Electrical box and air conditioner

A technology for electrical box and box body, which is applied in the direction of heating and ventilation cover/cover, mechanical equipment, etc. It can solve the problems of poor heat exchange and cooling effect of high-power components, lack of pertinence of high-power components, etc., to reduce the temperature , Improve the cooling effect, the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

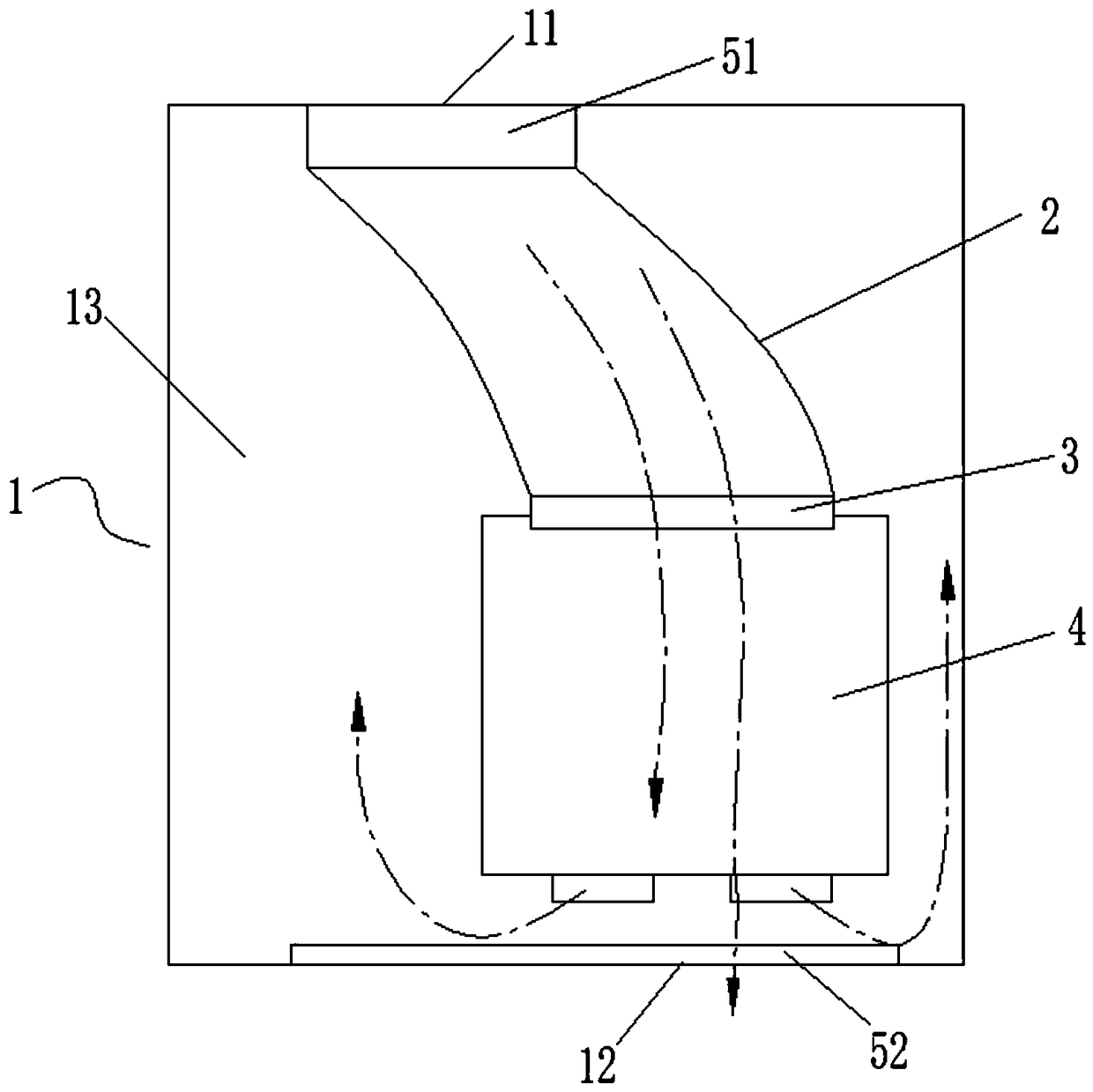

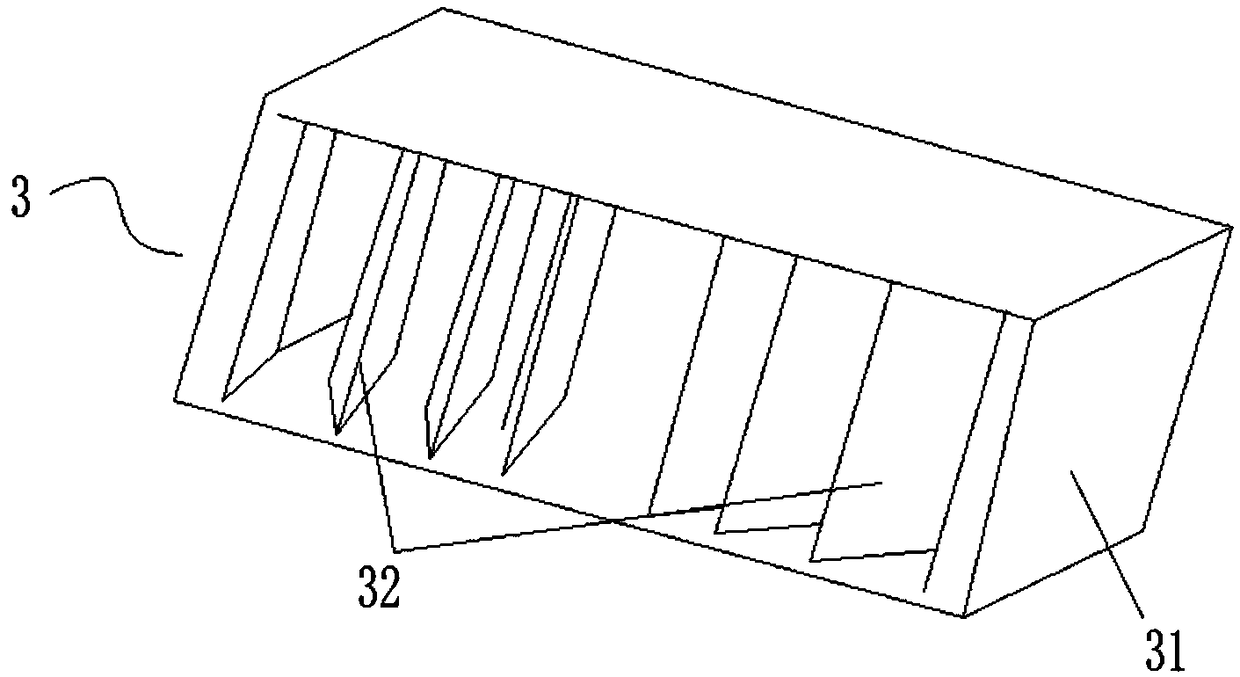

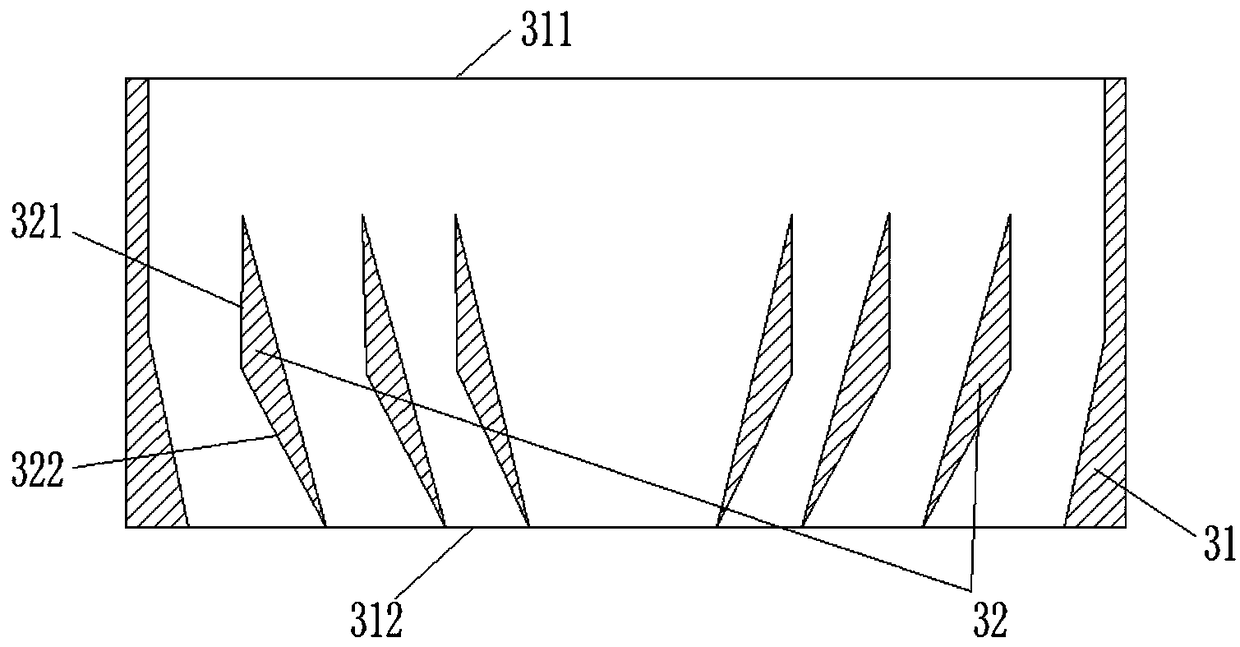

[0020] see in conjunction Figures 1 to 3 As shown, according to an embodiment of the present invention, an electrical box is provided, including a box body 1 and an electrical component module 4 in the box body 1, the box body has an airflow inlet 11, an airflow outlet 12, and the airflow inlet 11 An air guide duct 2 is provided between the electrical component module 4, and the air guide duct 2 can increase the flow rate of the air entering through the air inlet 11. The electrical component module can be an IPM module or a PFC module . In this technical solution, due to the use of a separate airflow channel for the electrical component module 4, the external cooling air enters the electrical box and then flows toward the electrical component module 4 in a targeted manner, that is, the external cooling air is avoided. Dispersion in the electrical box leads to the disadvantage of poor heat dissipation, which can greatly improve the heat dissipation effect of the electrical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com