Rapid paper cutting machine

A paper cutter, fast technology, applied in the direction of object supply, metal processing, pile separation, etc., can solve the problems of irregular shape, low cutting efficiency, large size error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

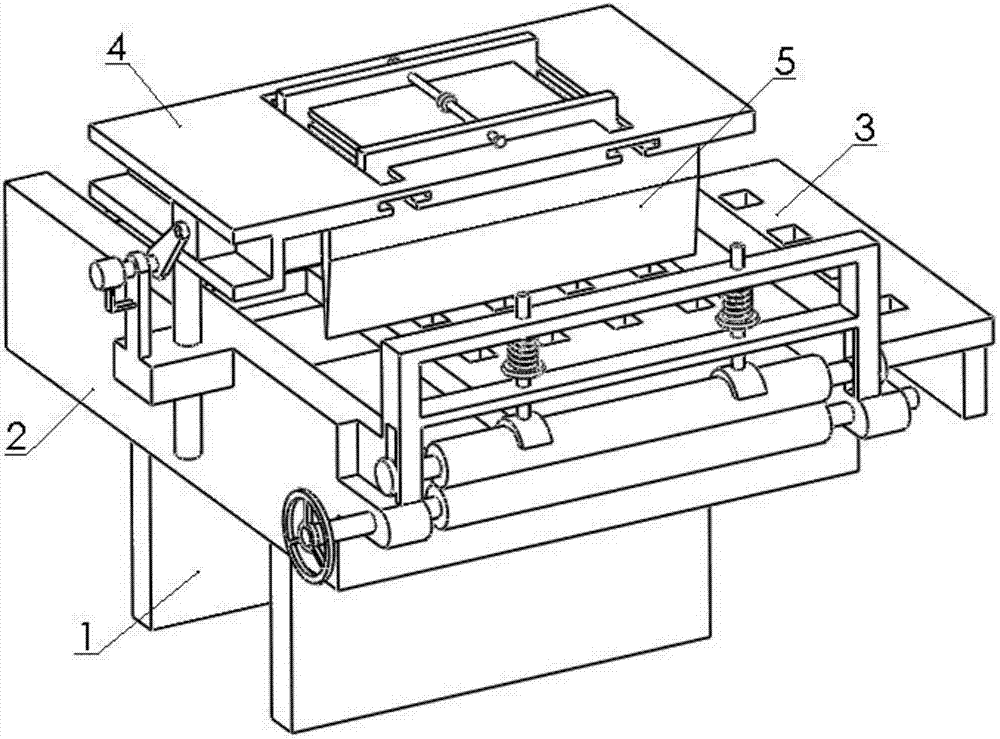

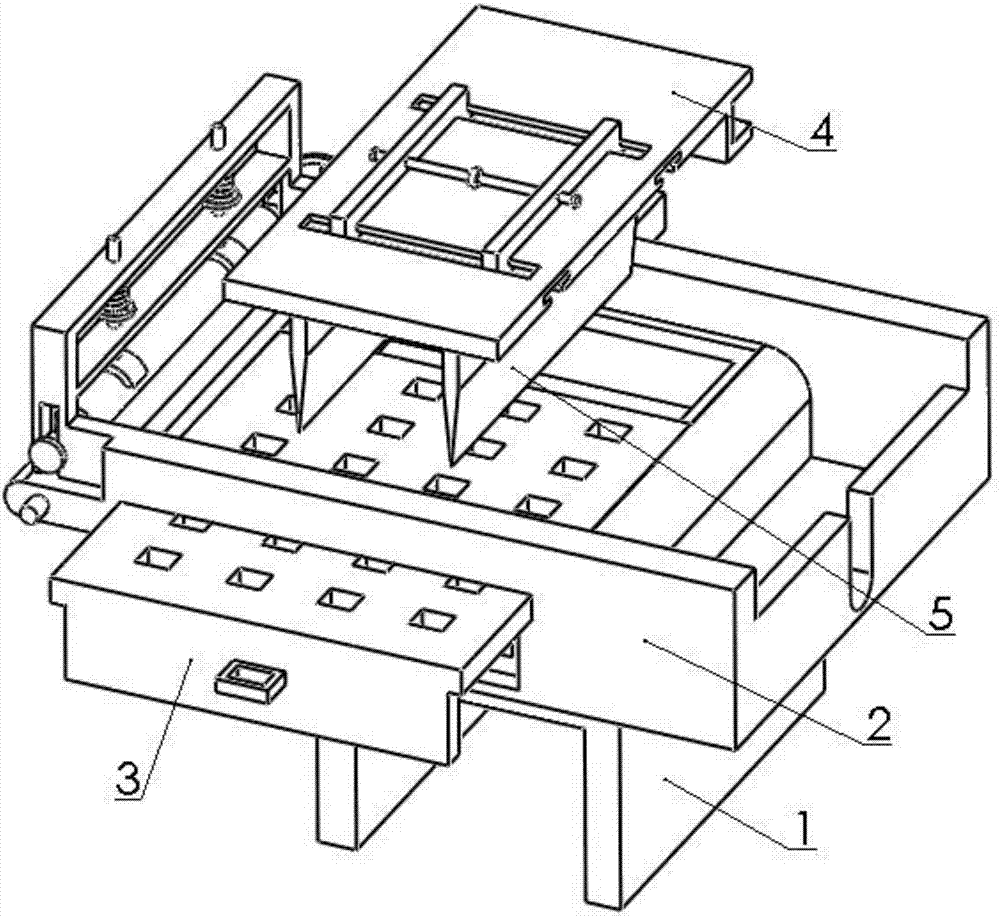

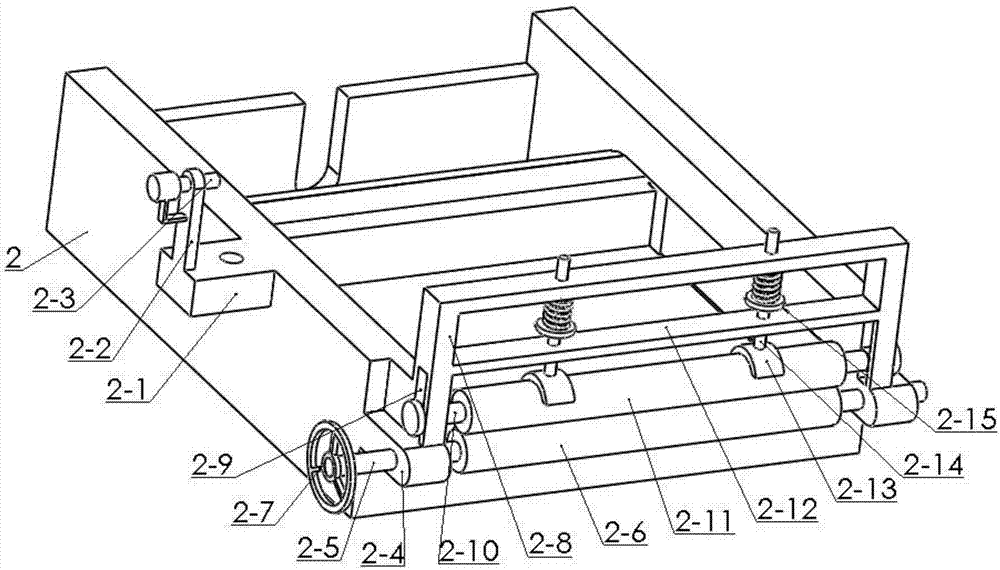

[0029] Combine below Figure 1-9 Describe this embodiment, the present invention relates to the paper cutter field, more specifically a kind of fast paper cutter, including support 1, base 2, cutting work panel 3, cutter seat 4 and cutter assembly 5, the lower The roller and the upper roller can feed the whole sheet of paper, so that the paper can enter the cutting panel straightly, and the paper can be cut continuously through the first cutter body and the second cutter body, so as to realize the automatic cutting of the paper , with a high degree of automation; the distance between the first knife body and the second knife can be adjusted to cut paper of different sizes; The scraps of paper generated by the paper machine fall into the scraps collection tank to prevent the operator from inhaling the scraps of paper for a long time to damage the lungs.

[0030] The upper end of the support 1 is provided with a base 2, the cutting work panel 3 is slidably connected to the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com