Straw stubble smashing and returning machine

A crushing mechanism and stubble technology, which is applied in the field of straw stubble crushing and returning machines, can solve the problems of low efficiency, time-consuming and laborious, and heavy workload, and achieve the effects of improving economic benefits, broad market prospects, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

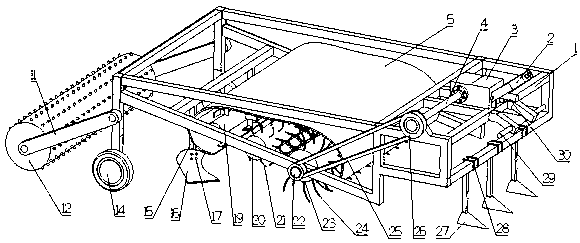

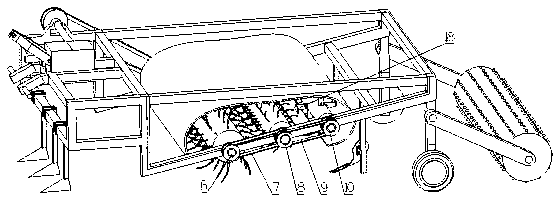

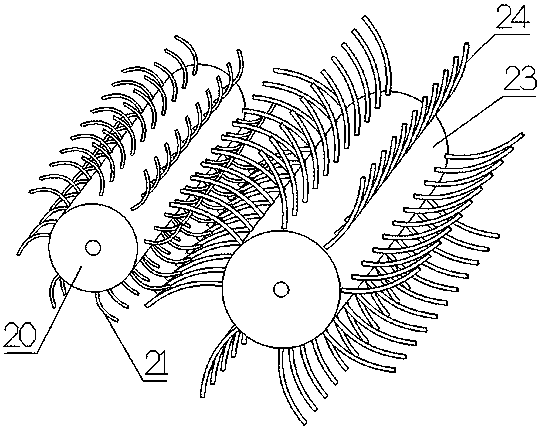

[0020] Embodiment 1: as Figure 1-5 As shown, a straw stubble crushing and returning machine includes a frame 1, a power transmission system, a wedge-shaped ditching shovel 27, a picking and crushing mechanism, and a covering and suppressing system;

[0021] The power transmission system is located at the upper part of the front end of the frame 1, the wedge-shaped ditching shovel 27 is located at the lower part of the front end of the frame 1, the picking and crushing mechanism is located at the middle of the frame 1, and the covering and suppressing system is located at the rear of the frame 1. The system transmits the power to the picking and crushing mechanism and the covering and suppressing system. The straw stubble excavated by the wedge-shaped ditching shovel 27 is picked up and crushed through the picking and crushing mechanism, and finally turned over and returned to the field through the covering and suppressing system.

[0022] Further, a cover plate 5 may be insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com