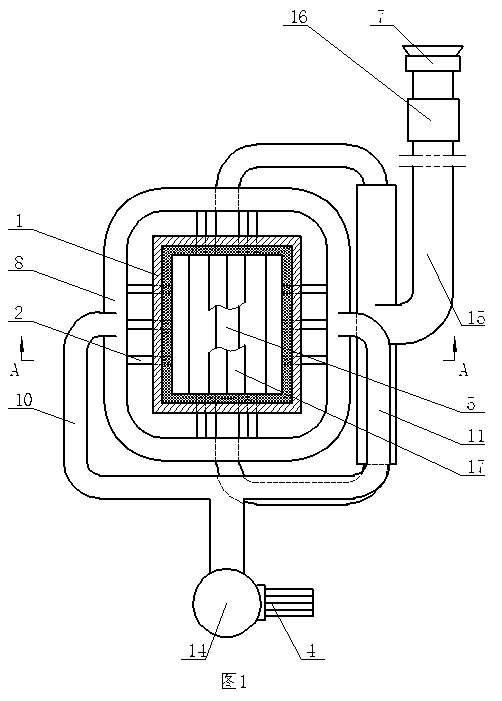

Internal cooling device of oxidized pellet shaft furnace

A cooling device and a technology for oxidizing pellets, which is applied in the field of oxidizing pellet shaft furnaces, and can solve problems such as inability to recover heat, inability to use pellets, and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

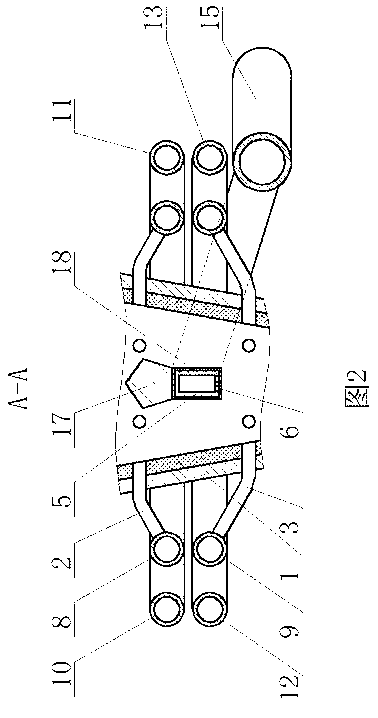

[0007] A built-in cooling device for an oxidation pellet shaft furnace according to the present invention includes a pellet shaft furnace cooling belt shell 1, a plurality of primary cooling air supply branch pipes 2 are evenly arranged on the upper circumference of the side wall of the cooling belt shell 1, and the cooling belt A plurality of secondary cooling air supply branch pipes 3 are evenly arranged around the lower part of the side wall of the housing 1, each of the primary cooling air supply branch pipe 2 and the secondary cooling air supply branch pipe 3 are connected to the blower 4 through pipelines, and the primary cooling air supply branch pipe 2 Cooling wind collecting beams 5 are installed in the cooling belt housing 1 between the secondary cooling air supply branch pipe 3, and a plurality of air collecting holes 6 are arranged on the bottom surface of the cooling wind collecting beams 5, and the two ends of the cooling wind collecting beams 5 are connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com