Glass crusher

A pulverizer and glass technology, applied in glass recycling, grain processing, recycling technology, etc., can solve the problem of long glass sheet jamming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

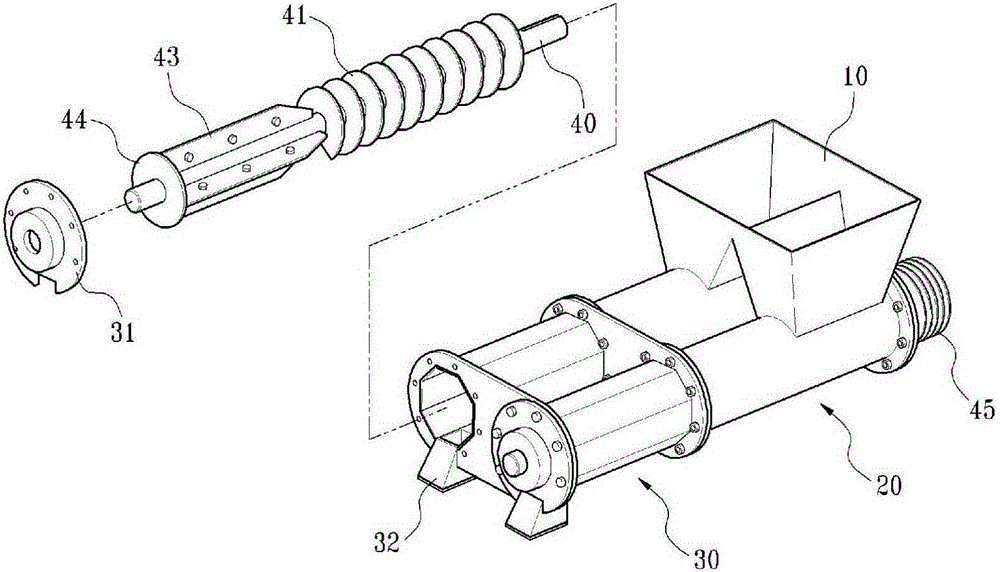

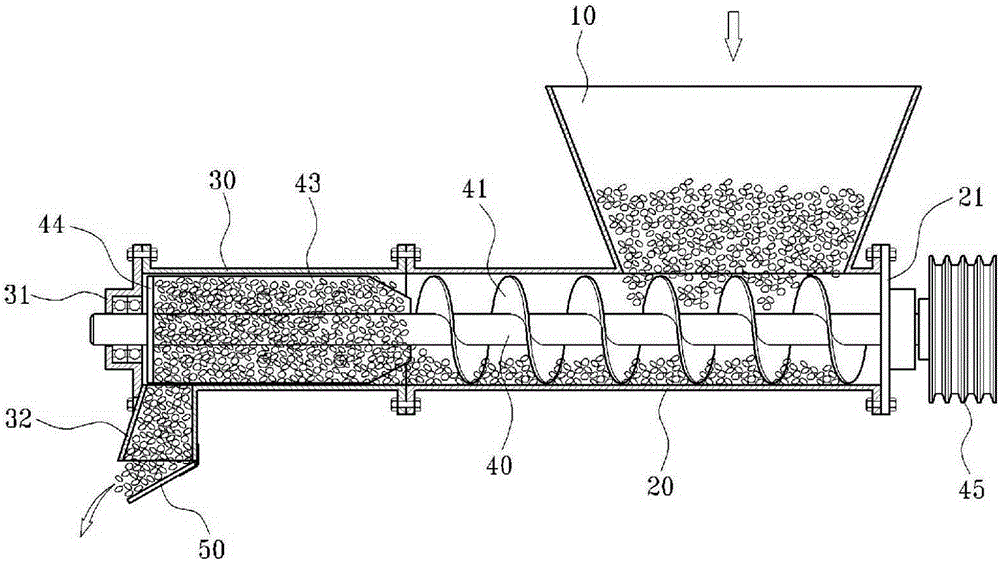

[0023] Such as figure 1 As shown, the glass pulverizer of this embodiment includes a housing, and is rotatably connected to two rotating shafts 40 inside the housing. 43. The housing includes two first cavities 20 for accommodating the auger knives 41 and two second cavities 30 for accommodating the stirring blades 43. The first cavity 20 is provided with a hopper 10, the second The second cavity 30 is provided with a discharge hopper 32 , and the inner cross section of the second cavity 30 is a regular hexagon corresponding to the number of the stirring blades 43 .

[0024] Such as figure 1 As shown, the first cavity 20 and the second cavity 30 are fixedly connected together through flanges, and the flanges at both ends of the second cavity 30 are connected as a whole. The input hoppers 10 on the two second cavities 30 are connected as a whole, and the output hoppers 32 on the two first cavities 20 are arranged at intervals. Such as figure 1 , 2 As shown, an airbag 45 fo...

Embodiment 2

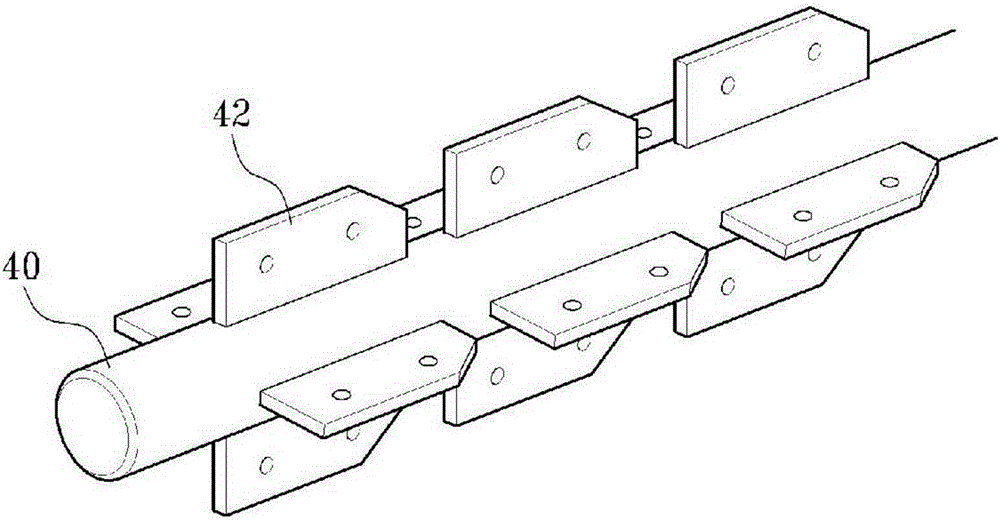

[0028] Such as image 3 As shown, the difference between this embodiment and the first embodiment is that there are four long-axis blades consistent with the length direction of the rotating shaft 40 , but each long-axis blade is divided into three stirring blocks 42 . Along the length direction of the rotating shaft 40, the distance between adjacent stirring blocks 42 is 2-3 cm.

Embodiment 3

[0030] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that there are two arc-shaped blades 24 that are consistent with the central axis of the rotating shaft 40 (the one at the bottom, in the Figure 4 not visible in ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com