Environment-friendly straw recycling device

A rice stalk and environmental protection technology, applied in application, cutting equipment, agricultural machinery and tools, etc., can solve problems affecting quality, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

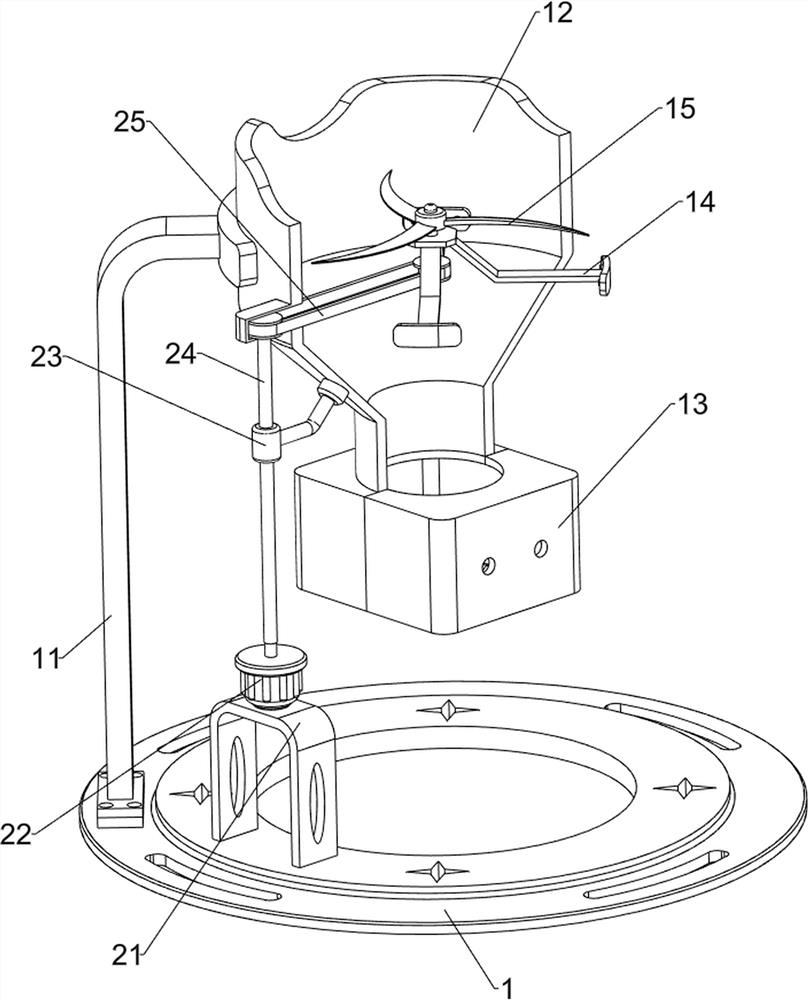

[0029] A device for reusing rice stalks for environmental protection, such as Figure 1-3 Shown, comprise base 1, pillar 11, discharging box 12, pulverizing box 13, first support 14, cutting cutter 15, rotating mechanism 2 and pulverizing mechanism 3, base 1 left side front and rear parts are all provided with pillar 11, two A discharge box 12 is provided between the tops of the root pillars 11, a crushing box 13 is provided at the bottom of the discharge box 12, a first support 14 is provided in the discharge box 12, and a cutting tool 15 is provided on the top of the first support 14 in a rotating manner. 1. A rotating mechanism 2 is provided on the left side, and a crushing mechanism 3 is provided in the crushing box 13.

[0030] When people need to pulverize, they can use this device for recycling rice stalks for environmental protection. First, people need to put the rice stalks in the discharge box 12, and then people start the rotation mechanism 2 to run, and the rotati...

Embodiment 2

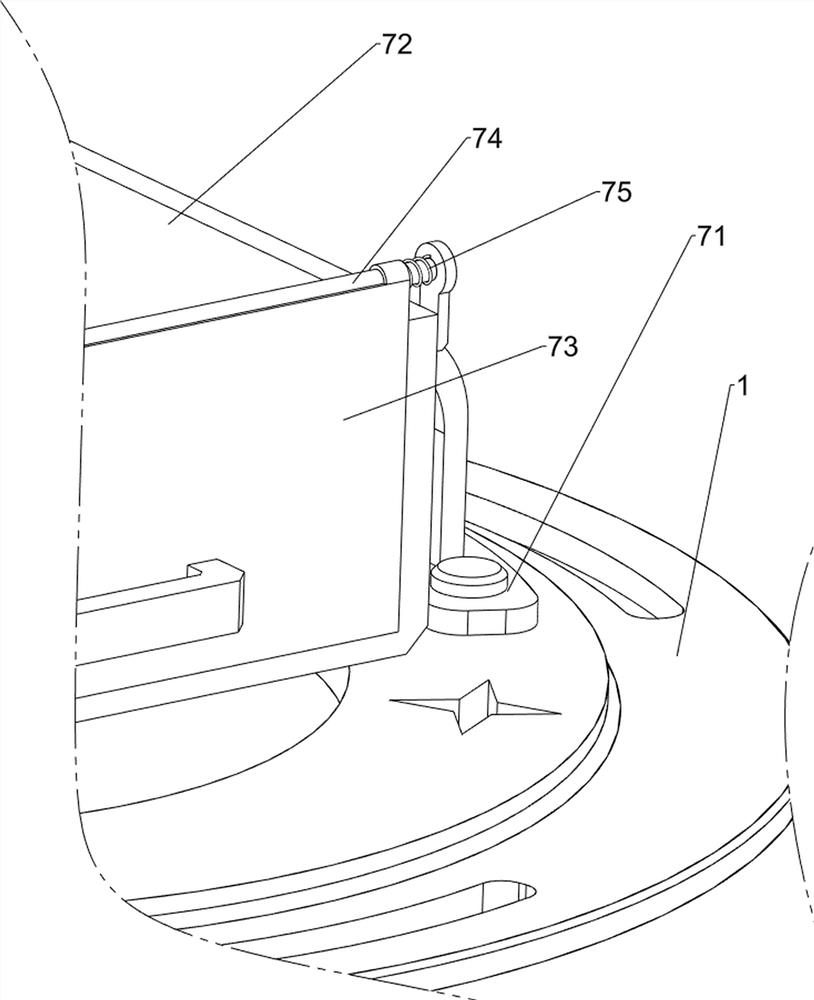

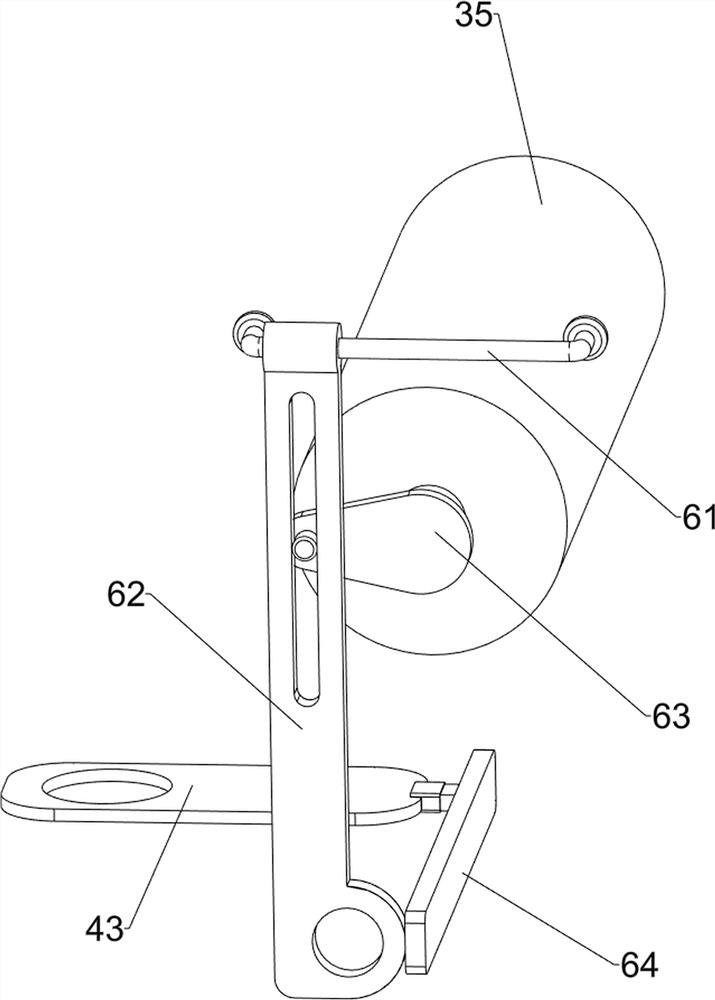

[0036] On the basis of Example 1, such as Figure 4-7 As shown, it also includes a stopper mechanism 4. The stopper mechanism 4 includes a fourth support 41, a slide bar 42, a stopper plate 43 and a first spring 44. Both sides of the bottom of the crushing box 13 are provided with a fourth support 41. , the bottom of the fourth bracket 41 is connected with a sliding rod 42, and the left side of the two sliding rods 42 is slidably connected with a material blocking plate 43, and the material blocking plate 43 cooperates with the crushing box 13, and the two sliding rods 42 are wound with The first spring 44 .

[0037]For the effect that the shredded rice stalks can be fully crushed in the crushing mechanism 3, people push the material retaining plate 43 to the right with their hands, and the front and rear sides of the material retaining plate 43 will slide to the right along the slide bar 42. The first spring 44 can be compressed, and now the crushing box 13 is opened, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com