Novel electric connector six point extrusion tool

A new type of technology for electrical connectors, applied in the field of electrical connector processing equipment, can solve problems affecting the accuracy of extrusion points, scratches on coatings, loose bolts, etc., achieve the effects of convenient loading and unloading and operation, reduce labor intensity, and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solution and advantages of the technical solution clearer, the technical solution will be further described in detail below in conjunction with specific implementation methods. It should be understood that these descriptions are only exemplary, and are not intended to limit the scope of the technical solution.

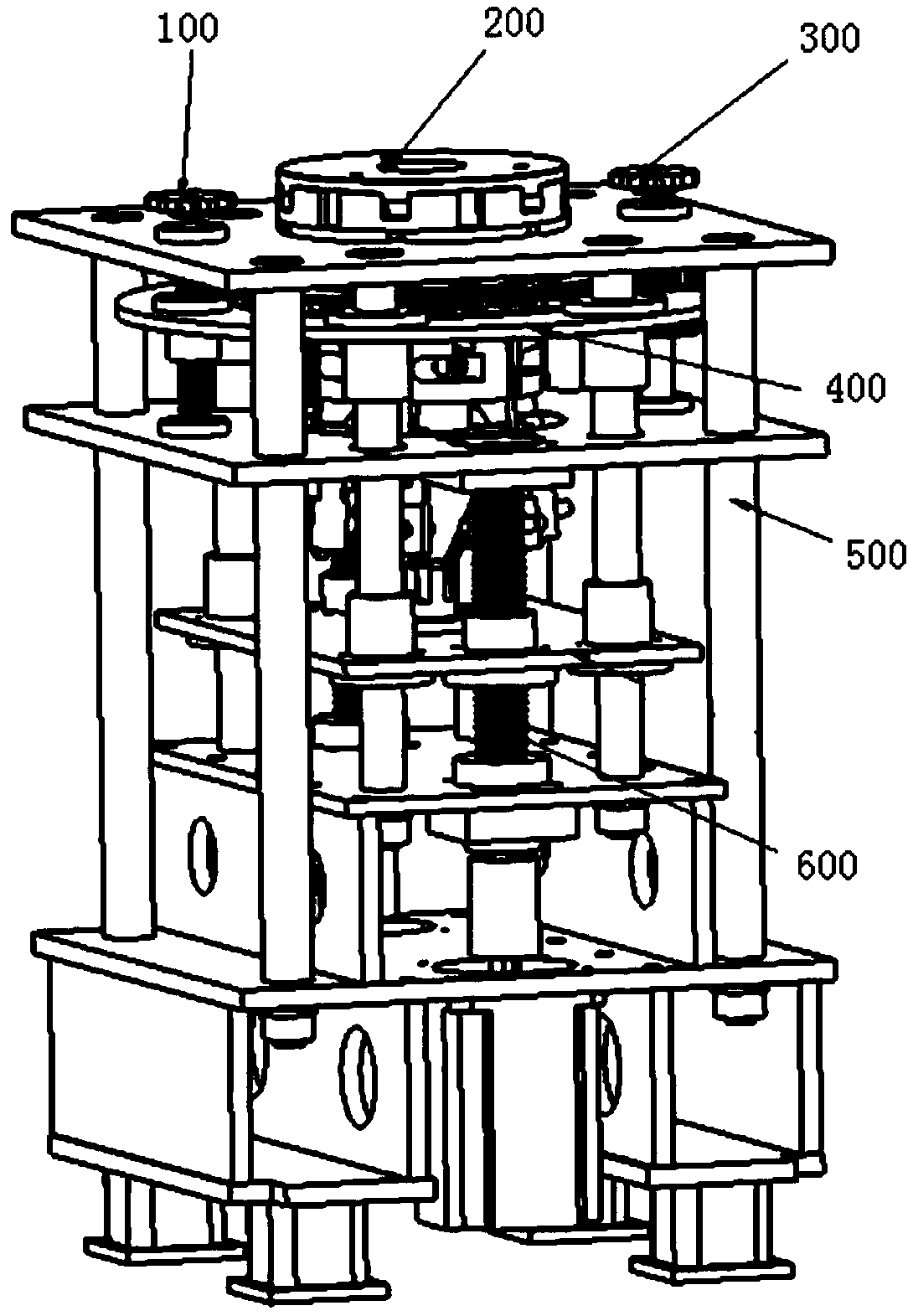

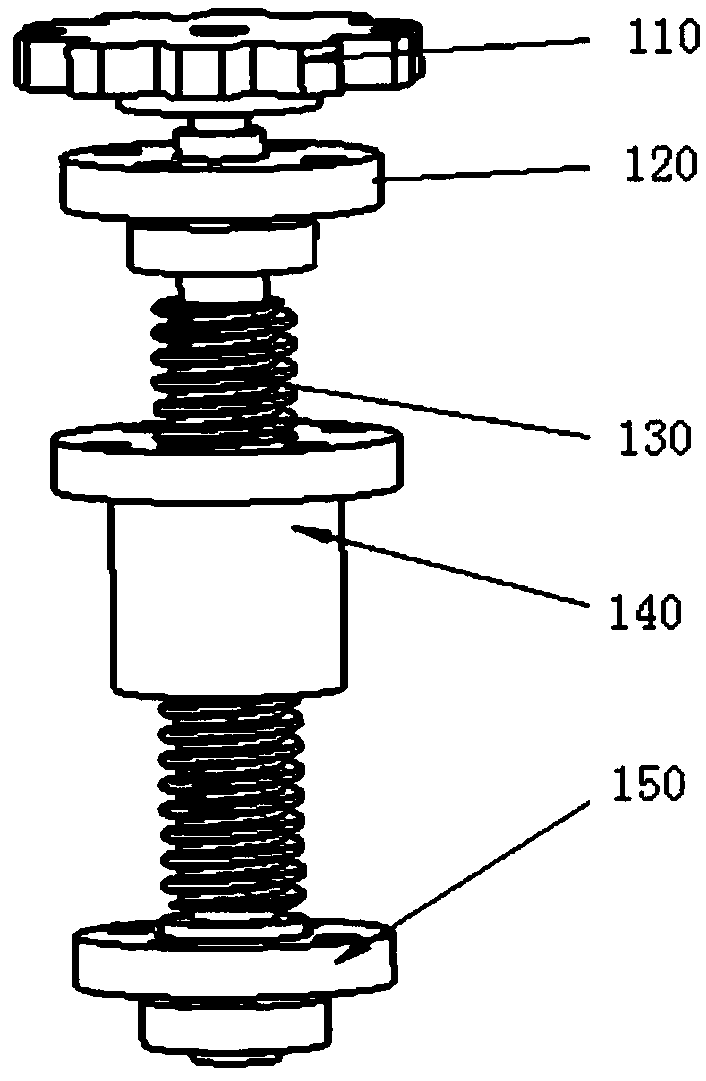

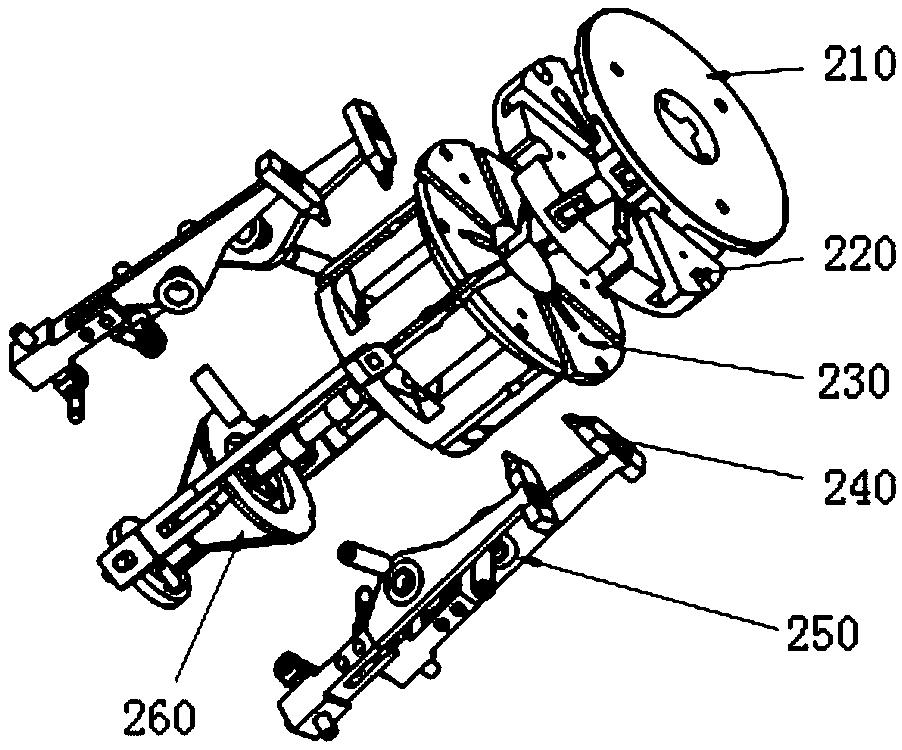

[0039] Such as Figure 1-Figure 14 As shown, this embodiment provides a new type of extrusion six-point tooling for electrical connectors, including a frame assembly 500, an extrusion six-point assembly 200, an extrusion six-point driving mechanism and a clamping assembly. The power end of the extrusion six-point driving mechanism is connected to the extrusion six-point The point component 200 can also drive the six-point assembly 200 to squeeze points on the electrical connector. The six-point drive mechanism has a point processing position, and the clamping component has a clamping position, and the point processing posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com