected with the temperature sensor and is used for comparing the exhaust temperature with preset exhaust temperature and outputting a signal after comparison; and the frequency converter is respectively connected with the at least one fan and the controller and is used for controlling the at least one fan to output cooling air volume corresponding to the signal after comparison according to the signal after comparison. When the cooling device is in use, a cooing temperature is firstly set, the exhaust temperature of the air compressor is detected by the temperature sensor, when the controller determines that the temperature is lower than the cooling temperature, the power supply frequency of the fan is reduced by the frequency converter, the power of the corresponding fan can be reduced, and the cooling air volume is reduced, therefore, the energy consumption is reduced, the energy sources are saved, and the service life of lubricating oil in the air compressor is effectively prolonged simultaneously. The invention also discloses a cooling method.

Owner:FUSHENG IND SHANGHAI

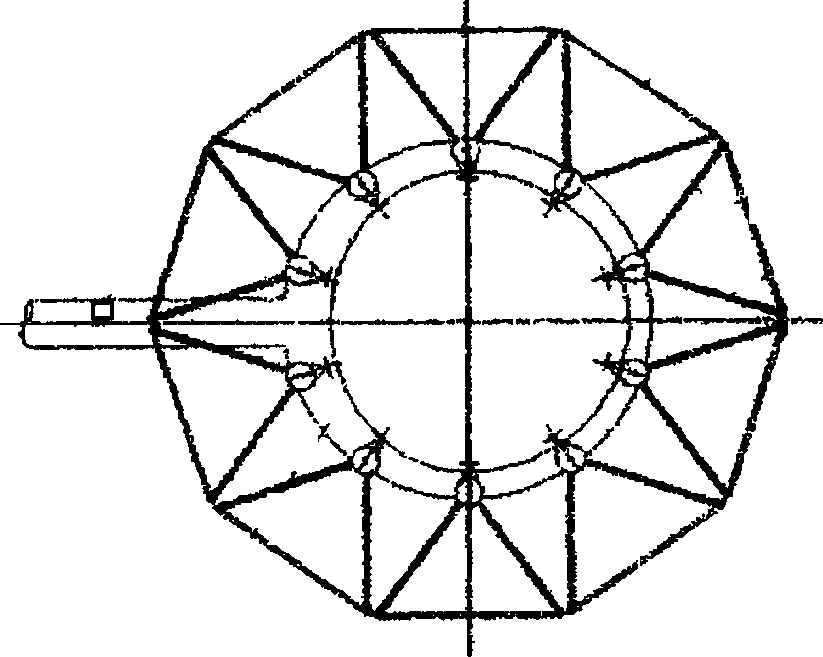

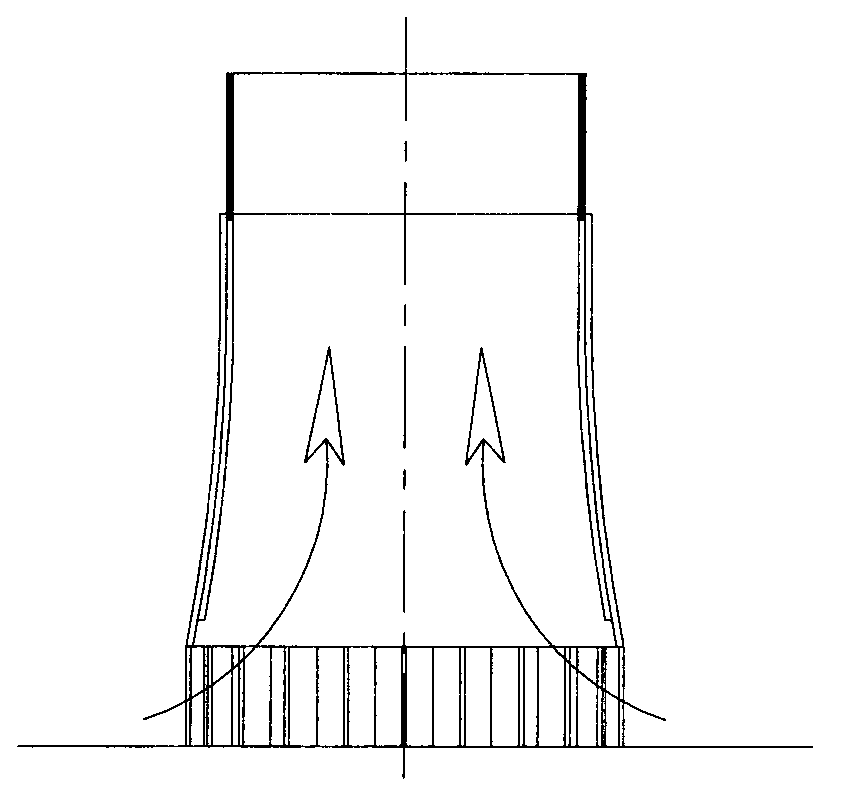

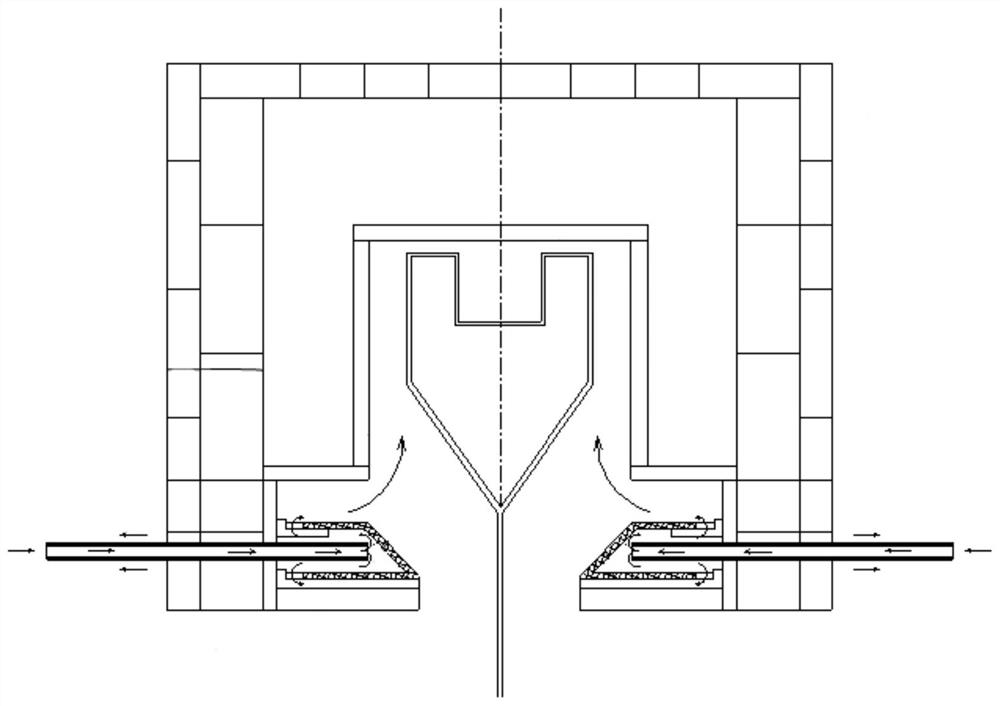

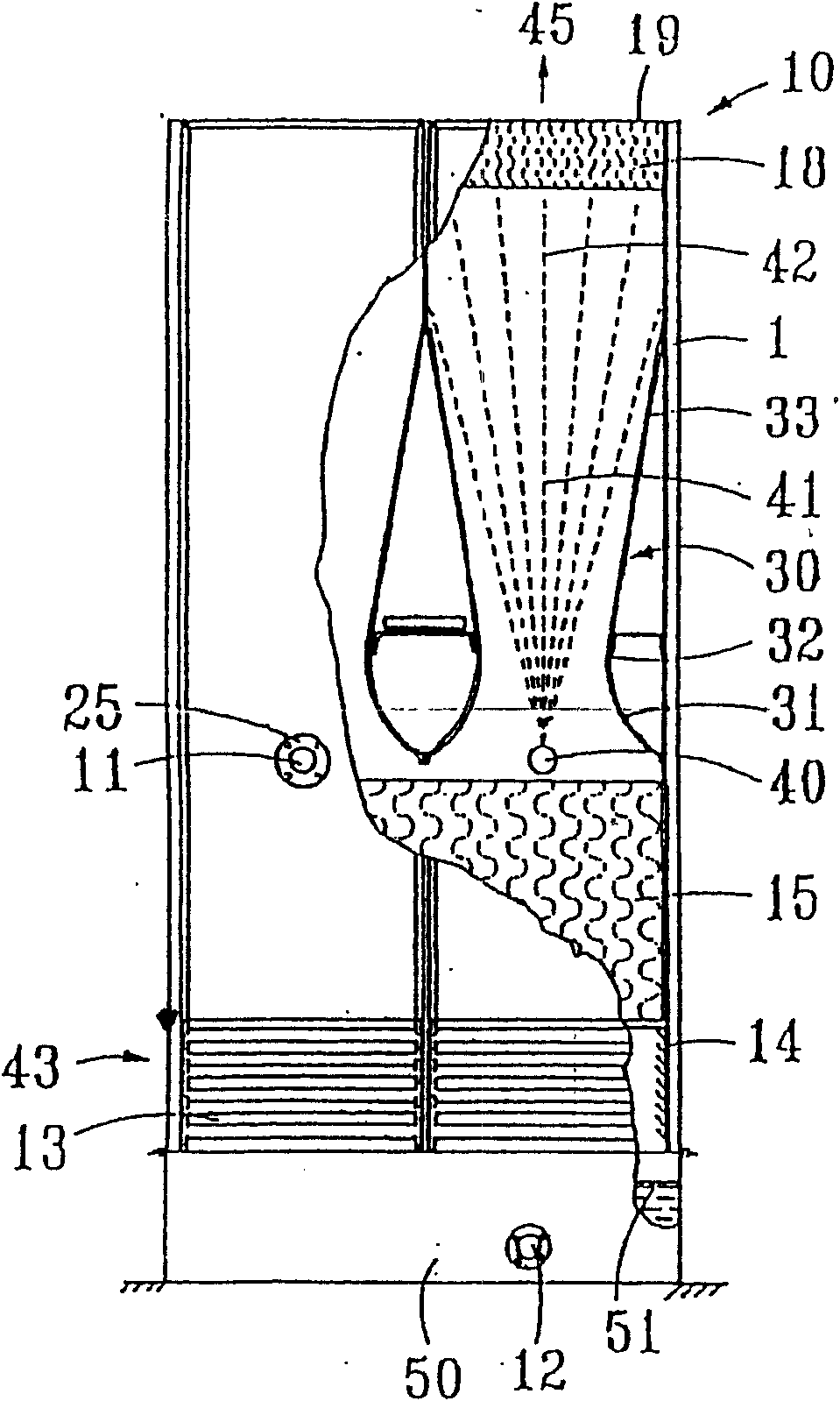

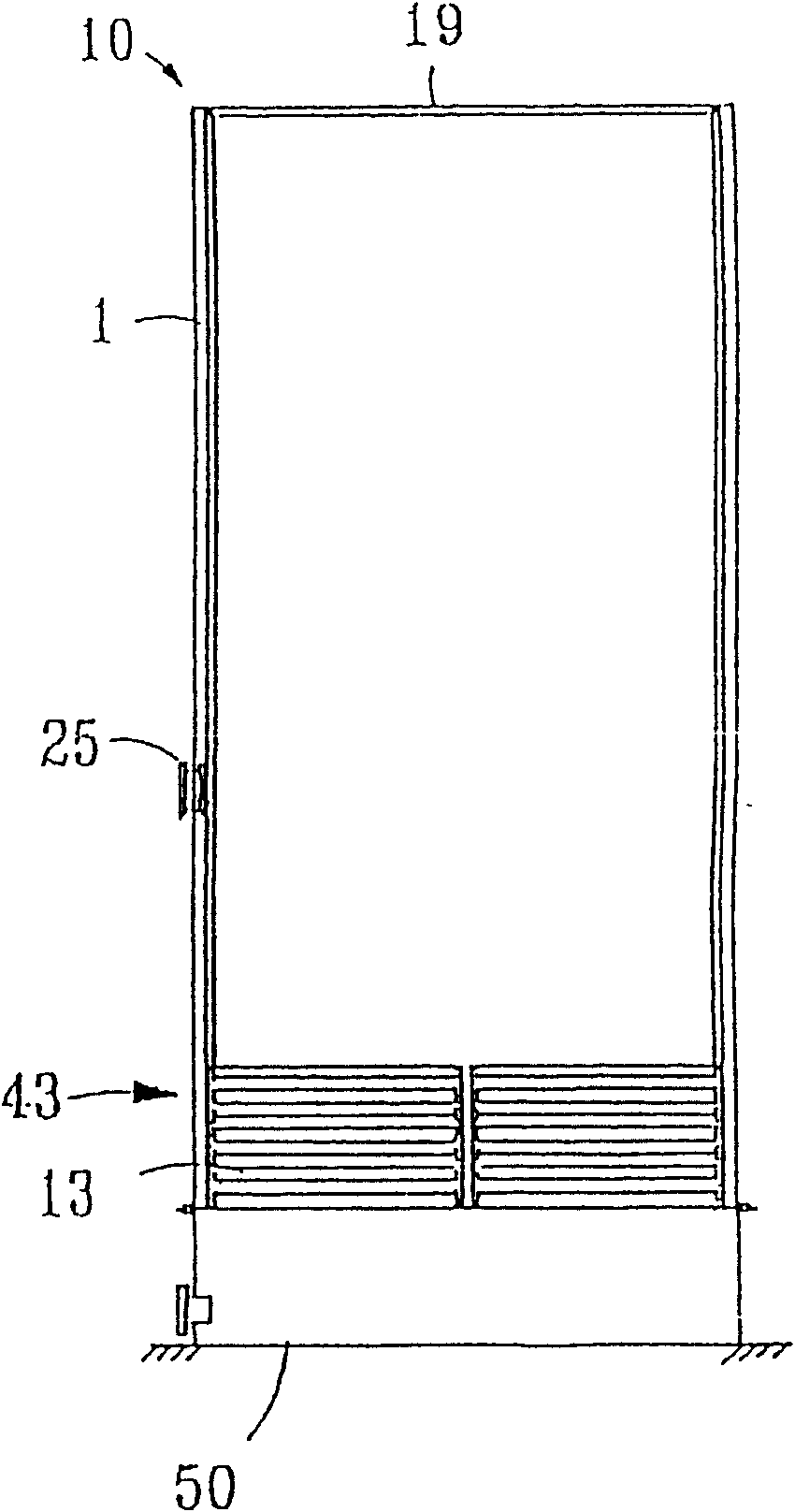

Boosted-ventilation direct air cooling tower

InactiveCN103712473AAdd adjustment functionImprove overall heat transfer coefficientSteam/vapor condensersAssisted ventilationCooling tower

The invention belongs to the field heat exchange, and relates to a boosted-ventilation direct air cooling tower, in particular to an air-cooling power generation air cooling island and an air driving mode. Due to winter-summer difference and day-night difference of air temperature, frequent natural wind and multiple changes of wind speed and wind direction, a pure natural ventilation and simple mechanical-assisted ventilation air cooling tower is difficult to meet current air cooling requirements. Condensation triangles composed of axial flow fans, finned tubes and the like are disposed around the lower portion of a natural ventilator. Cooling capacity of the air cooling tower in summer is greatly enhanced, damage of strong wind is weakened greatly, excess draft in the air cooling tower in winder can be utilized, energy is recovered through the axial flow fans, and hot air in the tower can be pumped out by reverse rotation of the fans to melt the accidentally-frozen fined tubes. The boosted-ventilation direct air cooling tower can be matched with direct air cooling and indirect air cooling units in various sizes.

Owner:李宁

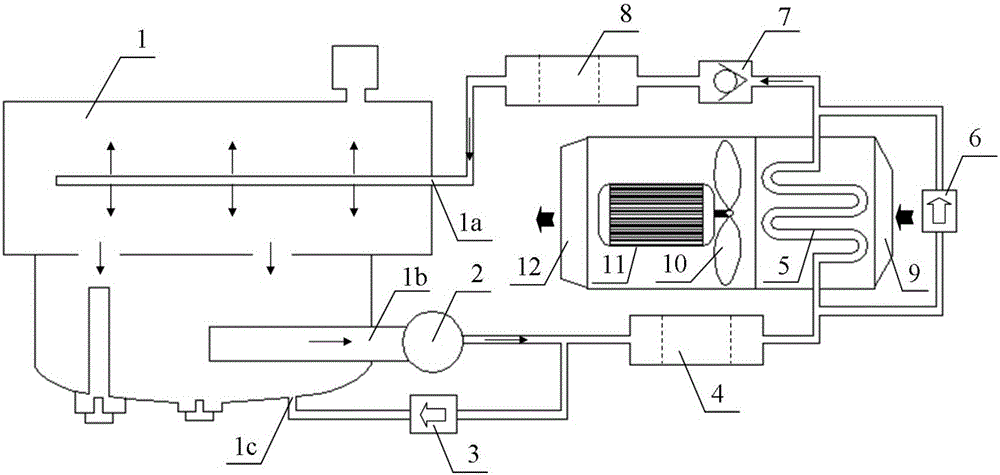

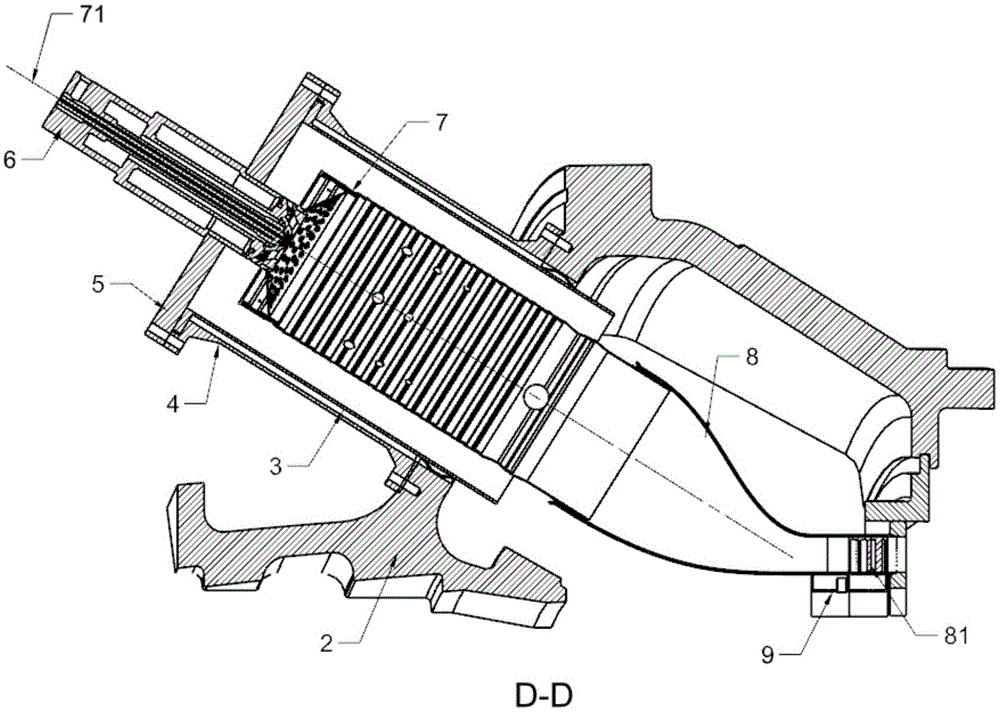

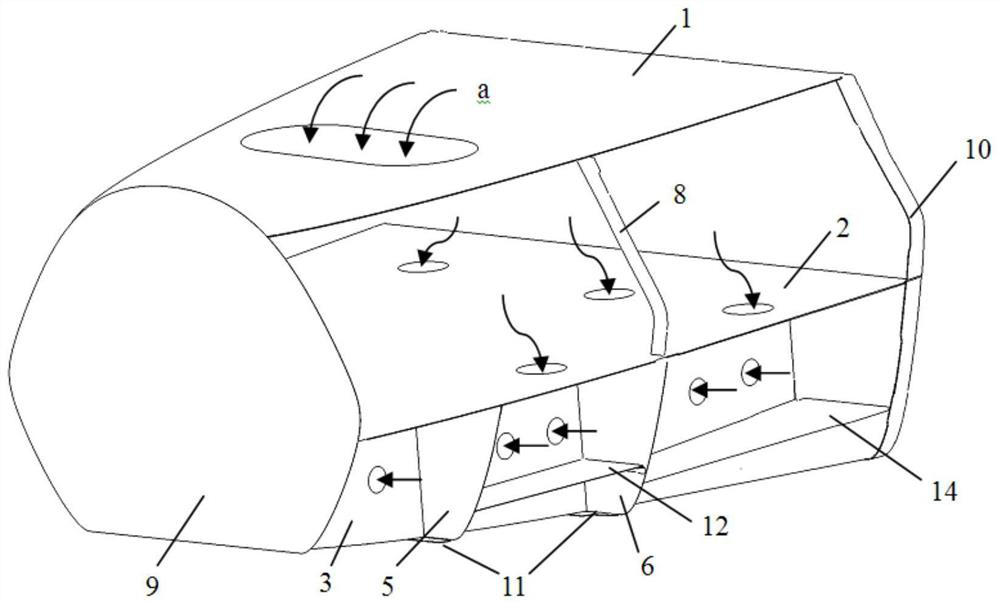

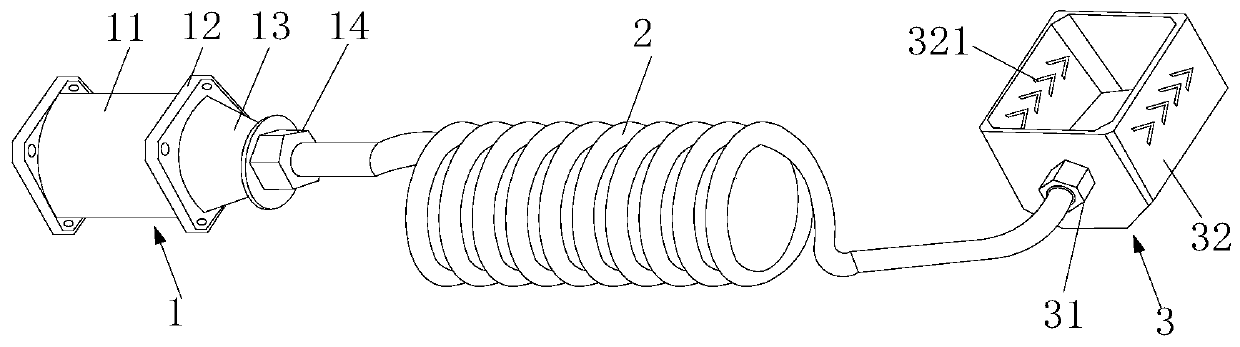

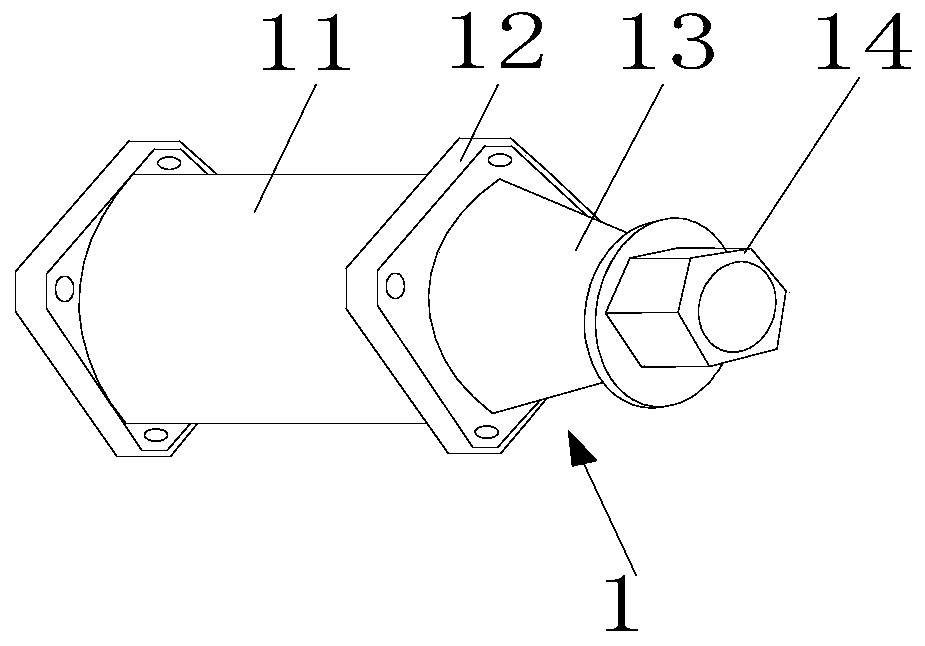

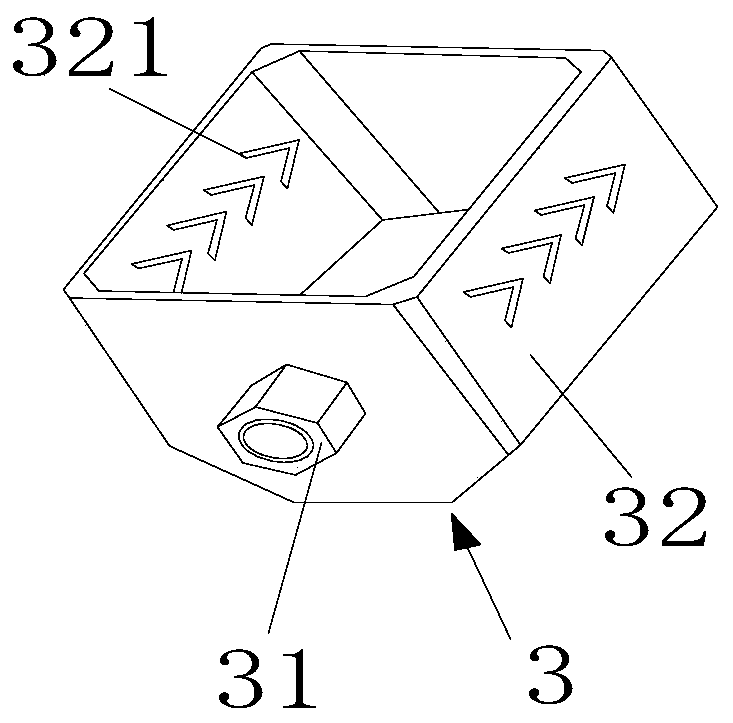

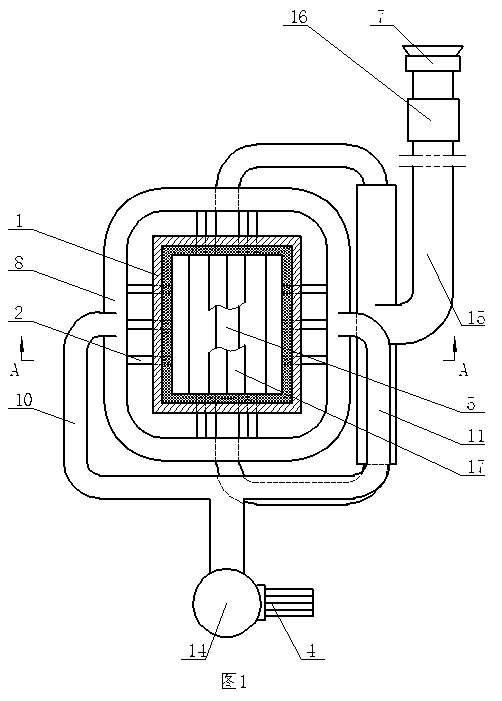

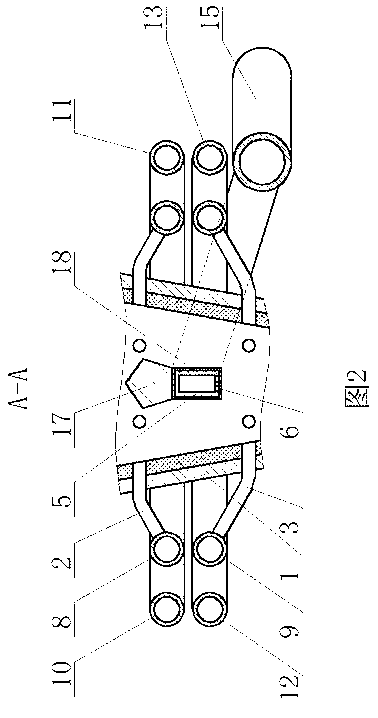

Airborne power generator cooling device

ActiveCN106505797ASolve Cooling ProblemsReduce adverse effectsCooling/ventillation arrangementAviationLow speed

The invention belongs to the aviation field, and relates to an airborne power generator cooling device, which is characterized by comprising a power generator set (1), an oil pump (2), a pressure relief valve (3), a first filter (4), a lubricating oil air cooling system, a temperature bypass valve (6), a non-return valve (7) and a second filter (8). The invention provides an airborne power generator cooling device, which solves the problem of cooling of the power generator in an aircraft full flight envelope range, particularly, in a low-speed condition, and avoids bad influences on the performance of the engine and the engine compartment appearance design.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

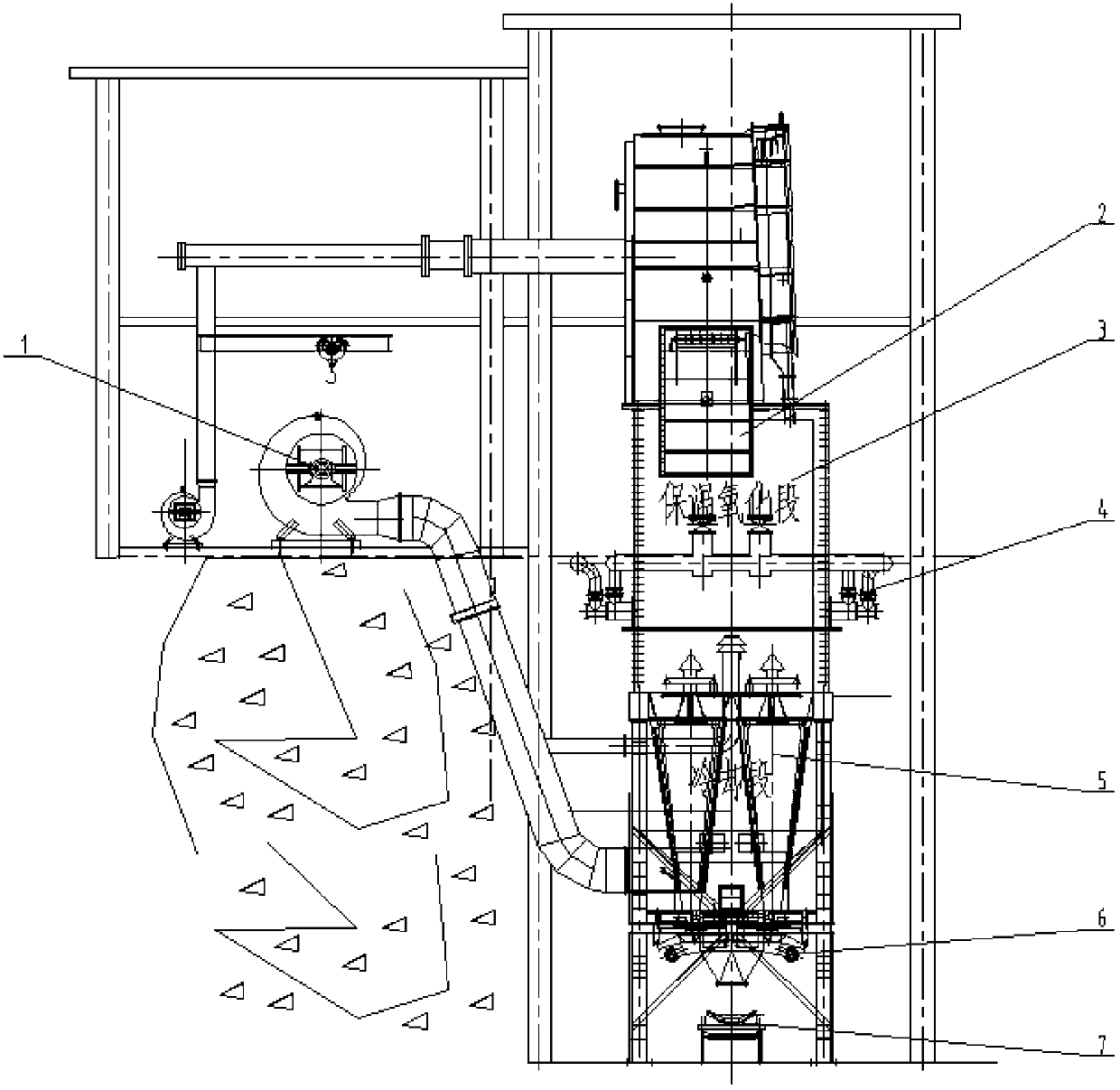

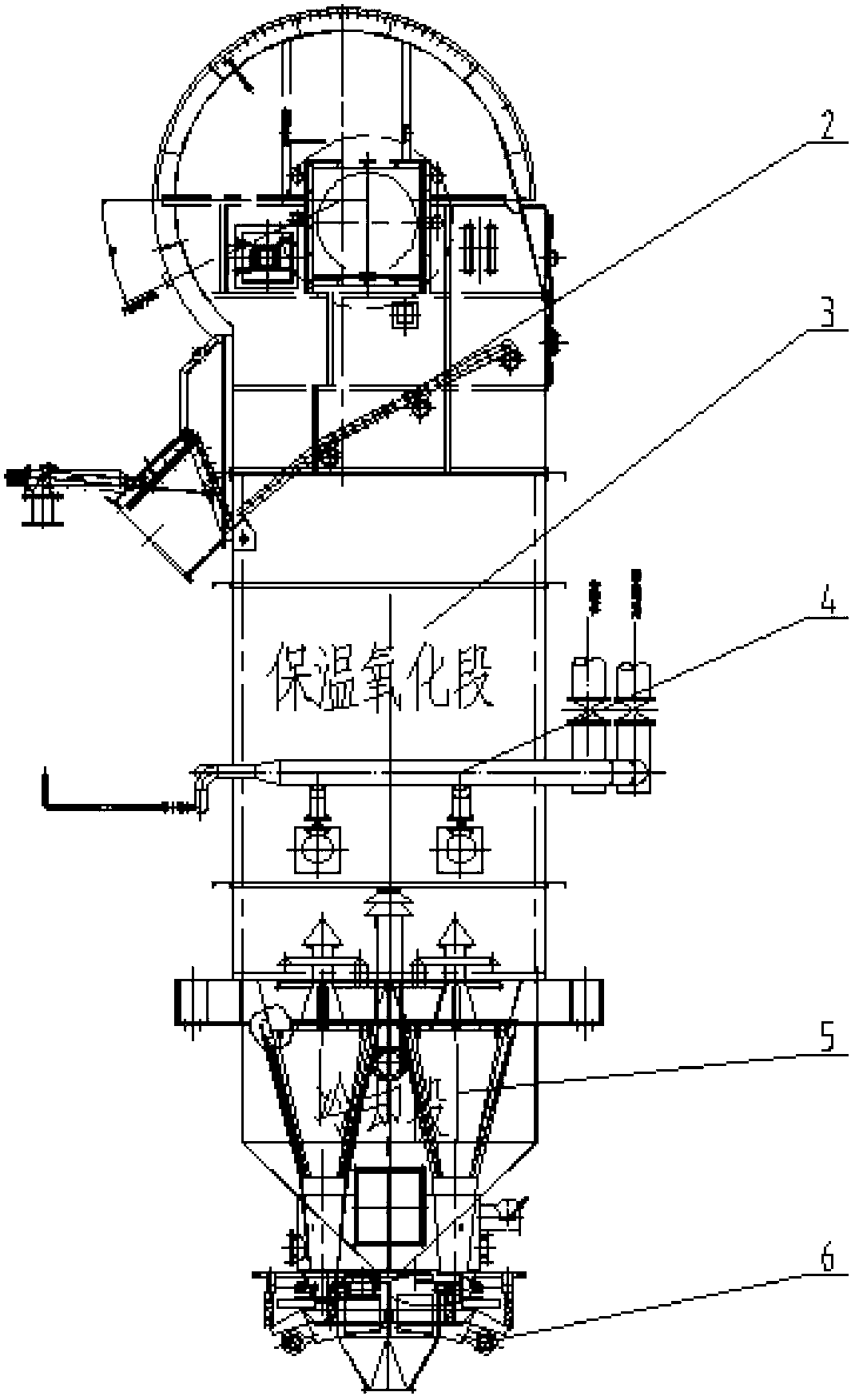

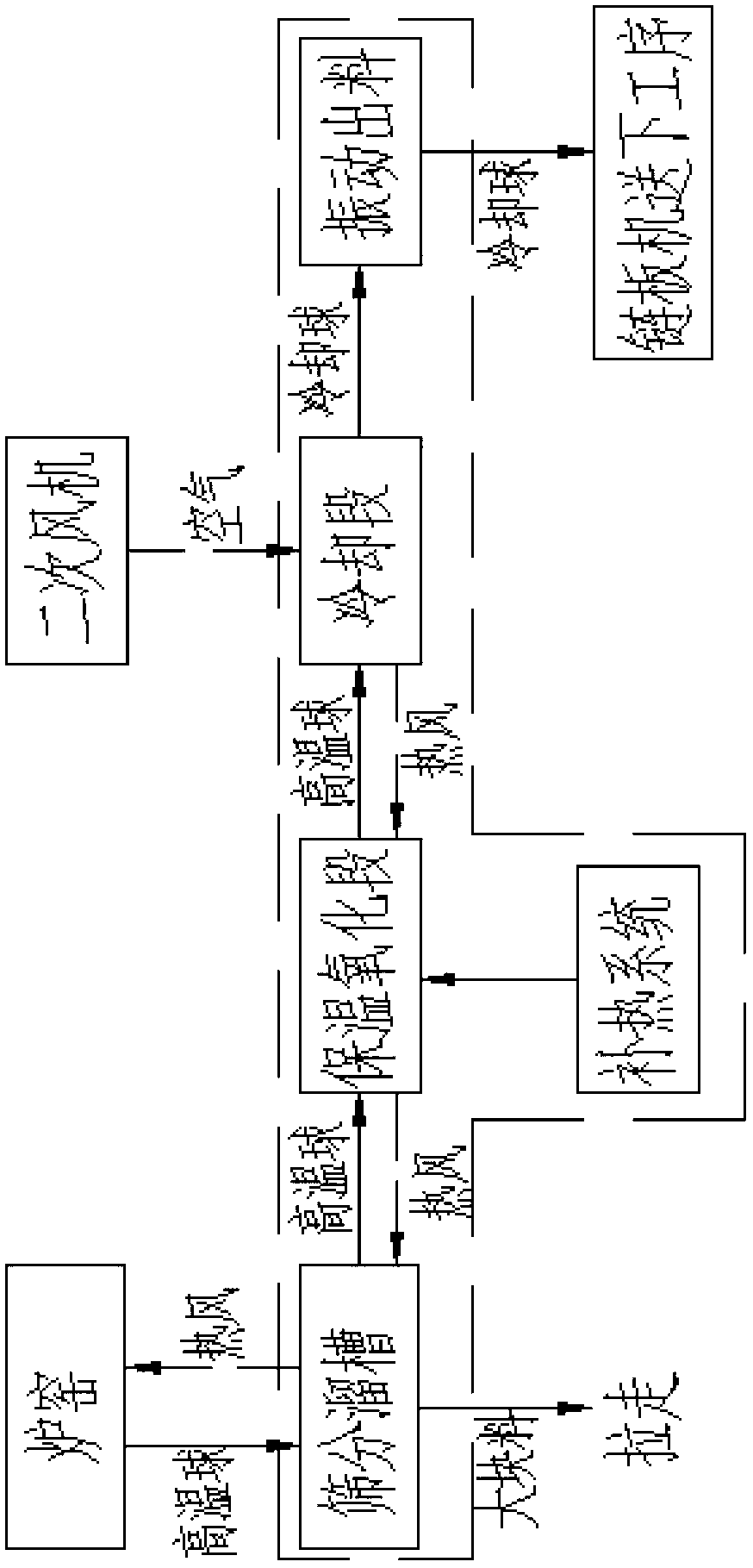

Thermal-insulating, oxidizing and cooling device used in vanadium extraction from stone coal and using method of device

The invention relates to a thermal-insulating, oxidizing and cooling device used in vanadium extraction from stone coal and a using method of the device, and the device belongs to the technical field of vanadium extraction. The thermal-insulating, oxidizing and cooling device comprises a secondary air fan, a screening chute, a thermal-insulating and oxidizing segment, a heat compensation system, a cooling segment, a vibrating discharge device and a chain-slat conveyor, wherein the screening chute is supported on a beam at the upper part of the thermal-insulating and oxidizing segment in an inclined way and an angle of 25 degrees is formed between the screening chute and the horizontal surface, the thermal-insulating and oxidizing segment is arranged under the screening chute, the cooling segment is arranged below the thermal-insulating and oxidizing segment; the cooling segment is directly communicated with the thermal-insulating and oxidizing segment in a welded way, the lower end of the cooling segment is connected with the vibrating discharge device through bolts; conveying equipment, namely the chain-slat conveyor is arranged at a 350mm part below the vibrating discharge device; the heat compensation system is arranged 300mm above the connection part of the thermal-insulating and oxidizing segment and the cooling segment; the heat compensation system is connected with the thermal-insulating and oxidizing segment through flange bolts; the secondary air fan is introduced into the cooling segment (5) through an air pipeline; and the air pipeline of the secondary air fan (1) is connected with the cooling segment (5) through flange bolts. The thermal-insulating, oxidizing and cooling device and the using method of the device have the advantages of solving the problems such as insufficient oxidizing atmosphere and short thermal insulation time in stone mine calcination.

Owner:XINXING ENERGY EQUIP

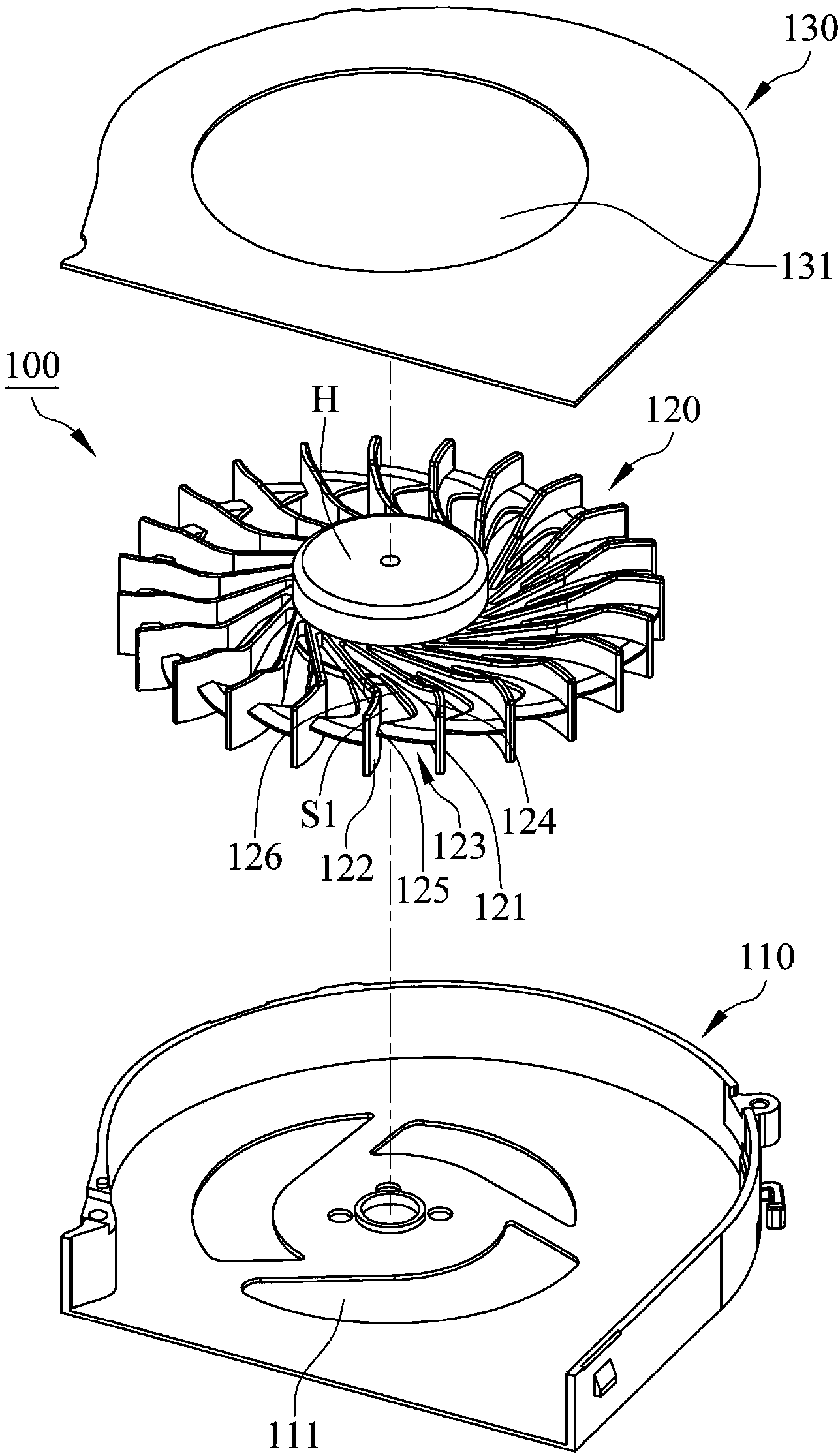

Cooling fan

Owner:ADDA

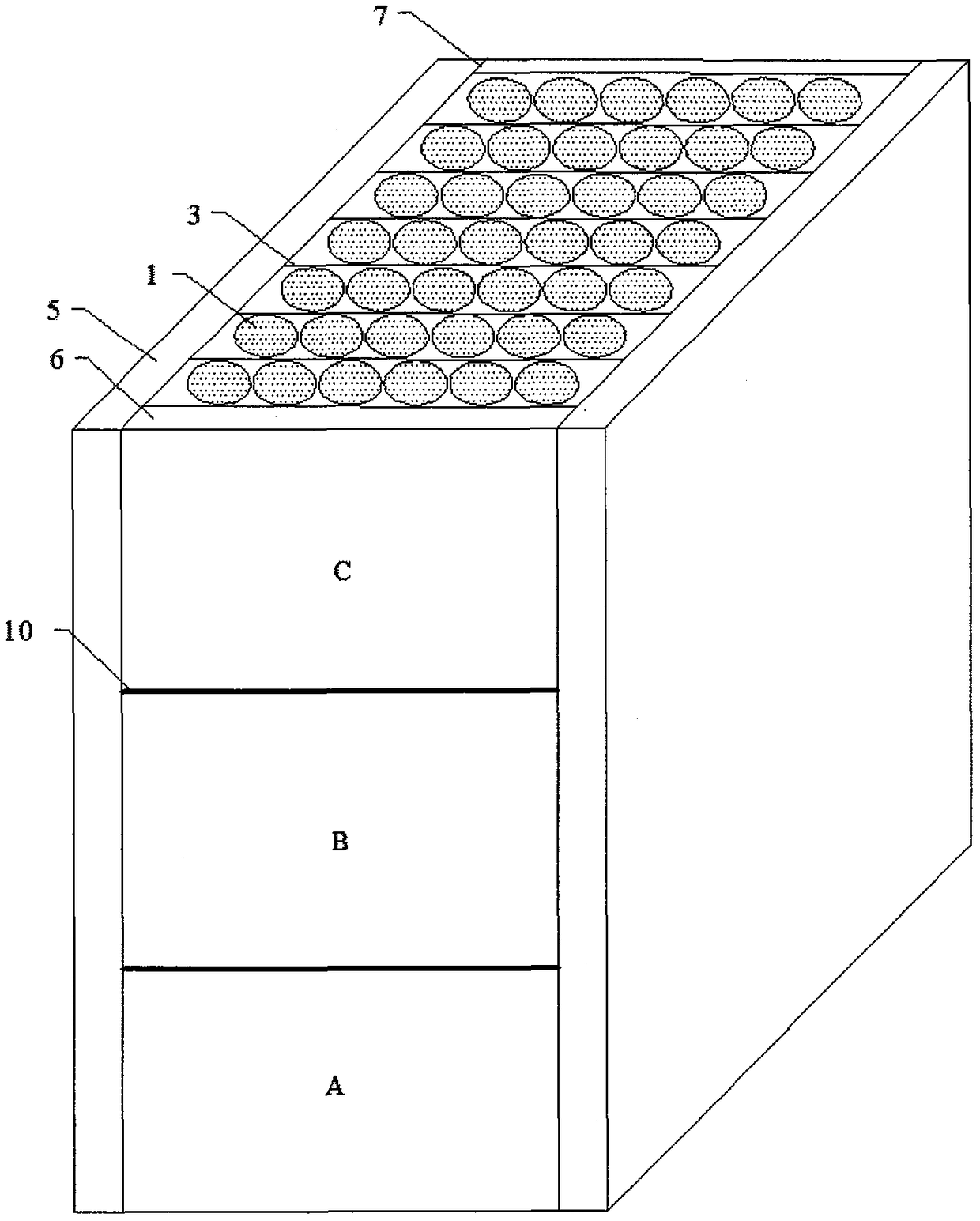

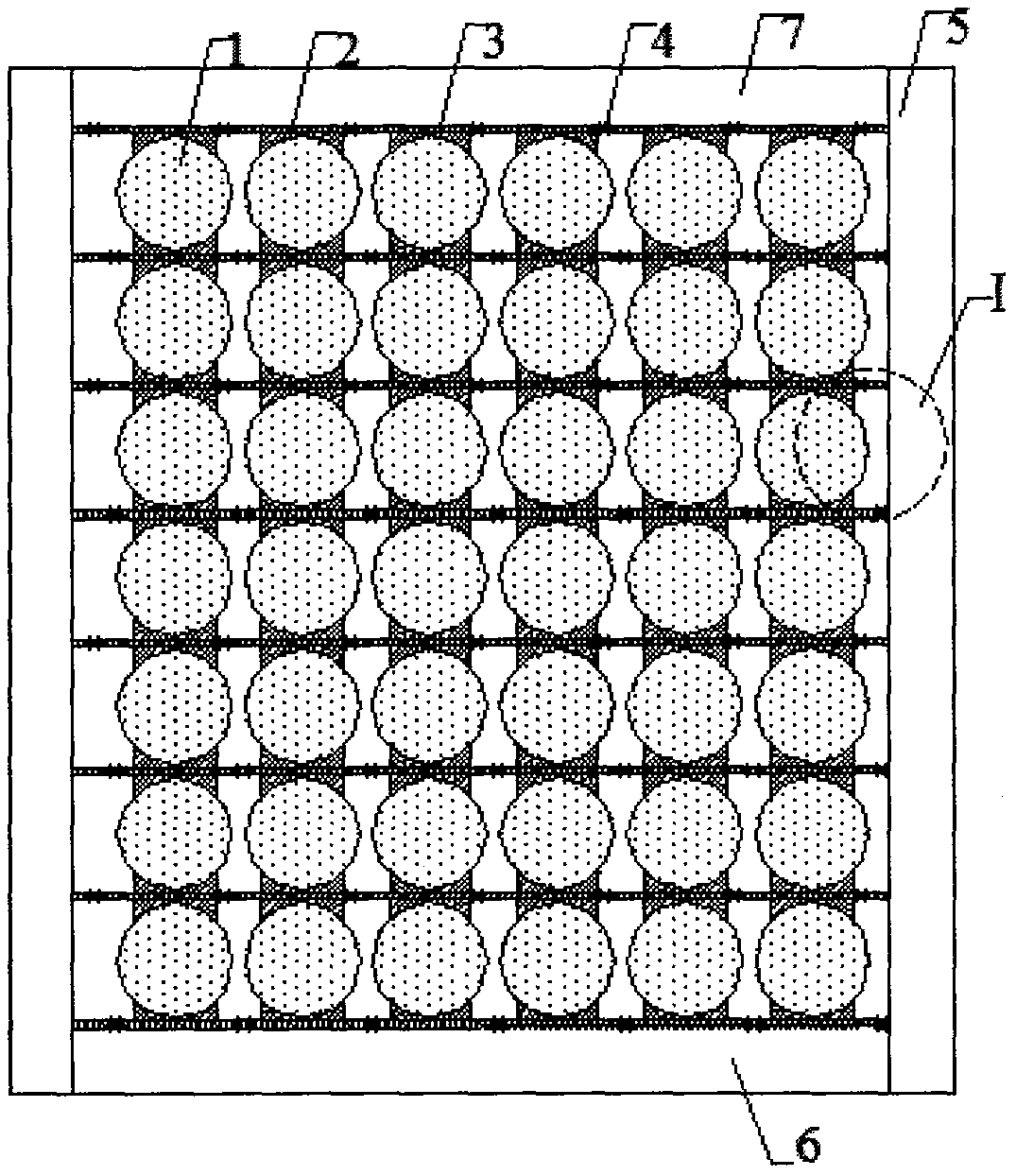

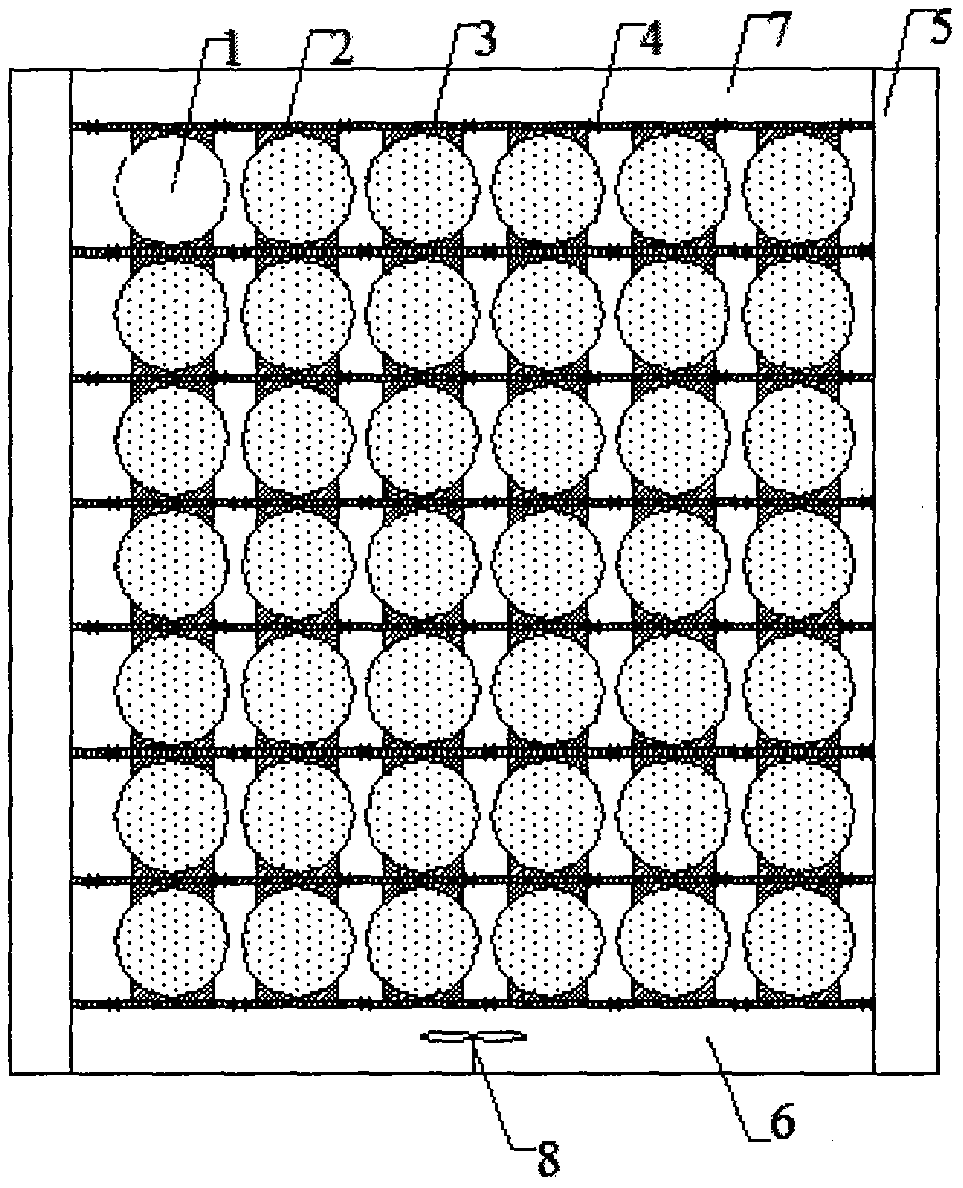

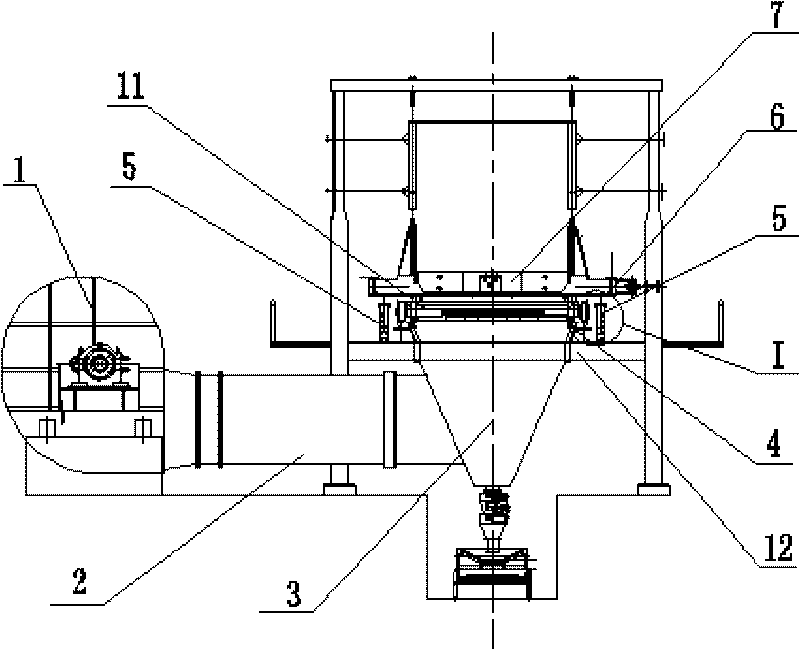

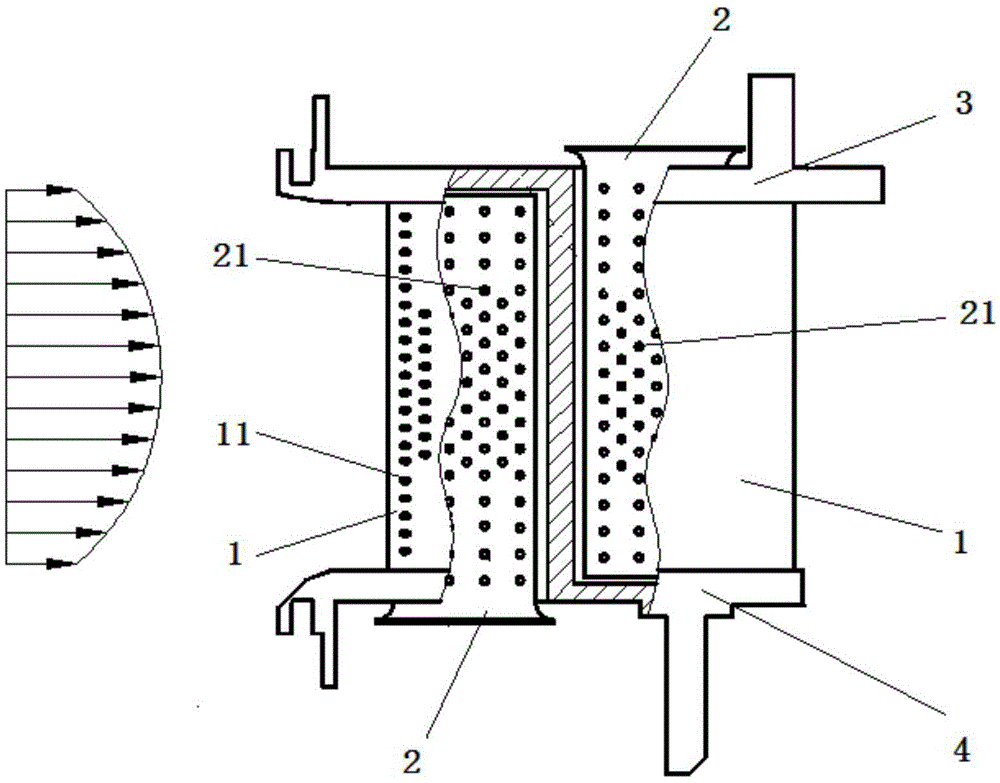

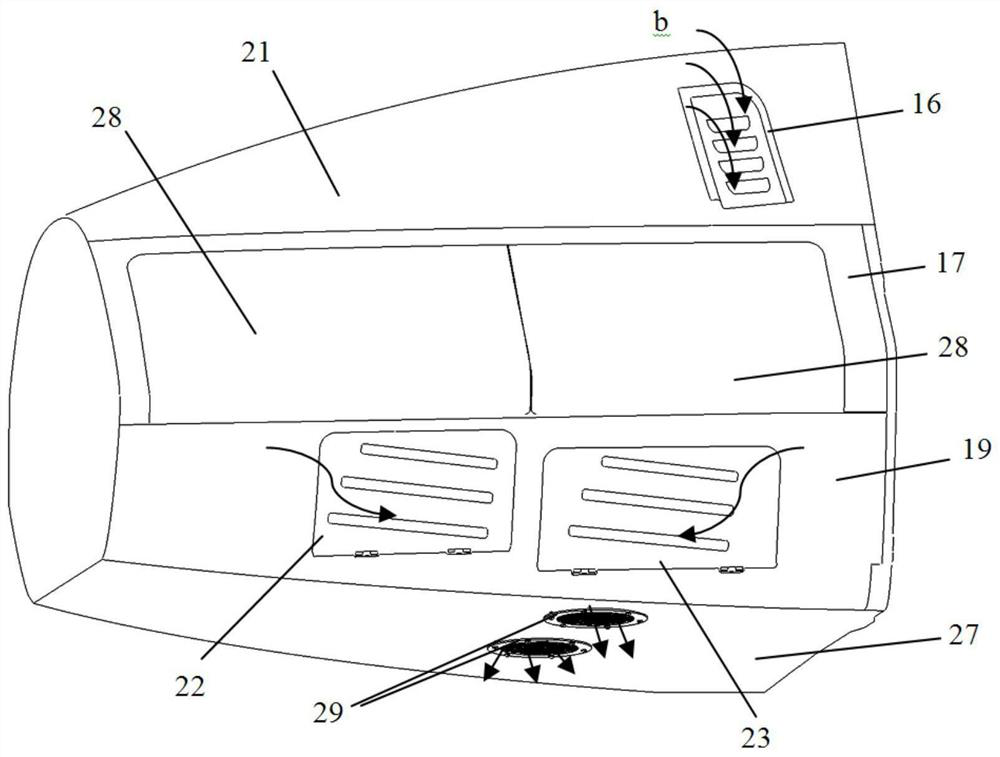

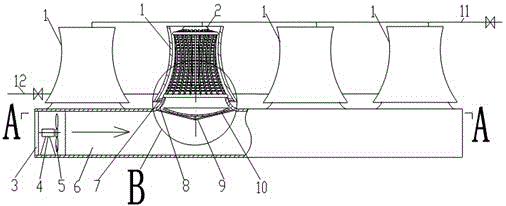

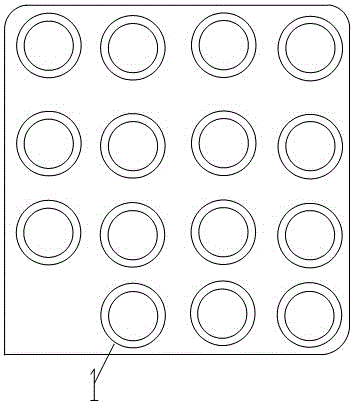

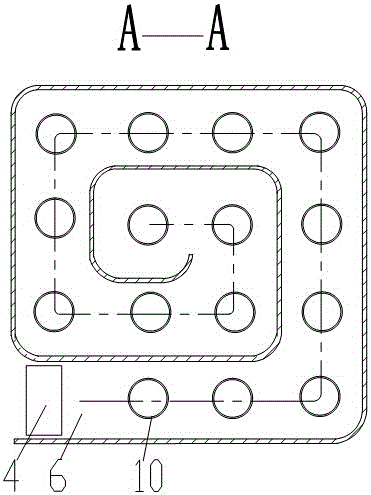

Mixed-flow temperature-uniform cylindrical battery pack

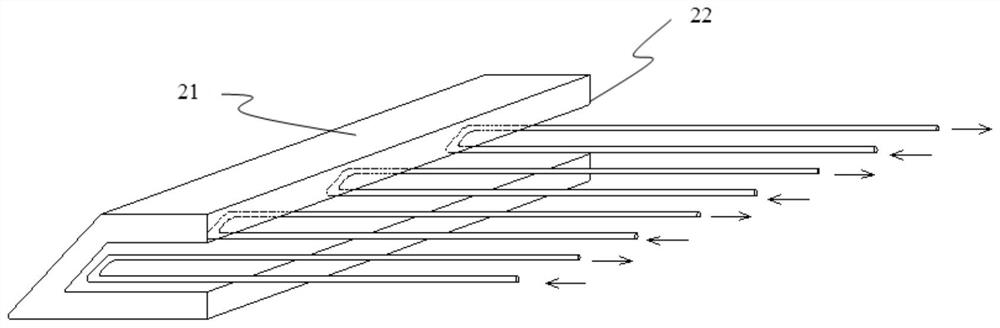

PendingCN108258359AEasy to collectIncrease cooling air volumeSecondary cellsElectrical batteryAirflow

The invention discloses a mixed-flow temperature-uniform cylindrical battery pack. According to the mixed-flow temperature-uniform cylindrical battery pack, a plurality of rows of batteries are bondedwith heat conductive sheets through high heat conductive glue; heat exchanged between a plurality of rows of heat conductive sheets with liquid flow plates on the two sides is realized; each heat conductive sheet is provided with gas flow holes; a small size fan is arranged in the mixed-flow temperature-uniform cylindrical battery pack to promote gas circulating in a battery pack chamber, and enhance mixed flow heat transfer effect of gas flow communication; the gas flow holes of adjacent rows of heat conductive sheets are arranged to be staggered with each other; from the top to the bottom,gaps between the heat conductive sheets and a battery pedestal is designed to be wide and narrow alternatively, so that gas flow longitudinal and transverse multi-dimensional flow disturbance is enhanced further, and heat transfer on the air side of the heat conductive sheets is enhanced. Pneumatic series flow, and hole / gap staggered multi-dimensional gas flow disturbance is capable of realizing auxiliary enhancing of the heat transfer capacity of the air side of the heat conductive sheets and batteries, increasing temperature uniformizing effect of pneumatic series flow among rows, improvingthe battery pack internal temperature uniformity and consistency. The mixed-flow temperature-uniform cylindrical battery pack is suitable for cold and warm heat control process in battery pack heat management, and is promising in application prospect.

Owner:JILIN UNIV

Flexible sealing and water sealing rotary forced-air cooler

InactiveCN101762159ADynamic flexible seal structure remains unchangedGuaranteed reliabilityEngine sealsFurnace typesElectricityEngineering

This invention discloses a flexible sealing and water sealing rotary forced-air cooler, adopting multiple air blowers to connect with an air box through an air pipe, wherein the outer circumference of the top of the air box is connected with a side of a flexible sealing device, the other side of the flexible sealing device is connected with a rotary beam of a trolley, a water sealing device is respectively installed at the outsides of the flexible sealing device and the rotary beam, the outer circumference of the trolley is movably connected with a rotary sealing device, the water sealing device comprises an annular water tank the top of which is connected with a cover board, the centre of the annular water tank is provided with an annular clapboard, the annular clapboard is fixed at the bottom of the trolley, and the annular water tank is fixed on a flat slab of the stand. The connection scheme of the flexible sealing device and the flat slab of the stand overcomes the disadvantages of the gap existence, gas leakage, low working efficiency of annular cooler and electricity waste of the movable-static flexible sealing which uses a rubber sealing plate as a main body, and the invention is suitable for cooling different kinds of ores rotating on trolley.

Owner:XIANGTAN COAL MINING MACHINERY & ELECTRIC INDAL

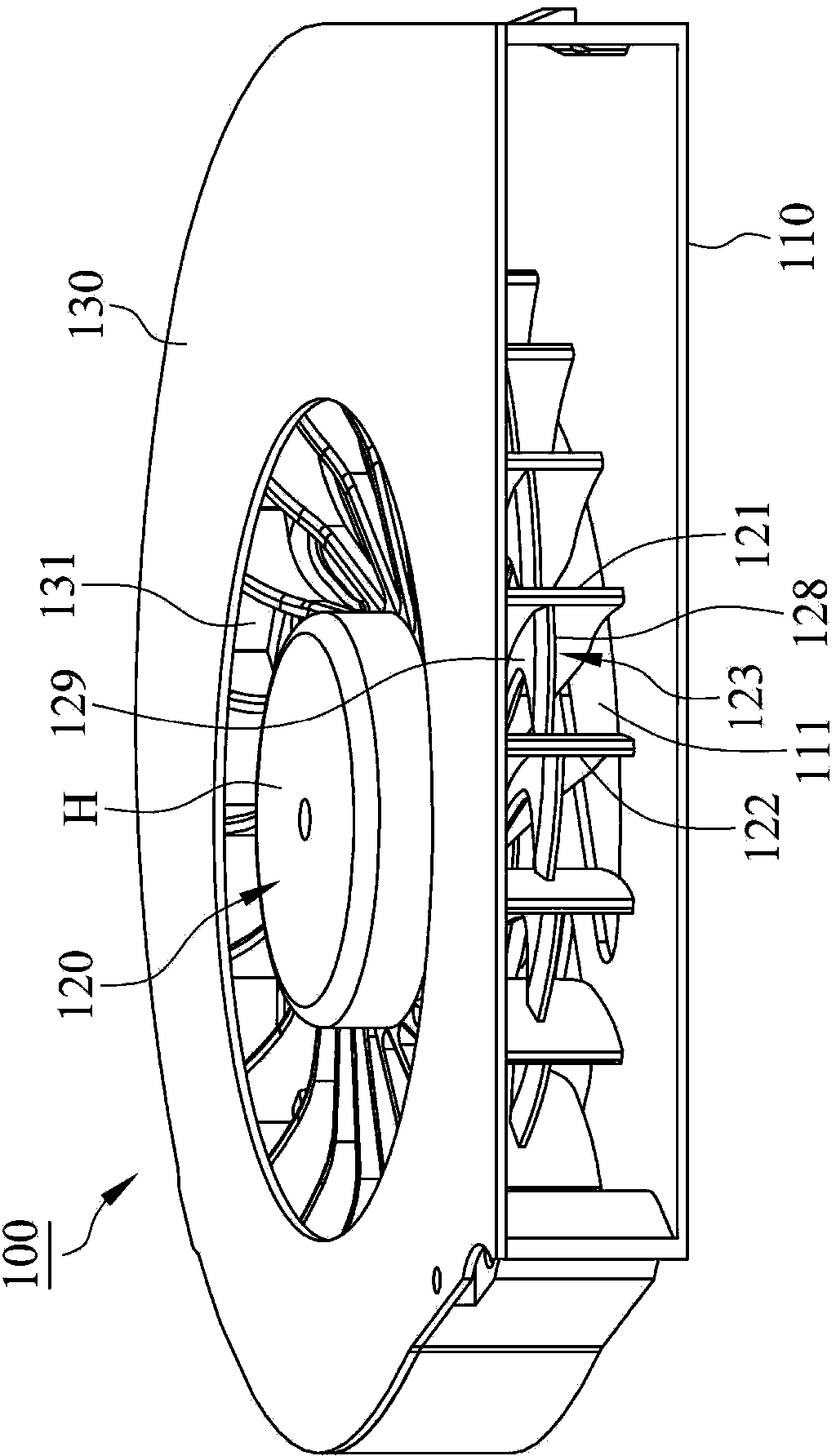

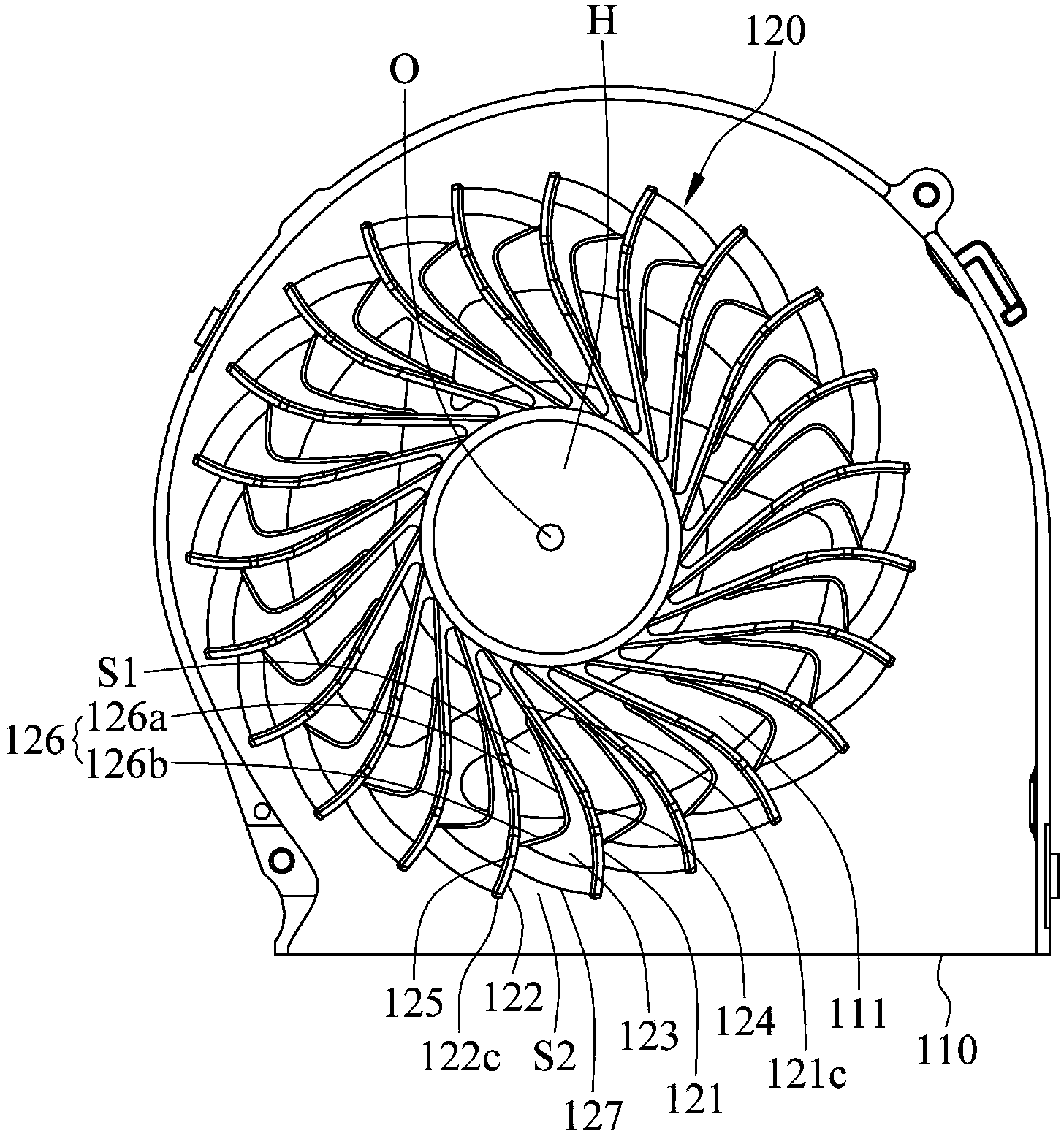

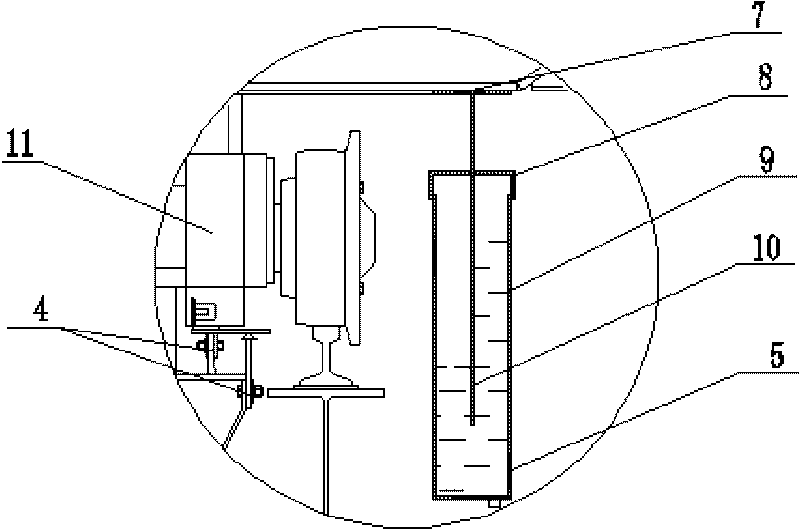

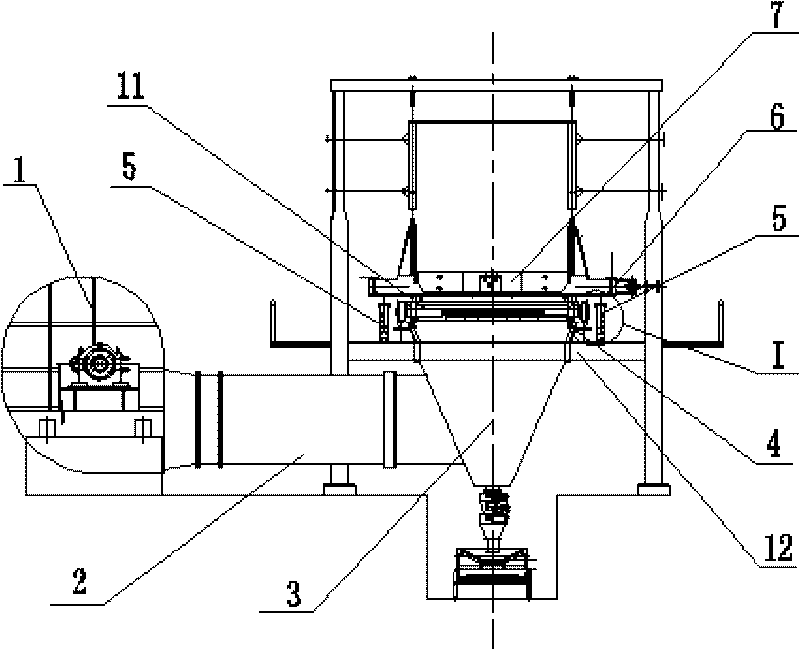

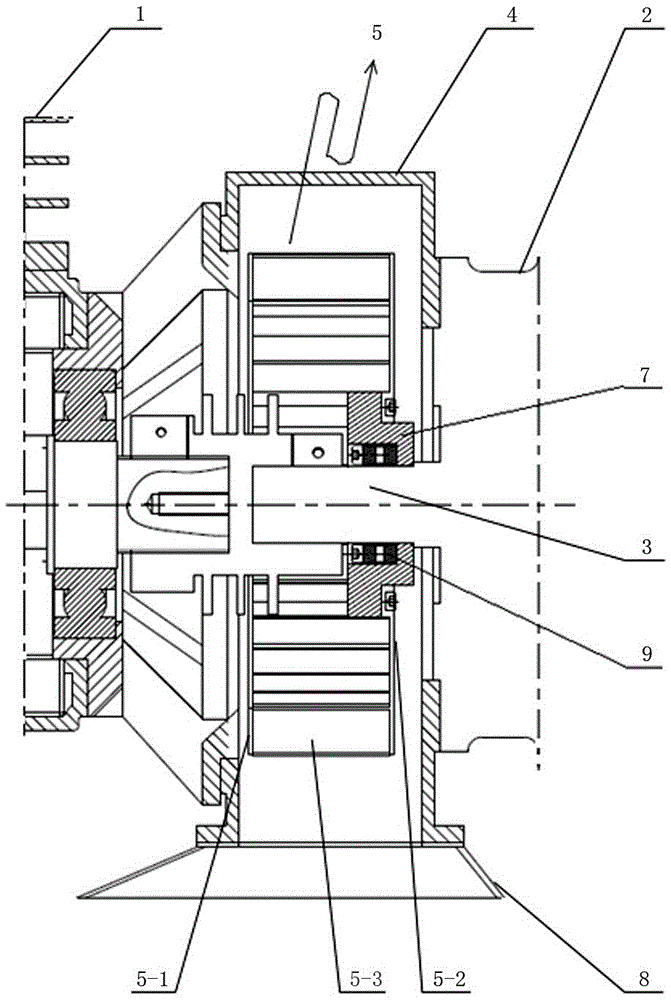

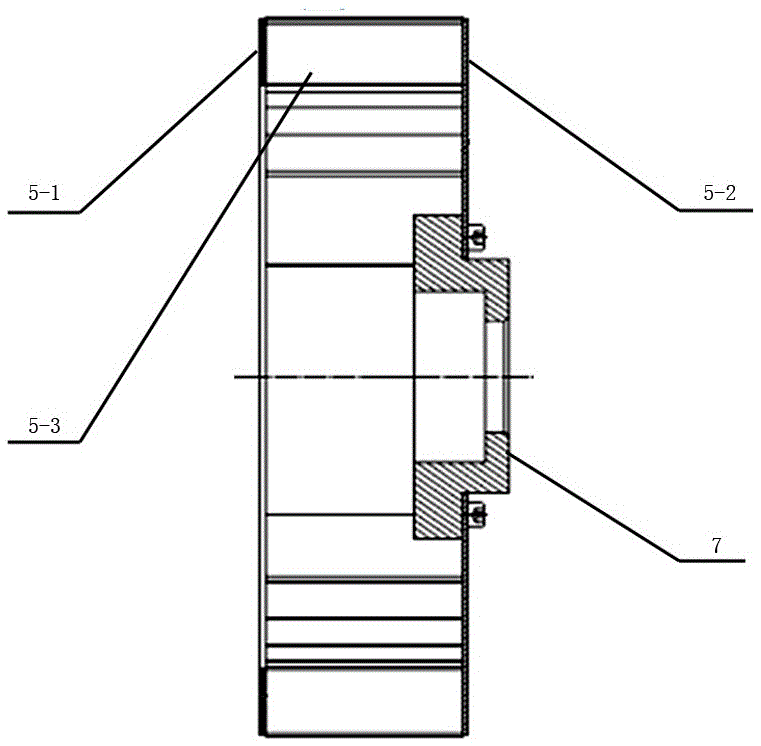

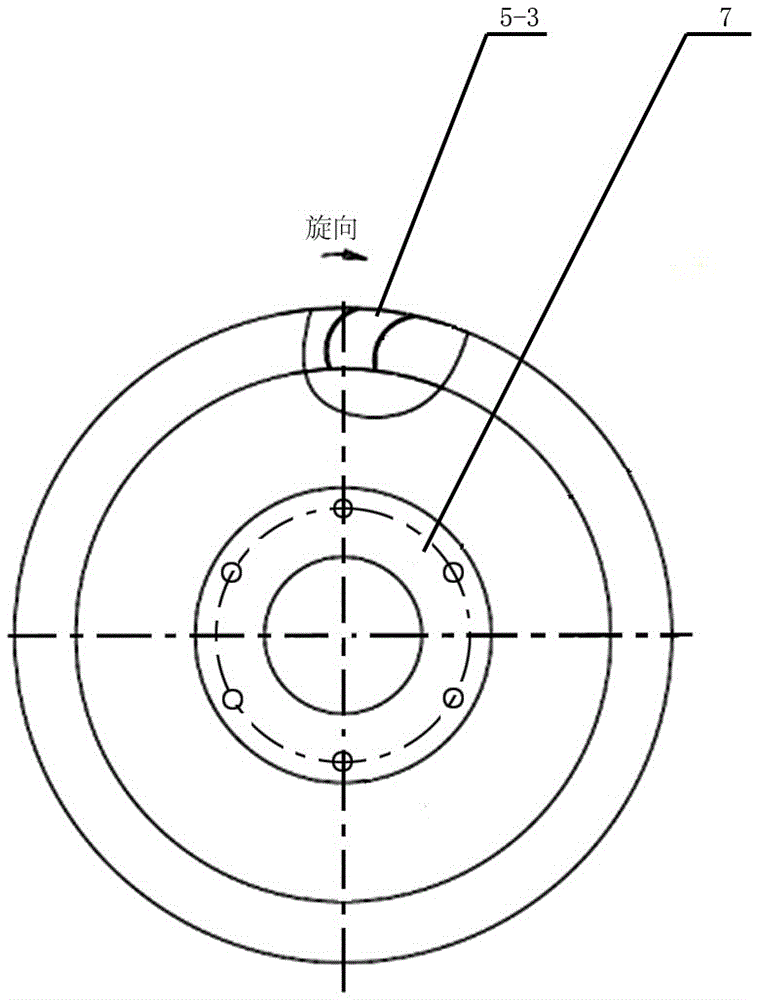

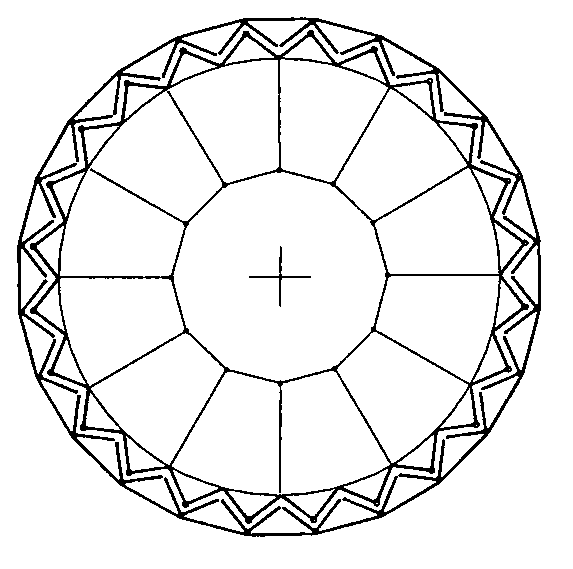

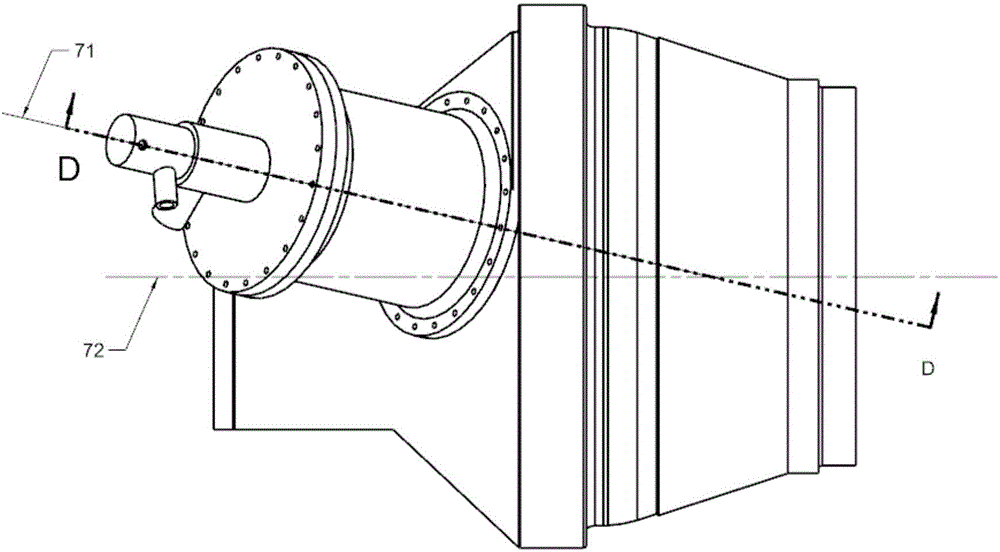

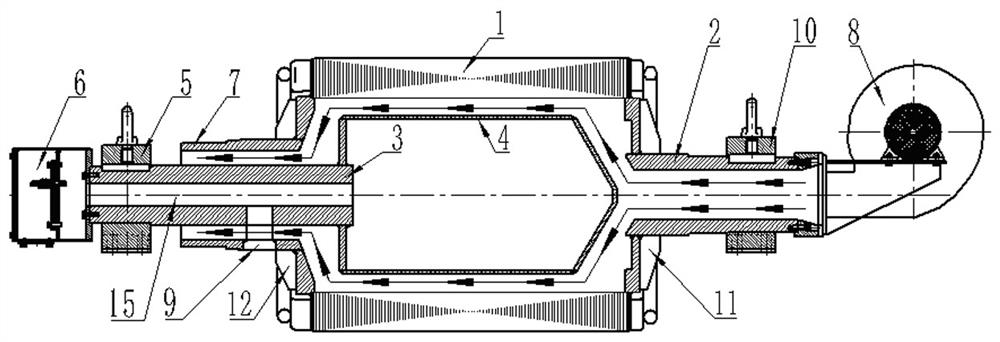

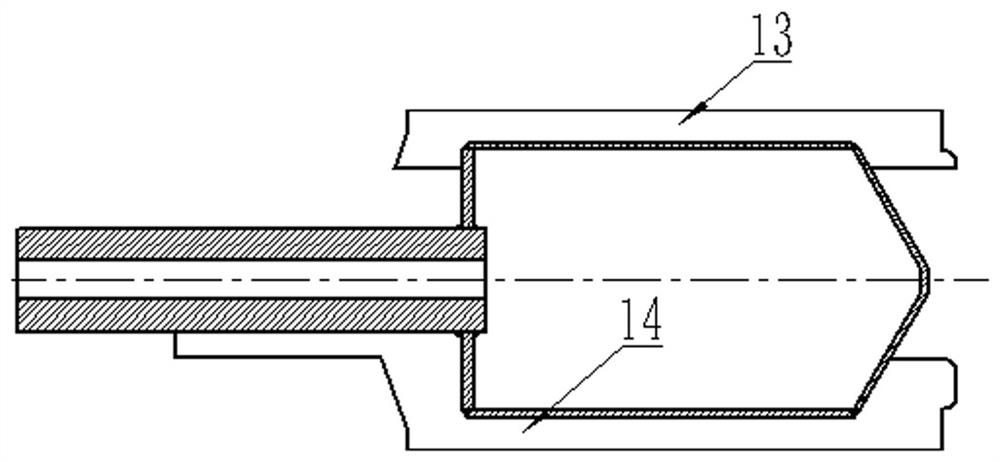

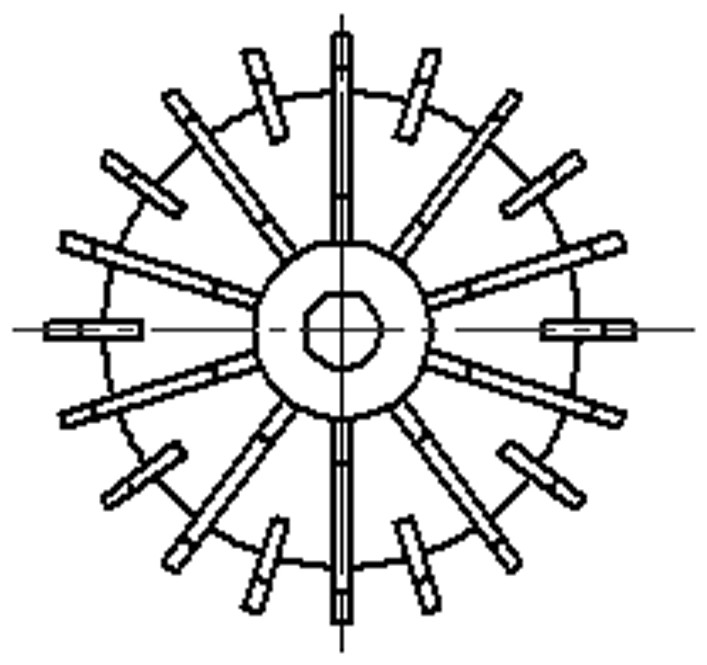

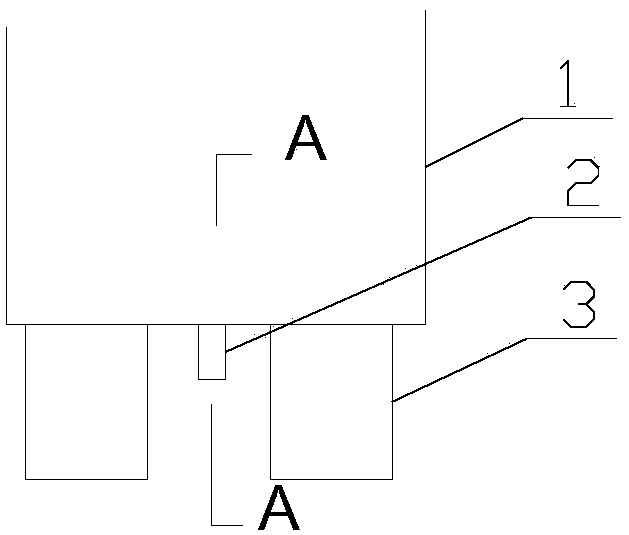

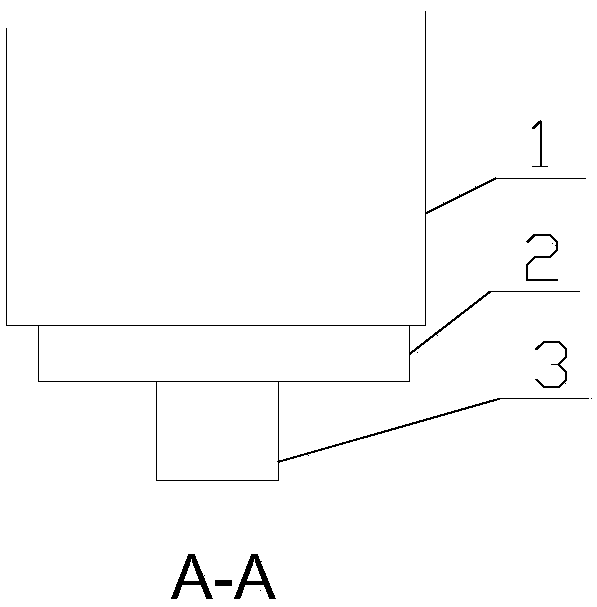

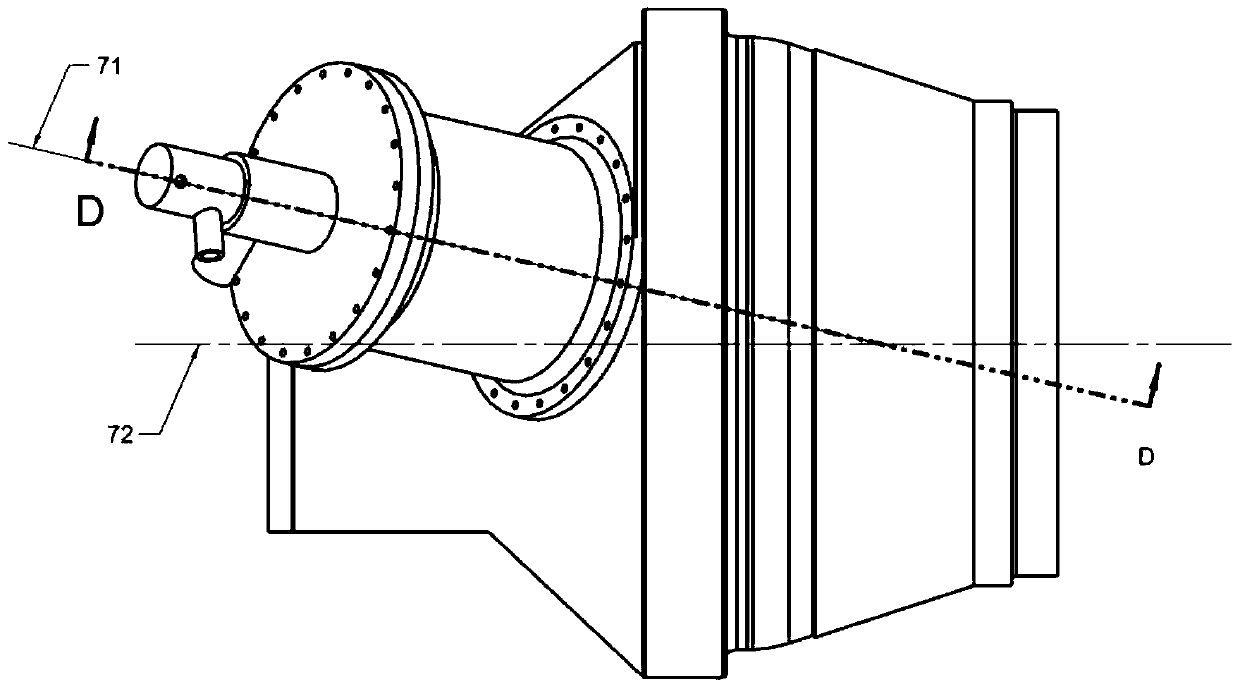

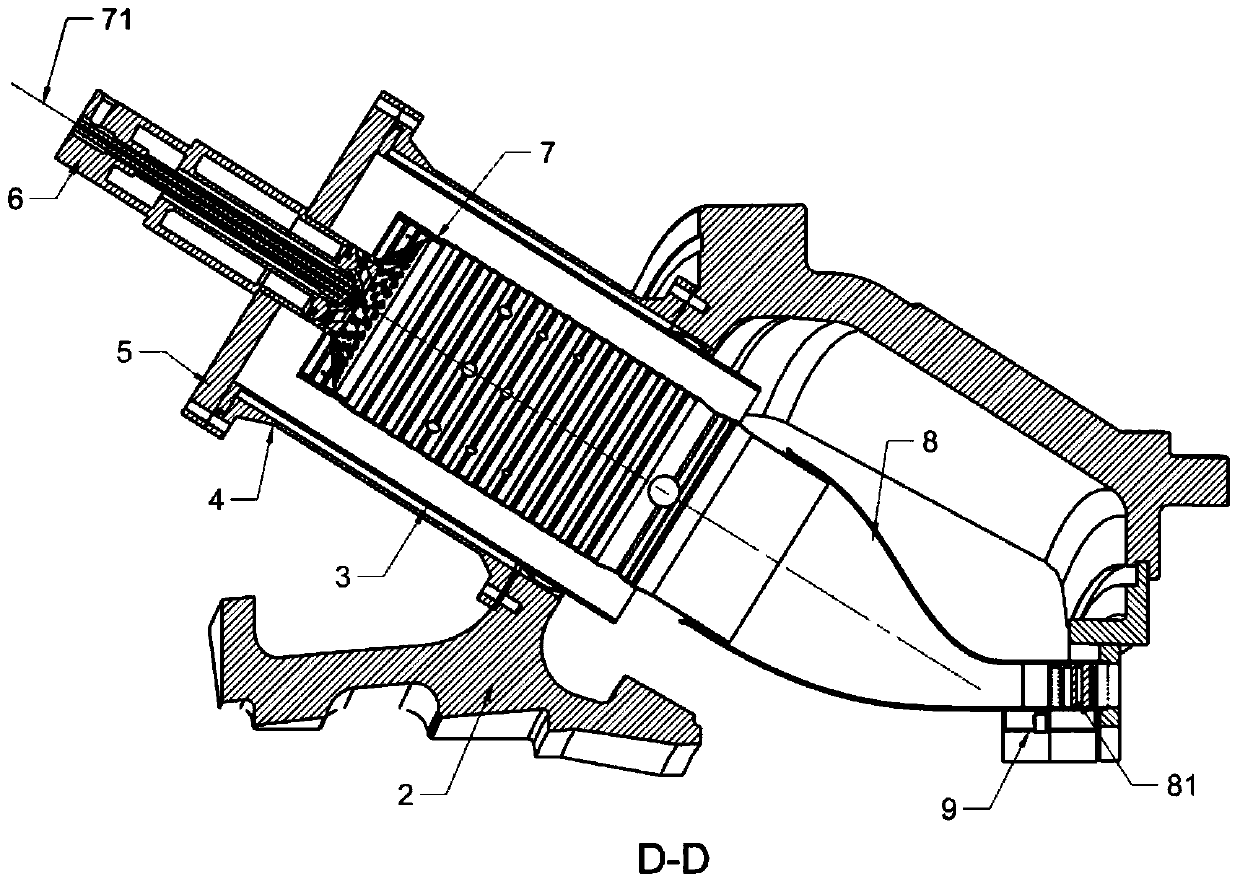

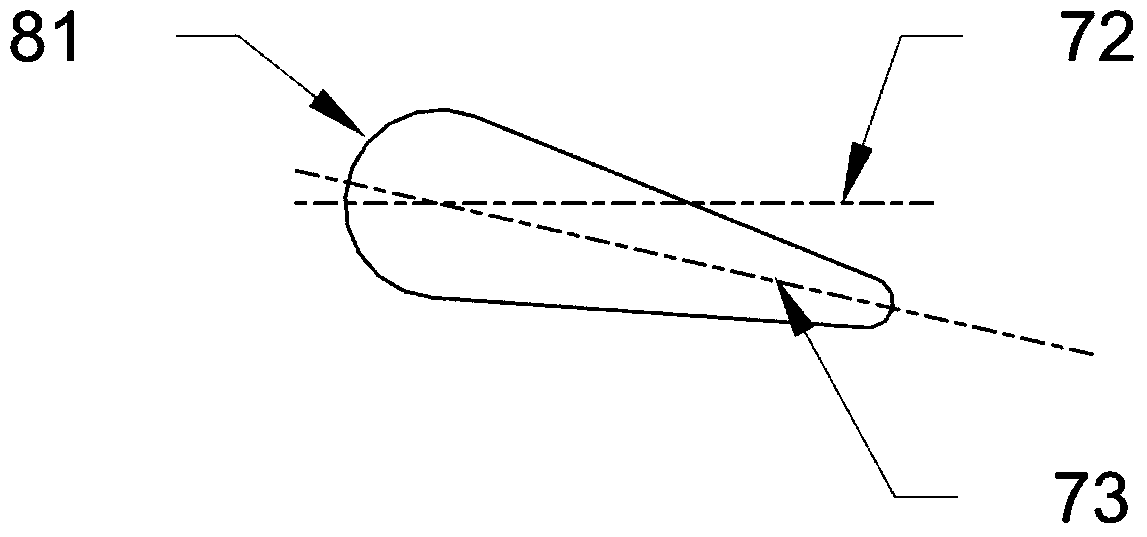

Centrifugal fan device of large-discharge-capacity oilless air compressor of rail transit and mounting method thereof

The invention provides a centrifugal fan device of a large-discharge-capacity oilless air compressor of a rail transit and a mounting method thereof. The centrifugal fan device comprises a volute and an impeller arranged in the volute, wherein the impeller comprises a front annular disc, a rear annular disc and multiple blades uniformly arranged at the outer periphery between the front annular disc and the rear annular disc; the center hole of the rear annular disc is provided with a fan flange used for connecting the impeller with a motor shaft; a tensioning sleeve is arranged between the fan flange and the motor shaft; the included angle between a tangent line of an outside spur line of the blade and the tangent line in a peripheral direction is less than 13 degrees. The centrifugal fan device is capable of shortening the axial size of installation space needed for a cooling fan, realizing an integrated design of an air supply device in the rail transit, greatly enhancing the compact type of the air supply device, supplying sufficient cooling air amount to the oilless air compressor in the rail transit by use of a limited space and completely meeting the cooling requirement of the oilless air compressor.

Owner:SHIJIAZHUANG JIAXIANG PRECISION MASCH CO LTD

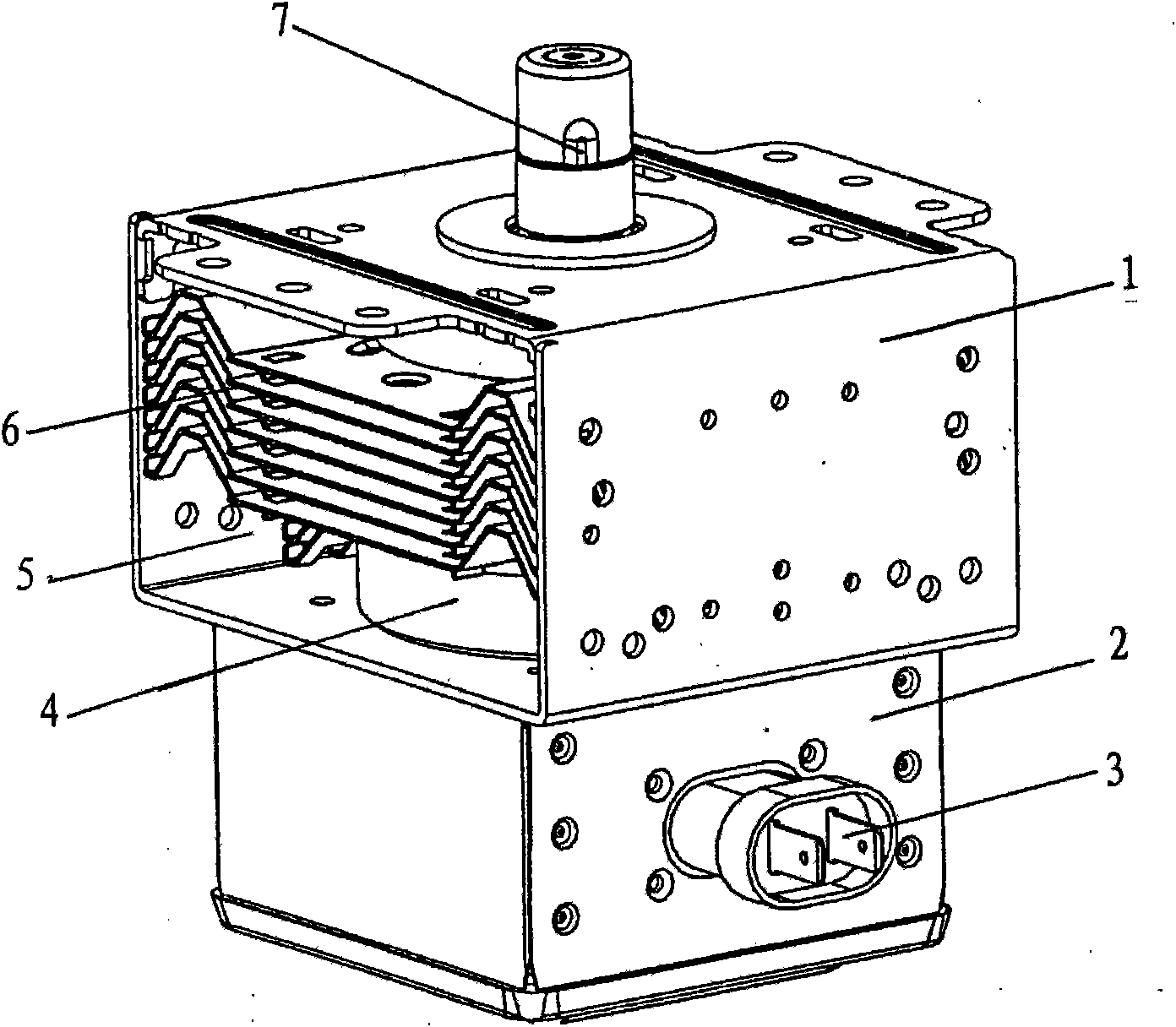

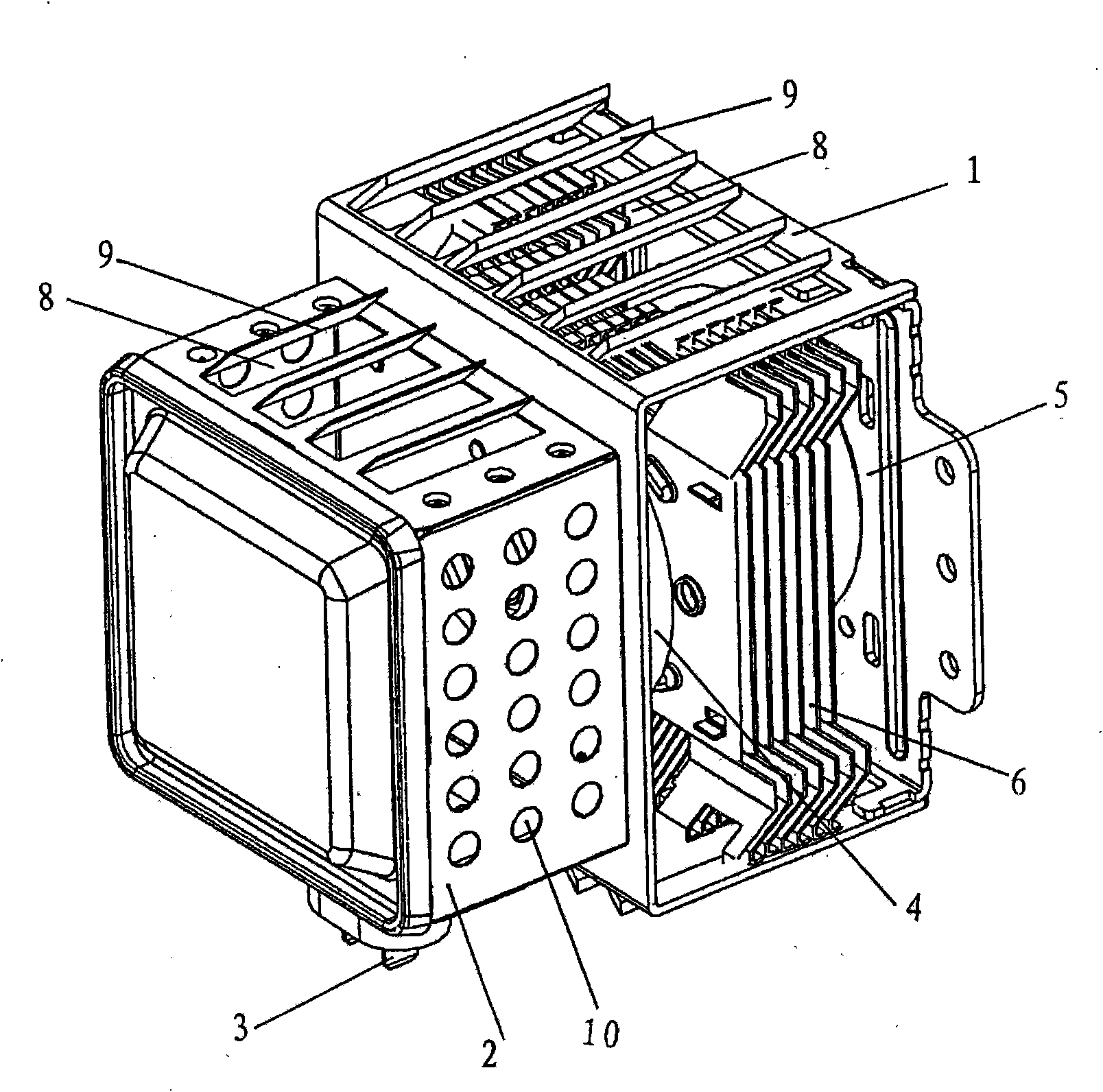

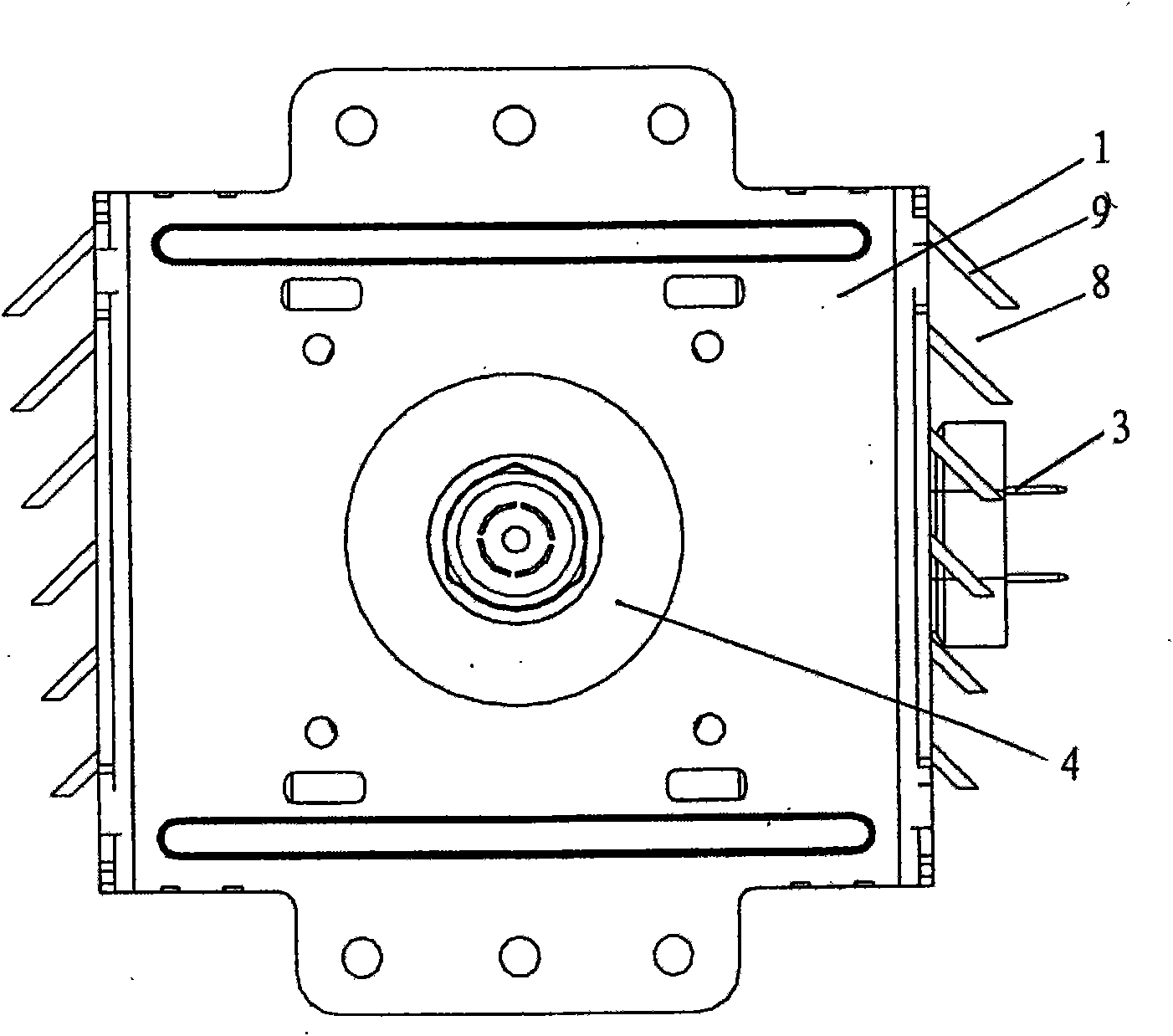

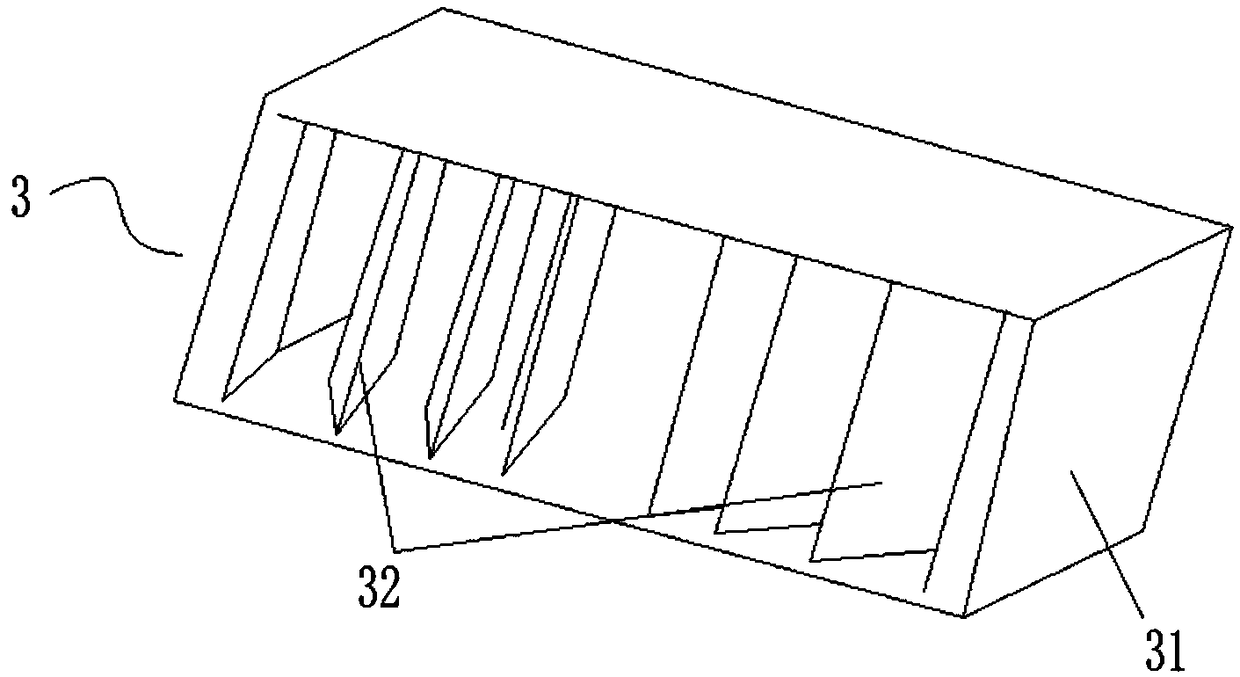

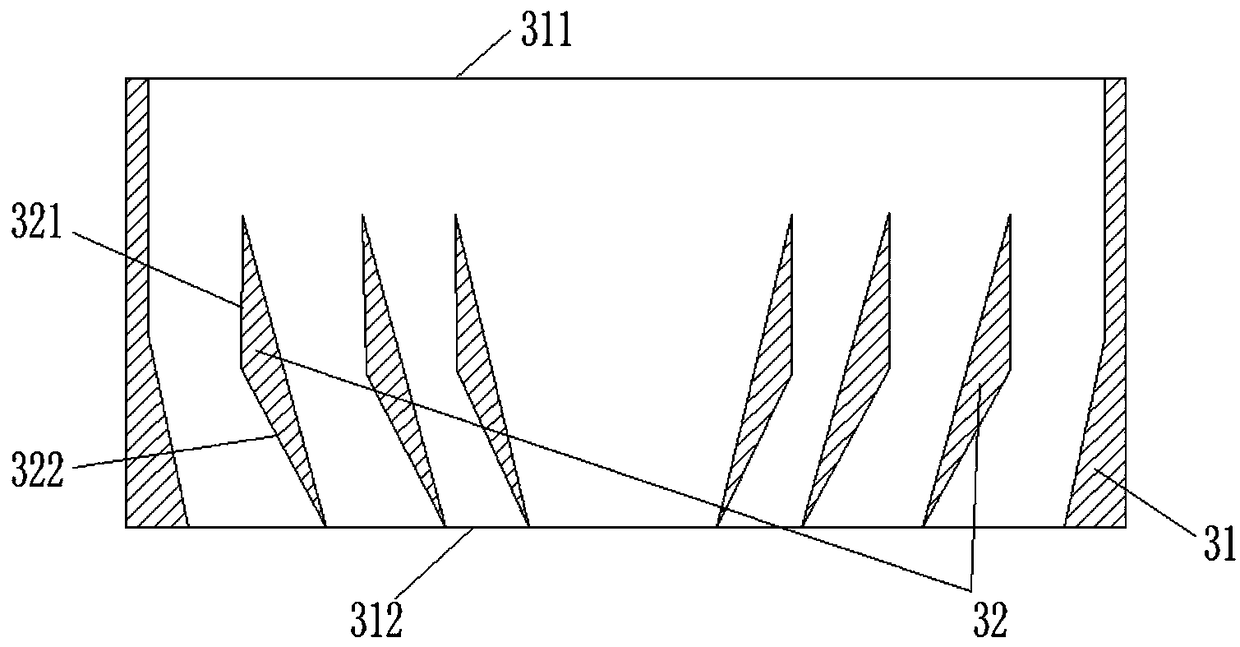

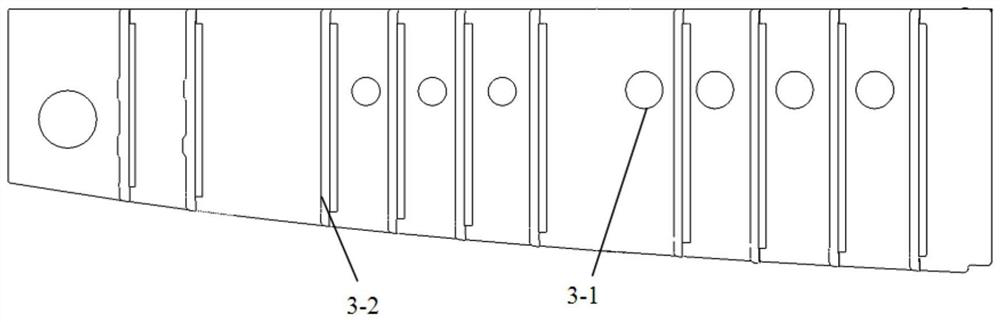

Radiating structure of shell having stream guidance opening of microwave oven magnetron

InactiveCN101645384AImprove heat dissipation and cooling efficiencyIncrease cooling air volumeTransit-tube vessels/containersDomestic stoves or rangesMicrowave ovenEngineering

The invention relates to a radiating structure of a shell having stream guidance openings of a microwave oven magnetron, which is characterized in that the lateral surface of the shell is provided with a plurality of stream guidance openings, and the lateral surface of the shell provided with the stream guidance openings comprises the lateral surfaces of an upper shell and a lower shell of the magnetron. A cutting piece for cutting the stream guidance openings extends outwards obliquely from the lateral surface of the shell; the stream guidance openings formed by the oblique outward extensionof the cutting piece face the direction of a fan; and the oblique outward extension of the cutting piece on the lateral surface of the shell along the blowing direction of the fan is gradually raised.Simultaneously, the lateral surface and the back surface of the shell on the lower part of the magnetron are provided with through holes, and the lateral surface of the shell on the lower part is over against the blowing direction of the fan. When the magnetron works, the air forced to flow by the fan can enter the shell of the magnetron from different directions and parts at the same time so asto enlarge an air flow passage, increase the radiating air quantity, and improve the radiating and cooling efficiency of the magnetron.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

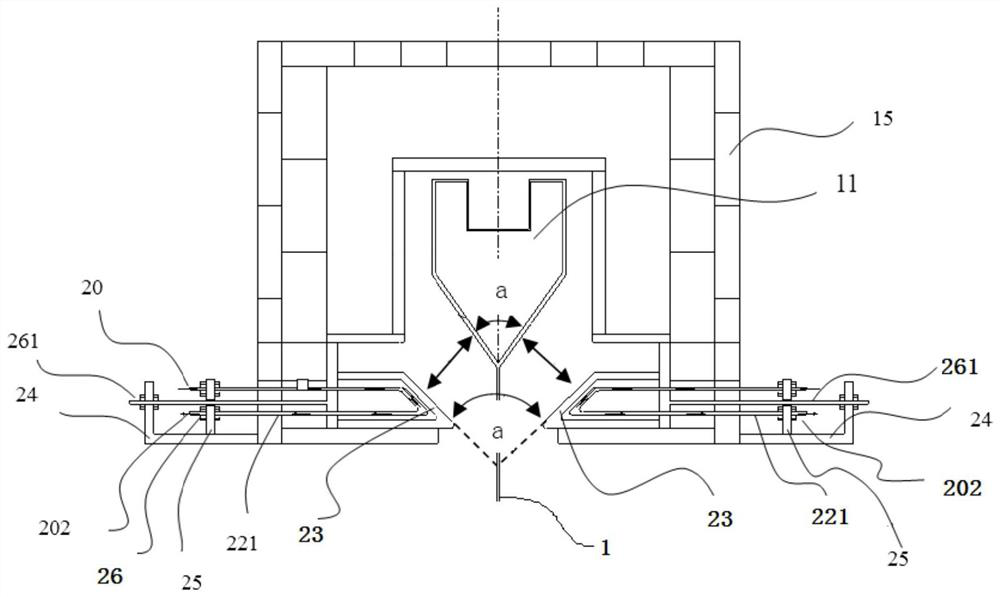

Boosted air cooling tower

InactiveCN103712472AReduce in quantityReduce the required powerSteam/vapor condensersCooling towerEngineering

The invention belongs to the field of heat exchange, and relates to a boosted air cooling tower, in particular to an air-cooling power generation air cooling tower structure and an air driving mode. Due to great difference of air temperature in winter and summer and dual action of strong wind, a pure natural ventilation air cooling tower is difficult to meet current cooling requirements. According to the boosted air cooling tower, a structure with axial flow fans of an electric and power generation dual-purpose motor, openable and closeable partition curtains and a warm passage disposed in a natural ventilator is adopted. Cooling capacity of the air cooling tower in summer is greatly enhanced, damage of strong wind is weakened greatly, excess draft in the air cooling tower in winder can be utilized, energy is recovered through the axial flow fans, and the warm passage is opened to melt an accidently-frozen heat exchanger. The boosted air cooling tower can be matched with direct air cooling and indirect air cooling units in various sizes.

Owner:李宁

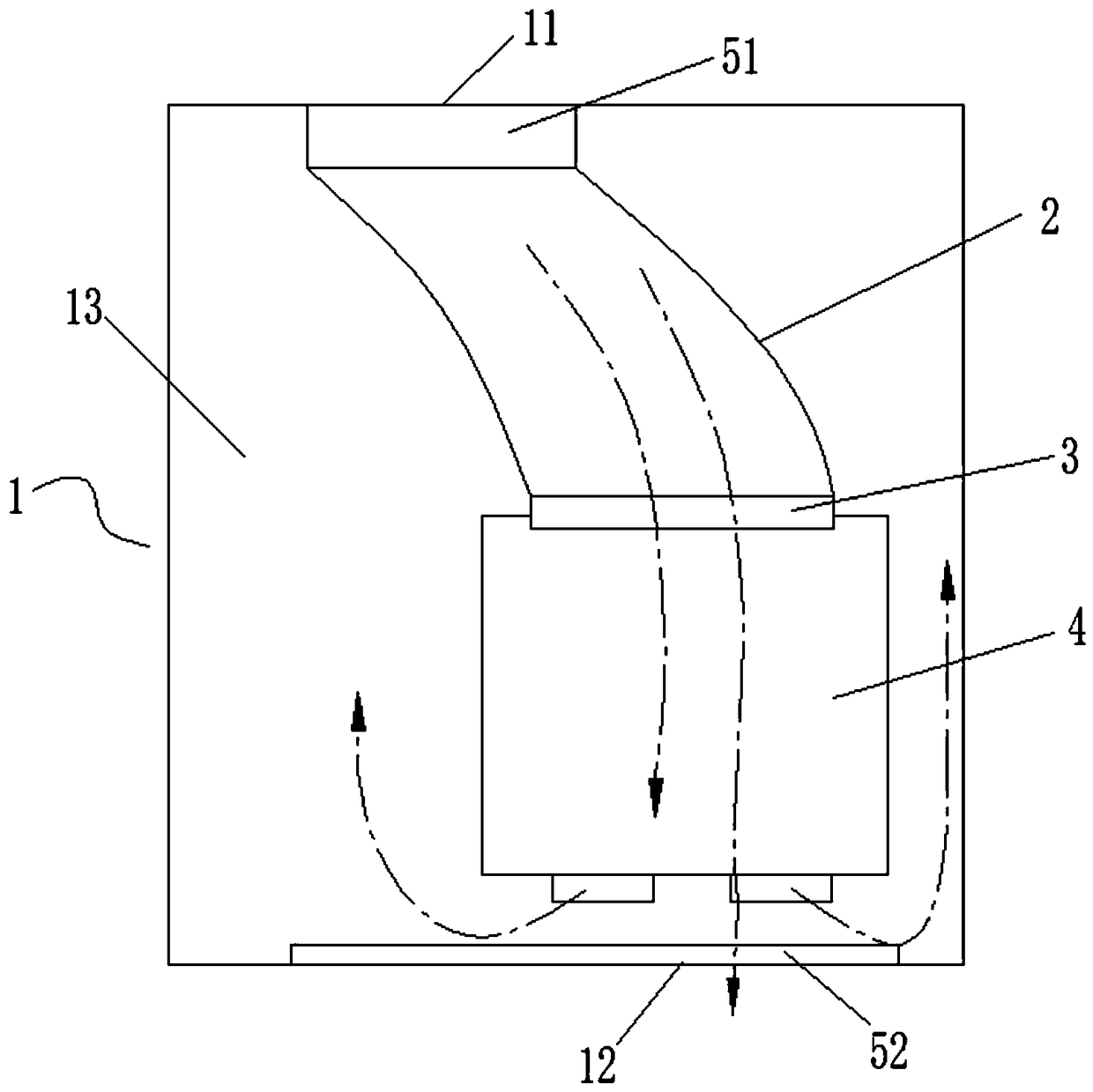

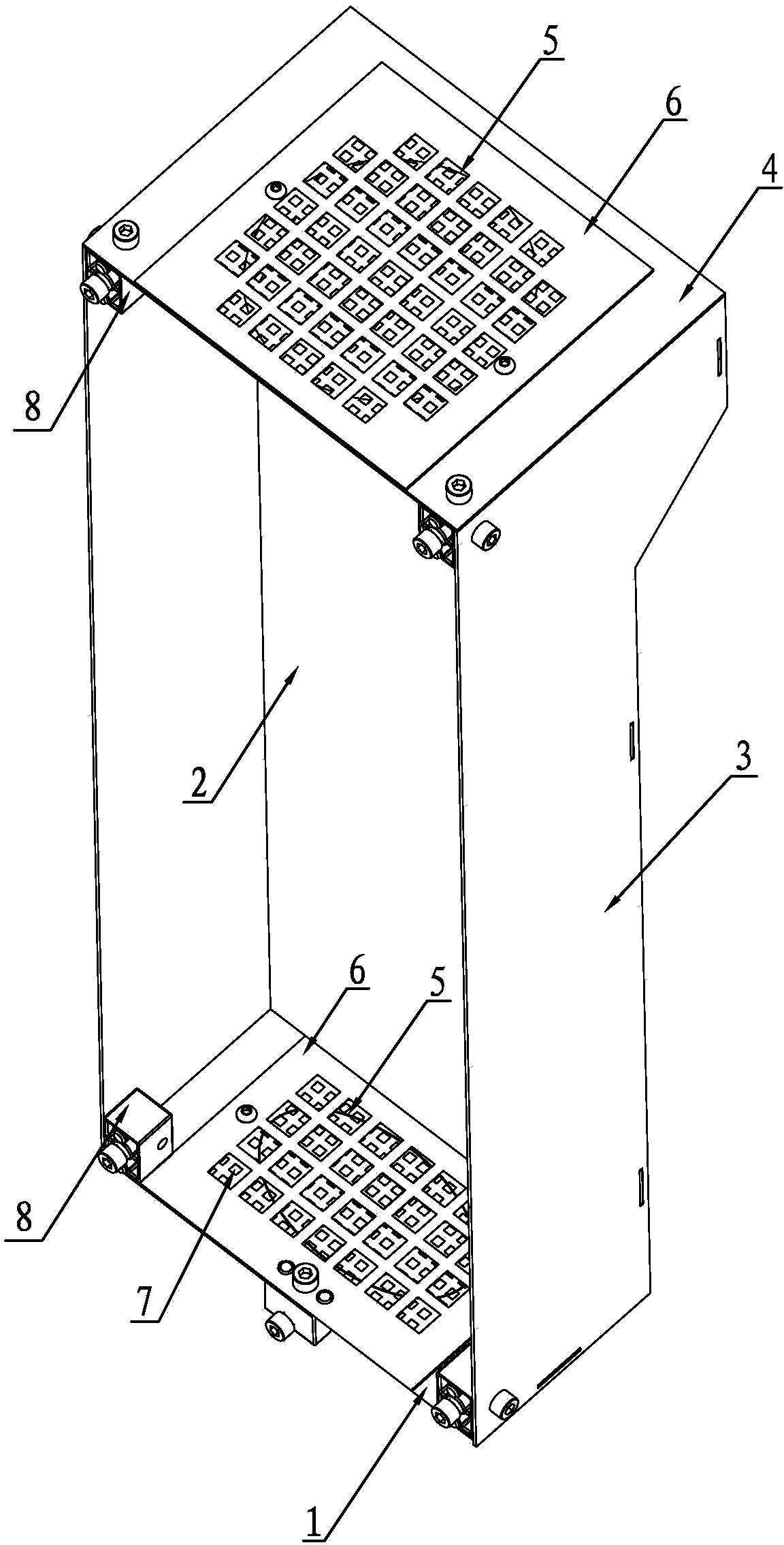

Electrical box and air conditioner

InactiveCN108775689AAvoid the disadvantages of poor heat dissipationImprove cooling effectMechanical apparatusHeating and ventilation casings/coversEngineeringPower component

The invention provides an electrical box and an air conditioner. The electrical box comprises a box body and an electrical component module located in the box body. The box body is provided with an airflow inlet, a flow guiding air duct is formed between the airflow inlet and the electrical component module, and the flow rate of airflow entering from the airflow inlet can be increased through theflow guiding air duct. According to the electrical box and the air conditioner, the heat dissipation efficiency of large-power components in the electrical box can be obviously improved, the temperature of the components is decreased, and the stability and reliability of the components are improved.

Owner:GREE ELECTRIC APPLIANCES INC

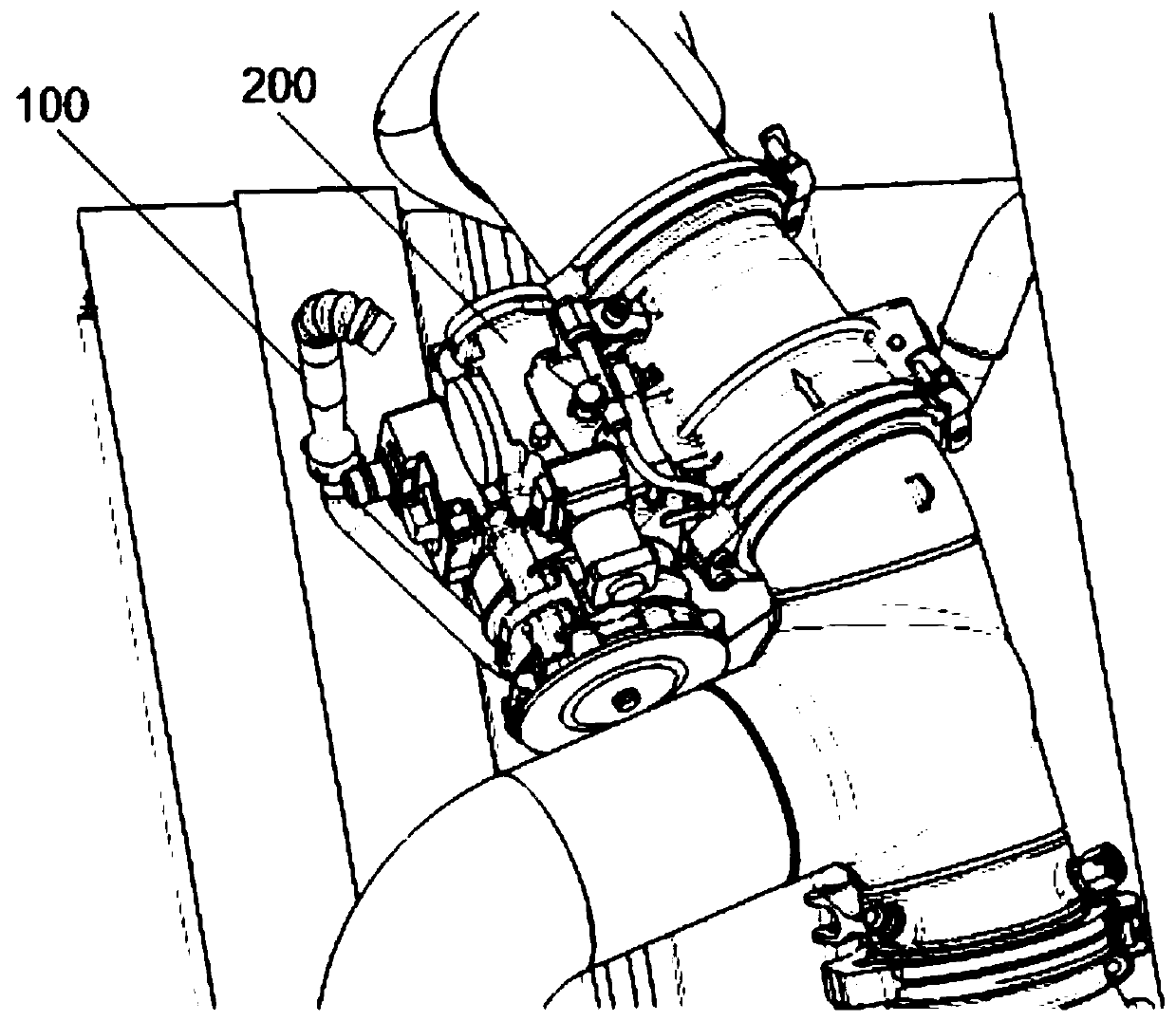

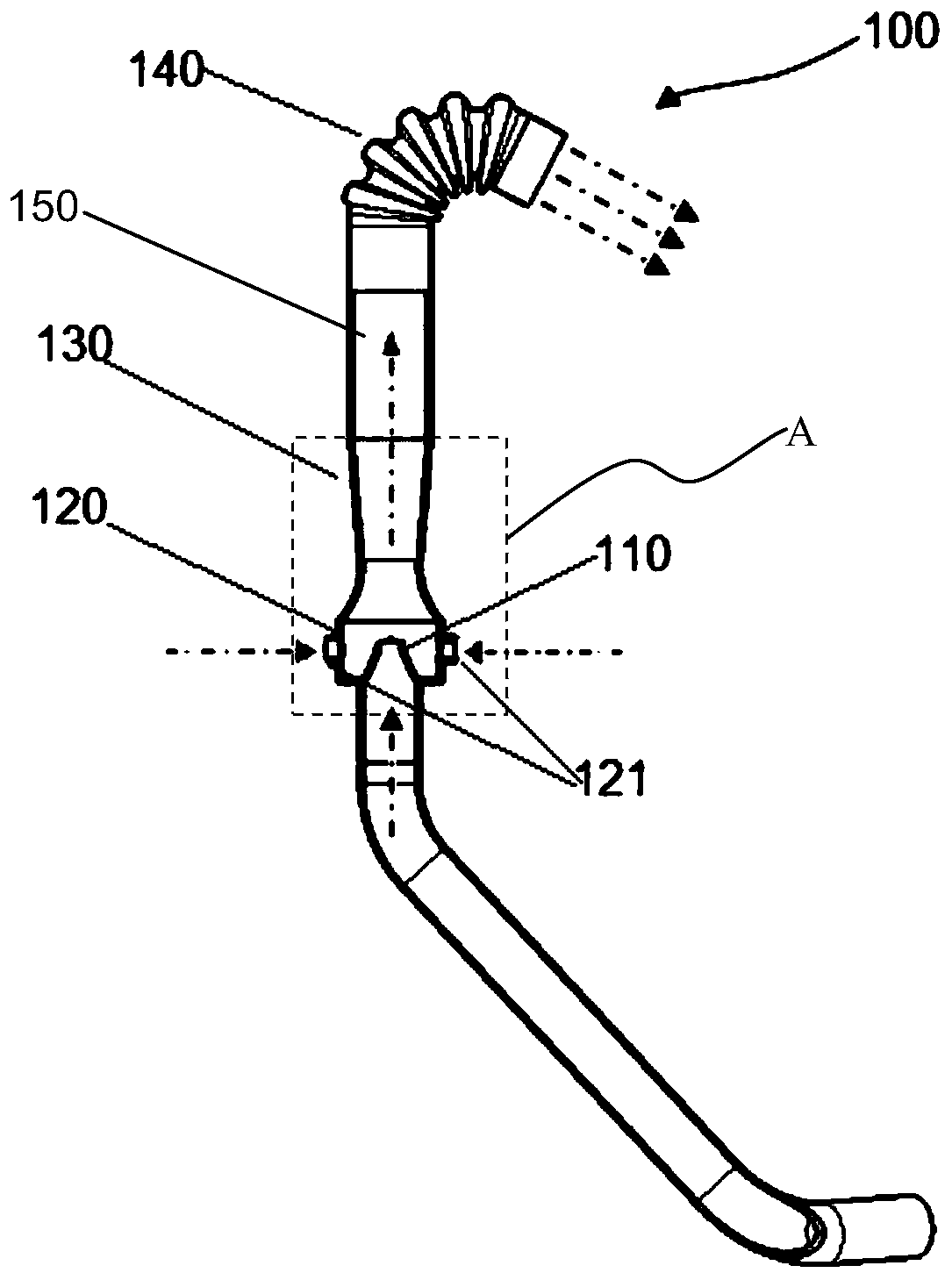

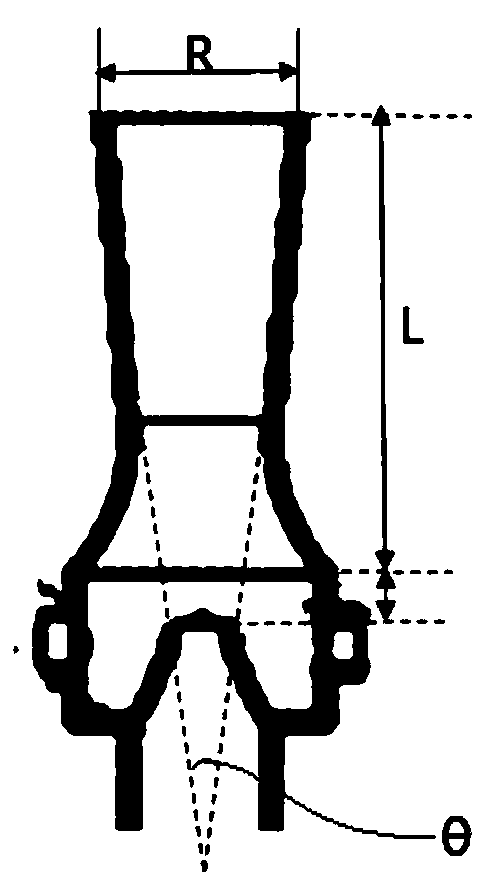

Ventilation cooling device for air-entraining valve

ActiveCN110500185AIncreased installation flexibilityIncrease cooling air volumeTurbine/propulsion engine coolingGas turbine plantsCold airEngineering

The invention relates to a ventilation cooling device for an air-entraining valve. The ventilation cooling device comprises a nozzle, a mixing chamber and a direction adjusting mechanism. The nozzle is in communication with a cold air source and is arranged at an inlet of the ventilation cooling device. The nozzle is provided with an internal passage with the tapered cross section. The mixing chamber is provided with a mixing cavity inside the mixing chamber and a plurality of vent holes in the circumferential wall of the mixing chamber. The vent holes are in communication with the inside andoutside environments of the mixing chamber. An outlet of the nozzle is located in the mixing cavity. The direction adjusting mechanism is connected to an outlet of the mixing chamber and is configuredto be capable of adjusting the ejection direction of the air. According to the ventilation cooling device, the external low-temperature environment temperature can be introduced into the system and used as one cooling source of the air-entraining valve; and meanwhile, the installation flexibility of the ventilation cooling device can be improved through the direction adjusting mechanism.

Owner:COMAC +1

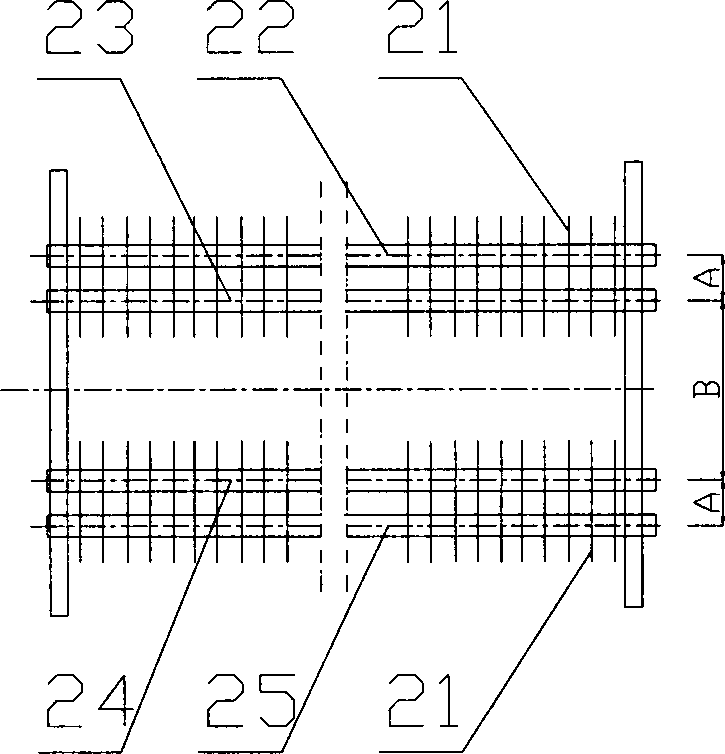

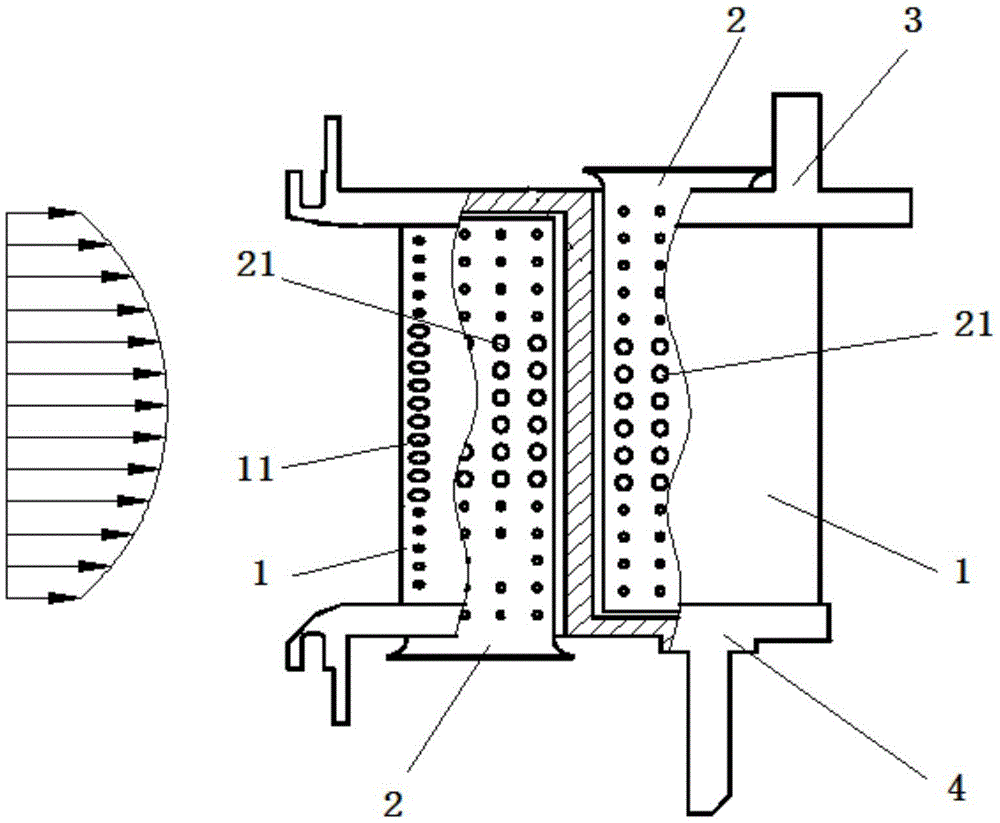

Annealing furnace air-cooling section cooling method and system

PendingCN108913870AImprove cooling effectIncrease cooling air volumeFurnace typesHeat treatment furnacesCooling effectEnergy conservation

The invention provides an annealing furnace air-cooling section cooling method and system. The method comprises the step that an air-cooling section is divided into multiple cooling units, wherein thecooling units are sequentially arranged in the direction of a conveying belt, and each cooling unit is provided with an independent cooling air supply system. The system further comprises one or moreair suction outlet systems and the one or more cooling units, wherein by means of the cooling units, after being delivered out of the cooling unit located at the rear end of the conveying belt, cooling air of the cooling unit is delivered into the front end of the cooling unit as new cooling air. The air outlet systems are used for exhausting the air for the cooling units other than the cooling unit. By means of the method, the excessive air capacity of a rear section of the cooling section can be reutilized, so that the excessive air capacity is used for increasing the cooling air capacity of a front section of the cooling section; and thus, the cooling effect of the cooling section is improved, the equipment structure is simplified, and energy is saved.

Owner:SHANDONG HONGWANG INDUSTRY CO LTD

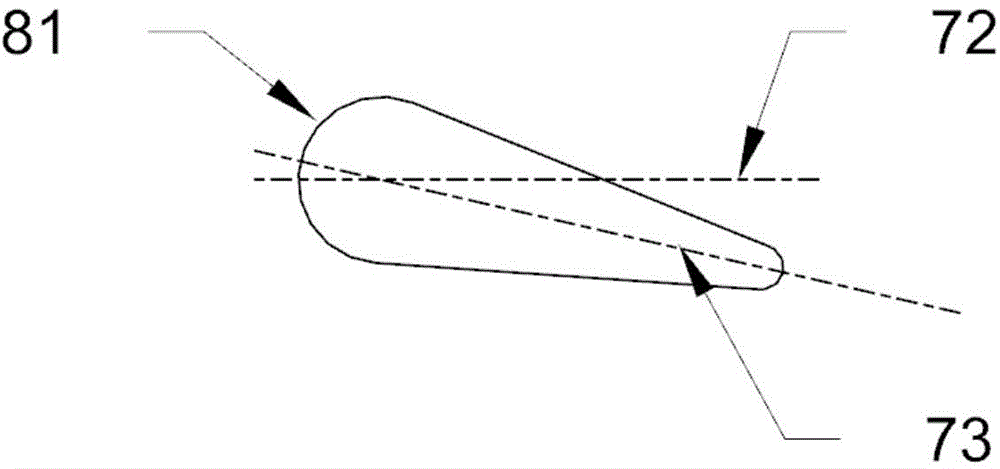

Turbine blade with uneven cooling intensity in radial direction

InactiveCN105626161AUniform temperatureIncrease cooling air volumeBlade accessoriesMachines/enginesCold airTurbine blade

The invention relates to cooling design for a turbine of an aircraft engine, in particular to a turbine blade with uneven cooling intensity in a radial direction. The turbine blade comprises blade bodies and cold air conduits, wherein a cooling cavity is formed in each of the blade bodies, a plurality of air film holes communicating with the cooling cavities are formed in the outer wall of each of the blade bodies, and the sizes and the arrangement positions of the gas film holes are matched with preset parameters of fuel gas; the cold air conduits are arranged in the cooling cavities, and cooling holes of which the number and the positions correspond to those of the air film holes in the blade bodies are formed in the cold air conduits. According to the turbine blade with uneven cooling intensity in the radial direction, disclosed by the invention, the flow of cooling air at the middle parts of the blade bodies can be increased, the flow of the cooling air at two ends of the blade bodies is reduced, the temperature of the whole blade bodies is even, the waste of energy sources is not liable to cause, an ablation phenomenon is also not liable to generate, and the safety is high.

Owner:AECC SHENYANG ENGINE RES INST

Combustion chamber of gas turbine

ActiveCN104654357AImprove cooling effectImprove efficiencyContinuous combustion chamberCombustion chamberFront edge

The invention relates to the technical field of a gas turbine, and particularly discloses a combustion chamber of the gas turbine. The combustion chamber comprises a combustion pressure cylinder, a turbine box, an end cover, a spray nozzle, a flow guiding bush, a flame tube and a transition section, wherein the rear end of the turbine box is connected with the combustion pressure cylinder, the end cover is connected to the front end of the turbine box, the spray nozzle is connected to the end cover, the flow guiding bush is connected to the inner side of the turbine box, the flame tube is positioned in the flow guiding bush, the front end of the flame tube is connected with the spray nozzle, and an inlet of the transition section is connected with the rear end of the flame tube; an output guide vane is arranged in an output of the transition section, the transition section and the output guide vane are of an integrated structure, and air distribution cavities are formed in the output guide vane and the end wall of the front edge of the output guide vane of the transition section. According to the combustion chamber of the gas turbine, disclosed by the invention, the cooling flow of the end wall of the front edge of a primary stationary blade is saved, and the overall efficiency is increased.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

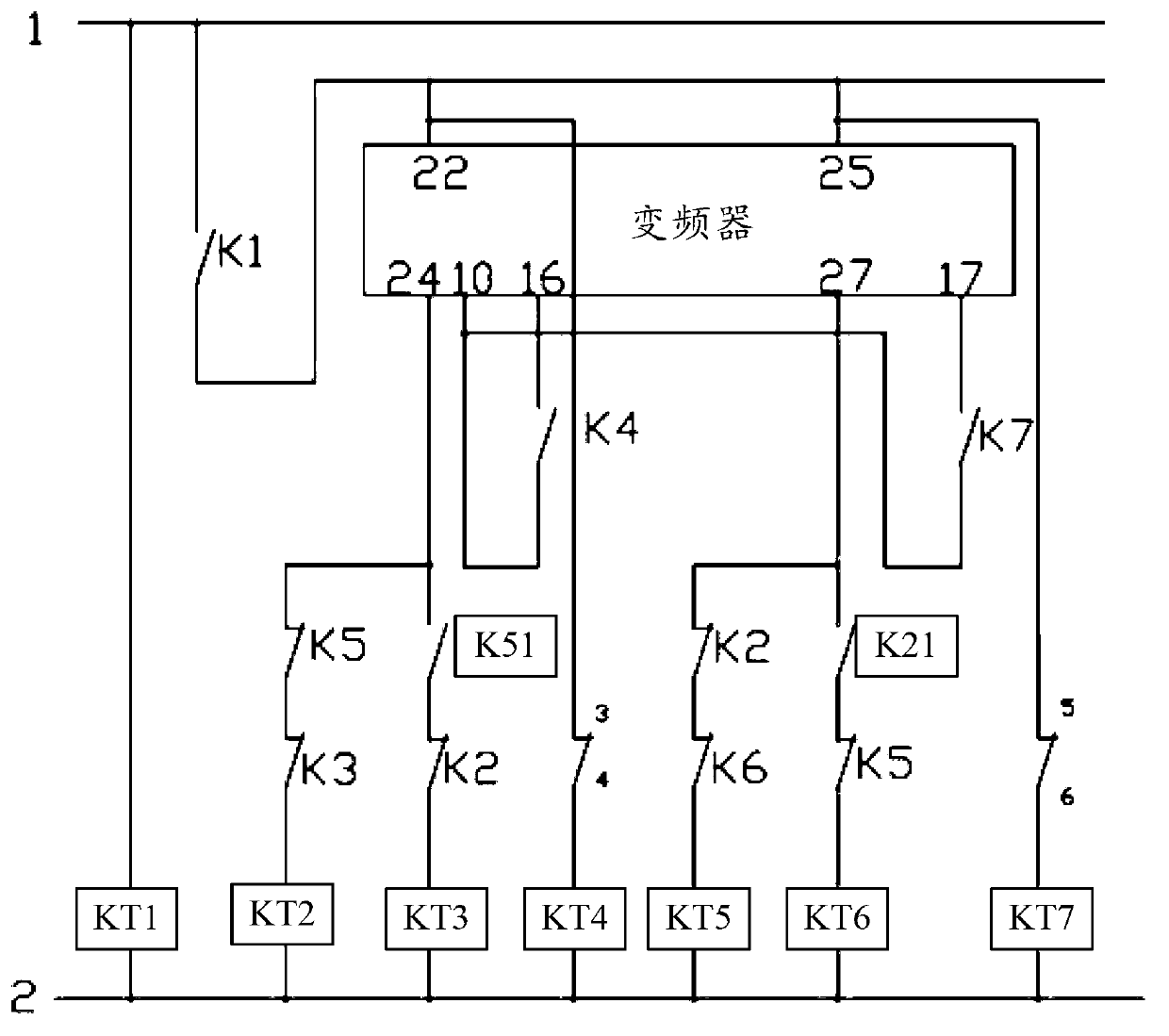

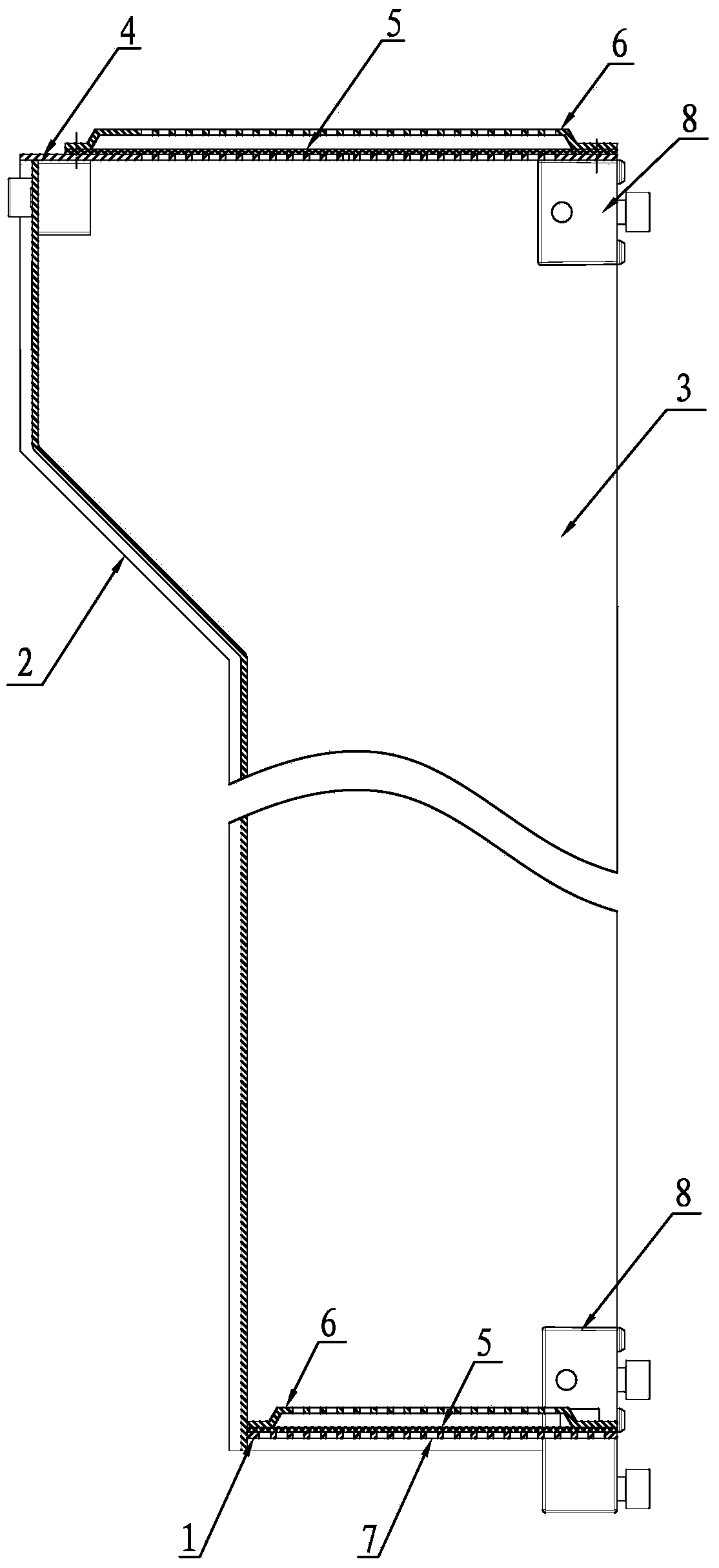

Anti-fiber aeration-cooling device for frequency converter of two-for-one twister

InactiveCN104213280AIncrease cooling air volumeImprove the cooling effect of dust extractionContinuous wound-up machinesFrequency changerVariable-frequency drive

The invention discloses an anti-fiber aeration-cooling device for a frequency converter of a two-for-one twister. The anti-fiber aeration-cooling device comprises a bottom plate, a front panel, two side plates, a top cooling cover plate, short fiber filter screens, filter screen cover plates and mesh-shaped air inlet ducts, wherein the front panel and the two side plates are arranged on the bottom plate in an enclosure manner; the two side plates are arranged in parallel; the top cooling cover plate covers the front panel and the two side plates; an opening shell formed by the top cooling cover plate, the two side plates, the front panel and the bottom plate sheathes the back face of a control cabinet frame of the two-for-one twister; cooling screen meshes are formed in the top cooling cover plate; the side face or the bottom part of the opening shell is provided with the mesh-shaped air inlet ducts; seen from the height direction, the mesh-shaped air inlet ducts are lower than the position of the frequency converter; each short fiber filter screen is arranged the inner side of the corresponding mesh-shaped air inlet duct; each short fiber filter screen is pressed by four peripheral edges of the corresponding filter screen cover plate; anti-fiber air inlets are formed in each filter screen cover plate; a gap exists between each filter screen cover plate and the corresponding short fiber filter screen. According to the anti-fiber aeration-cooling device for the frequency converter of the two-for-one twister, the frequency converter can be better protected from the influences of dust and fiber fluffs, and a good aeration-cooling effect is achieved in a limited space.

Owner:SAURER (JIANGSU) TEXTILE MASCH CO LTD

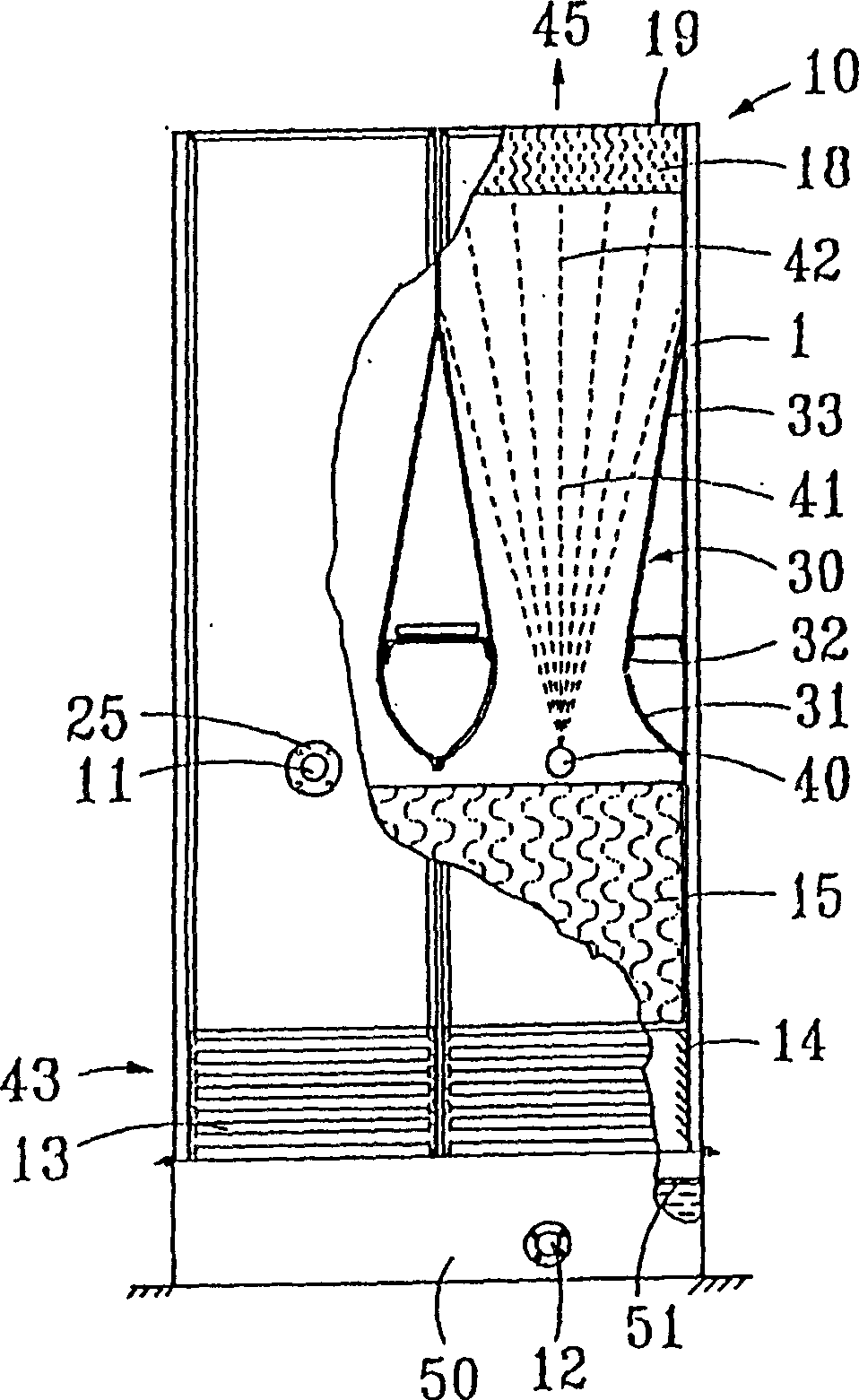

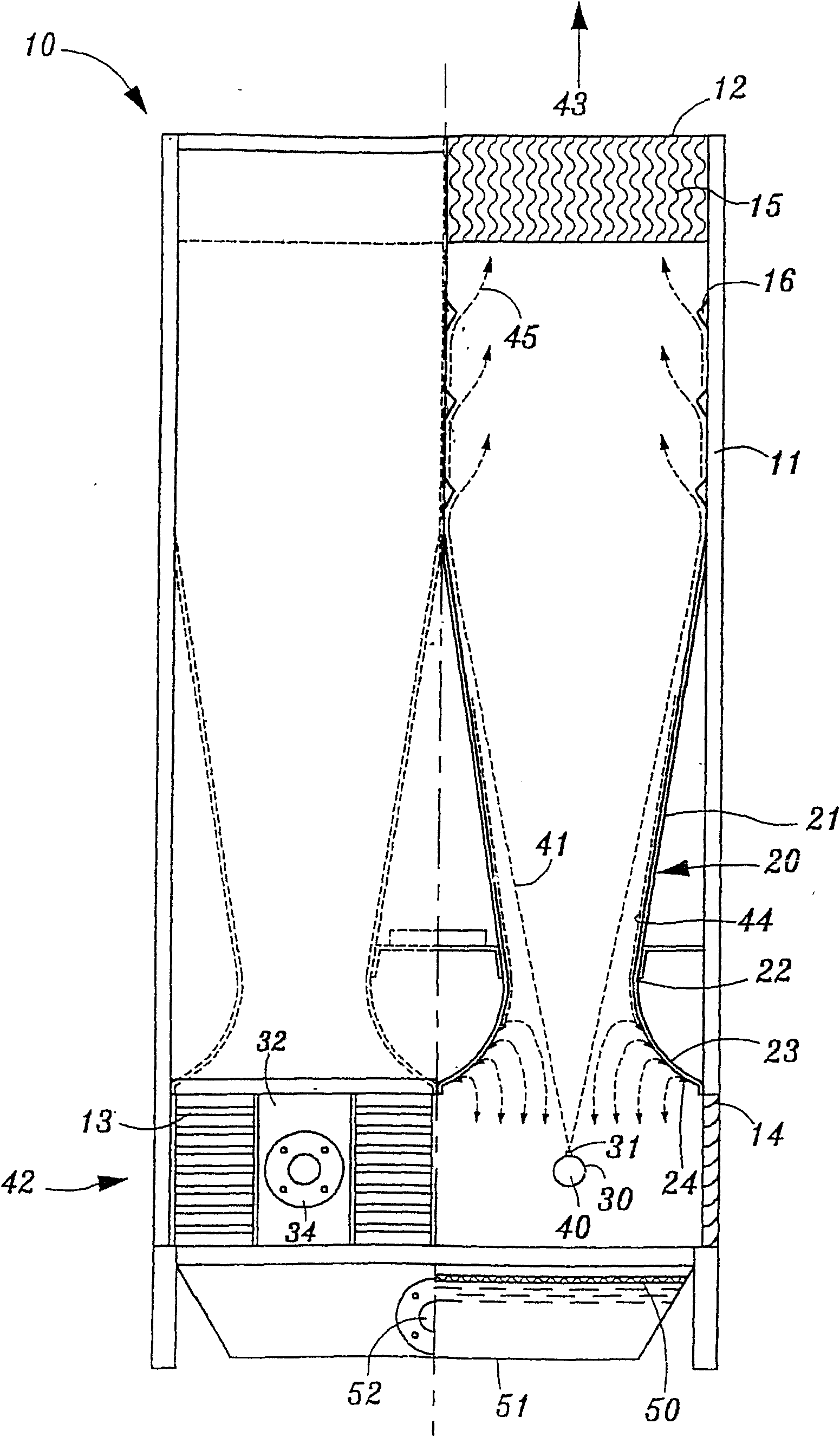

Non-filler flow cooling tower

A non-filler flow-type cooling tower is composed of tower body with air exhaust outlet on top and cold air inlets at lower part, multiple groups of diffuser consisting of gradually widening part, throat and gradually narrowing part in the tower body, a spray tube with several V-shaped nozzles under each group of diffusers, a water remover before air exhaust outlet, and a liquid collecting tray. Its advantages include high heat sinking performance, low air resistance and high quantity of air coming into tower body.

Owner:陈家贤

Device and method for controlling forming thickness of glass substrate by overflow method

PendingCN112811793AExtended cooldownSolve the problem of different temperature adjustmentsGlass forming apparatusAir velocityScrew thread

The invention provides adevice and method for controlling the forming thickness of a glass substrate by an overflow method. A soaking box body and a U-shaped cooling air pipe capable of independently controlling the air speed are arranged below an overflow brick tip, and the soaking box body and the U-shaped cooling air pipe are connected to the outer walls of the two sides of the lower end of a furnace body through threads and nuts correspondingly; aiming at the condition that the thicknesses of the glass bodies in the same plane are not consistent, independent control sliding of the soaking box body and the U-shaped cooling air pipe is realized by rotating threads and nuts, so that the distance between the soaking box body and the U-shaped cooling air pipe and the glass bodies is finely and regionally adjusted, rapid cooling of corresponding positions is realized, the viscosity of the glass is improved, and the flowing performance is weakened; and the goal of unifying the thickness is realized, meanwhile, the problems of low cooling efficiency, slow reaction and poor controllability in the prior art are solved, and the process margin of thickness adjustment is expanded.

Owner:IRICO DISPLAY DEVICES

An air-cooled structure of an outer rotor permanent magnet motor

ActiveCN113965015BImprove cooling effectIncrease the power level of air coolingWindingsMagnetic circuit stationary partsElectric machineEngineering

The invention discloses an air-cooled structure of an outer rotor permanent magnet motor, which comprises a stator core, an air inlet side half shaft and an outlet side bearing bracket, and the wind inlet side half shaft and the outlet side bearing bracket are connected to both ends of the stator iron core , and the three are connected to form a hollow passage for ventilation. A cooling fan is installed at the air inlet end of the half shaft on the air inlet side. There is an inner retaining ring of the air duct, which is connected to the semi-shaft on the outgoing line side. There are multiple air duct baffles on the inner retaining ring of the air duct. One side of the air inlet of the side half shaft is connected on the support seat of the air inlet side. The invention has compact layout, convenient and fast installation, heat exchange between the cooling air and the stator core directly, the design of the air duct baffle increases the heat dissipation area, the inner retaining ring of the air duct increases the flow rate of the cooling air, improves the heat dissipation capacity of the motor, and Increased air cooling power rating.

Owner:承德盛乾特种电机制造有限公司

A kind of rapid prototyping method of glass bottle cold machine

Owner:四川天马玻璃有限公司

An avionics bay with a ventilation circuit

ActiveCN111432589BReduce the numberSolve the clutter problem of ventilation incompatibilityCasings/cabinets/drawers detailsFuselage bulkheadsCold airAviation

The invention belongs to the technical field of helicopter structure design, and relates to an avionics equipment cabin with a ventilation circuit. The equipment cabin adopts an upper and lower double-layer equipment platform design to avoid messy equipment layout, cable interference and heat dissipation difficulties caused by the messy layout. The cabin platform is equipped with a ventilation circuit as a whole, and an exhaust fan is installed at the bottom to form a negative pressure in the cabin, and the cold air is sucked into the equipment cabin from the air vent cover of the body, increasing the air flow rate, and the entire passage is smooth; A box-section sub-compartment is formed with the frame beam and the skin, the horizontal plate can transmit the load, and the sub-compartment is suitable for placing equipment.

Owner:CHINA HELICOPTER RES & DEV INST

Method for prolonging service life of RH insertion tube

The invention relates to a method for prolonging the service life of an RH insertion tube. The method comprises the following steps: 1) when an on-line insertion tube is used no more than 80 times, producing the type of steel with the carbon content of molten steel being more than 0.03%, wherein no more than 7 tanks of molten steel is treated in one gunning period, and producing the type of steelwith the carbon content of molten steel being no more than 0.03%, wherein no more than 6 tanks of molten steel is treated in one gunning period; and when the on-line insertion tube is used more than 80 times, producing the type of steel with the carbon content of molten steel being more than 0.03%, wherein no more than 5 tanks of molten steel is treated in one gunning period and the production ofthe type of steel with the carbon content of molten steel being no more than 0.03% is not implemented; and 2) when a new insertion tube is used for the first time, subjecting a vacuum chamber to online heating for more than 0.5 h before the treatment of molten steel, with heating temperature being 950 DEG C or above, and performing tank sticking operation 3-4 times during treatment of molten steelso as to prevent the influence of quenching and rapid heating on a refractory material. The method has the advantage of capacity of improving the service life of the RH insertion tube and enhancing RH operation rate, and reducing refractory cost per ton of steel.

Owner:ANGANG STEEL CO LTD

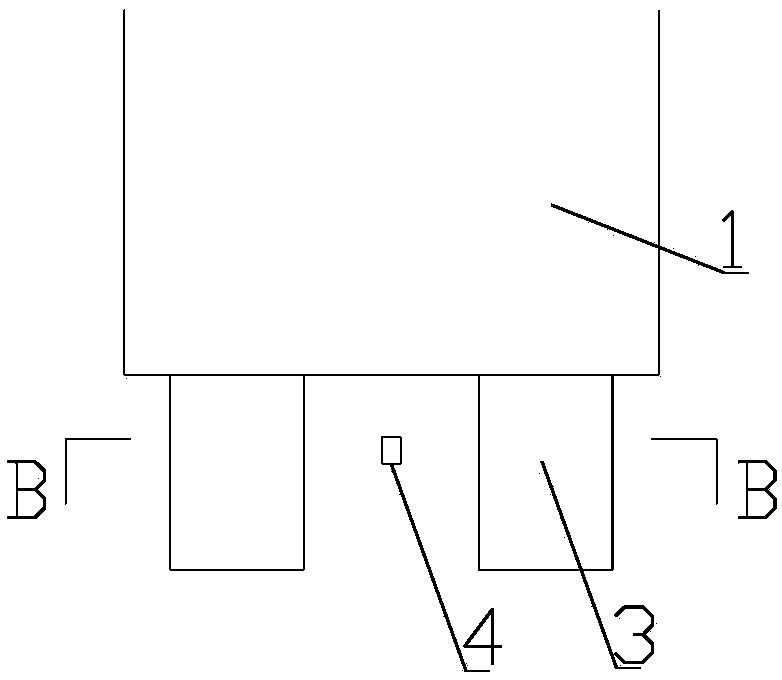

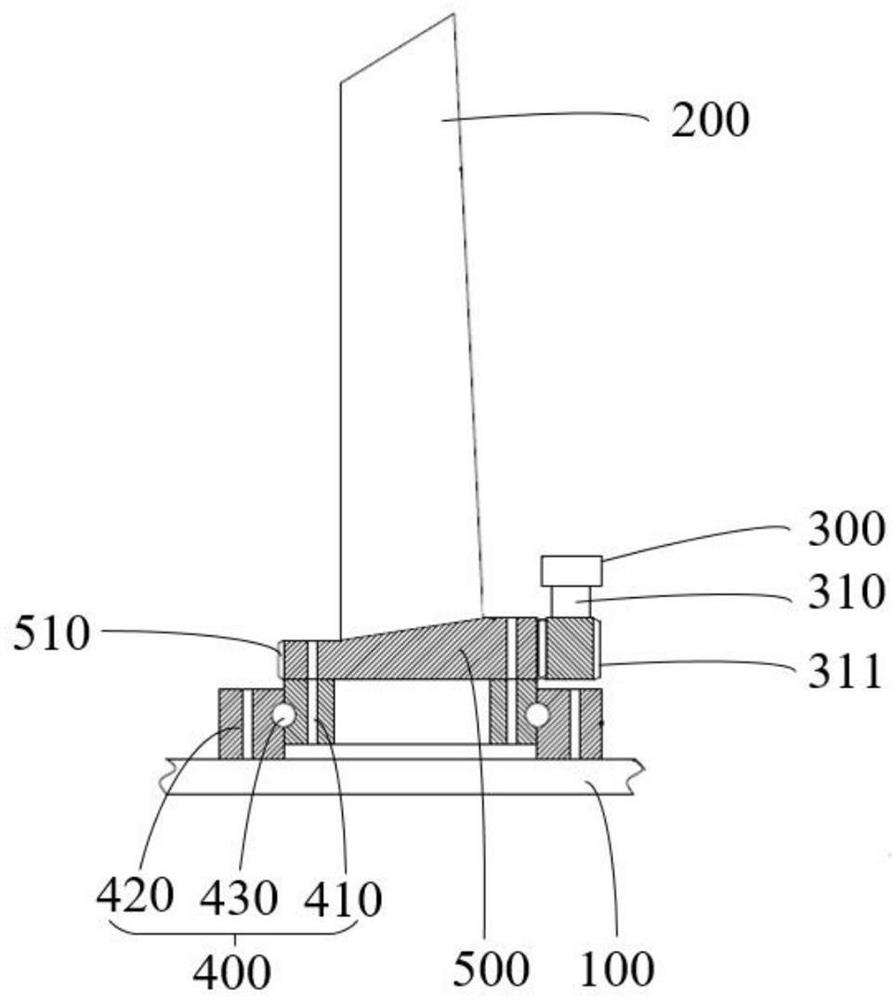

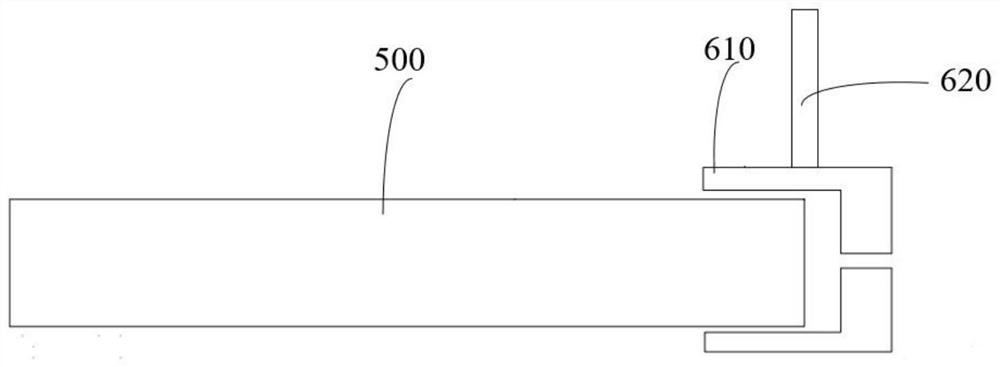

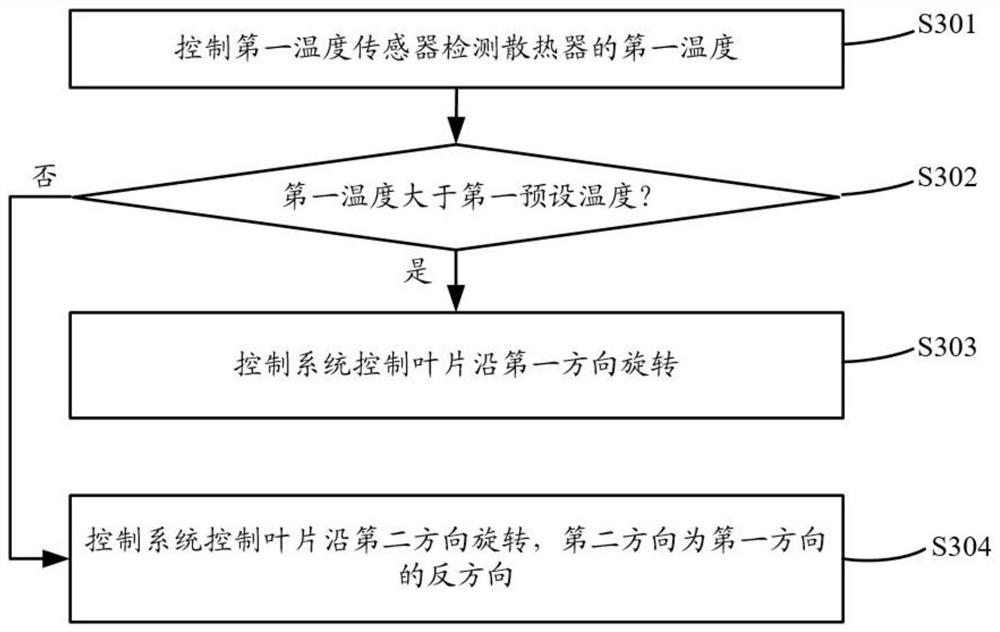

Fan, nitrogen generation equipment and control method of nitrogen generation equipment

The invention discloses a fan, nitrogen making equipment and a control method of the nitrogen making equipment, and belongs to the technical field of nitrogen making equipment. The fan comprises an impeller, blades, a first driving mechanism and a second driving mechanism, the blades are rotatably connected to the impeller, the first driving mechanism is in driving connection with the impeller so as to drive the impeller to drive the blades to rotate, and the second driving mechanism is in driving connection with the blades so as to adjust the included angle between the blades and the impeller by driving the blades to rotate. According to the scheme, the problem of relatively high power consumption of a heat dissipation device of nitrogen generation equipment in the related technology can be solved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

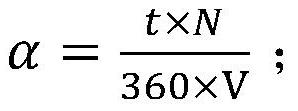

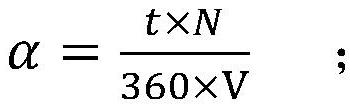

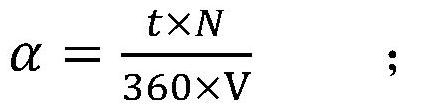

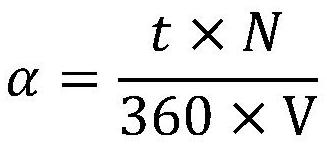

Glass bottle cold start-up rapid forming method

The invention belongs to the technical field of glass bottle production, and discloses a glass bottle cold start-up rapid forming method, which is used for a preheating production stage of a rank machine, the forming method comprises positive blowing, initial mold cooling and mold forming cooling, and the opening timing of the positive blowing is delayed by 70-90 units of periodicity from the opening timing during normal production; the opening timing of the primary mold cooling is delayed by 15-25 units of periodicity from the opening timing during normal production, and the stopping timing of the primary mold cooling is advanced by 50-70 units of periodicity from the stopping timing during normal production; the start timing of mold forming cooling is delayed by 60-80 units of periodicity from the start timing during normal production; wherein the periodicity of one unit is alpha, and alpha meets the following formula: alpha=(t*N) / (360*V). The rejection rate of the glass bottles is greatly reduced and the cost is reduced by delaying the start timing and stop timing of positive blowing, mold forming cooling and initial mold cooling and reducing the cooling air of the bottle conveying machine.

Owner:四川天马玻璃有限公司

A fdm type 3d printer cooling device

InactiveCN107866971BImprove flowIncrease cooling air volumeAdditive manufacturing apparatus3D object support structuresAir volumeEngineering

The invention discloses a heat sink for a FDM type 3D printer. The heat sink comprises a pressure air flow generating device, a pressure air flow conveying pipeline and a 3D printing head shell, wherein the pressure air flow conveying pipeline is connected with the pressure air flow generating device and the 3D printing head shell; the pressure air flow generating device is provided with a pressure air flow generator, an air flow guiding member and a pneumatic quick connector at an outlet; the pressure air flow generator is connected with the quick connector through the air flow guiding member; the quick connector is connected with the 3D printing head shell through the pressure air flow conveying pipe; and air ducts are arranged on both sides of the 3D printing head shell. According to the heat sink for the FDM type 3D printer, the pressure air flow generating device uses a turbocharging fan to generate air flow with pressure, and the generated pressure air flow is delivered to the inside of the printing head shell through the pressure air flow conveying pipeline so as to realize heat dissipation of a 3D printing head; the volume of the heat-dissipation air flow is large and the speed of the air flow is fast; and the inclined air ducts are distributed on both sides of the 3D printing head shell and divert the pressure air flow, so the flowing direction and heat dissipation area of the pressure air flow are optimized and heat dissipation efficiency is improved.

Owner:北京紫熙科技发展有限公司

Internal cooling device of oxidized pellet shaft furnace

The invention provides an internal cooling device of an oxidized pellet shaft furnace, comprising a cooling zone shell of the pellet shaft furnace, wherein a plurality of primary cooling air supply branch tubes are uniformly arranged on the circumferential ring of the upper part of the sidewall of the cooling zone shell; a plurality of secondary cooling air supply branch tubes are uniformly arranged on the circumferential ring of the lower part of the sidewall of the cooling zone shell; each of the primary cooling air supply branch tubes and each of the secondary cooling air supply branch tubes are connected with an air blower via pipelines; a cooling air collection beam is installed in the cooling zone shell between the primary cooling air supply branch tubes and the secondary cooling air supply branch tubes; a plurality of air collection holes are formed in the bottom surface of the cooling air collection beam; both ends of the cooling air collection beam are connected with an air collection main tube via pipelines; and the air collection main tube is connected with a negative-pressure fan. According to the invention, the ore discharge temperature of the pellet shaft furnace can be effectively reduced, the service life of equipment can be prolonged, and the heat carried by pellet ores can be recycled simultaneously.

Owner:JIGANG INT ENG & TECH CO LTD

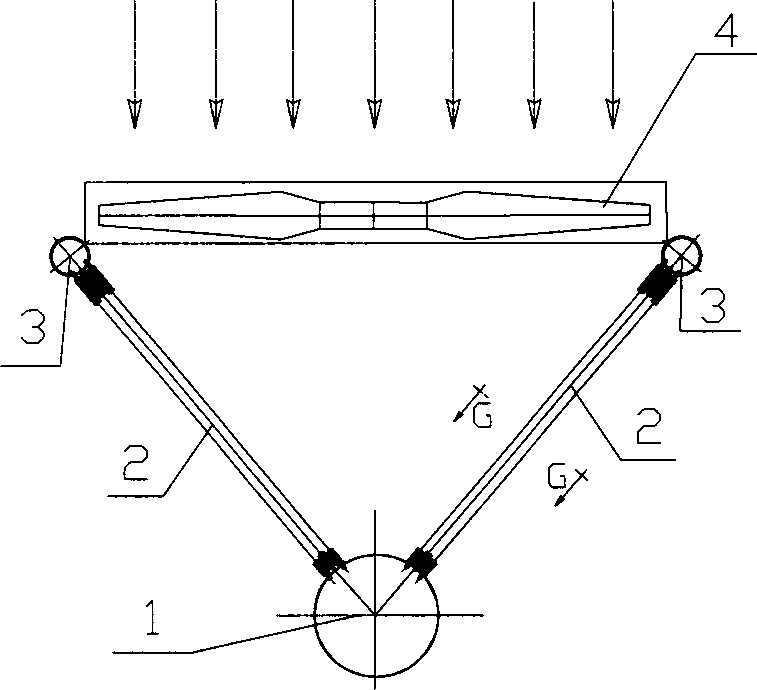

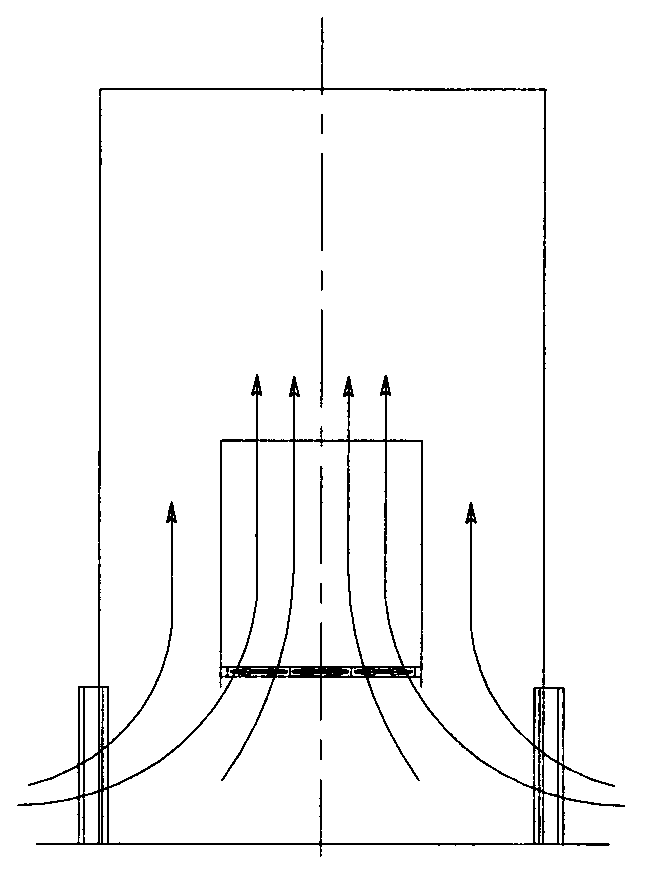

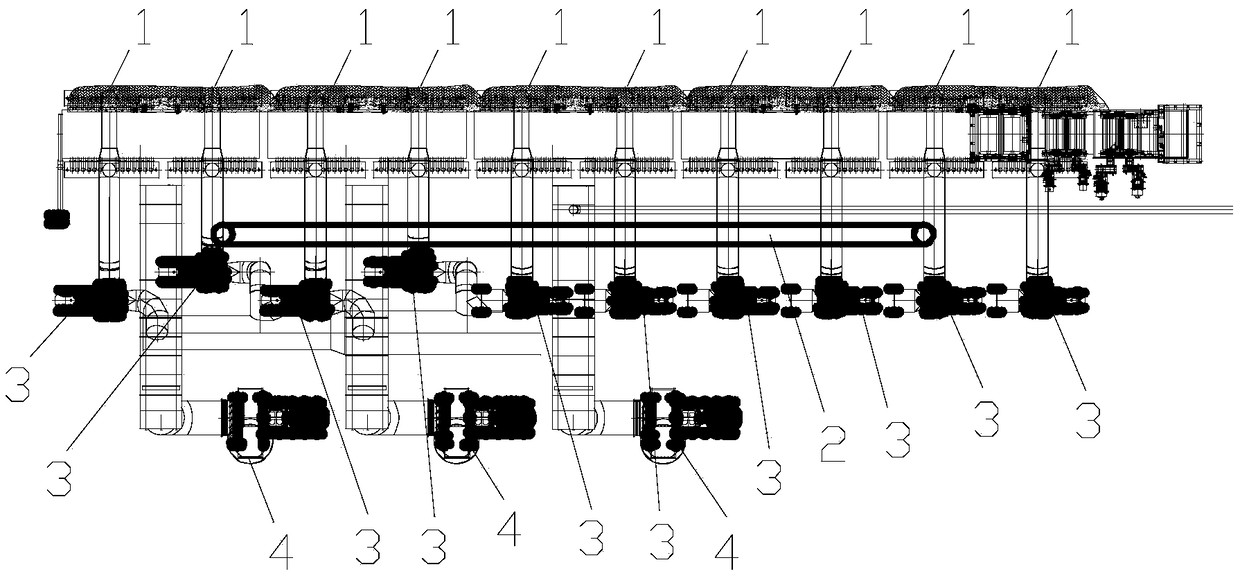

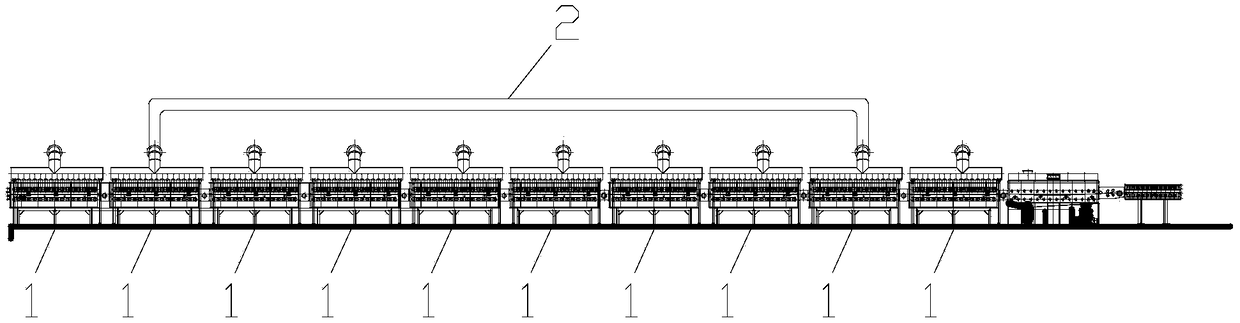

Central air supply air cooling island of a power plant

InactiveCN104764344BImprove cooling effectReduce power consumptionSteam/vapor condensersPeaking power plantPower station

A concentrated air supply air cooling island of a power plant comprises an air feeder, air cooling radiators and an air delivery pipeline. The upper ends of the air cooling radiators are communicated with a steam distribution pipe, and the lower ends of the air cooling radiators are communicated with a condensate pipe. The air delivery pipeline is provided with an air inlet which is provided with the air feeder. A plurality of air outlet pipes are arranged on the upper end face of the air delivery pipeline, the air cooling radiators are arranged above the air outlet pipes, and the air cooling radiators are in a double-curved-line shape. The concentrated air supply air cooling island of the power plant can generate spray air flow to cool the air cooling radiators, the cooling air volume is increased through the wall attachment effect, and the radiating capability of the air radiators is further improved; the multiple air cooling radiators can share one or two draught fans for cooling, the total power consumption amount of the air cooling radiators of the power plant is reduced, and the auxiliary power supply index of the power plant is decreased; the spiral turning line layout or the rectangular layout is adopted for the air delivery pipeline, the occupied land area can be reduced, observation and maintenance are facilitated, and the natural environment is protected.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

gas turbine combustor

ActiveCN104654357BImprove cooling effectImprove efficiencyContinuous combustion chamberCombustion chamberSpray nozzle

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Packless fluid hydraulic cooling tower

InactiveCN101619937AReduce flow field resistanceLower the altitudeDirect contact heat exchangersCold airCooling tower

The invention relates to a packless fluid hydraulic cooling tower, which comprises a tower body. The inside of the tower body is provided with a spouting pipe and a diffuser; the top part of the tower body is provided with a water eliminator, and the periphery of lower end of the tower body is provided with cold air inlets; and a plurality of baffles are arranged above and on the lower edge of the diffuser. When hot liquid is upwards spouted from the spouting pipe in form of high speed fluid which is shaped into a continuous water curtain, the high speed fluid upwards flows along the outer wall surface of the diffuser and is veered after passing through the plurality of baffles arranged above, and then the veered fluid performs heat exchange with air in the region; when the hot liquid returning back along the outer wall surface of the diffuser is led to the baffles on the lower edge, the hot liquid is spouted evenly to be mixed and exchange heat with incoming cold air for improving the heat dispersion of the cooling tower.

Owner:SHANGHAI LIANGJI COOLING EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com