Slurry dewatering and curing construction device and method

A construction device and mud technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as mud pump blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

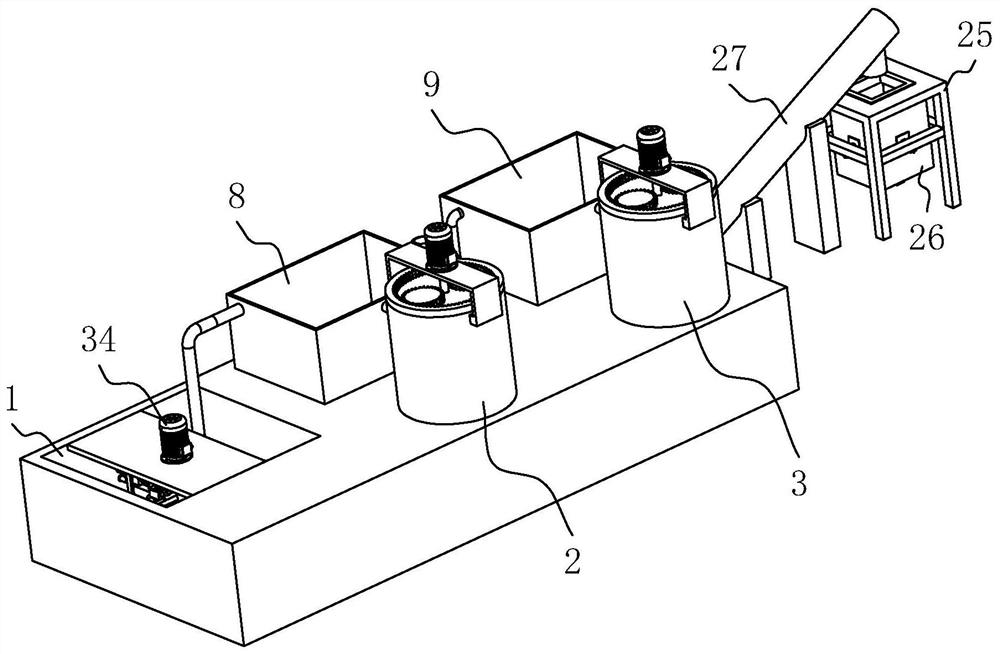

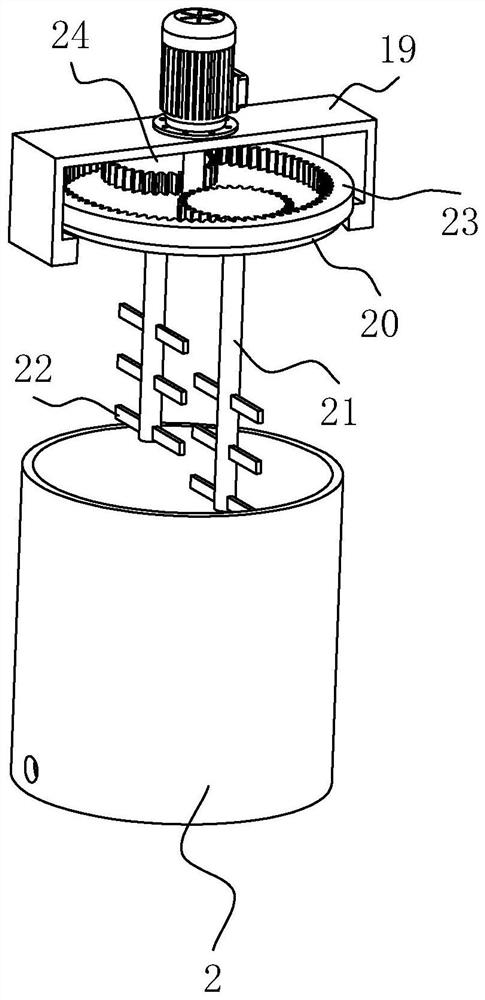

[0044] The embodiment of the present application discloses a construction device for dehydrating and solidifying mud. refer to figure 1 and figure 2 A mud dehydration and solidification construction device includes a mud tank 1, an inorganic flocculation tank 2, an organic flocculation tank 3 and a filter device. A mud pump 4 is installed in the mud tank 1, and the output end of the mud pump 4 is connected to the inorganic flocculation tank 2. The first settling tank 8, the first settling tank 8 is used for the flocculation of inorganic matter in the mud, the first settling tank 8 is connected with the second settling tank 9 connected with the organic flocculation tank 3, the second settling tank 9 is connected with the filter device, filters The device is connected with the second settling tank 9 and the first settling tank 8 and the second settling tank 9 are connected by a screw conveyor, which is convenient for transporting mud.

[0045] In order to prevent the mud at t...

Embodiment 2

[0057] The embodiment of the present application discloses a construction method for mud dehydration and solidification. A kind of mud dehydration solidification construction method comprises the following steps,

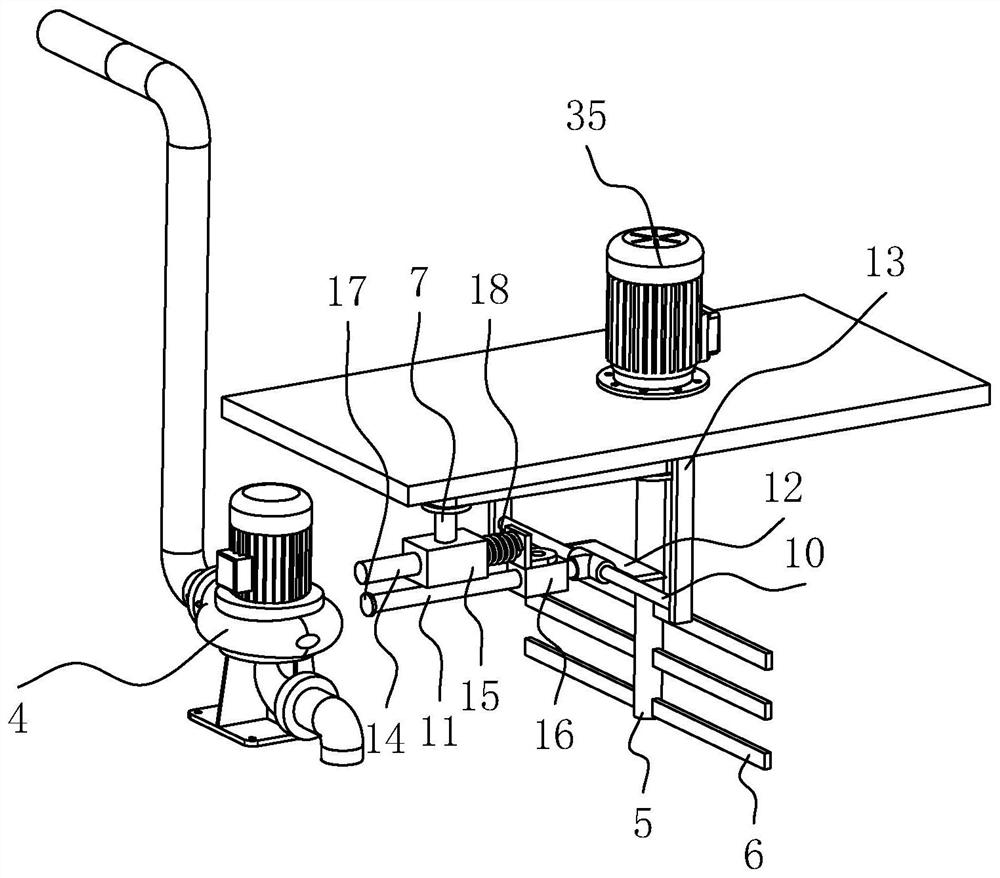

[0058] S1. Slurry and sludge extraction, the crushing rod 5 drives the crushing piece 6 to rotate, the rotating shaft 7 rotates, and drives the sliding sleeve 15 to rotate, the driving rod 14 slides in the sliding sleeve 15 and drives the slider 16 to reciprocate on the cutting rod 11 Movement, under the limiting action of the first limiting block 13 and the second limiting block 17, the cutting knife is reciprocated along with the cutting rod 11, and the reciprocating movement of the cutting piece 12 realizes chopping the mud silt near the mud pump 4;

[0059] S2, mud sludge sedimentation, the mud sludge in the mud tank 1 flows through the first sedimentation tank 8 and the second sedimentation tank 9 in sequence, and the inorganic flocculant or organic flocculant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com