Anti-fiber aeration-cooling device for frequency converter of two-for-one twister

A ventilation cooling, double twisting machine technology, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the overheating alarm of the inverter, the damage of the power device of the inverter, and the electrical components such as the inverter. The heat dissipation performance plummeted and other problems to achieve the effect of increasing the cooling air volume, ensuring normal work, and improving the effect of dust removal and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

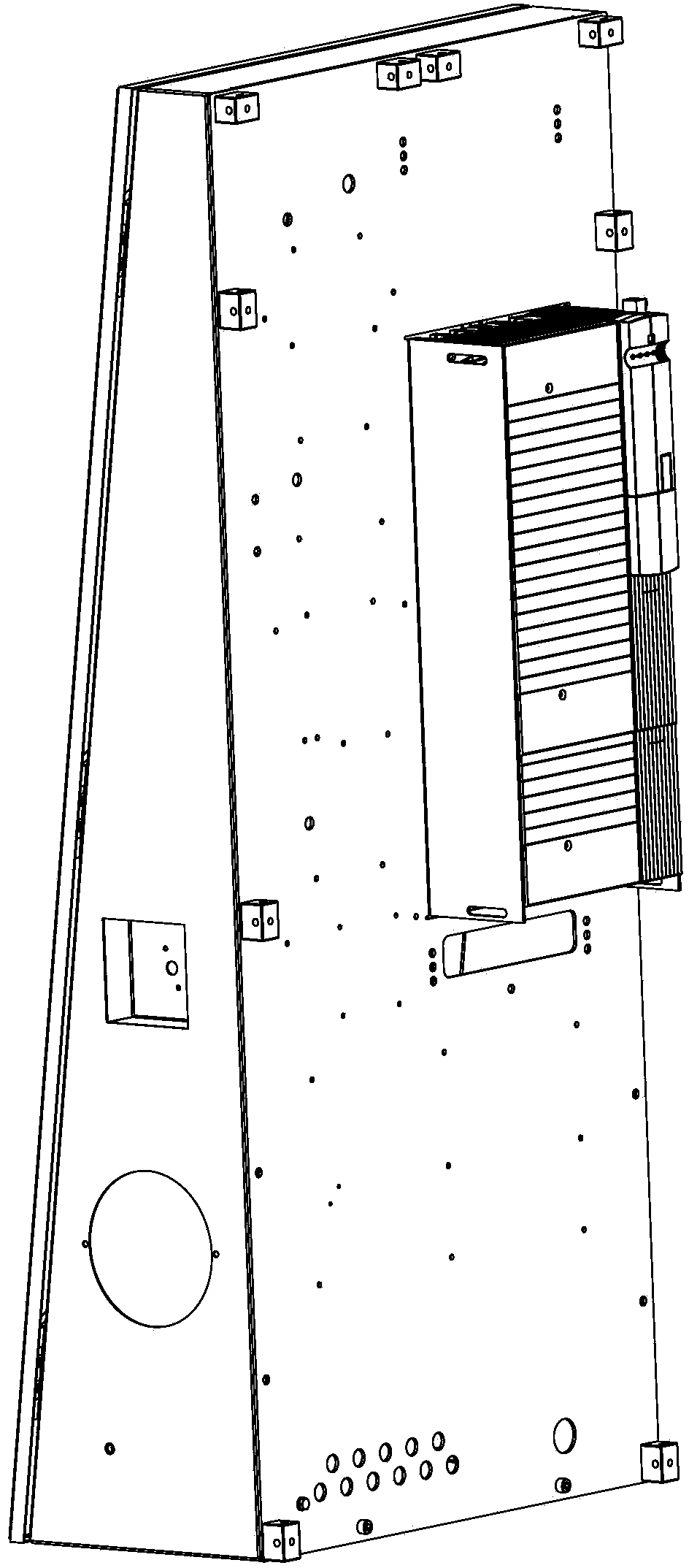

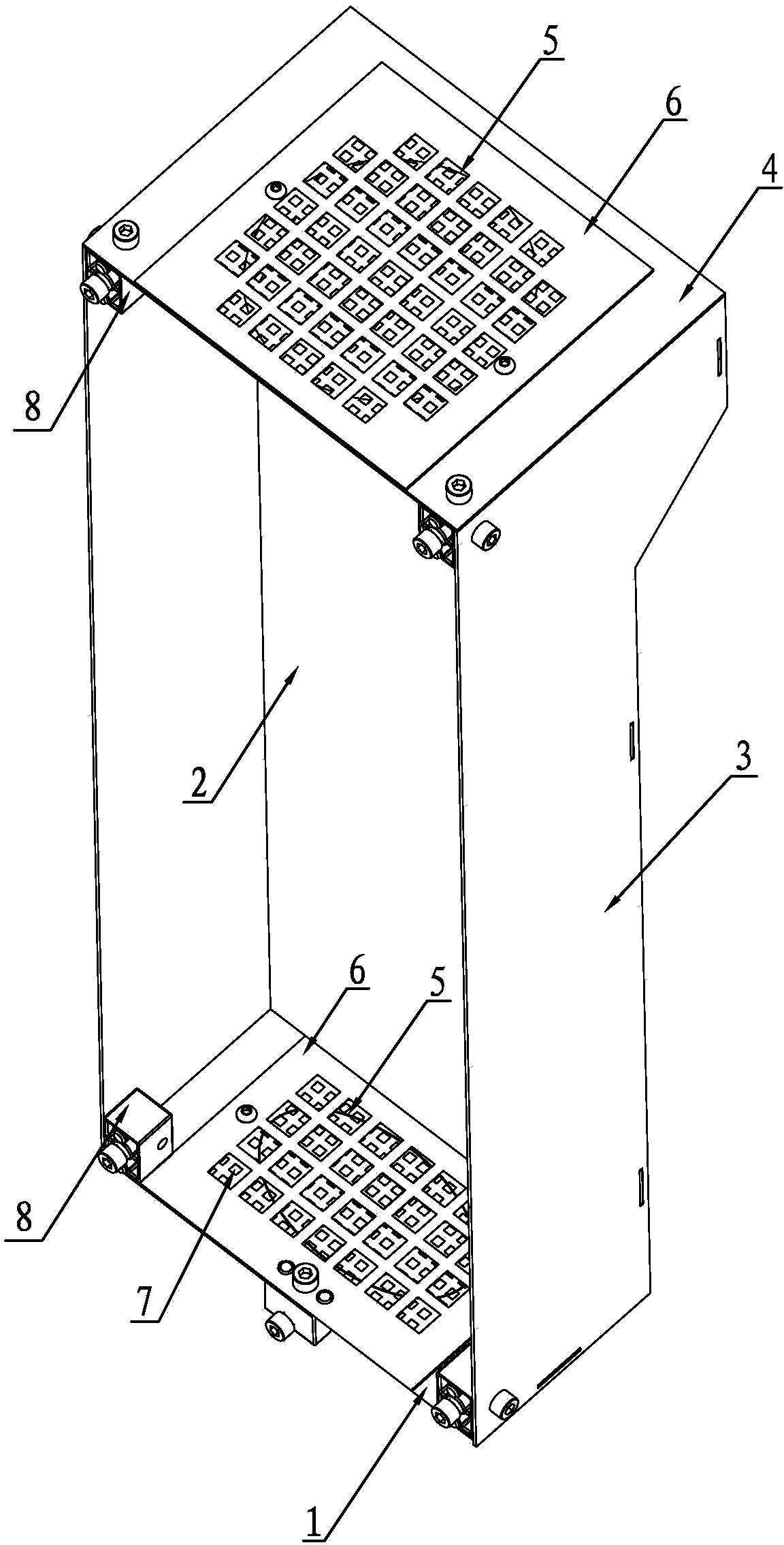

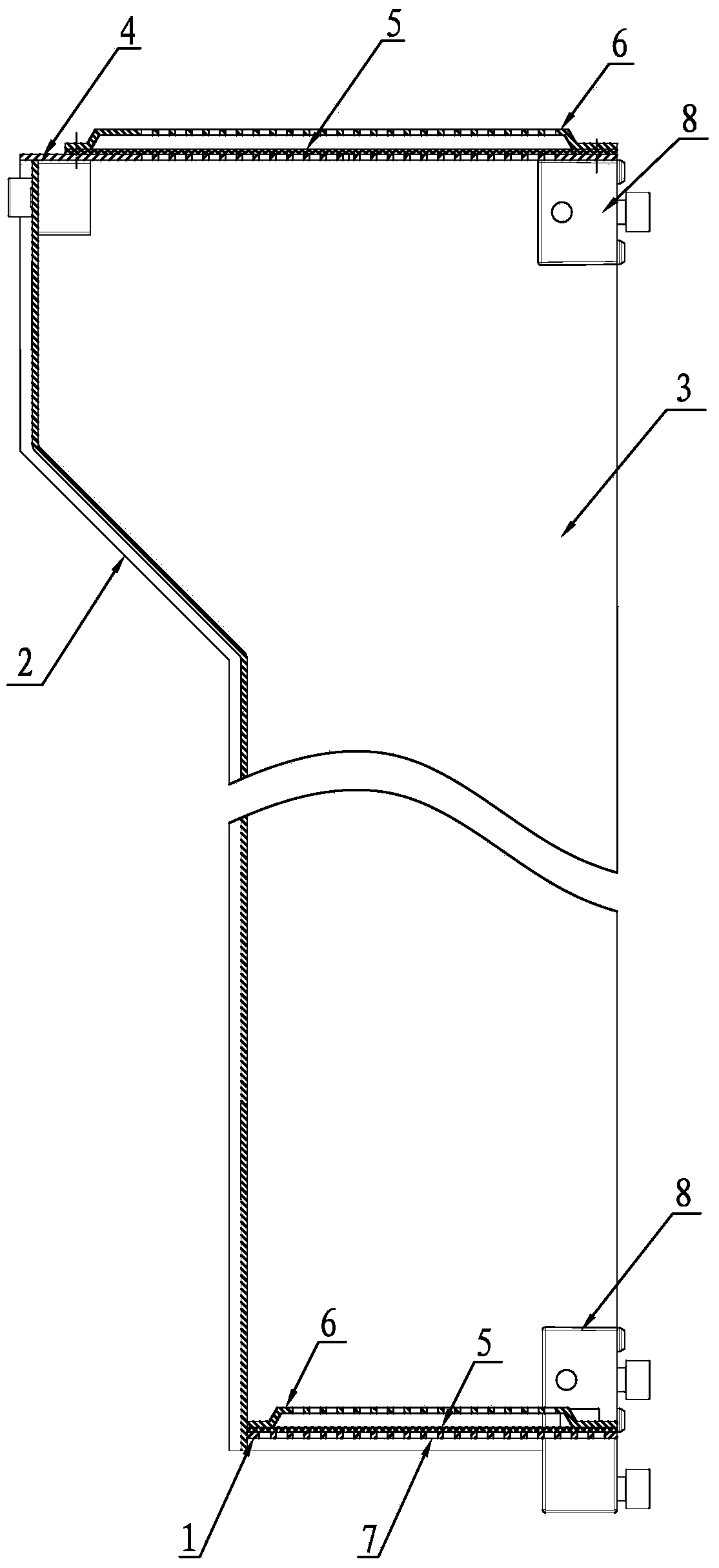

[0024] A two-for-one twister frequency converter anti-fiber ventilation cooling device, including a bottom plate 1, a front plate 2, two side plates 3, a top heat dissipation cover plate 4, a short-pile filter screen plate 5, a filter screen cover plate 6 and a mesh-shaped air inlet Road 7, the front panel 2 and two side panels 3 are enclosed and arranged on the upper end of the bottom panel 1, the two side panels 3 are arranged in parallel, the top heat dissipation cover 4 is fixed on the upper ends of the front panel 2 and the two side panels 3, and the top An open shell is formed between the heat dissipation cover 4, two side plates 3, the front plate 2 and the bottom plate 1. The open shell is set on the back of the control cabinet frame of the two-for-one twister, and a heat dissipation is provided on the top heat dissipation cover 4. Mesh hole, on the bottom plate 1 of the open housing, a mesh air inlet channel 7 is provided, and a short-pile filter screen plate 5 is arra...

Embodiment 2

[0025] Embodiment 2: On the basis of Embodiment 1, a short-pile filter screen 5 is provided on the top heat dissipation cover 4, and the short-pile filter screen 5 is compressed by the four peripheries of the filter screen cover 6, and the filter screen cover There is space between 6 and the short velvet filter screen plate 5.

Embodiment 3

[0026] Embodiment 3: The difference from Embodiment 1 is that the mesh air inlet duct 7 is arranged on the front panel 2, and the height direction of the mesh air inlet duct 7 is lower than the installation height of the frequency converter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com