Automatic multi-station glass sheet carving machine provided with magazine tools and carving technology of machine

A glass sheet, multi-station technology, applied in engraving, decorative arts, painting tools, etc., can solve the problems of defective products, high equipment cost, difficult process control, etc., and achieve the effect of improving the efficiency of fine carving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

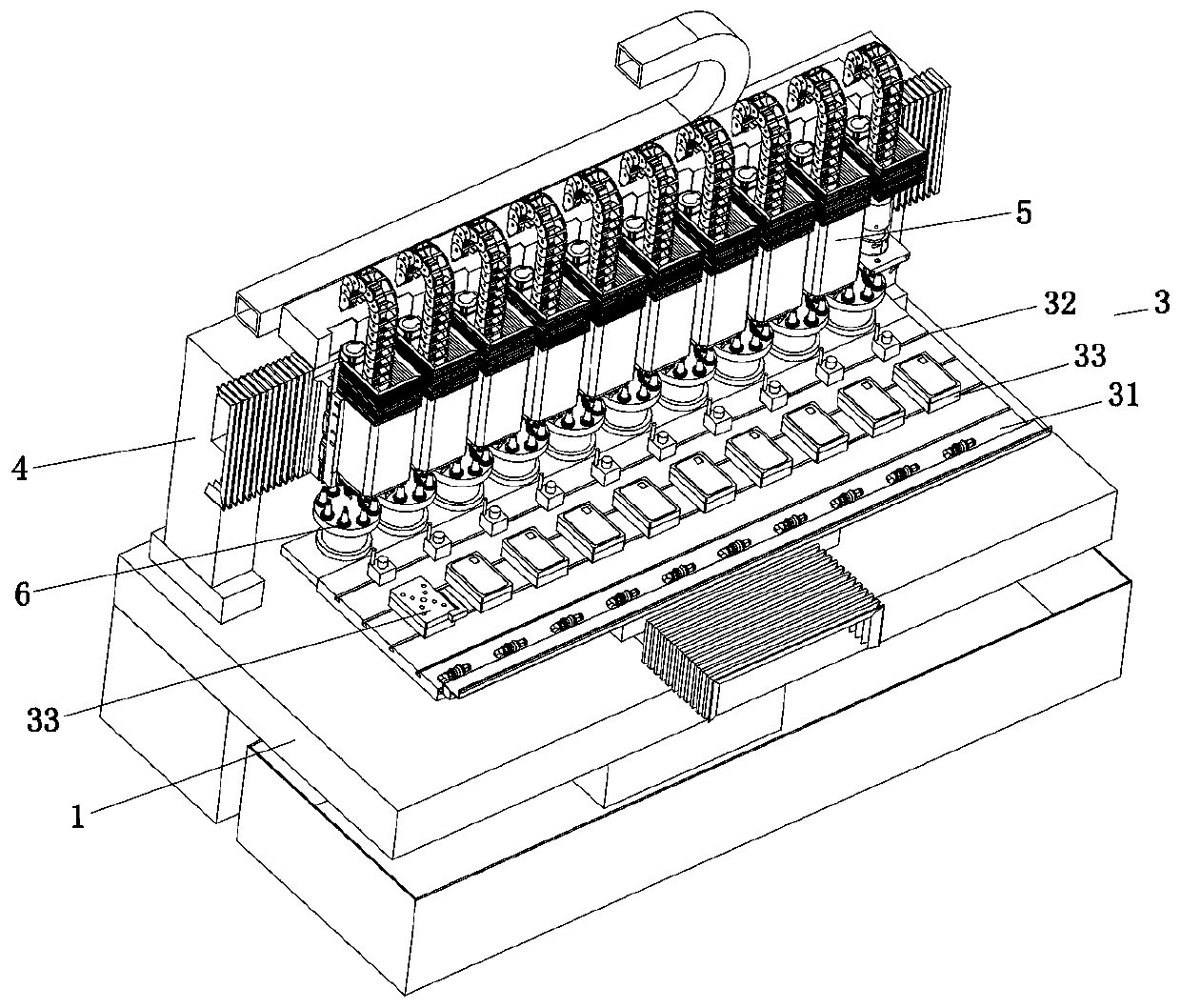

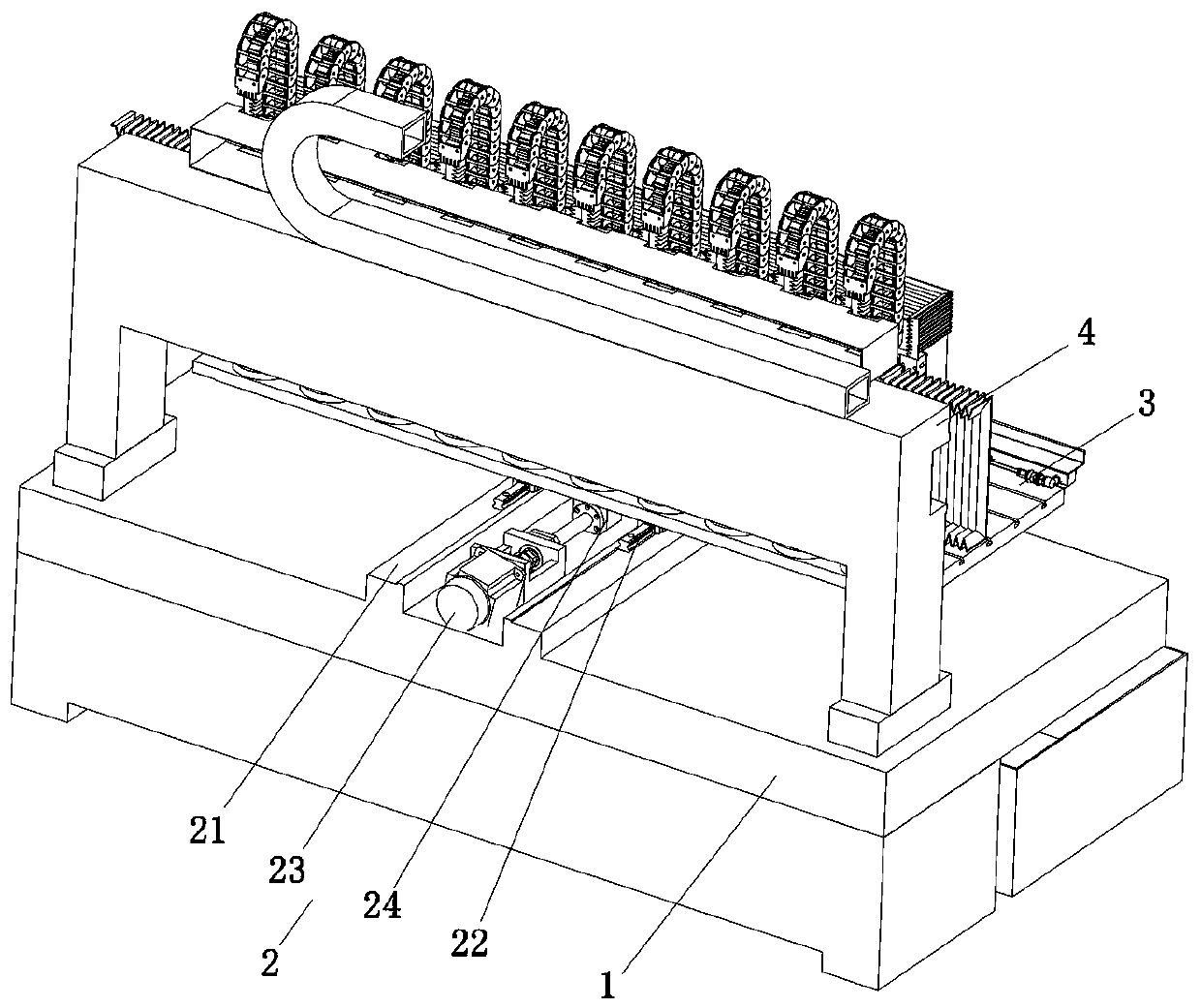

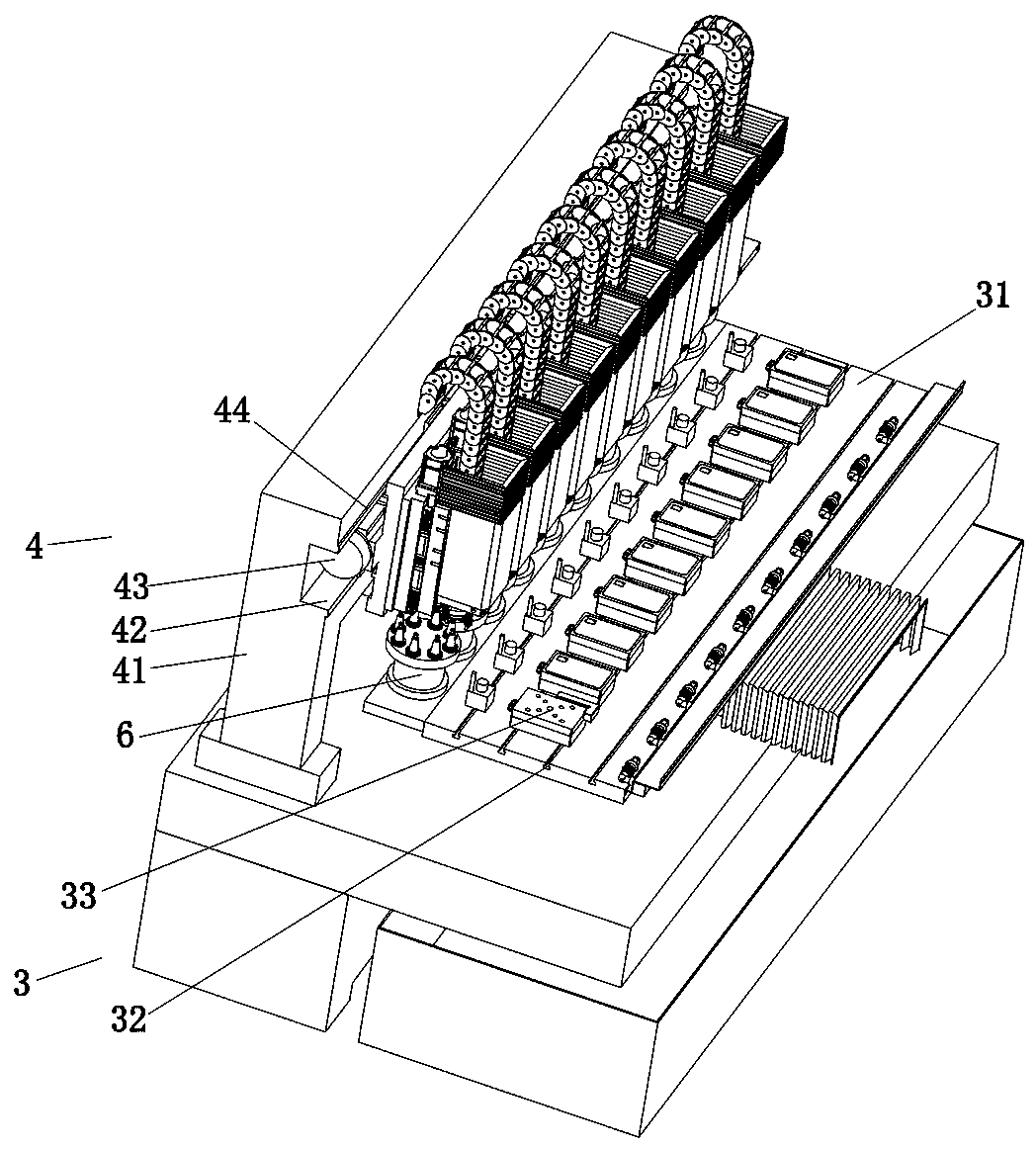

[0042] Embodiment 1: as Figure 1 to Figure 9 As shown, it is Embodiment 1 of the present invention, and the technical solution adopted in this embodiment is as follows: a multi-station automatic fine engraving machine for glass sheets with a tool magazine, including a machine platform 1, a longitudinal sliding assembly 2, a processing platform 3, The horizontal sliding assembly 4, the Jingdiao assembly 5 and the tool magazine 6, wherein the above-mentioned machine platform 1 is arranged horizontally, and a processing space with a top opening is provided inside the machine table 1; the above-mentioned vertical sliding assembly 2 includes at least two sets, and the vertical sliding assembly The component 2 is set on the machine platform 1 along the left and right direction; the above-mentioned processing platform 3 includes at least two. The sliding assembly 2 is driven to move linearly back and forth along the front and rear directions; the above-mentioned lateral sliding asse...

Embodiment 2

[0061] Embodiment 2: as Figure 9 Shown is Embodiment 2 of the present invention. This embodiment adopts the same structural design, the principle of fine carving of glass sheets and the steps of fine carving of glass sheets as in Embodiment 1. The difference is that, compared with Embodiment 1, the There are 9 sets of vertical sliding components, processing platforms and engraving components. Through this structural design, the precise engraving of 9 glass sheets can be independently completed on a single machine at the same time; compared with Example 1, the volume of the machine is reduced , but the production capacity of Jingdiao is reduced.

Embodiment 3

[0062] Embodiment 3: as Figure 10 Shown is Embodiment 3 of the present invention. This embodiment adopts the same structural design as Embodiment 1, the principle of fine carving of glass sheets and the steps of fine carving of glass sheets. The difference is that, compared with Embodiment 1, the There are 8 sets of longitudinal sliding components, processing platforms and engraving components. Through this structural design, the precise engraving of 8 pieces of glass sheets can be independently completed on a single machine at the same time; compared with Example 1, the volume of the machine is reduced , but the production capacity of Jingdiao is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com