Coating robot and control method thereof

A control method and robot technology, applied in manipulators, manufacturing tools, construction, etc., can solve problems such as difficulty in controlling coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

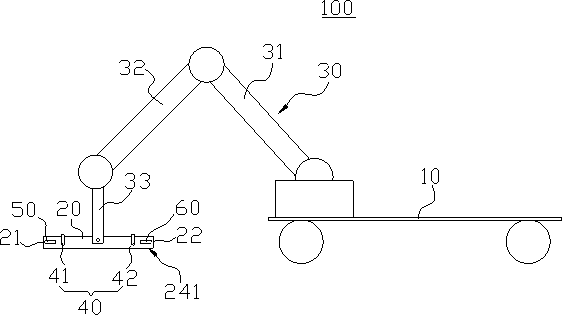

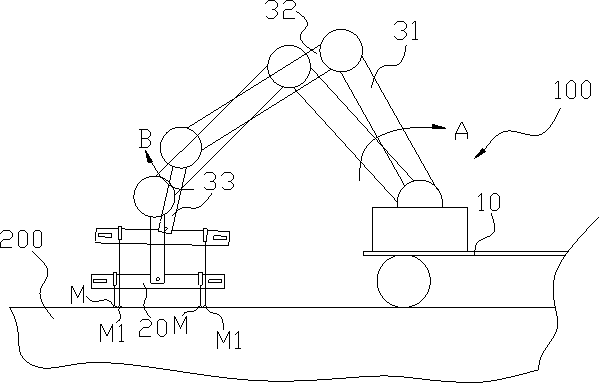

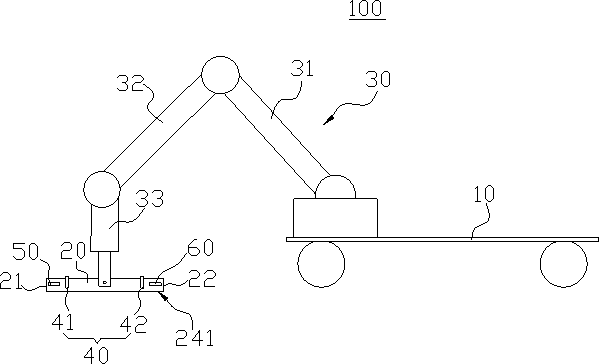

[0041] Such as figure 1 As shown, the embodiment of the first aspect of the present application provides a coating robot 100, the coating robot 100 is used to coat the first object 200, the coating robot 100 includes a walking device 10, a scraper 20, an execution Mechanism 30, first distance detection member 40 and control system. The squeegee coating element 20 has a squeegee coating surface 241 . The scraper 20 is connected with the traveling device 10 through the actuator 30 . The first distance detector 40 is used to obtain a first distance signal representing the distance between the first target 200 and the scraping surface 241 . The control system is used to control the action of the actuator 30 according to the first distance signal, so as to adjust the distance between the scraping surface 241 and the first target 200 to a first preset value. The first distance detector 40 can detect the distance between the scraping surface 241 and the first object 200, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com