Scratch control system and control method for sapphire substrate polishing

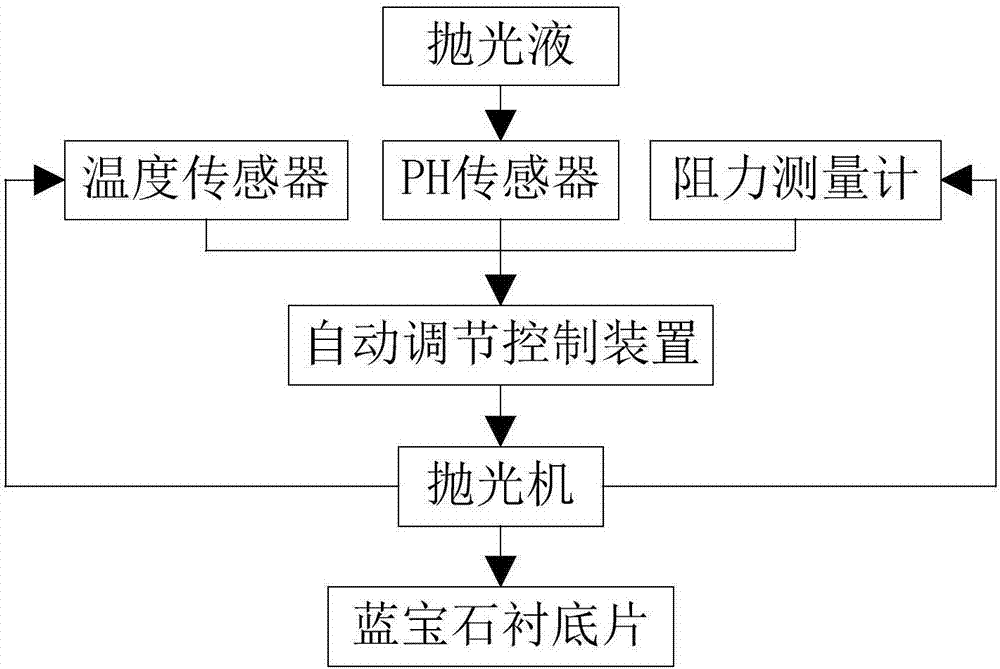

A sapphire substrate and control system technology, applied in the polishing field, can solve the problems of unstable product quality, high rework rate, slow efficiency, etc., and achieve the effect of improving efficiency, improving quality and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

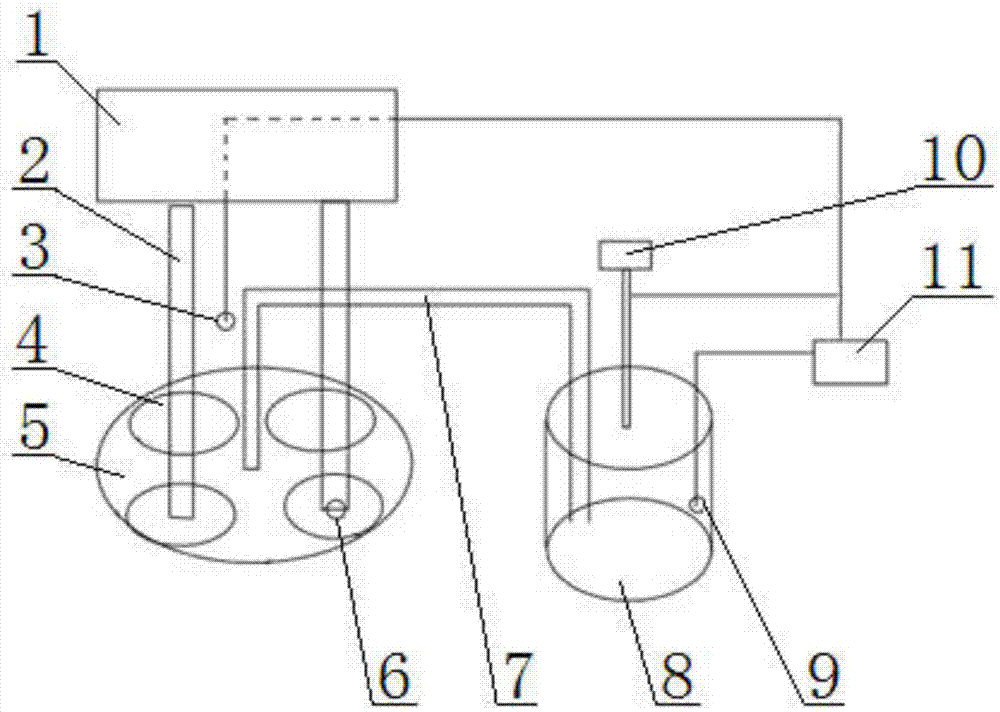

Embodiment 1

[0038] The following process conditions are set: the processing temperature of the polishing disc is 50°C, the pH value of the polishing liquid in the polishing liquid tank 8 is 11.5, the flow rate of the polishing liquid is 10ml / min, the rotational speed of the polishing disc is 45rpm, the rotational speed of the rotating shaft 2 is 43rpm, and the frictional resistance is 80kg / cm 2 , the polishing processing time is 100min; after the process conditions are set, the automatic adjustment control device 11 and the polishing machine 1 are started to polish the sapphire substrate.

Embodiment 2

[0040] Set the following process conditions: the processing temperature of the polishing disc is 40°C, the pH value of the polishing solution in the polishing solution tank 8 is 11, the flow rate of the polishing solution is 10ml / min, the rotational speed of the polishing disc is 45rpm, the rotational speed of the rotating shaft 2 is 43rpm, and the frictional resistance is 50kg / cm 2 , the polishing processing time is 120min; after the process conditions are set, the automatic adjustment control device 11 and the polishing machine 1 are started to polish the sapphire substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com