gas turbine combustor

A technology for gas turbines and combustion chambers, which is applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., and can solve the problems of shortened life of sealing structures, impact of post-installation edge seal cooling, adverse effects of post-installation edge seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

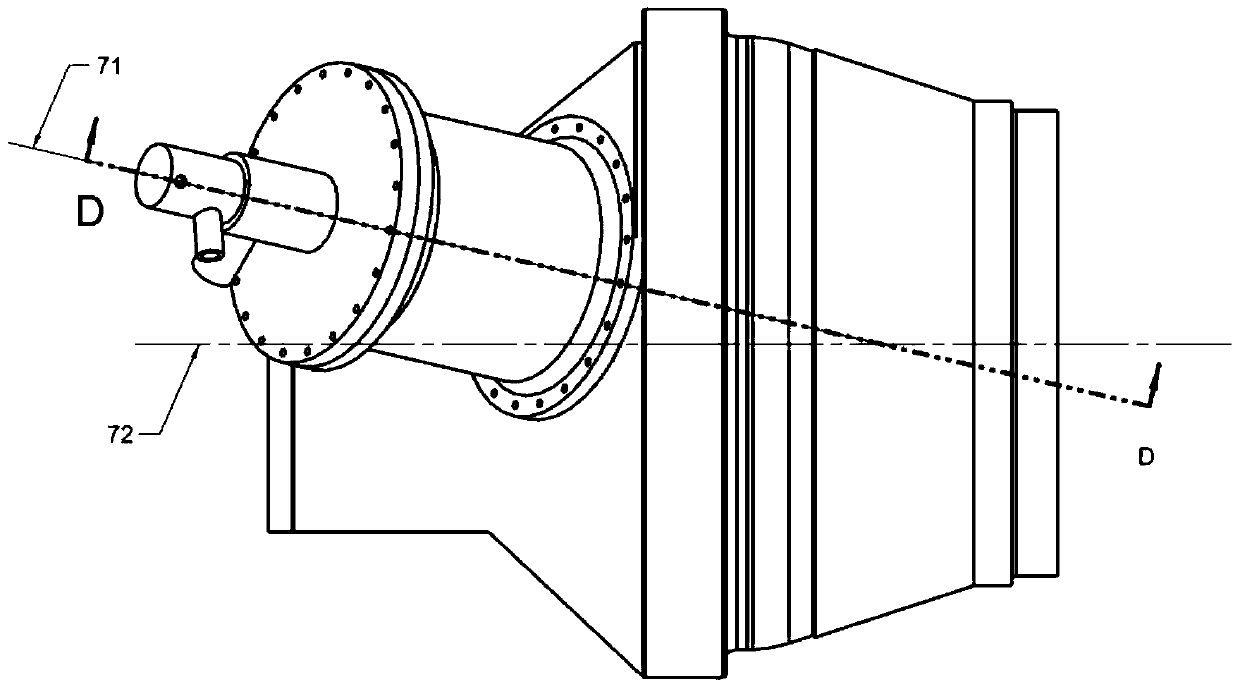

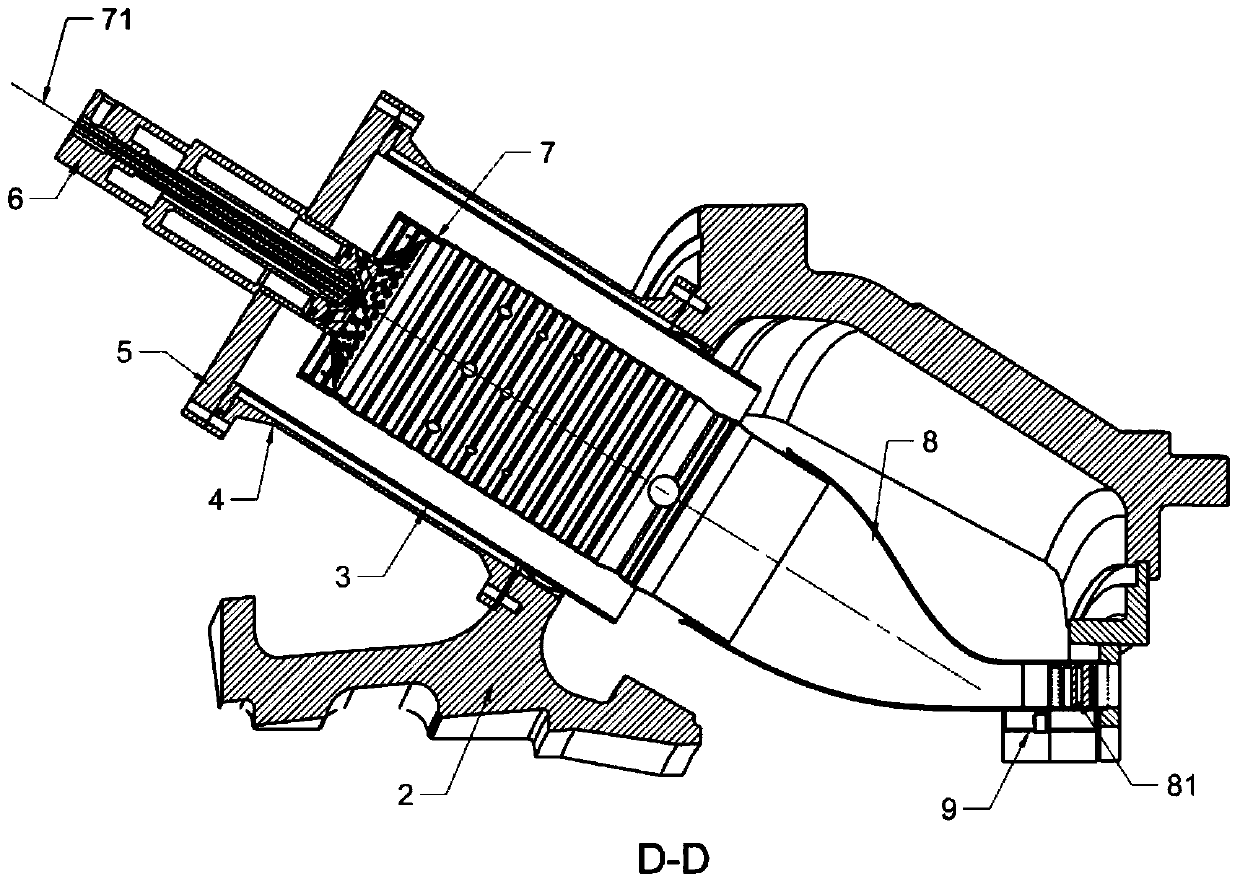

[0029] like Figure 1-4 As shown, the combustion chamber of the gas turbine in this embodiment includes: a fuel pressure cylinder 2, a casing 4 connected to the fuel pressure cylinder 2 at the rear end, an end cover 5 connected to the front end of the casing 4, and a nozzle 6 connected to the end cover 5 , the guide bush 3 connected to the inner side of the casing 4, the flame tube 7 located inside the guide bush 3 and the front end connected to the nozzle 6, and the transition section 8 whose inlet is connected to the rear end of the flame tube 7 .

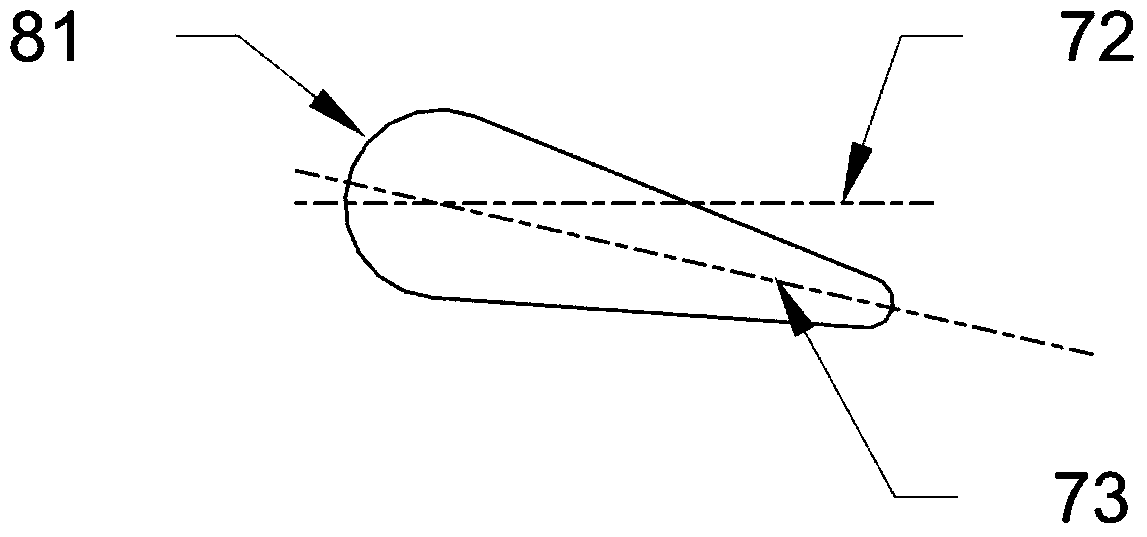

[0030] The outlet of the transition section 8 is provided with an outlet guide vane 81, the transition section 8 and the outlet guide vane 81 are an integrated structure, and the transition section 8 is provided with an air distribution chamber 9 at the outlet guide vane 81 and the front edge end wall 82 of the outlet guide vane . According to the different positions of the air distribution cavity 9, the cooling air flow control...

Embodiment 2

[0036] like Figure 5 As shown, the gas turbine combustor of this embodiment is different from that of Embodiment 1 in that the lower edge of the leading edge end wall 82 of the outlet guide vane is not provided with divergent cooling holes 93, but the air distribution chamber passage 94 and the outlet The internal cooling means of the vane 81 communicates.

[0037] Part of the cooling air that cools the leading end wall 82 of the outlet guide vane through the impact cooling hole 91 of the air distribution chamber 9 flows downstream into the internal cooling device of the outlet guide vane 81 , and the other part enters the outlet guide vane through the air distribution chamber 9 81 The cooling air from the internal cooling device is mixed, and finally enters the hot aisle 62 through the air film hole 61 on the surface of the outlet guide vane 81 .

[0038] The combustor of the gas turbine of the present invention is provided with a cooling structure at the integrated connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com