An air-cooled structure of an outer rotor permanent magnet motor

A permanent magnet motor, air-cooled structure technology, applied in the magnetic circuit shape/style/structure, electric components, electromechanical devices, etc., can solve the problem of the limited power level of the outer rotor permanent magnet motor, the poor air-cooled heat dissipation capacity, the increase of the motor temperature rise and other problems, to achieve the effect of convenient and fast processing, improved heat dissipation capacity, and increased cooling air flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

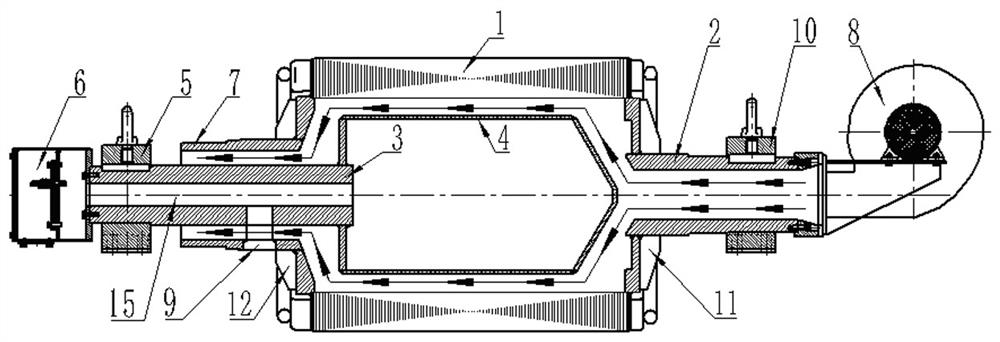

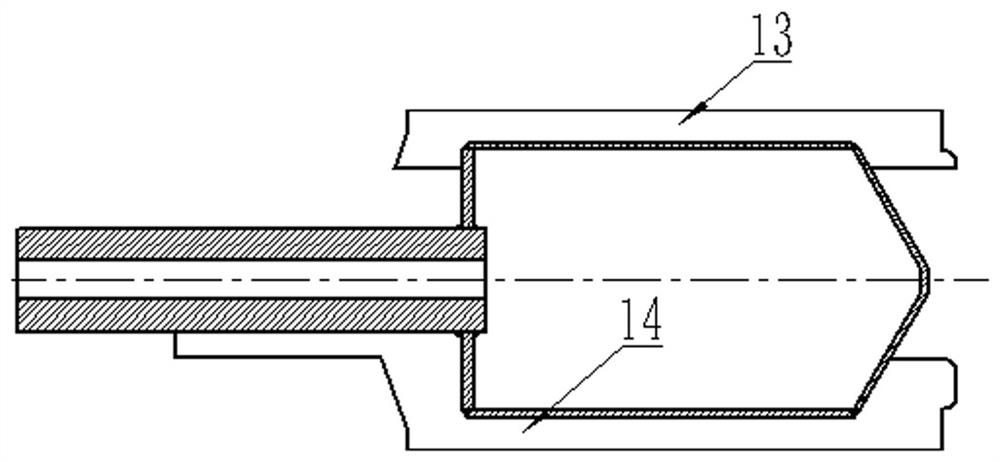

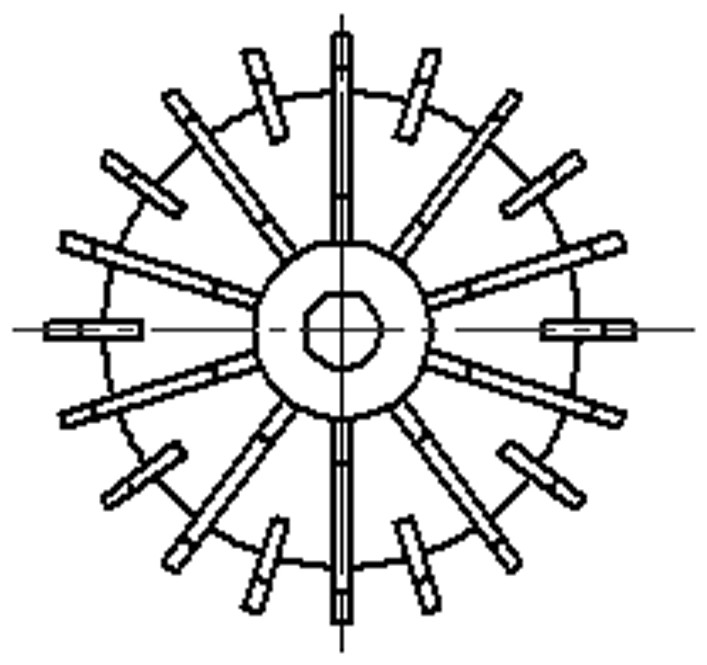

[0022] Such as Figure 1-4 As shown, an air-cooled structure of an outer rotor permanent magnet motor includes a stator core 1, an air inlet side half shaft 2 and an outlet side bearing bracket 7, and the air inlet side half shaft 2 and the outlet side bearing bracket 7 are connected to The two ends of the stator core 1, and the stator core 1, the air inlet side half shaft 2 and the outlet side bearing bracket 7 are connected to form a hollow passage for ventilation, wherein the stator core 1 is 0.5mm thick DW470-50 is laminated, with pressure plates at both ends, and axially fastened by cylindrical pins, windings are arranged in the stator core slot; a cooling fan is installed at the air inlet end of the half shaft 2 on the air inlet side 8. The central through hole of the outlet side bearing bracket 7 is provided with an outlet side half shaft 3, and the central through hole of the stator core 1 is provided with an air duct inner retaining ring 4, and the air duct inner reta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com