Boosted-ventilation direct air cooling tower

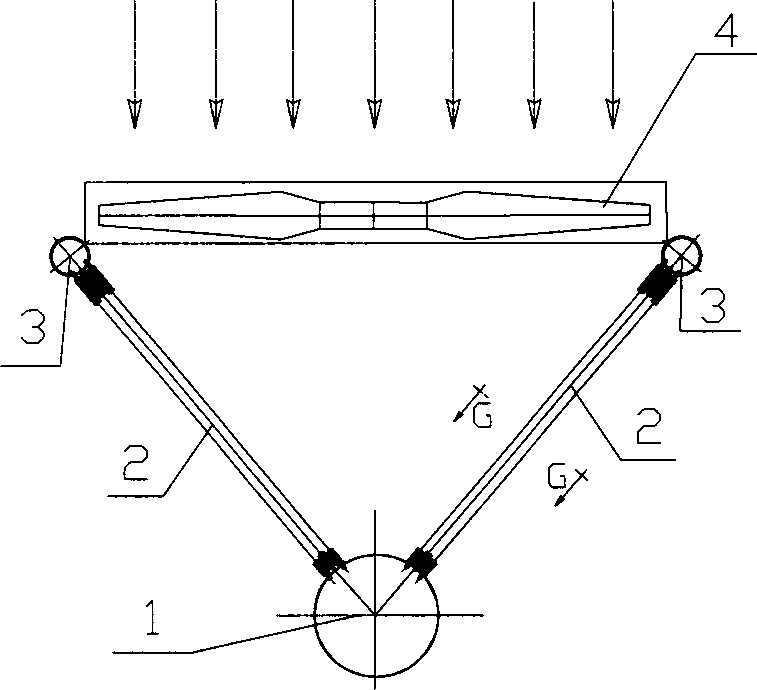

An air-cooling tower, a direct technology, applied in the field of heat exchange, can solve problems such as lack of solutions, achieve the effect of reducing the amount of cooling air, increasing the overall heat transfer coefficient, and enhancing the regulation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

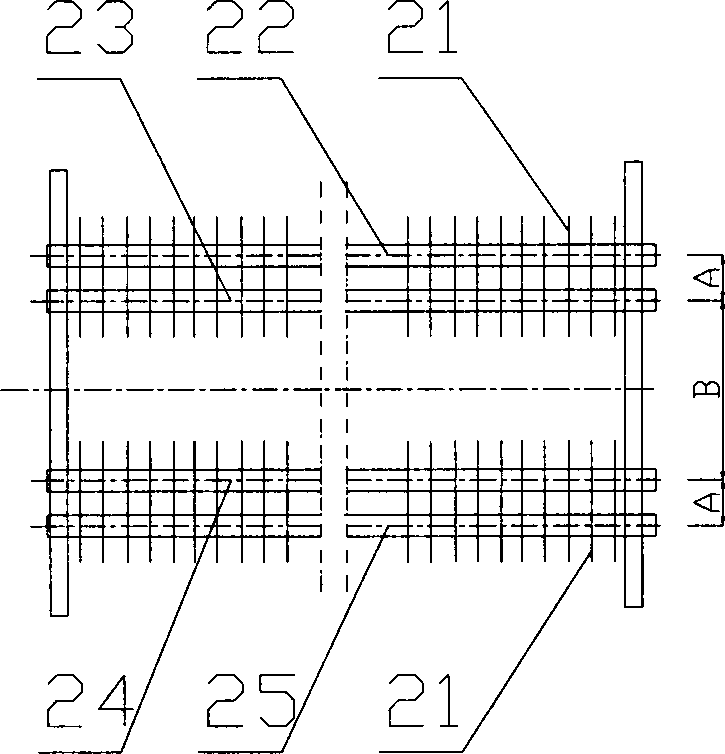

[0055] The zero-meter diameter of the air-cooling tower is 120 meters, the outlet diameter is 90 meters, and the total height of the air-cooling tower is 150 meters; the height of the hot air inlet is 30 meters; m; wing ratio 120.

[0056] The temperature is 35°C, the suction force of the air duct is 90Pa, the maximum wind speed on the windward side is 2.7 meters, and the number of fans is 72. The fans provide the air supply power with a total pressure of 50Pa, and the air volume is 585m 3 / s, the diameter of the fan is 9.14 meters, the total power consumption is 3000kw, and the back pressure of the turbine is 18kPa.

[0057] The temperature is 20°C, the suction force of the air duct is 100Pa, the maximum wind speed on the windward side is 2.7 meters, the number of fans is 72, the fans provide 40Pa partial pressure, and the air volume is 585m 3 / s, the diameter of the fan is 9.14 meters, the total power consumption is 2400kw, and the back pressure of the turbine is 10kPa;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com