Method for prolonging service life of RH insertion tube

A technology of inserting tubes and life, which is applied in the field of iron and steel smelting, can solve the problems of spray guns not being able to handle, and achieve the effect of increasing the upper limit, improving the RH operation rate, and increasing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

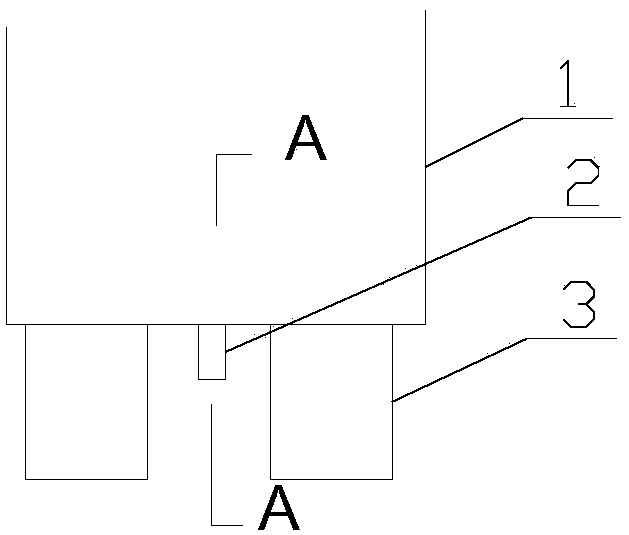

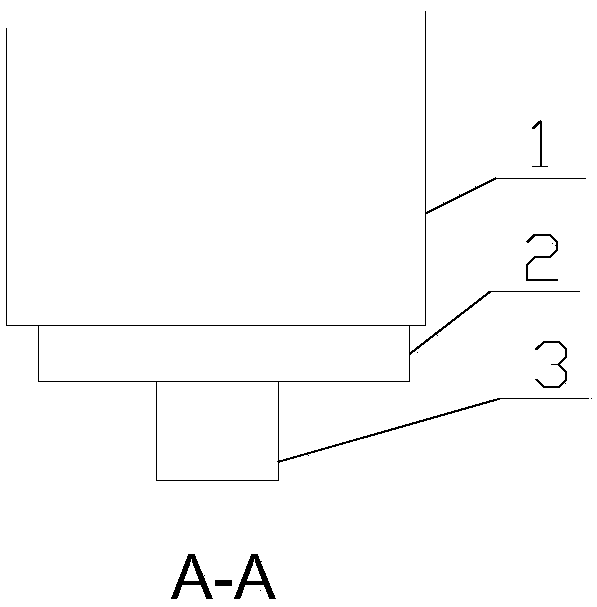

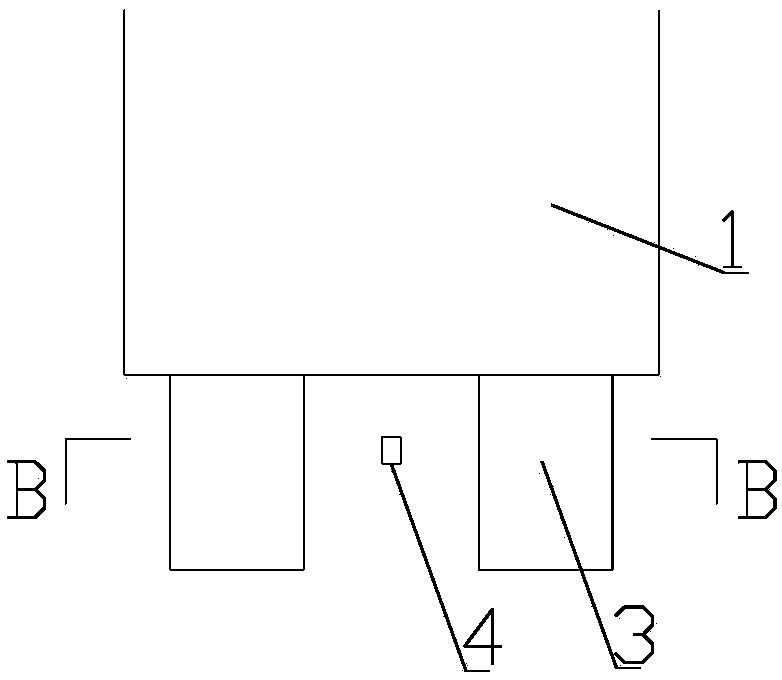

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0023] A method for improving the service life of the RH insertion tube 3, comprising the following steps:

[0024] 1) When the online insertion pipe 3 is used within 80 times: for the production of steel grades with a carbon content of molten steel > 0.03%, one gunning cycle treats ≤ 7 cans of molten steel; for the production of steel grades with a carbon content of molten steel ≤ 0.03%, one gunning cycle Handle ≤6 tanks of molten steel;

[0025] When the online insertion pipe is used more than 80 times: produce steel grades with a carbon content of > 0.03% in molten steel, process ≤ 5 cans in one gunning cycle, and do not produce steel grades with a carbon content of ≤ 0.03%;

[0026] 2) When the new insertion tube 3 is used for the first time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com