Radiating structure of shell having stream guidance opening of microwave oven magnetron

A heat dissipation structure and magnetron technology, which are applied in the directions of magnetrons, collectors of transit time electron tubes, shells/containers of transit time electron tubes, etc. Insufficient air volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

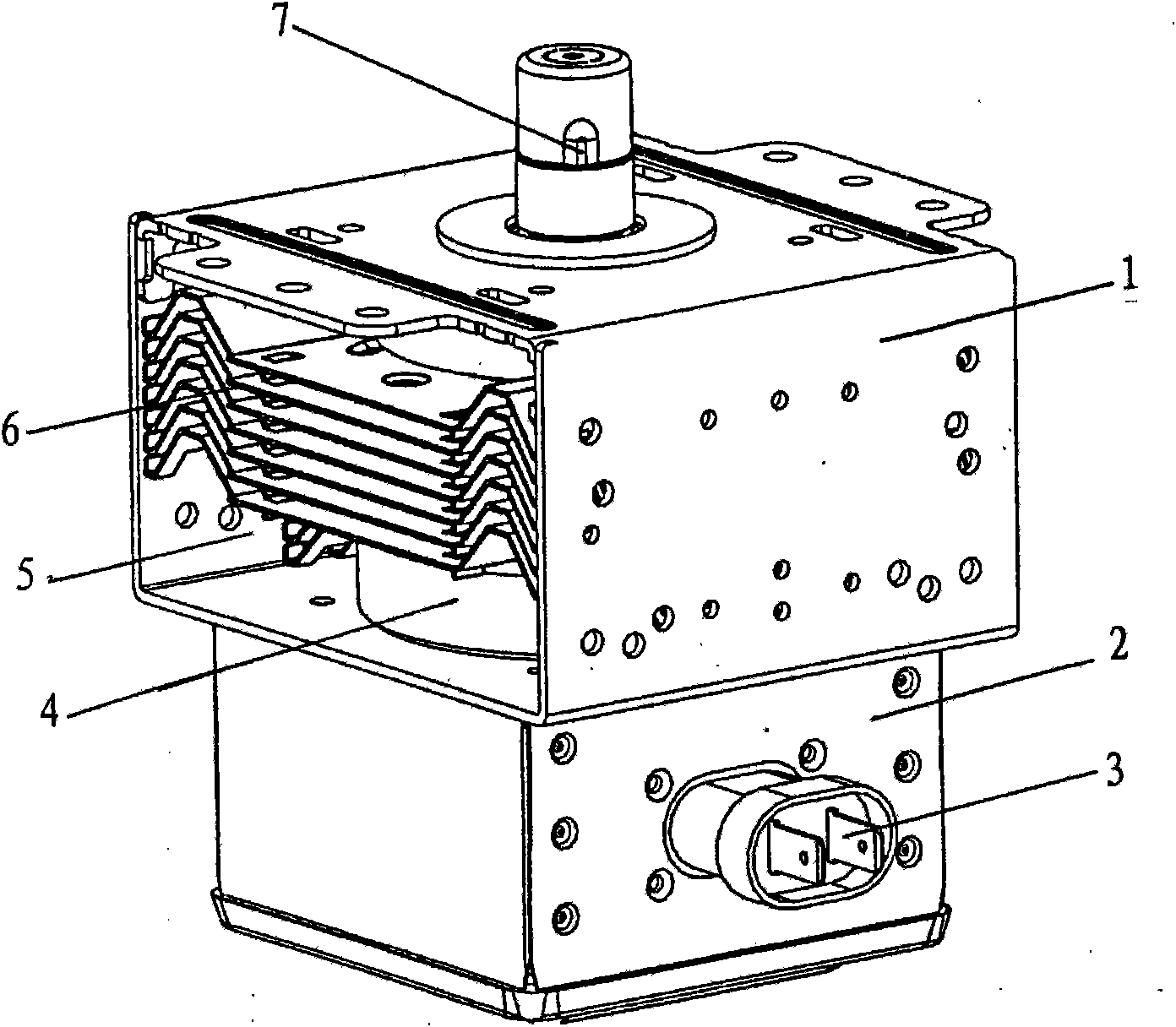

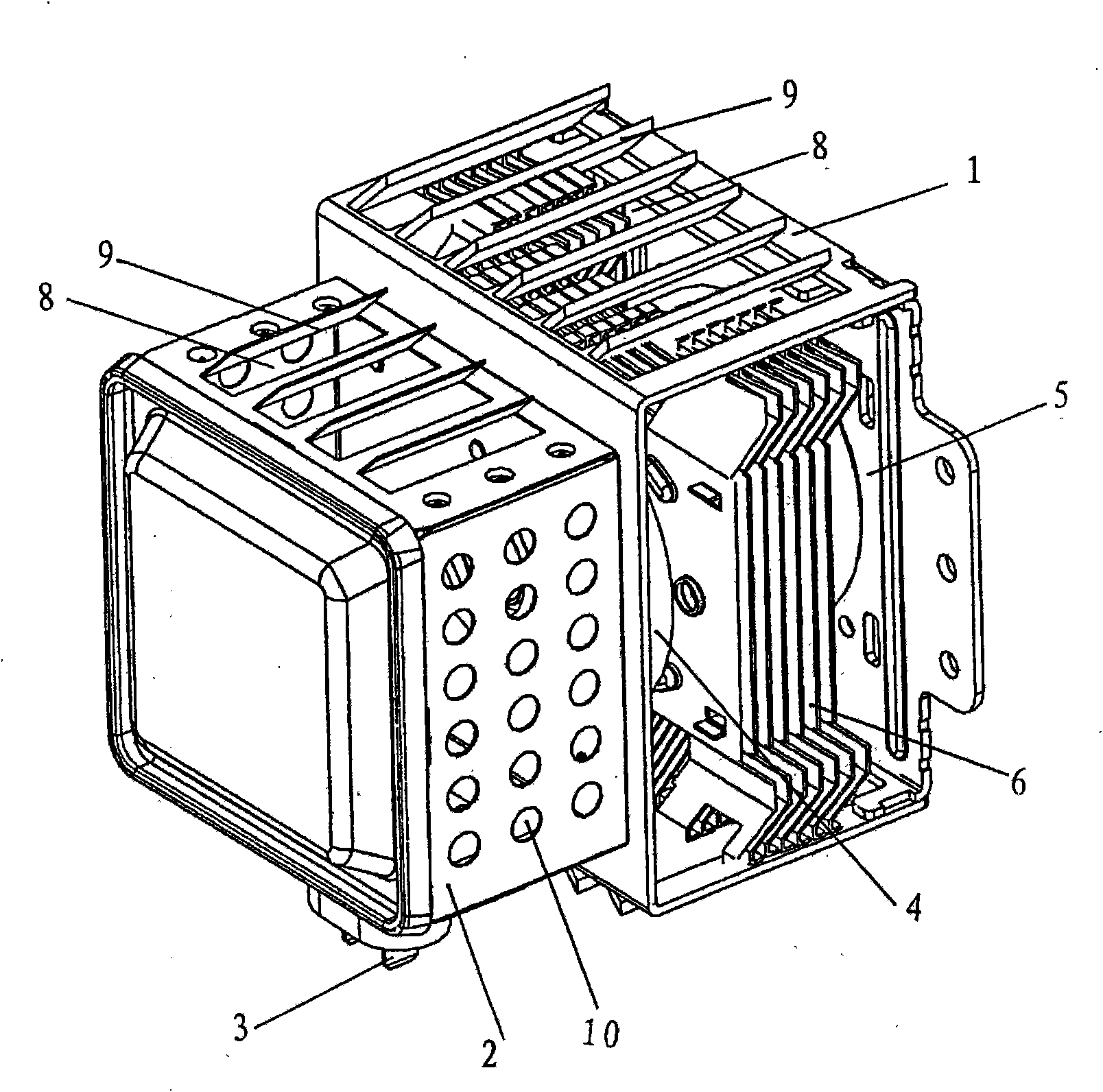

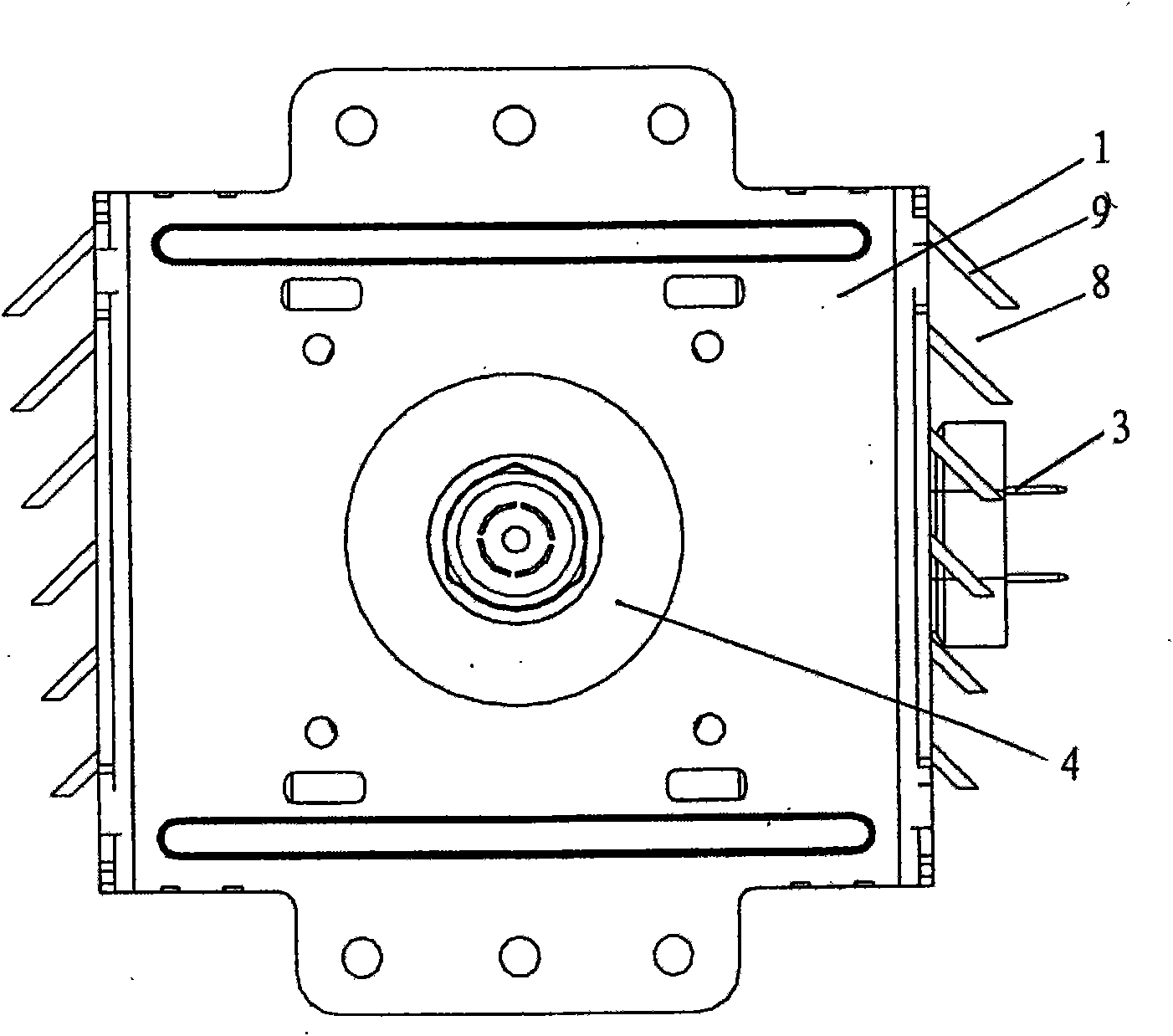

[0020] Now in conjunction with the accompanying drawings, the present invention will be further described. figure 2 It is a structural schematic diagram of the microwave oven magnetron involved in the present invention. image 3 It is a top view of the microwave oven magnetron shell involved in the present invention.

[0021] Such as figure 2 and image 3 As shown, the housing of the microwave oven magnetron involved in the present invention is divided into upper and lower parts, the upper housing 1 is provided with a tube core, including a cathode and an anode 4, and the lower housing 2 is provided with a connecting device for the tube core and an external power supply. Connect with external power supply through power plug 3. Radiating fins 6 are arranged on the outside of the anode 4 , and the cooling fins 6 are plate-shaped aluminum sheets arranged alternately along the axial direction of the anode 4 . The cooling fins 6 surrounding the anode 4 are exposed to the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com