Potato starch rapid forming equipment for food processing

A technology for forming equipment and food processing, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, solid separation, etc., and can solve the problems of poor processing of potato flour, low flour yield and high labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

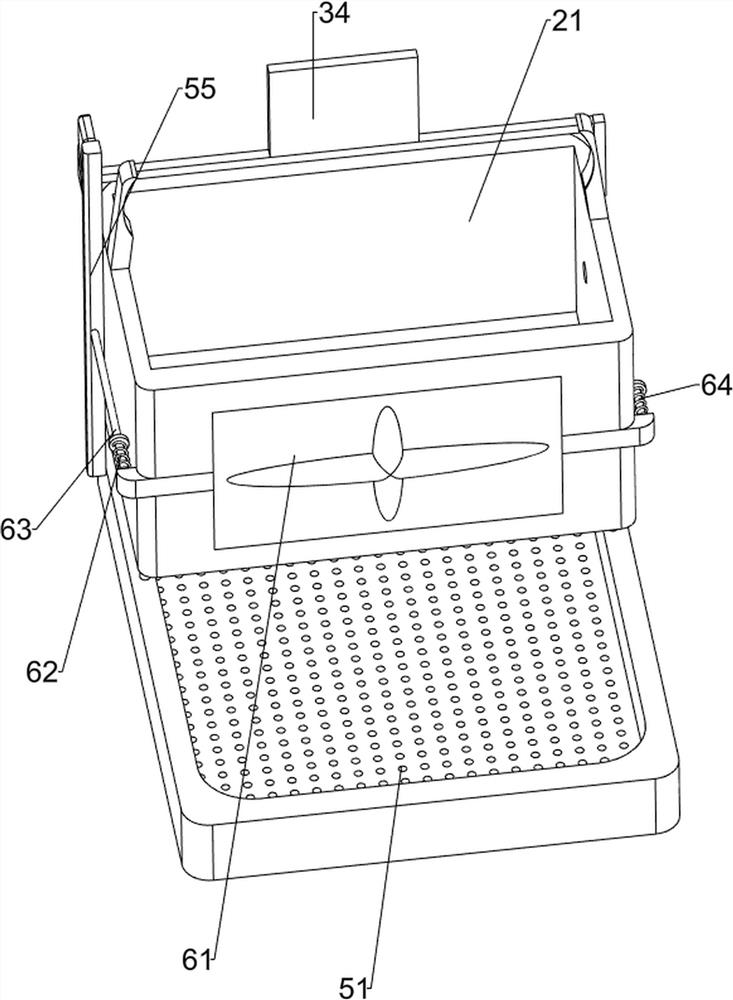

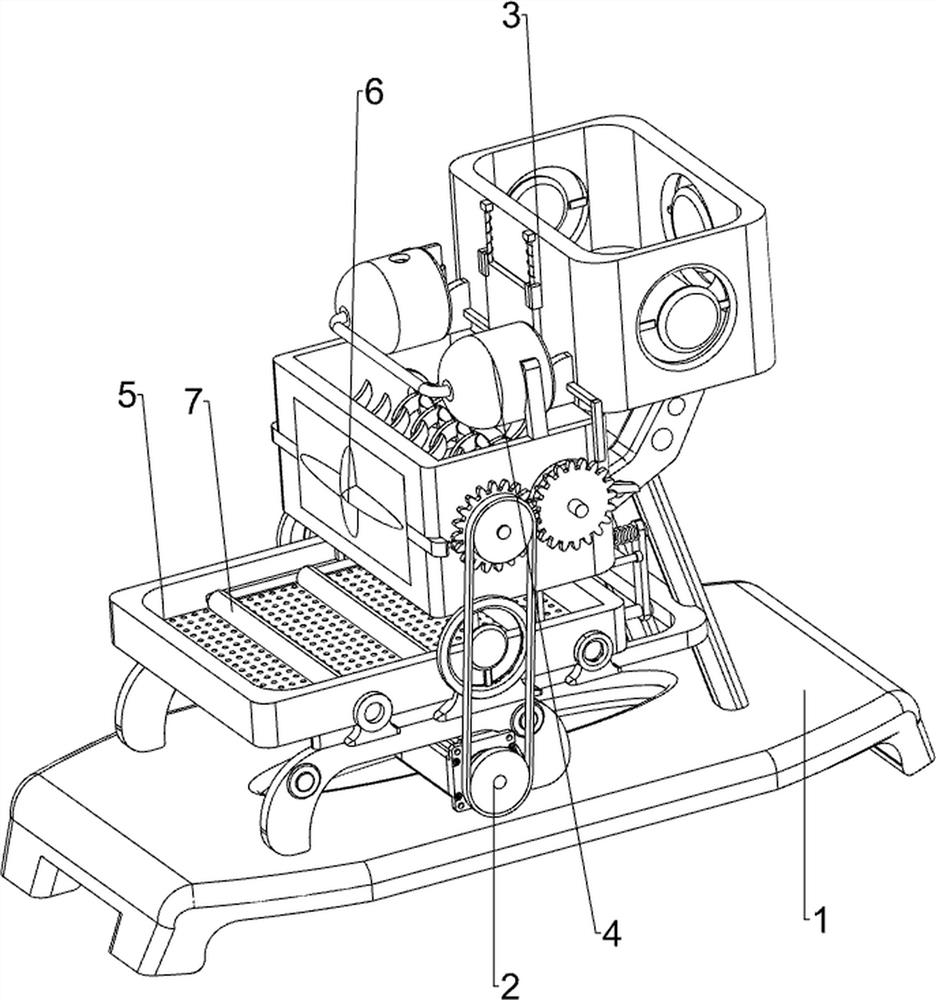

[0061] A kind of potato flour rapid prototyping equipment for food processing, such as figure 1 As shown, it includes a support frame 1, a crushing mechanism 2 and a first unloading mechanism 3. The crushing mechanism 2 is provided in the middle of the support frame 1, and the first unloading mechanism 3 is provided on the upper right side of the support frame 1.

[0062] When people need to make potato flour from potato crops, they can use this potato flour rapid prototyping equipment for food processing. First, people put the potato crops into the first feeding mechanism 3, and then start the crushing mechanism 2 to crush them. The rotation of the mechanism 2 makes the first feeding mechanism 3 reciprocate up and down, so that the potato crops intermittently fall into the crushing mechanism 2. When the crushing mechanism 2 rotates, the crushing mechanism 2 crushes the potato crops, and the crushed potato crops The powder falls from the left side of the crushing mechanism 2, ...

Embodiment 2

[0064] On the basis of Example 1, such as figure 2 and image 3 As shown, the crushing mechanism 2 includes a crushing box 21, a crushing shaft 22, a servo motor 23, a spur gear set 24 and a transmission assembly 25, and a crushing box 21 is arranged between the front and rear sides in the middle of the support frame 1, and the inside of the crushing box 21 is left and right. Both sides are equipped with pulverizing shafts 22 which are rotated, a spur gear set 24 is arranged between the two pulverizing shafts 22 front sides, a servo motor 23 is installed on the middle front side of the support frame 1, and the output shaft of the servo motor 23 is connected to the left side. A transmission assembly 25 is connected between the crushing shafts 22 .

[0065] After people put the potato crops into the crushing box 21, after starting the servo motor 23, the output shaft of the servo motor 23 drives the transmission assembly 25 to drive, thereby driving the crushing shaft 22 on th...

Embodiment 3

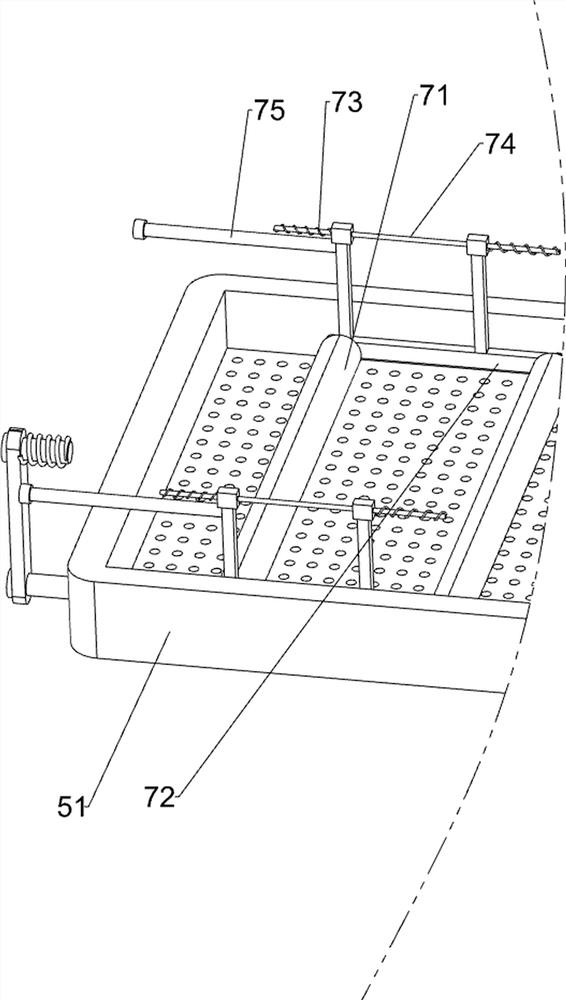

[0069] On the basis of Example 2, such as Figure 4-Figure 7 As shown, flushing mechanism 4 is also included, and flushing mechanism 4 includes water tank 41, water pipe 42, piston rod 43, first spring 44 and first wedge-shaped block 45, and both sides inner wall before and after crushing box 21 tops are all provided with water tank 41, There is a small hole on the top of the water tank 41 on the rear side, and a water pipe 42 is connected between the left side of the water tank 41 on both sides, and the bottom of the water pipe 42 is uniformly provided with small holes. A first spring 44 is wound in the middle, and the two ends of the first spring 44 are connected with the piston rod 43 and the water tank 41 respectively. The first wedge-shaped block 45 is arranged on both sides of the first connecting rod 35, and the first wedge-shaped block 45 is connected with the piston rod 43. Cooperate.

[0070] People first inject water from the small hole of the water tank 41 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com