Non-filler flow cooling tower

A cooling tower without filler technology, which is applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of fouling and blockage of sheet heat dissipation materials, reduce the heat dissipation performance of cooling towers, etc., and achieve The effect of reducing air flow resistance, improving heat dissipation performance, and reducing tower height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

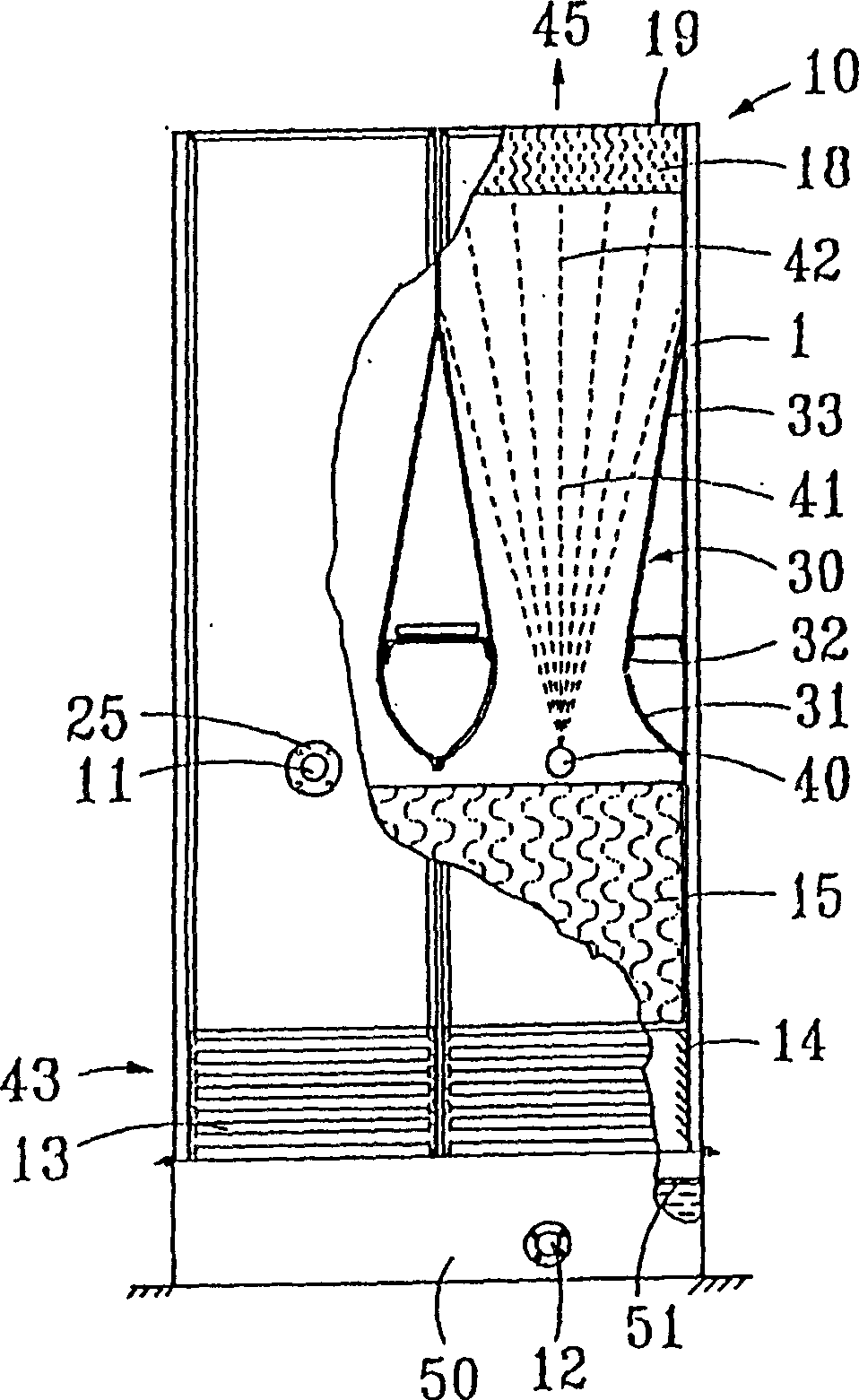

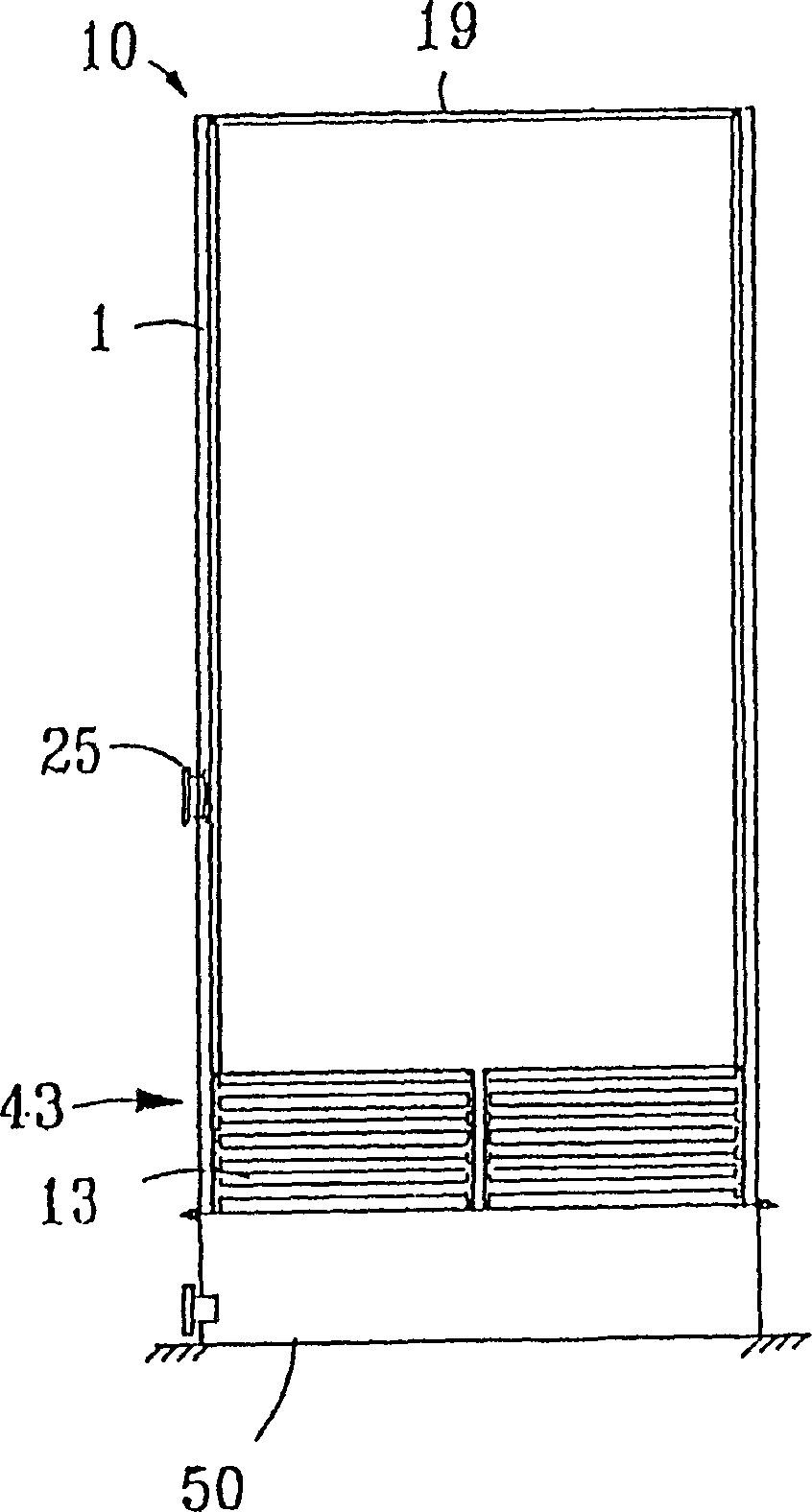

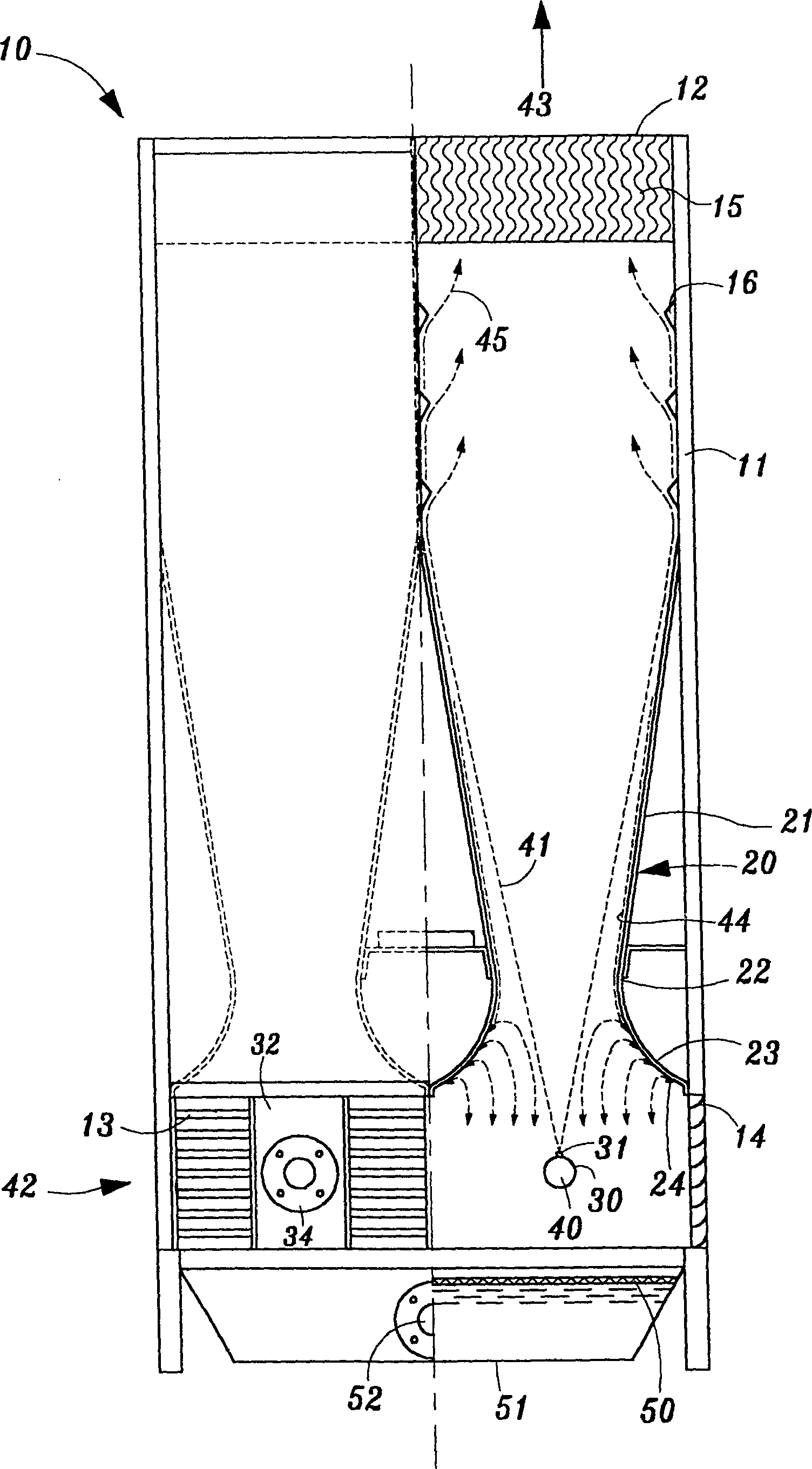

[0025] see figure 2 , 3 As shown, the non-filler flow cooling tower 10 of the present invention includes a tower body 11 , which is a structure made of plastic material or steel plate. The top of the tower body 11 has a hot air discharge port 12 . A cold air inlet 13 is provided near the bottom circumference of the tower body 11, so that the cold air from the outside enters therefrom. The cold air inlet 13 is composed of louvers (LOVERS) blades 14, and the blades 14 are inclined from outside to inside to introduce cold air42. A plate 32 is arranged between the louver blades 14 .

[0026] Inside the tower body 11, multiple groups of symmetrical diffusers 20 (DIFFUSER) are arranged above the cold air inlet 13, and a spray tube 30 is provided below each group of diffusers 20, and several radial outer walls of the spray tube 30 are provided. The V-shaped nozzles 31 arranged equidistantly allow the hot liquid flowing into the spray pipe 30 to be ejected from the V-shaped nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com