Boosted air cooling tower

An air-cooling tower and machine power technology, applied in the field of heat exchange, can solve the problems of large number of fans, high investment, and large area occupied by the air-cooling system, and achieve the effect of reducing the number and power of fans and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

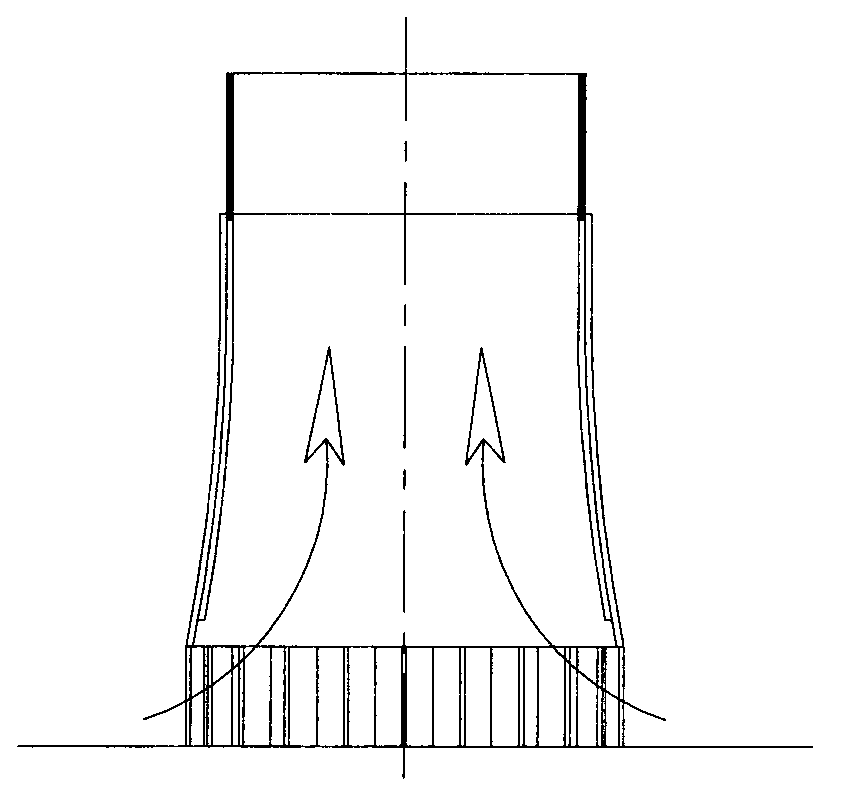

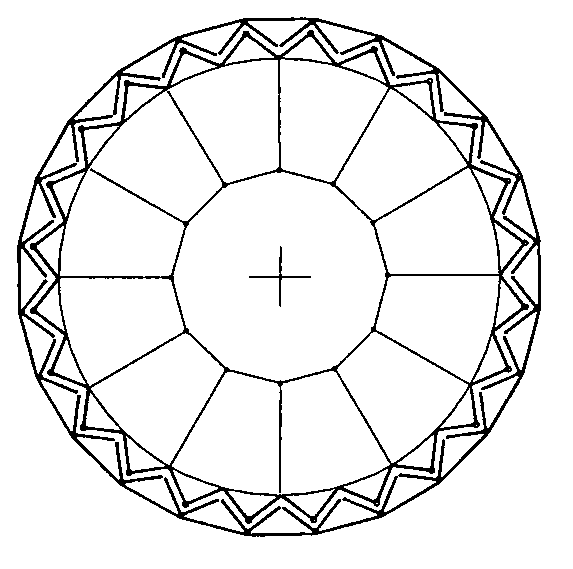

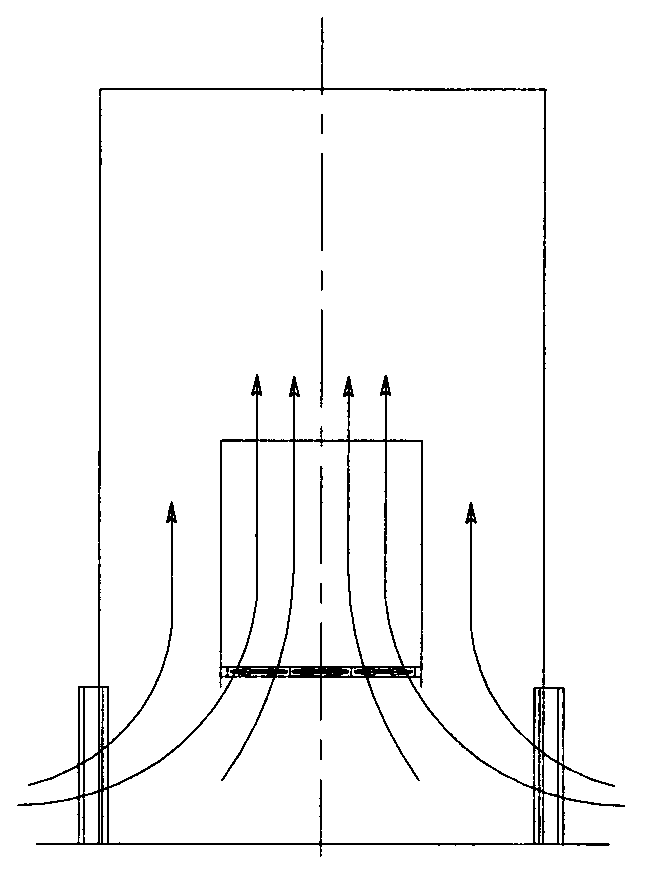

[0054] Axial fan (4) as attached image 3 , 4 , 5 and 6, horizontally arranged in the center of the natural ventilation tube (6): 600MW unit, the height of the natural ventilation tube (6) is 150 meters, the outlet diameter of the natural ventilation tube (6) is 96 meters, and the outer diameter of the radiator at the bottom of the tower is 140 meters , 68 meters in diameter of machine power blower (5), 80 meters in height, radial partition curtain (10), up and down partition curtain (7), annular partition curtain (3) quantity present embodiment is respectively 12, and the axial flow fan total The installed power is 2500kw, the total pressure of the fan is 60Pa, and the exhaust volume is 28000m 3 / s, plus natural ventilation 14000m 3 / s, a total of 42000m 3 / s. In summer or high temperature period, the axial flow fan is driven by electricity to increase the air volume, the actual power consumption is 2000kw, and the back pressure of the turbine is reduced by 40%. The pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com