Patents

Literature

66results about How to "Clearance is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

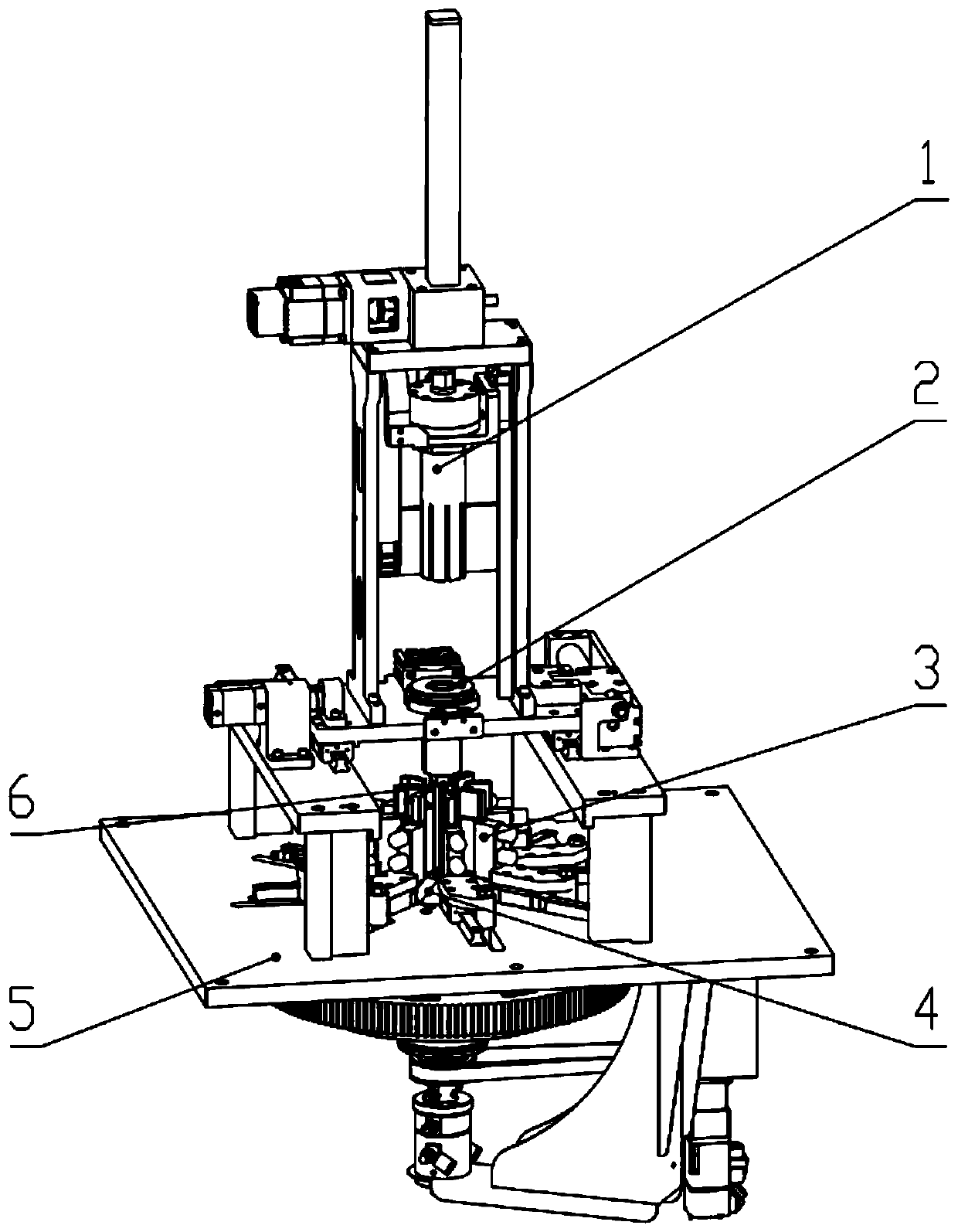

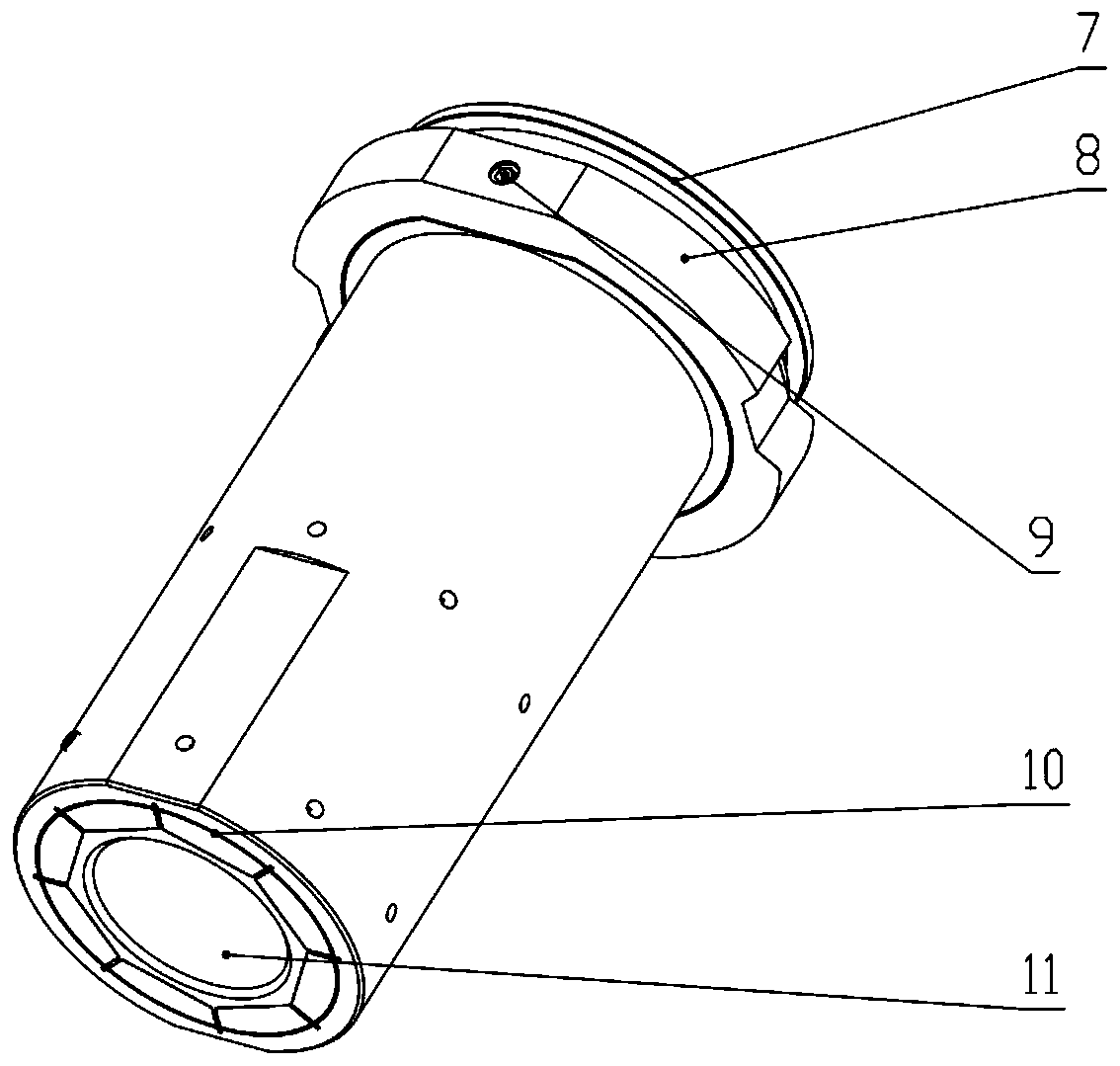

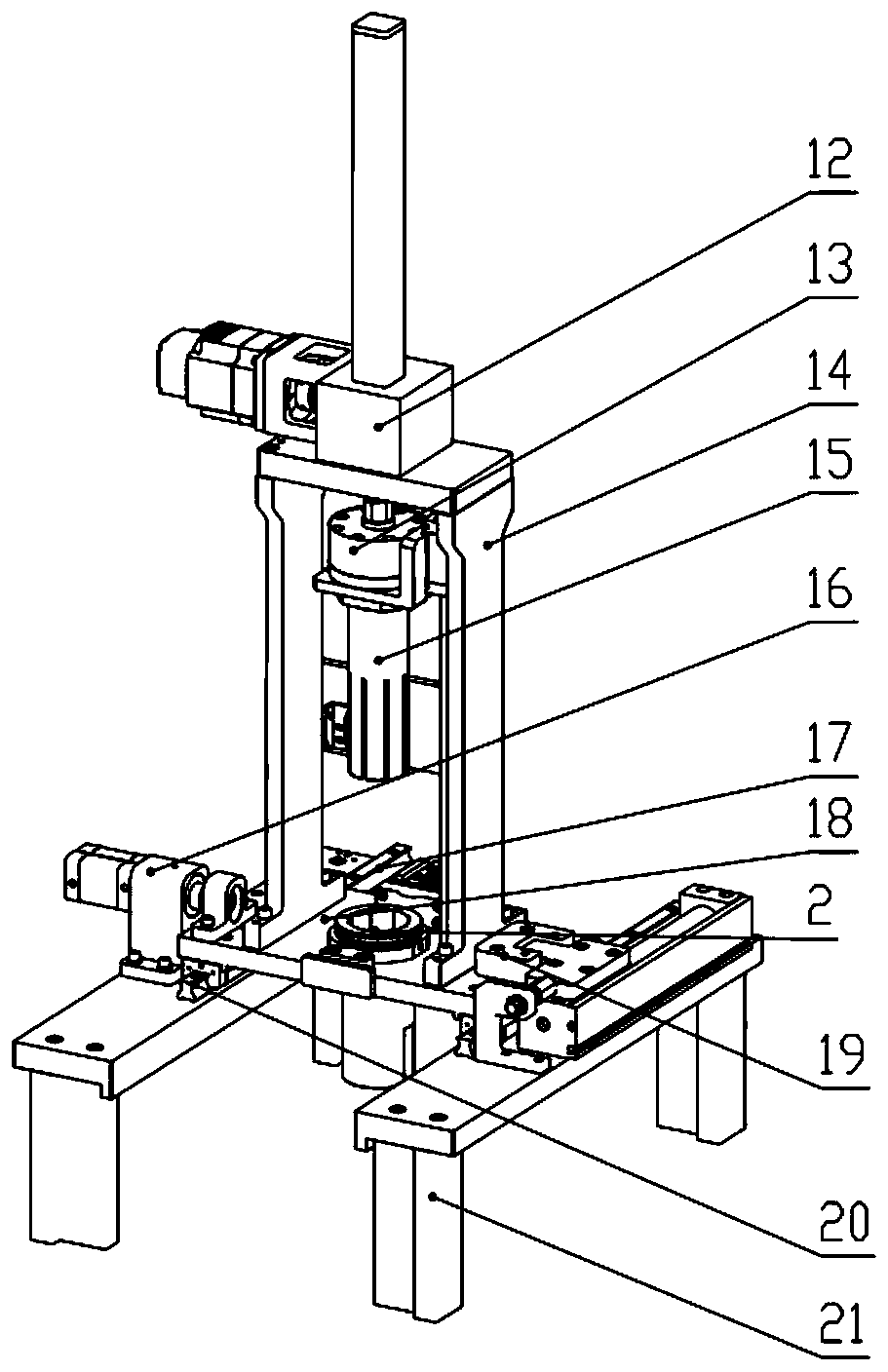

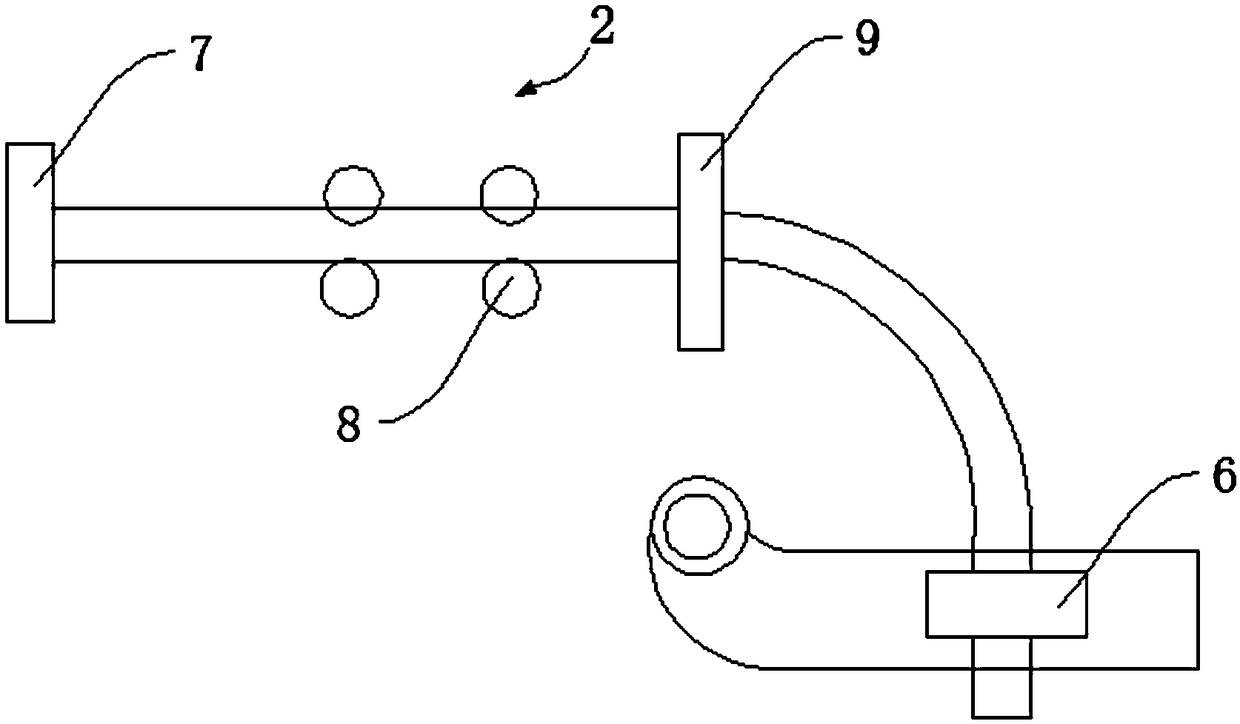

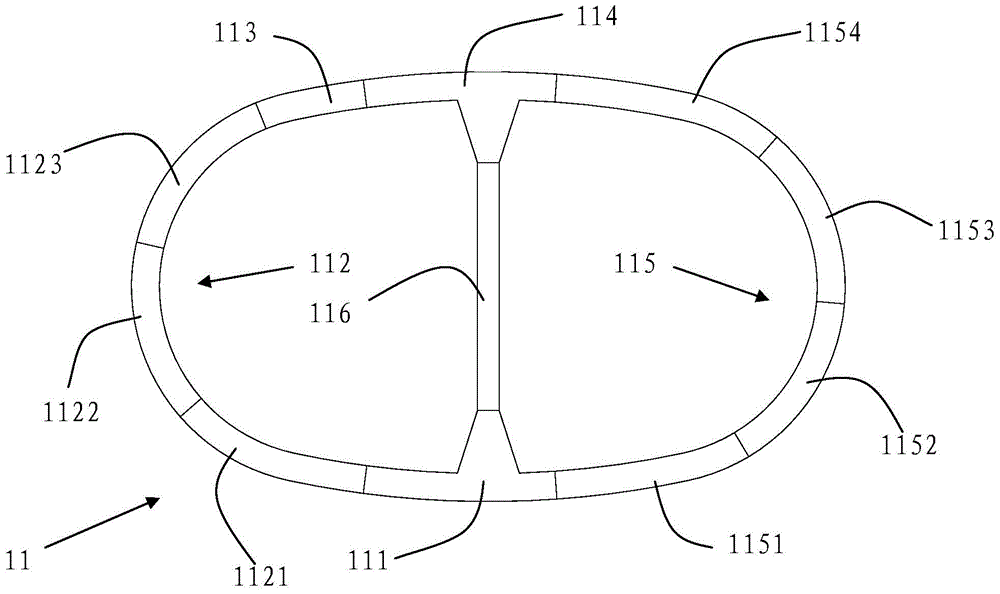

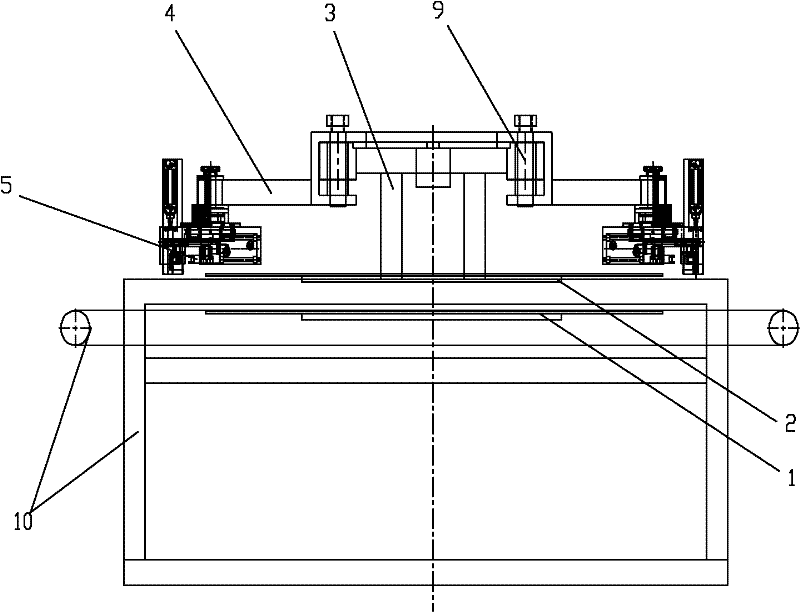

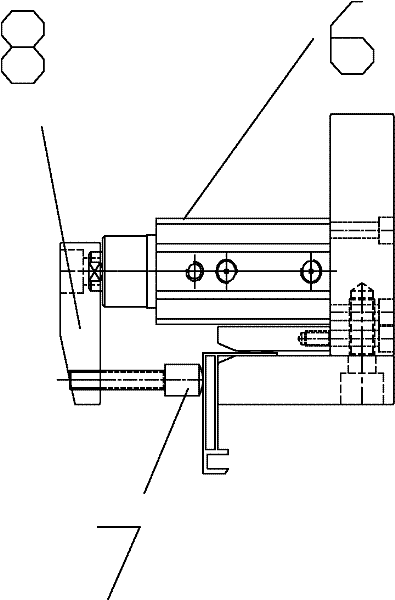

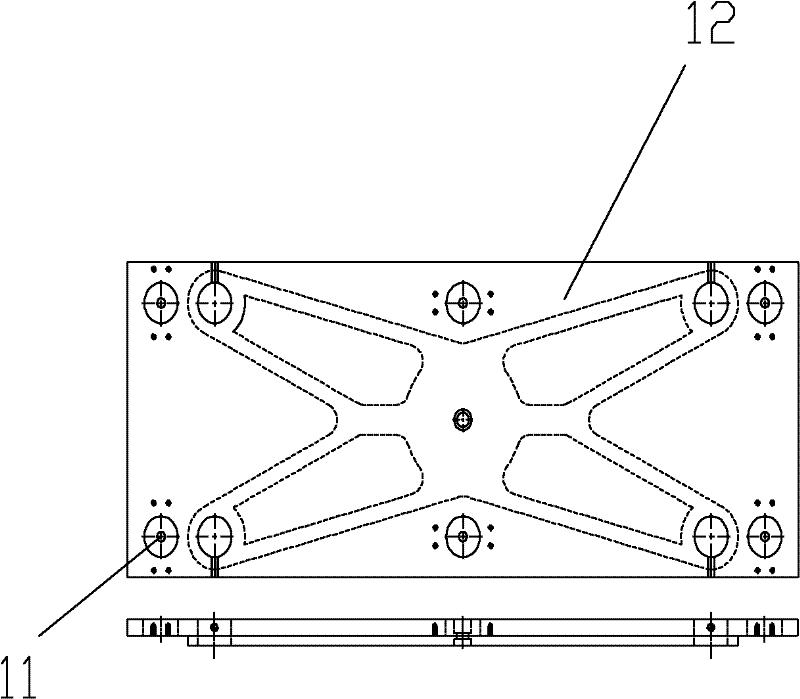

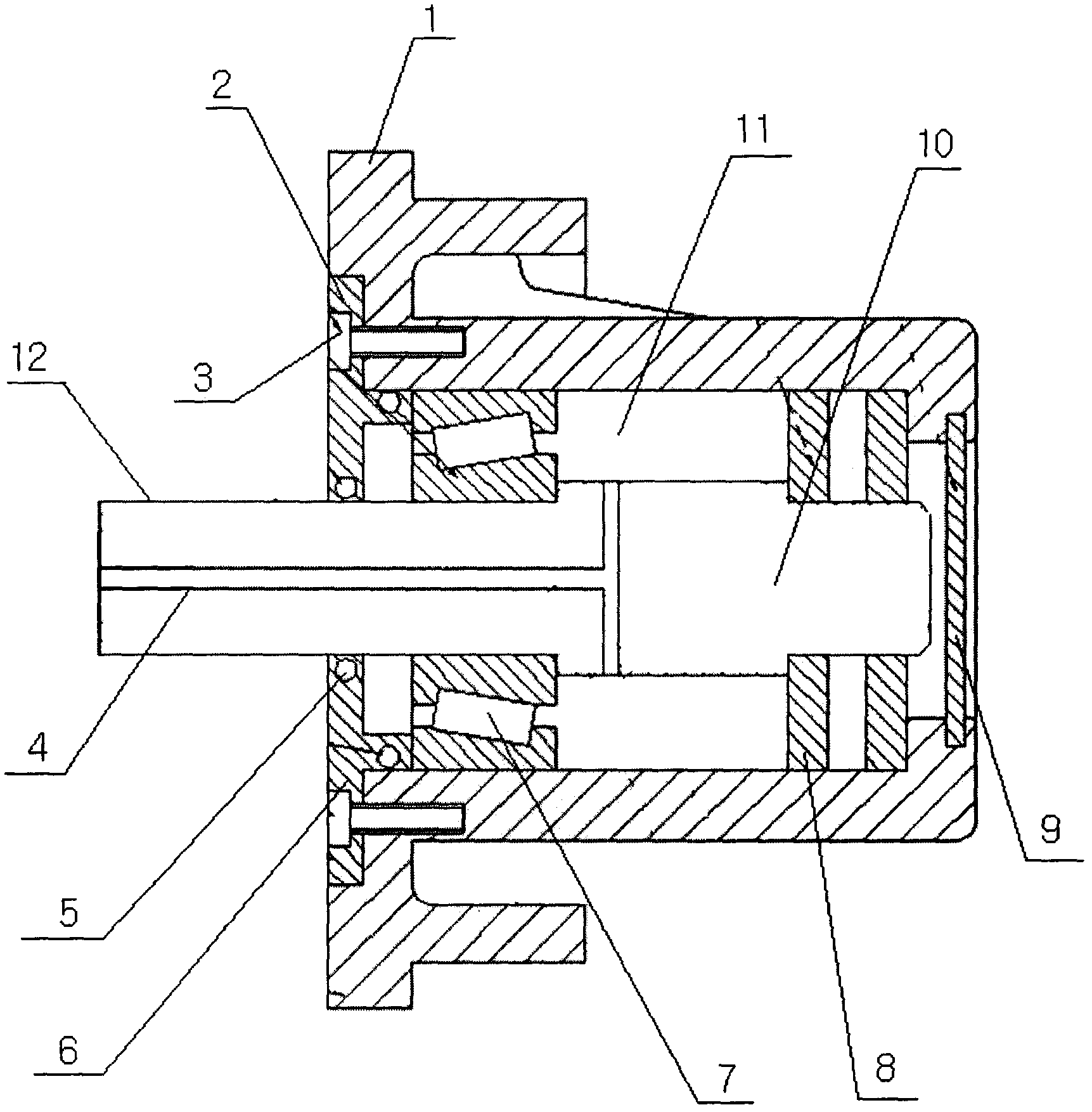

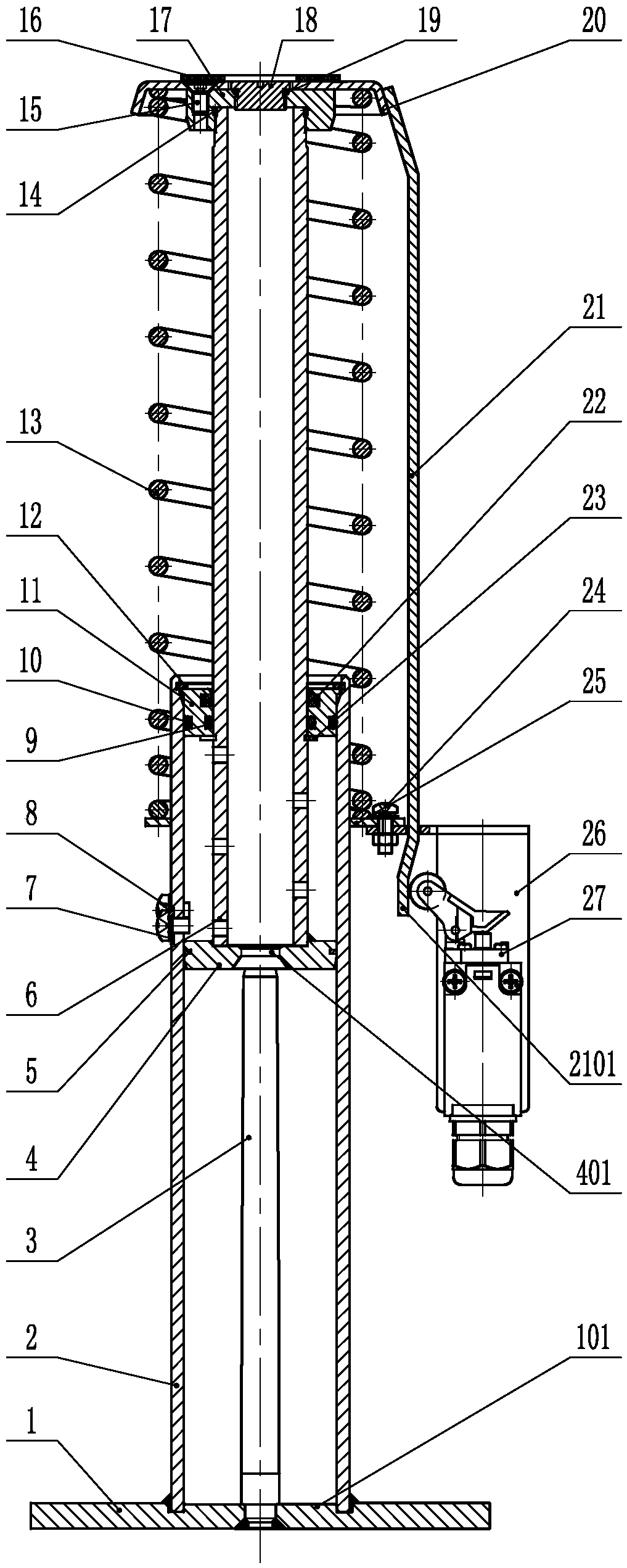

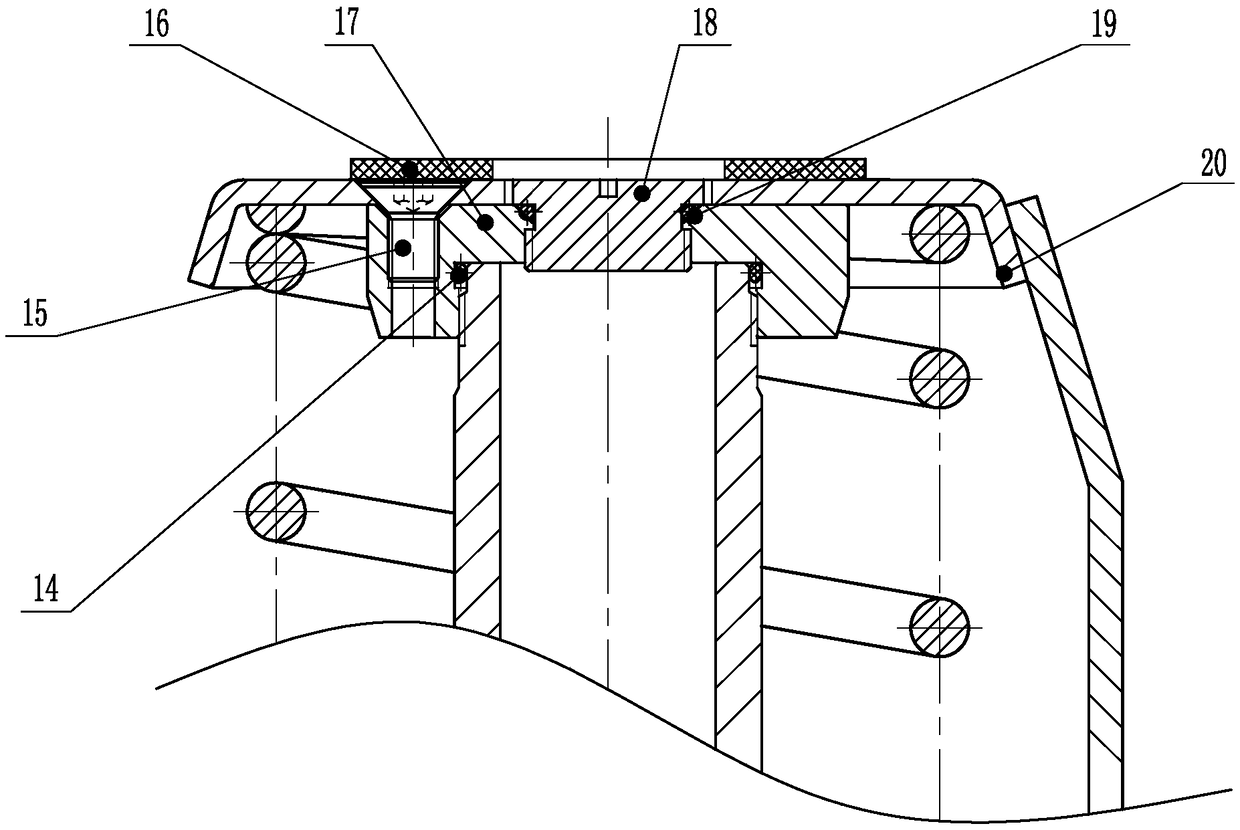

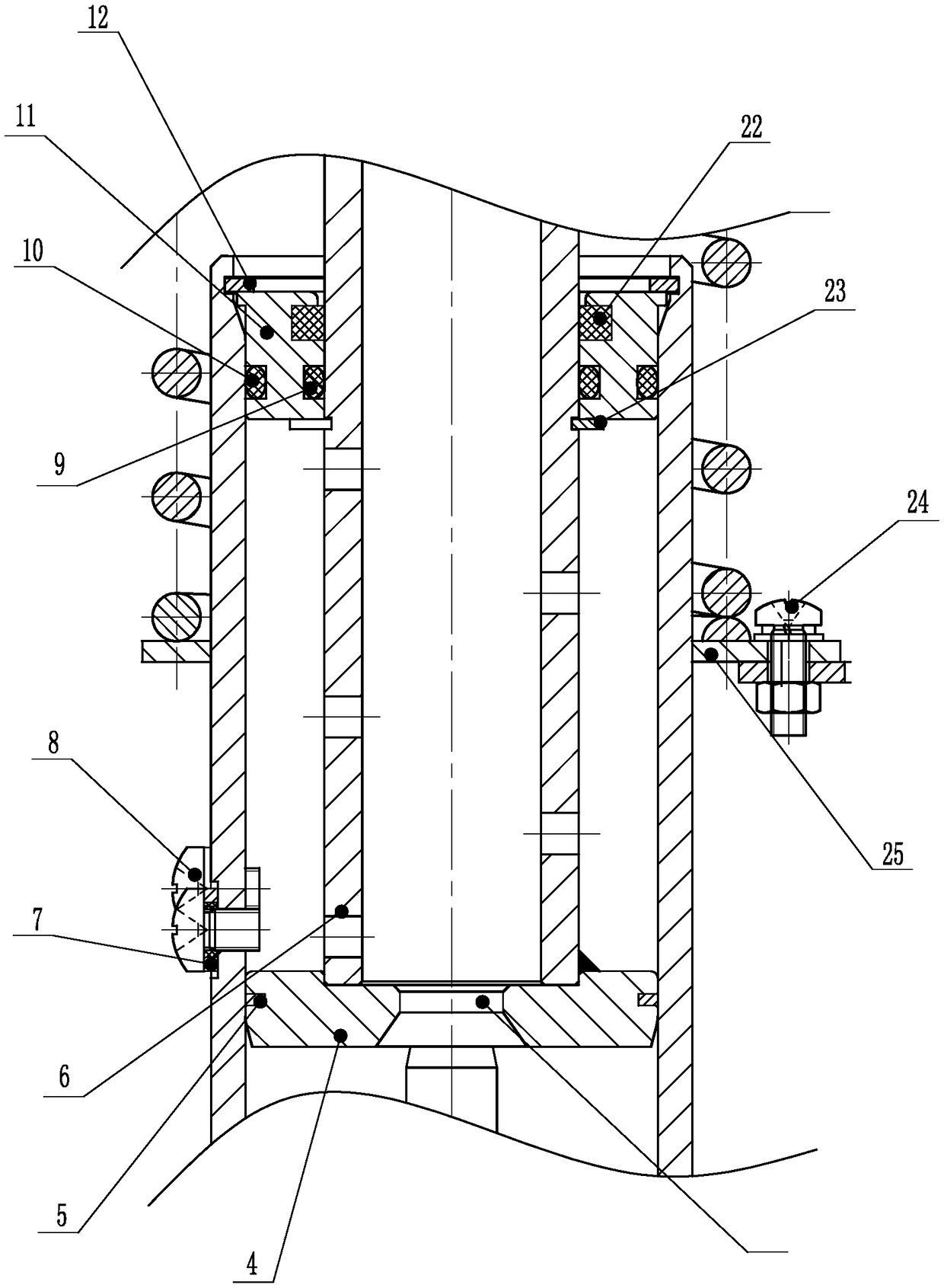

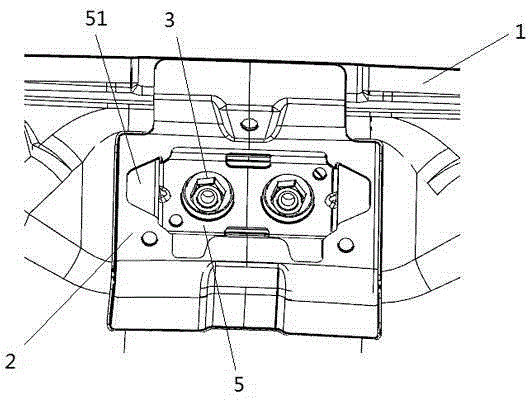

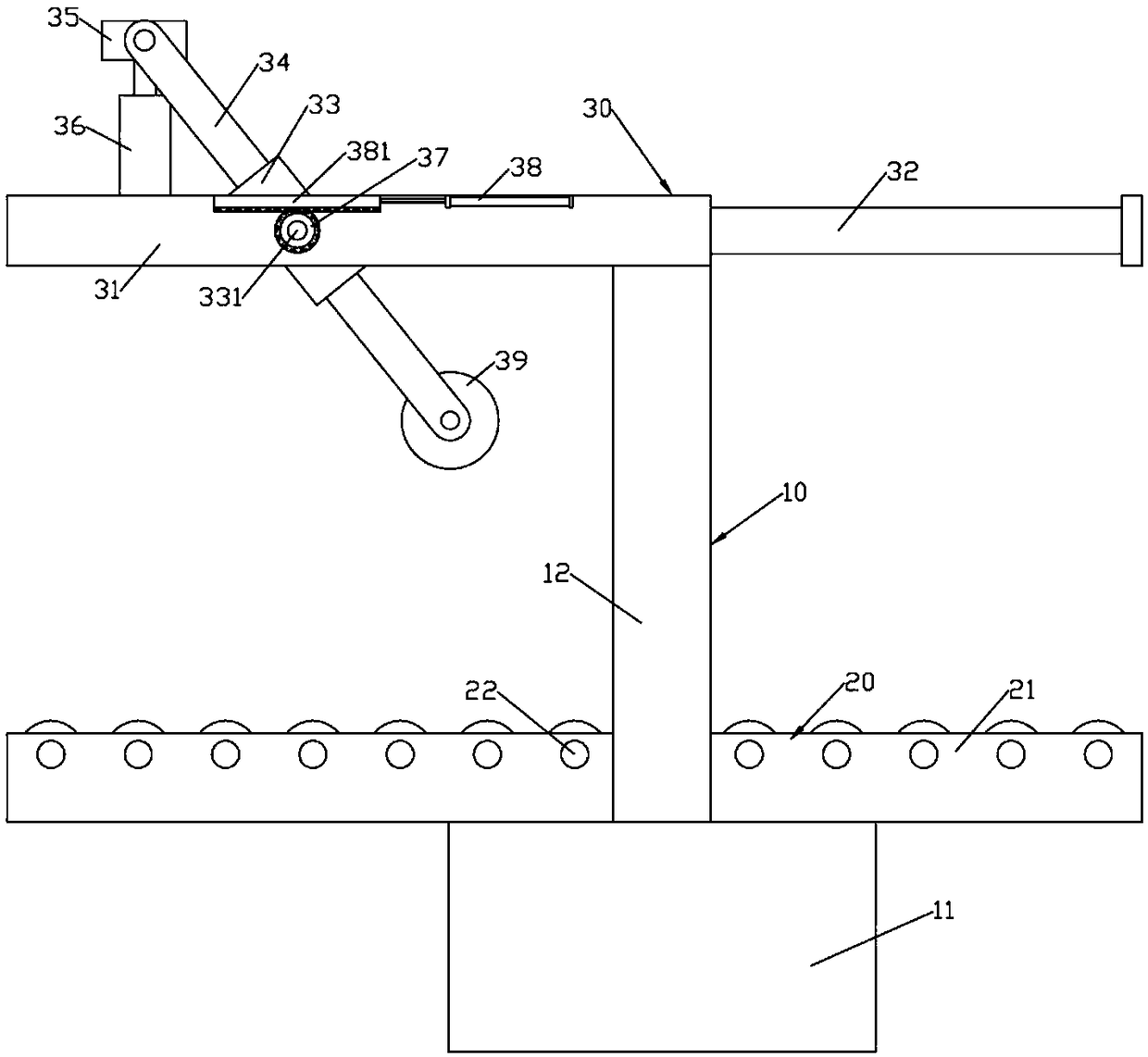

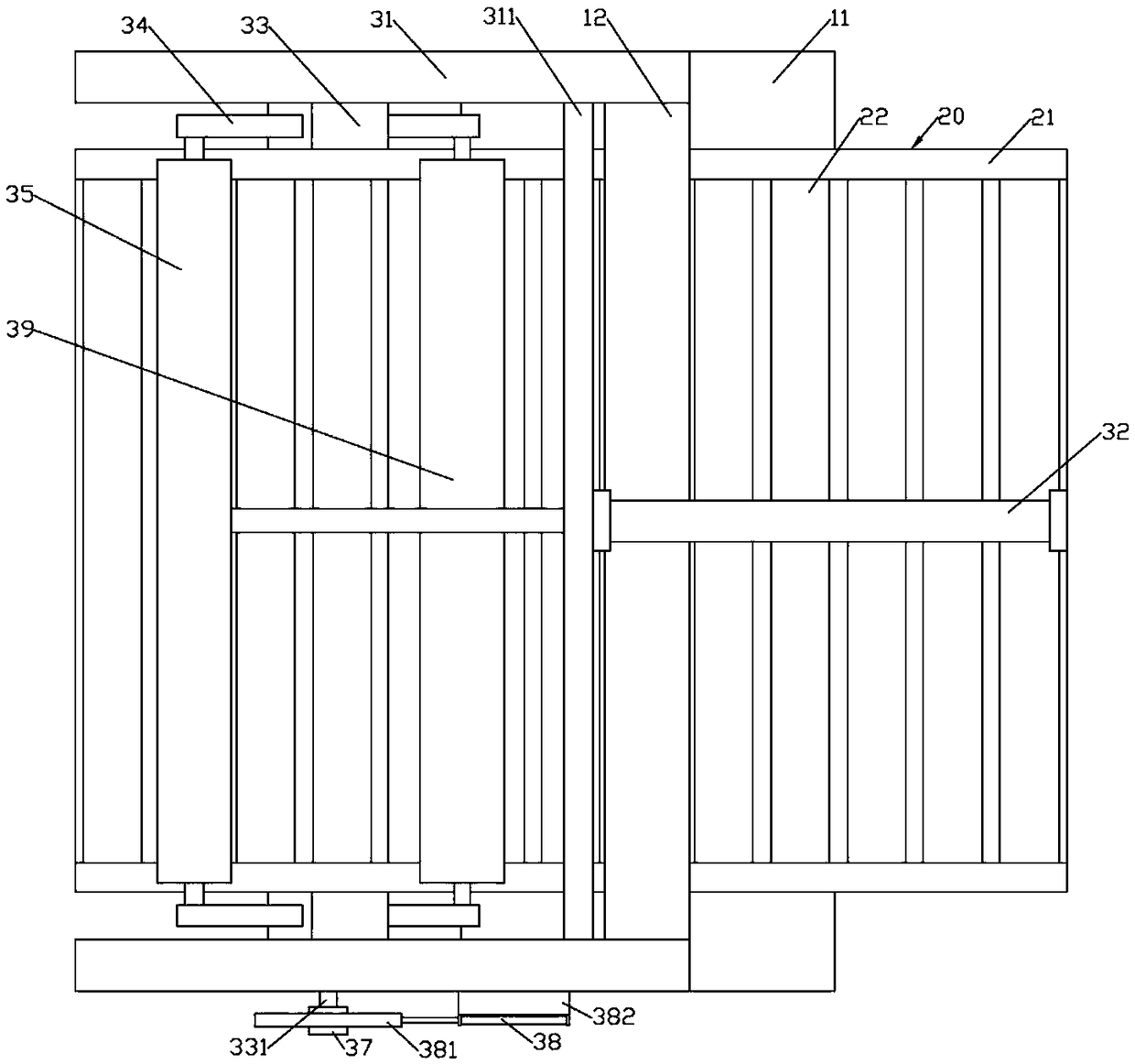

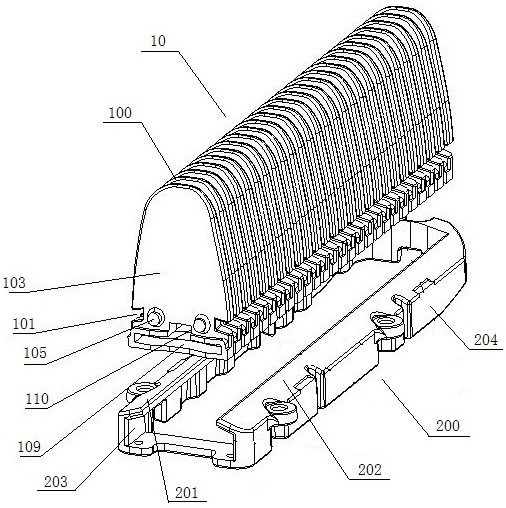

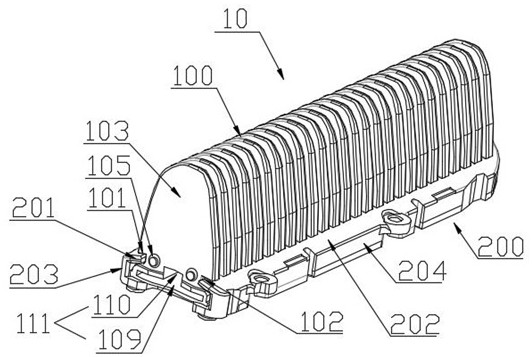

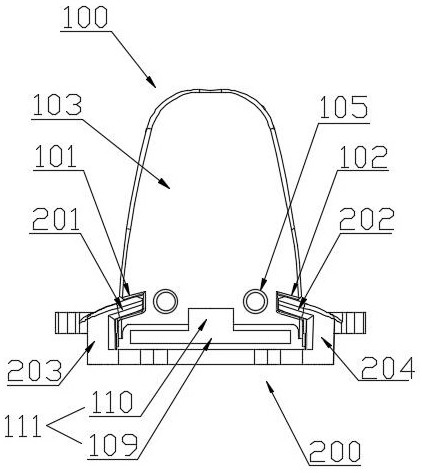

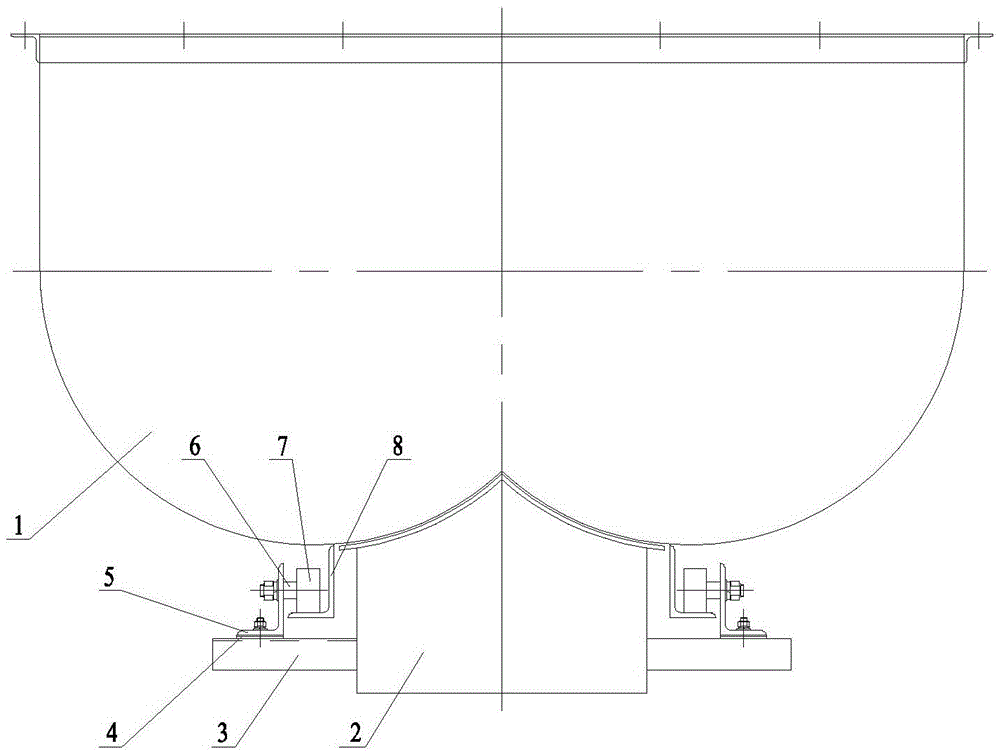

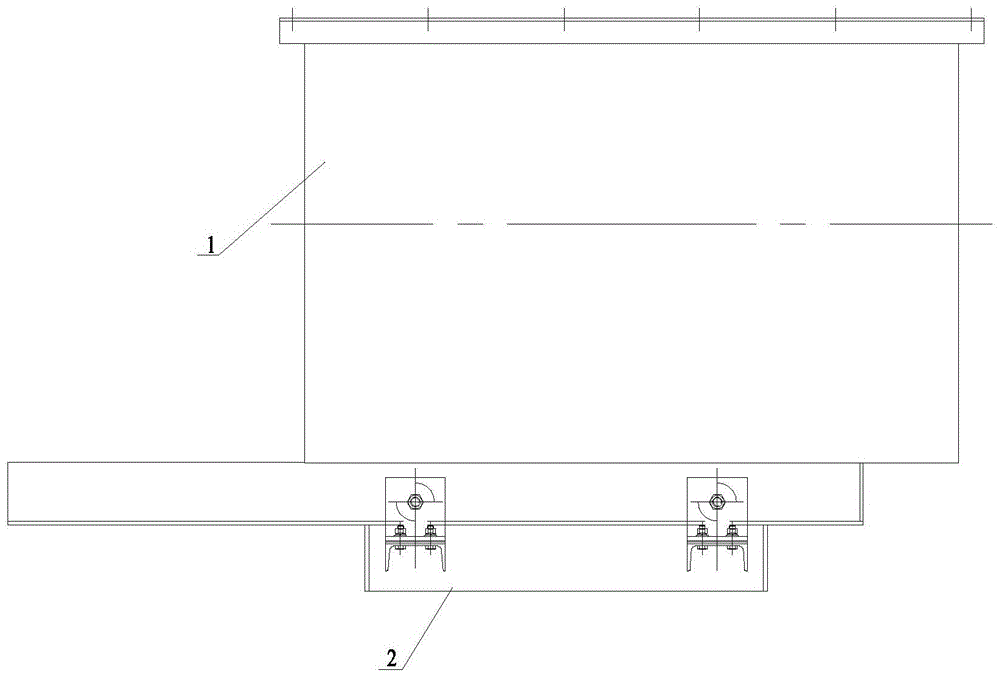

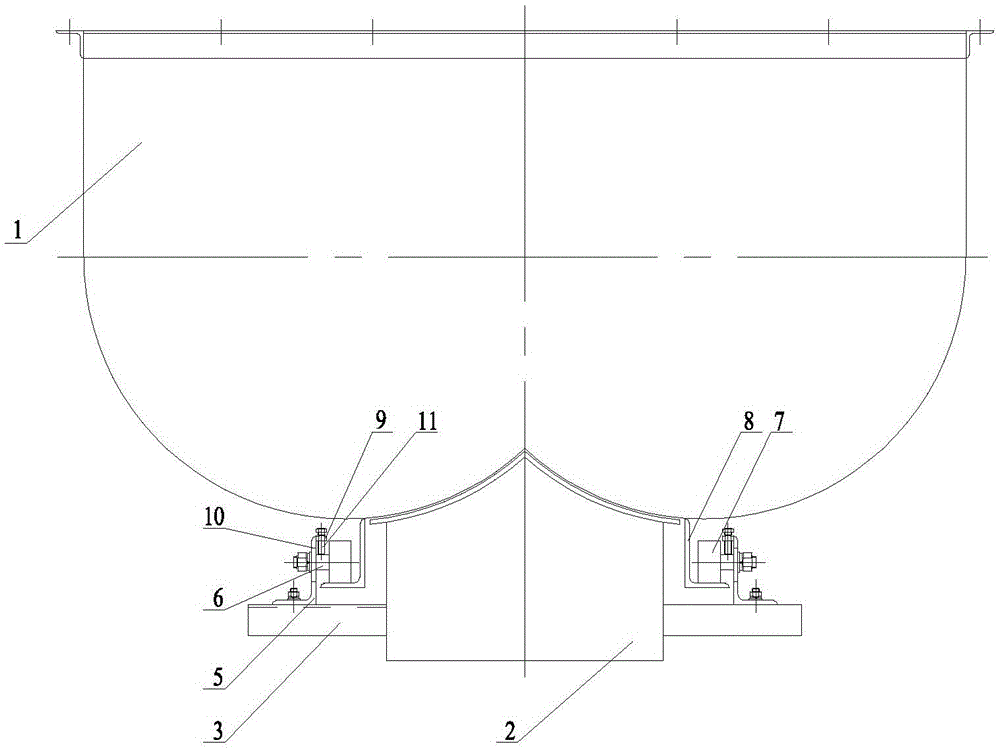

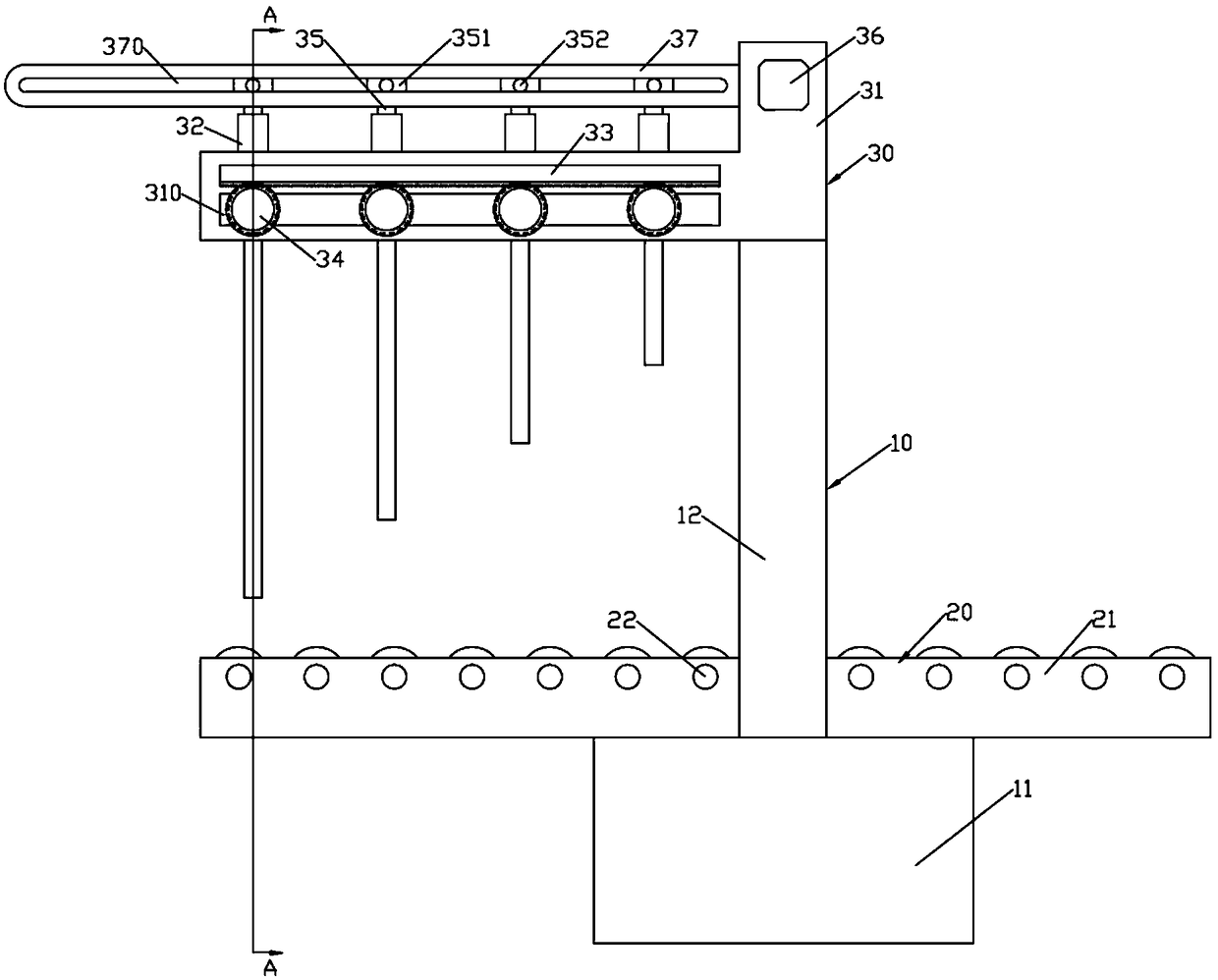

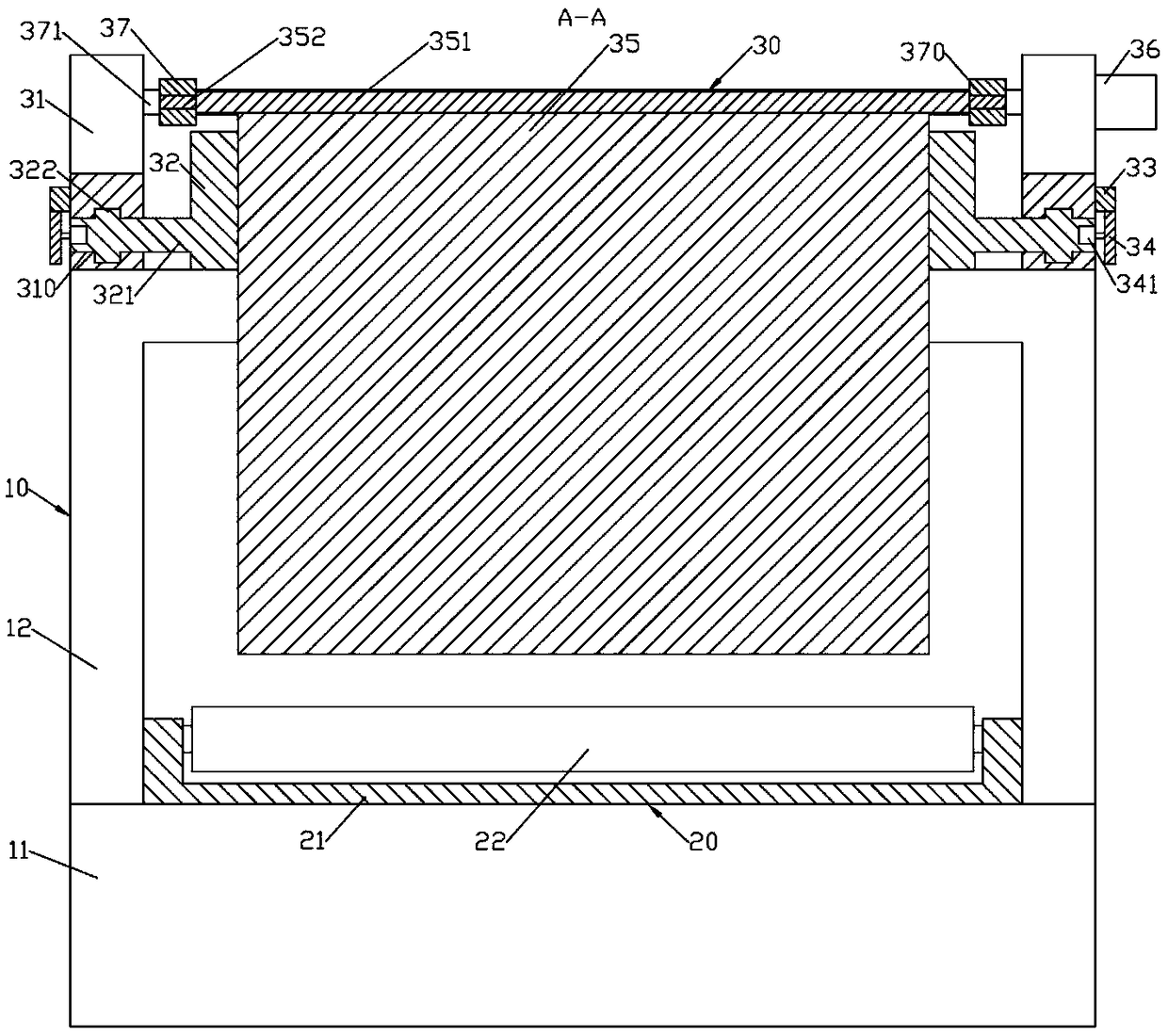

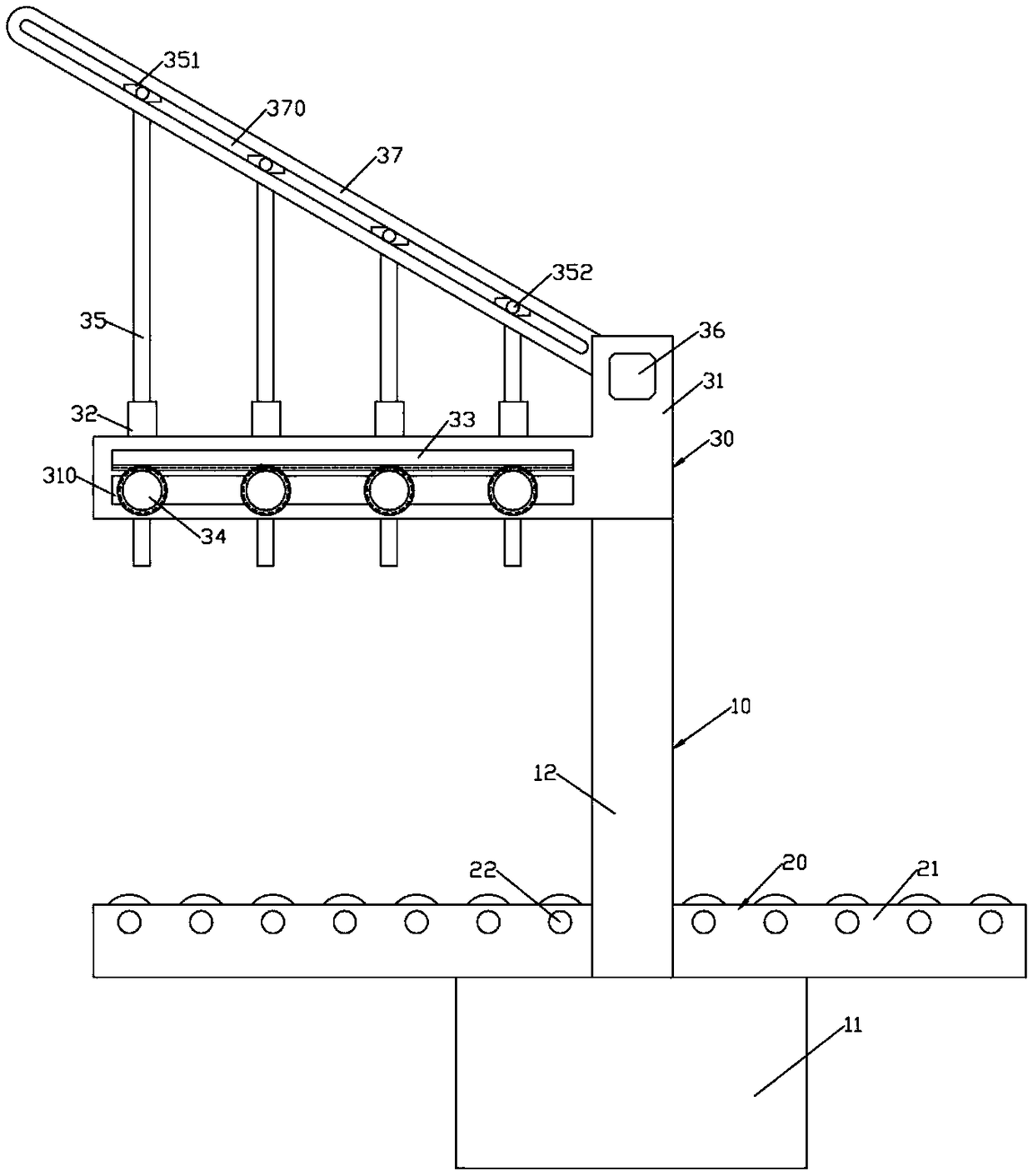

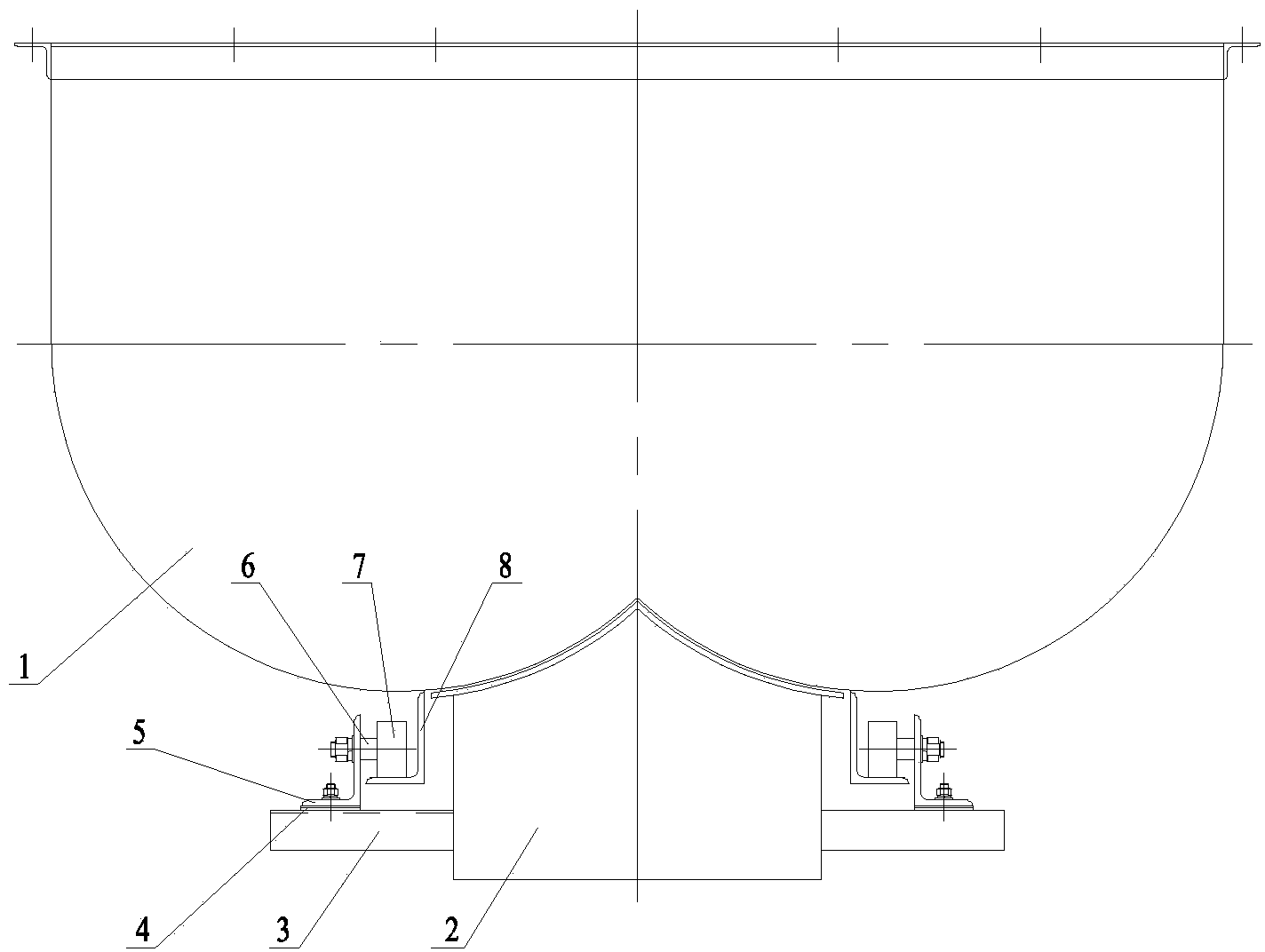

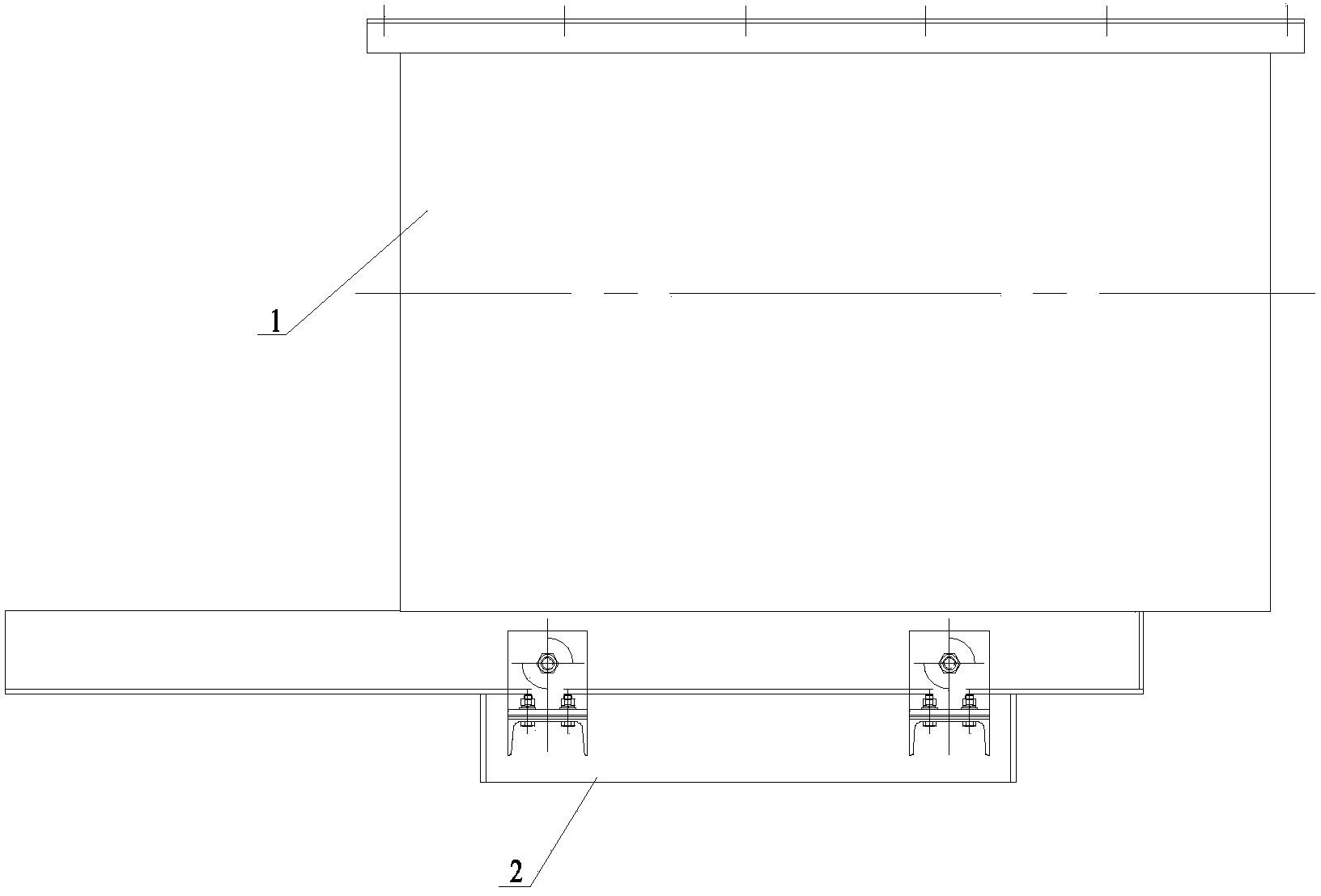

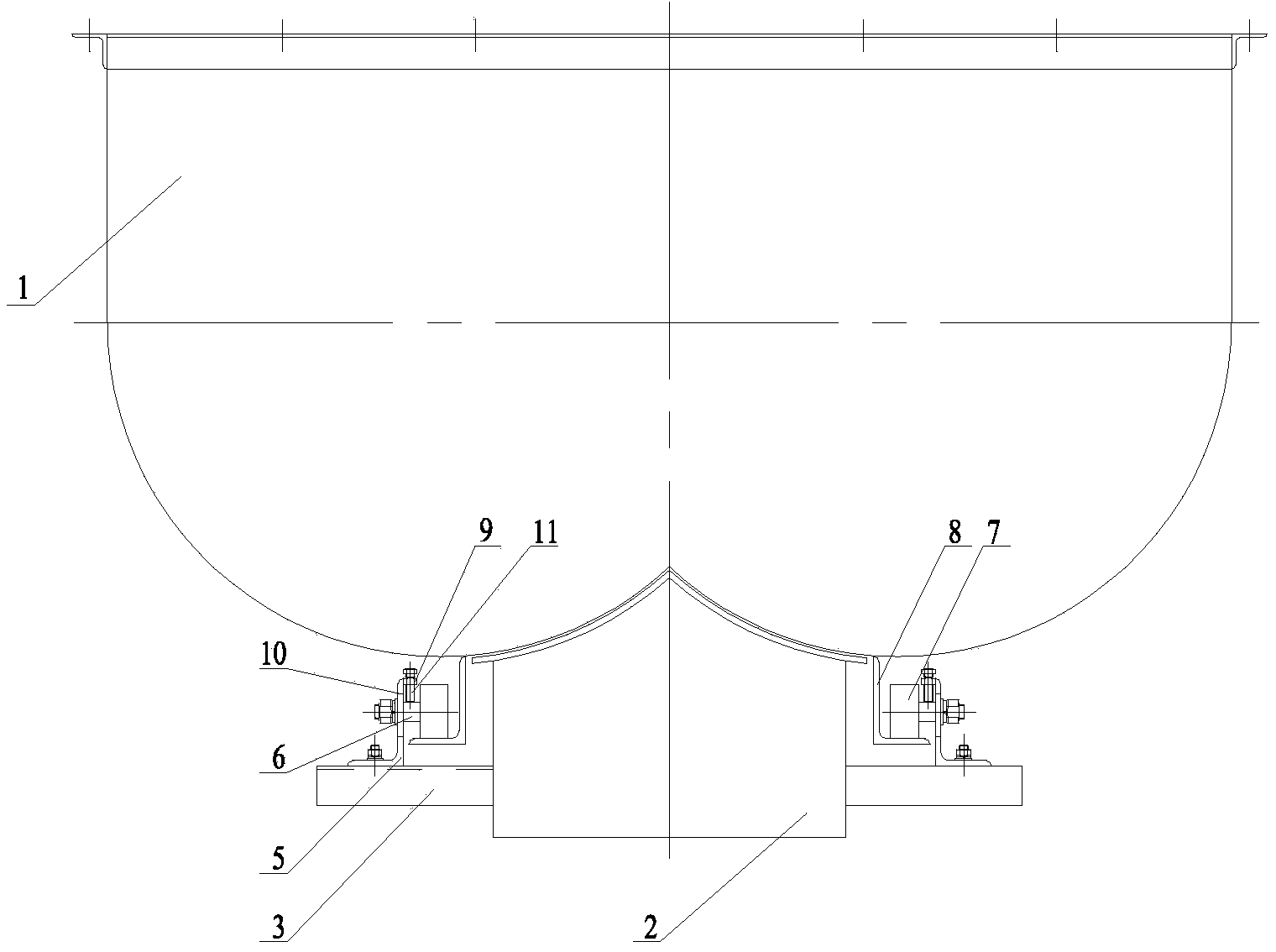

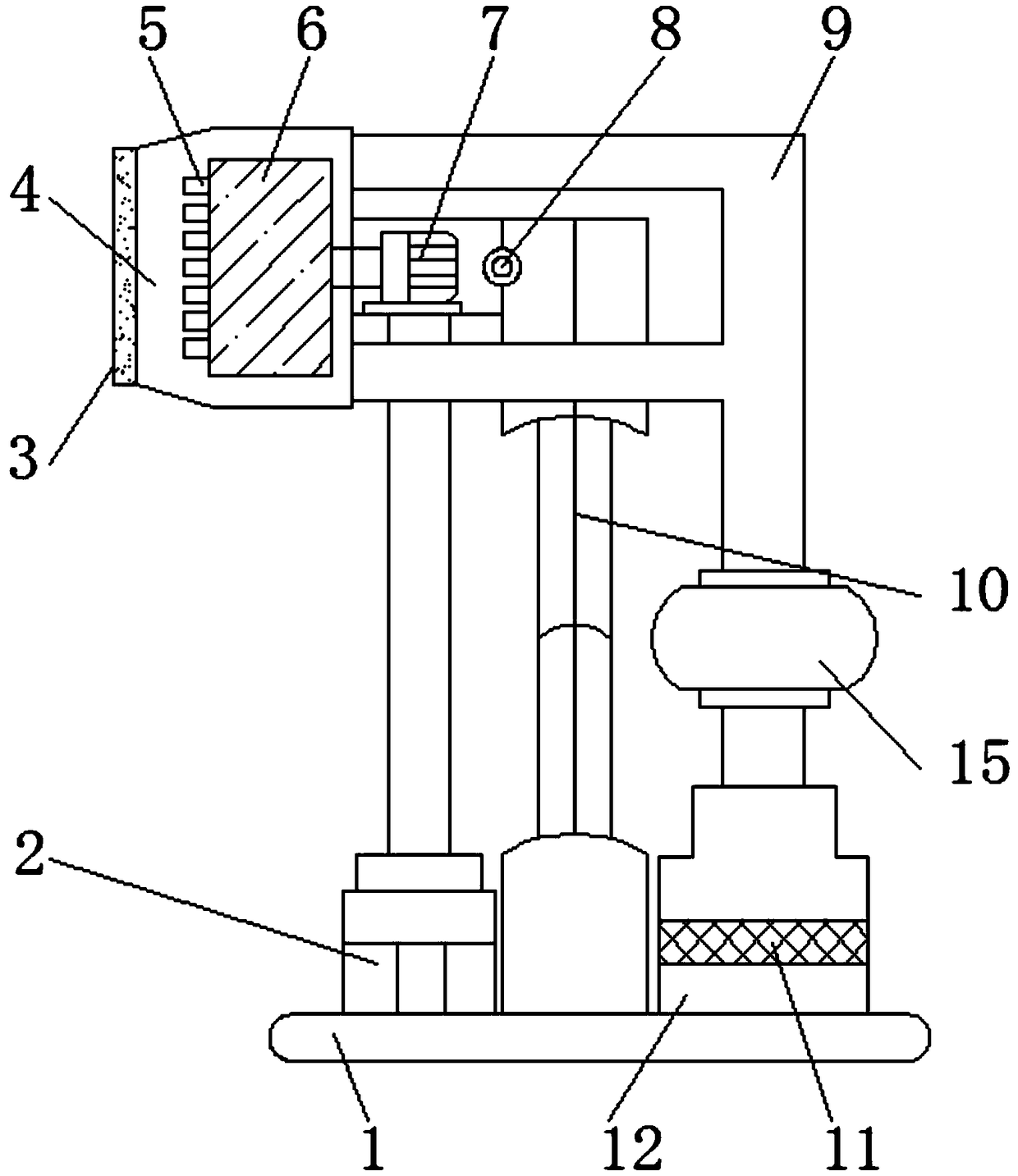

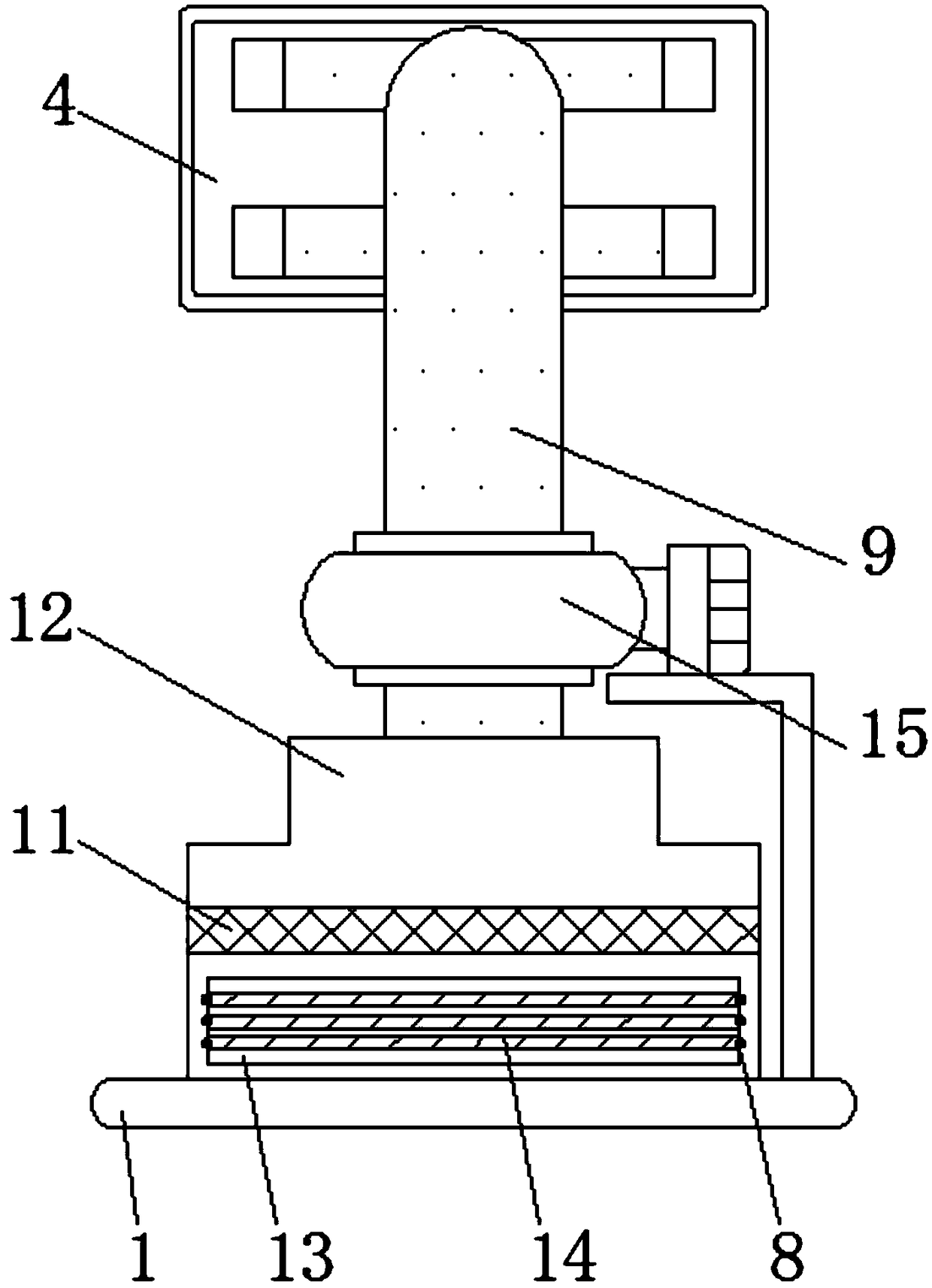

Permanent magnet brushless direct current motor rotor magnet pasting device

ActiveCN110855106ALimit gap sizeClearance is easy to controlManufacturing stator/rotor bodiesRotor magnetsEngineering

The invention discloses a permanent magnet brushless direct current motor rotor magnet pasting device. The device comprises an iron core clamping and positioning mechanism, a magnetic steel preset tool, a magnetic steel pushing mechanism and a magnetic steel pressing and isolating mechanism, wherein the iron core clamping and positioning mechanism is used for clamping and fixing a to-be-assemblediron core on an iron core station of a working platform, a tool main body of the magnetic steel preset tool is arranged above the iron core station and is provided with an accommodating cavity for accommodating to-be-assembled magnetic steel, the magnetic steel pushing mechanism extrudes the magnetic steel in the accommodating cavity to the periphery of the iron core from top to bottom, the magnetic steel pressing and isolating mechanism comprises a magnetic steel pressing block arranged on the periphery of the iron core station, the magnetic steel pressing block is provided with a positioningface used for being attached to a side face of the magnetic steel, and the magnetic steel pressing block is fixedly connected with an isolating piece which protrudes out of the positioning face and is used for stretching into a gap between the adjacent magnetic steel. The permanent magnet brushless direct current motor rotor magnet pasting device can position, guide, isolate and compress the magnetic steel, and assembly precision and assembly efficiency are improved.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

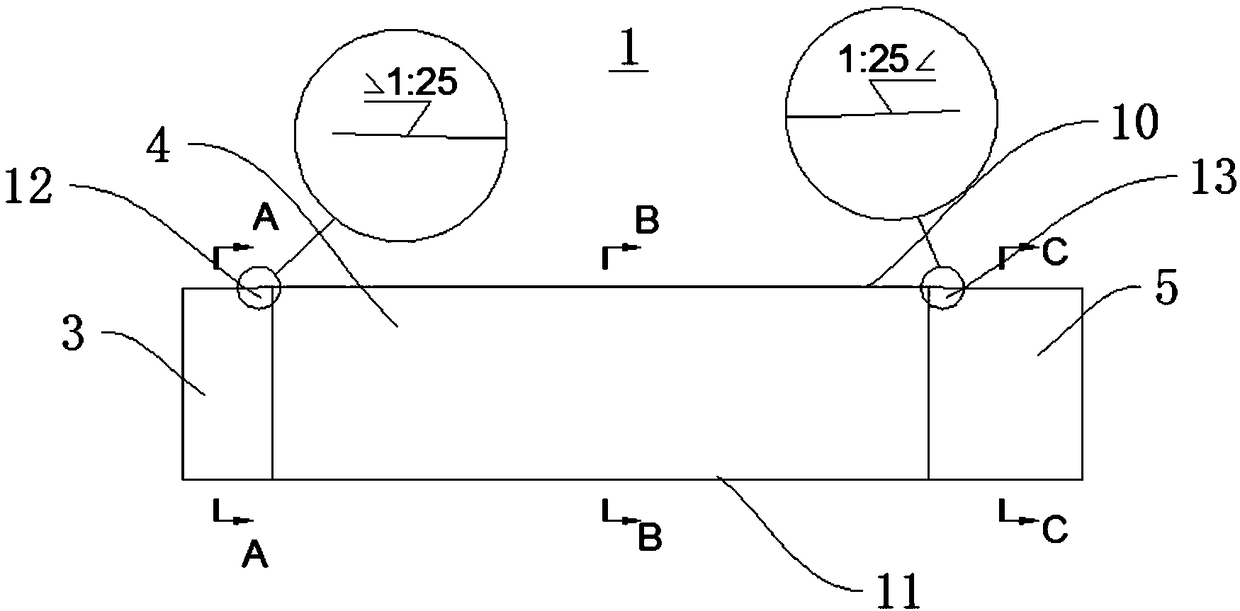

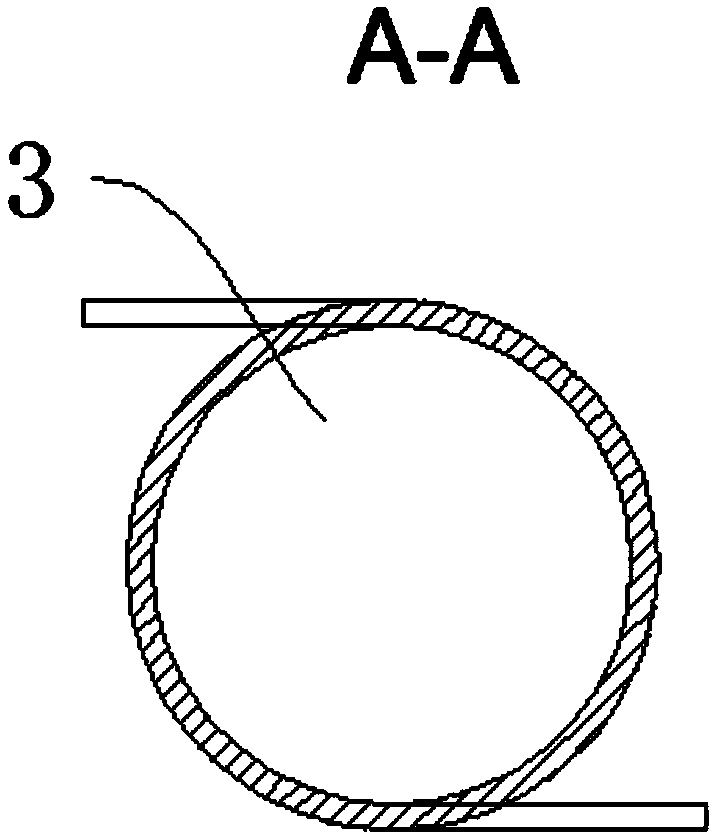

Bent pipe machining method and bent pipe

The invention provides a bent pipe machining method and a bent pipe, and belongs to the technical field of bent pipe machining. The method adopts an eccentric straight pipe and an induction heater. The method comprises the steps that S1, the eccentric straight pipe is mounted on a support table, a to-be-bent section is sleeved with an intermediate frequency induction heating ring, a first pipe section is movably mounted in a guiding assembly, the end of a second pipe section is clamped through a front chuck, and a rear pushing bent chuck clamps the end of the first pipe section and pushes thefirst pipe section to move in the direction of the to-be-bent section; and S2, intermediate frequency current is introduced into the intermediate frequency induction heating ring, the to-be-bent section is heated, when the temperature of the to-be-bent section is increased to a plastic state, the first pipe section is advanced through mechanical thrust, the to-be-bent section is bent, and the bentto-be-bent section is quickly cooled with a coolant. The bent pipe machining method adopts the eccentric straight pipe with the outer diameter being changed, the inner side thickening amount of the machined bent pipe is reduced, and the weight of a pipe system is reduced.

Owner:JIANGSU POWER EQUIP

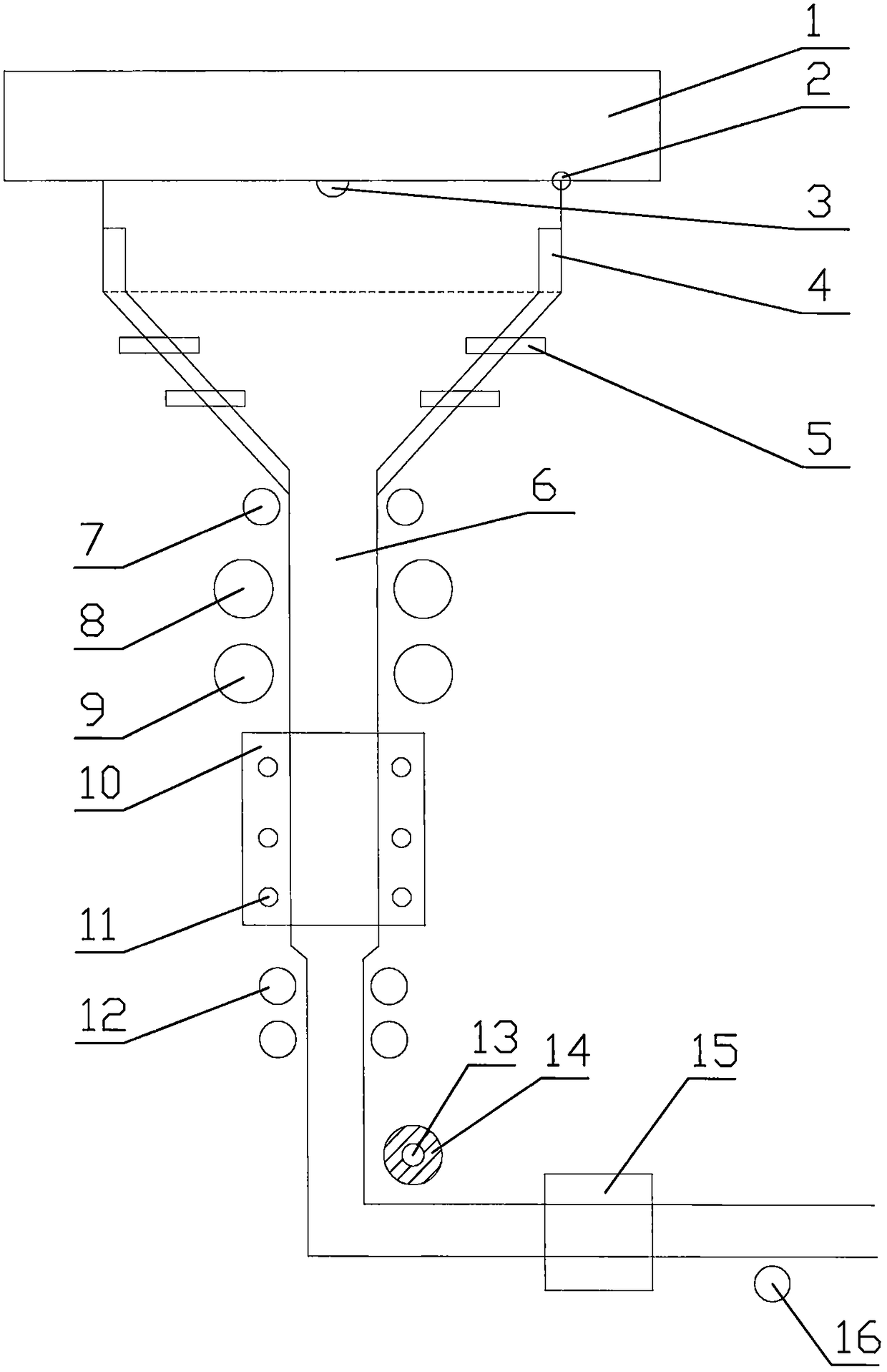

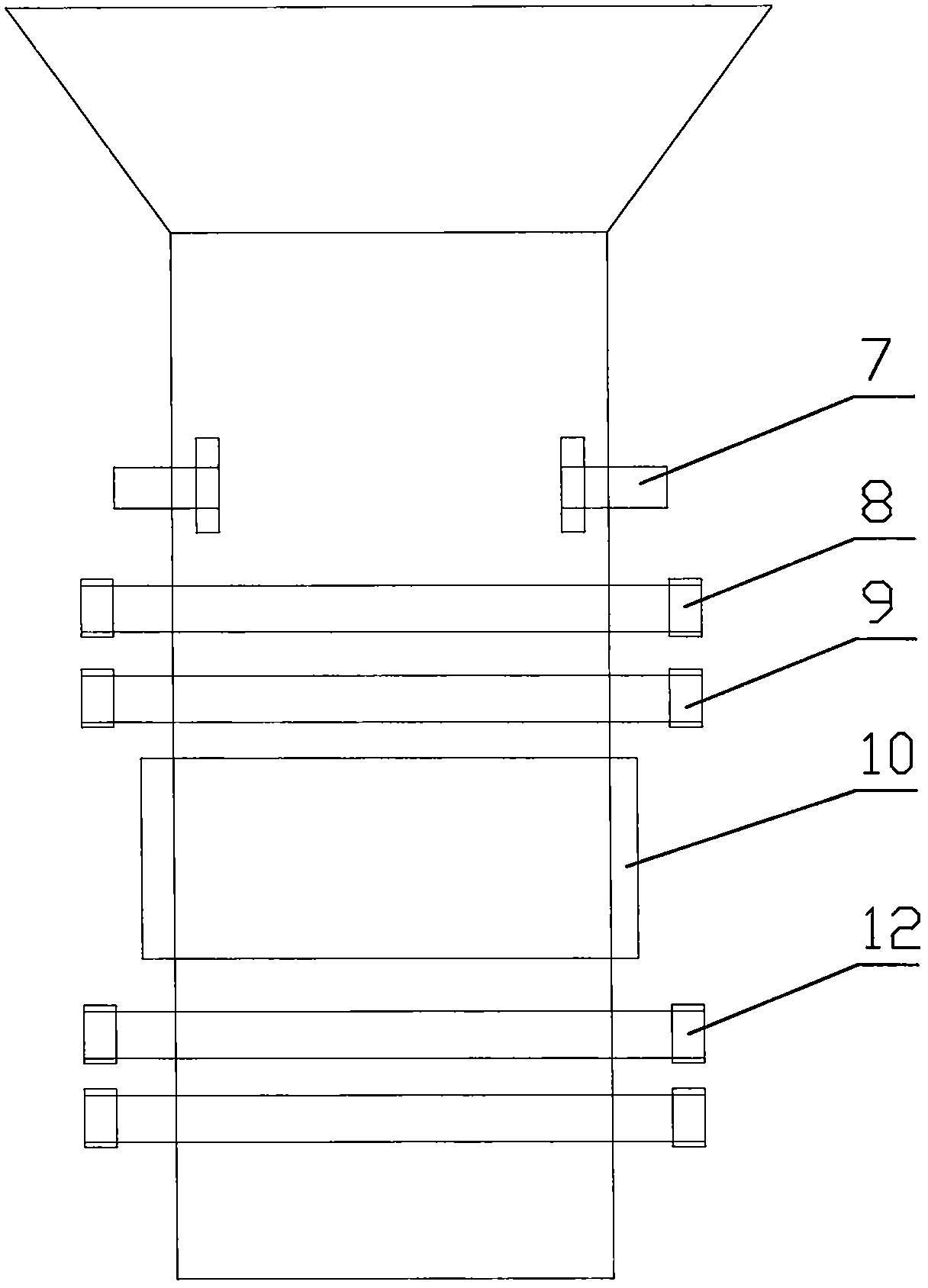

Equipment and method for preparing ultra-thin glass by utilizing glass fiber melting furnace discharge materials

PendingCN108996890AImprove comprehensive utilization efficiencyReduce wasteGlass drawing apparatusProtection layerRaw material

Glass fiber melting furnace discharge materials are adopted as raw materials for preparing ultra-thin flexible glass, so that the comprehensive utilization efficiency of the glass fiber melting furnace discharge materials is improved, waste of glass materials is reduced, and ultra-thin glass products with high utilization value can be produced. The regulator is regulated, so that the gaps of glassforming grooves are controllable, regulation can be performed according to heat shrinkage characteristics of the glass, the primary stretching and forming thickness of the glass can be regulated by matching a first leading-down roller and a second stretching roller, the width of the prepared glass is determined by a vertical edge roller, the vertical edge roller can also be used for fixing two sides of the downwards stretched glass, and shrinkage of the glass while downward stretching is reduced. After the stretched glass turns by a drum, the glass is changed from a vertical state to a horizontal state, and convenience is brought to production. The glass surface can be effectively protected by a glass fiber protection layer on the outer side of the drum, and the quality of the ultra-thinglass is improved. The equipment is simple in structure, reasonable in design, reasonable in design, low in modification degree, low in investment operating cost, obvious in production efficiency andbeneficial to popularization and application.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

Rectangular staggered joint shield based capping segment and post segment assembling structure and method

ActiveCN104695976AImprove molding qualityAvoid the problem of not being able to insertUnderground chambersTunnel liningHeight differenceEngineering

The invention discloses a rectangular staggered joint shield based capping segment and post segment assembling structure and method. The method comprises steps as follows: lower T-shaped segments at the bottom of assembling space as well as left waist segments and right waist segments located on two sides of each lower T-shaped segment respectively are assembled; a first assembling zone is reserved at the top of the assembling space; a second assembling zone is reserved on the left side or the right side of the top of the assembling space; upper T-shaped segments are assembled in the first assembling zone; capping segments are assembled in the second assembling zone; post segments are assembled between the upper T-shaped segments and the lower T-shaped segments. The upper T-shaped segments, the capping segments and the post segments are sequentially mounted, and the capping segments and the abutted waist segments are not staggered, the ring height difference between adjacent rings and an assembling gap between the adjacent segments are effectively controlled, the problem that the capping segments cannot be inserted into the gaps is solved, a gap between the upper and lower T-shaped segments is easier to control, and the longitudinal insertion stability of the middle post segments is high.

Owner:SHANGHAI TUNNEL ENG CO LTD +2

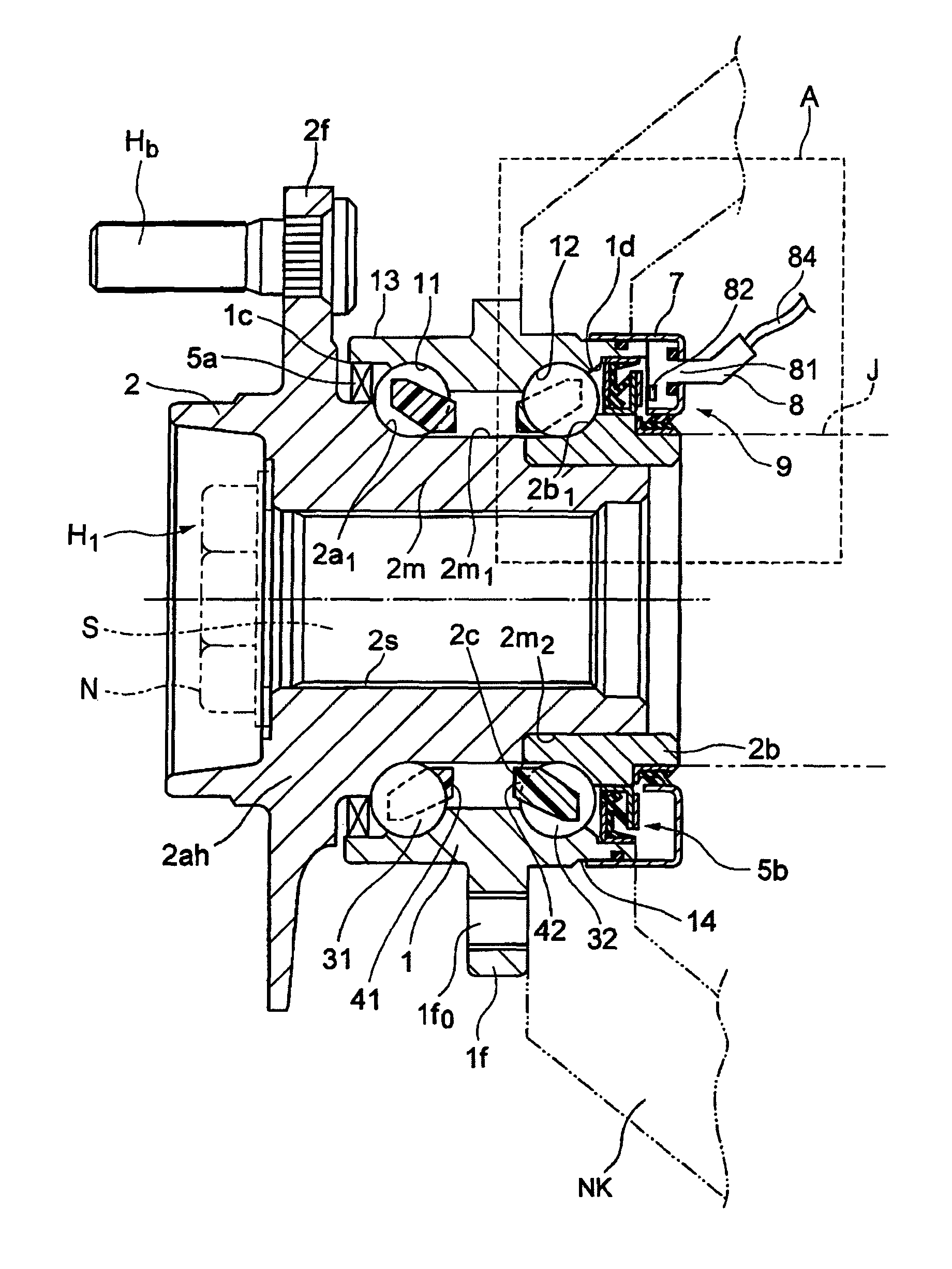

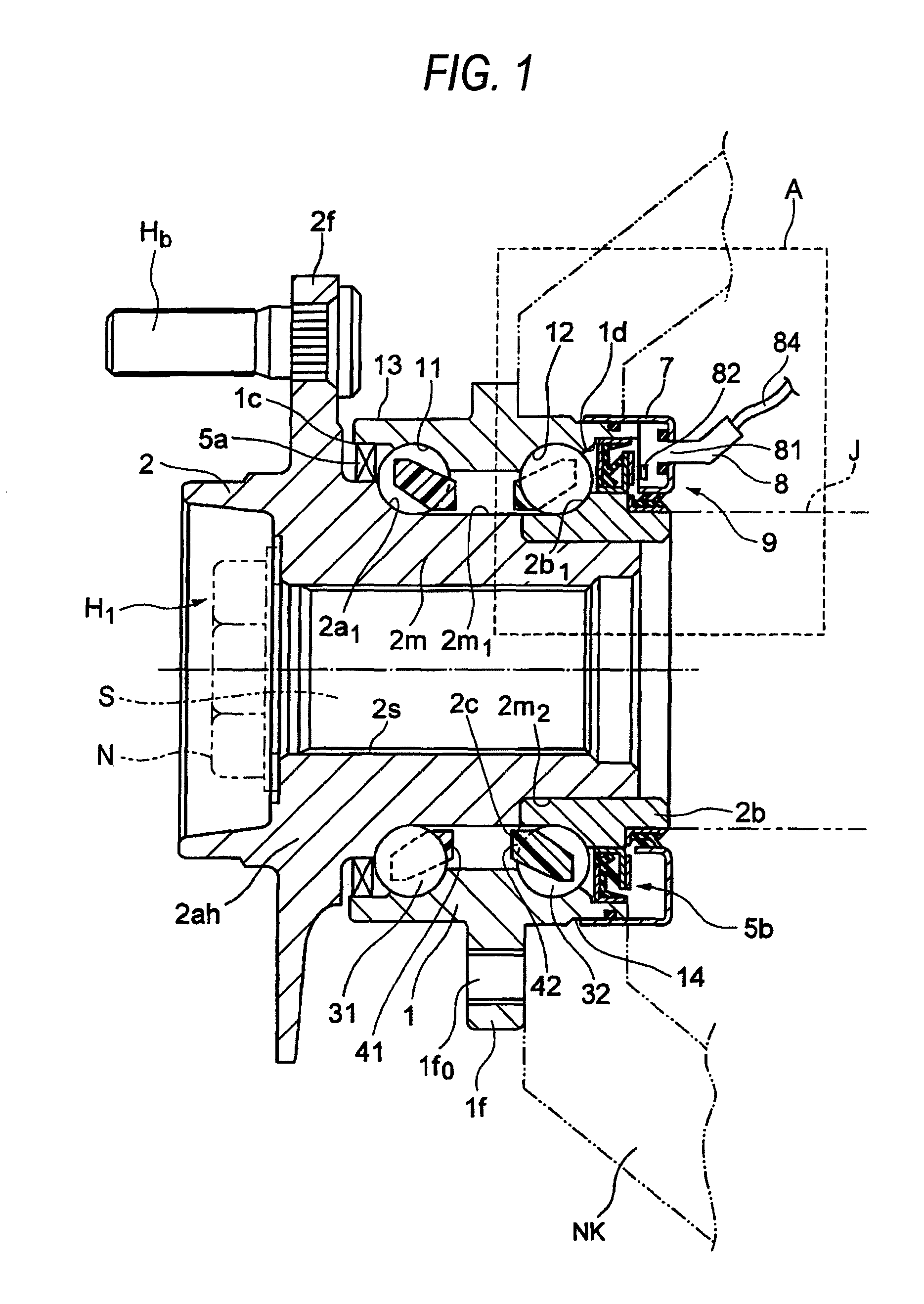

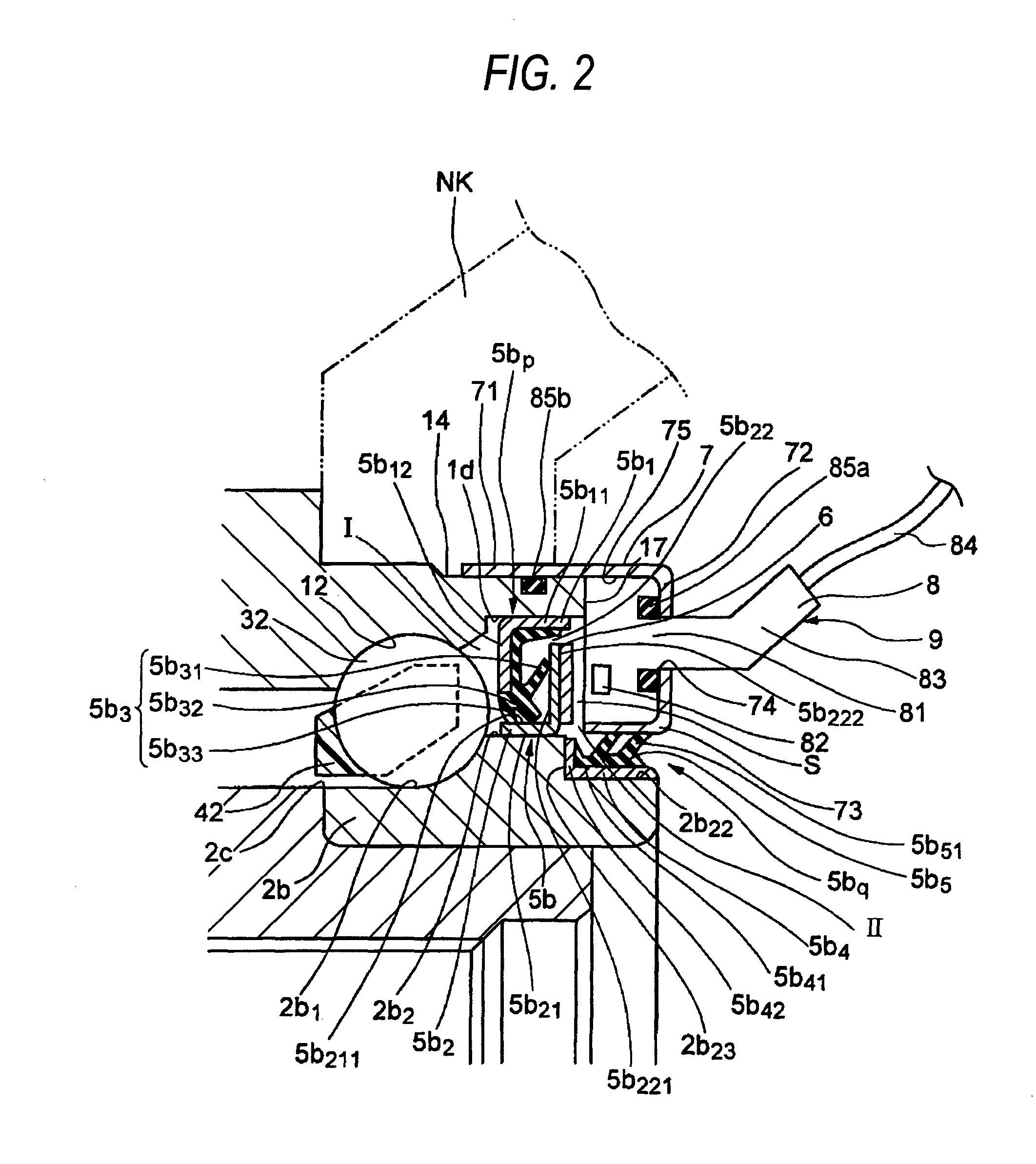

Hub unit bearing

ActiveUS8419288B2Clearance is easy to controlEngine sealsRolling contact bearingsMechanical engineering

A hub unit bearing H1 includes a rotational speed detector 9 which is made up of an encoder 6 and a sensor 8. A seal 5b on a side facing a center side of a vehicle includes a primary seal 5bp and a secondary seal 5bq which are disposed in that order in an axial direction from rolling elements 32 on a side facing the center side of the vehicle towards the center side of the vehicle so as to define a primary sealed space portion I between the vehicle's center side facing rolling elements 32 and the primary seal 5bp and a secondary sealed space portion II between the primary seal 5bp and the secondary seal 5bq, with the rotational speed detector 9 disposed within the secondary sealed space portion II.

Owner:NSK LTD

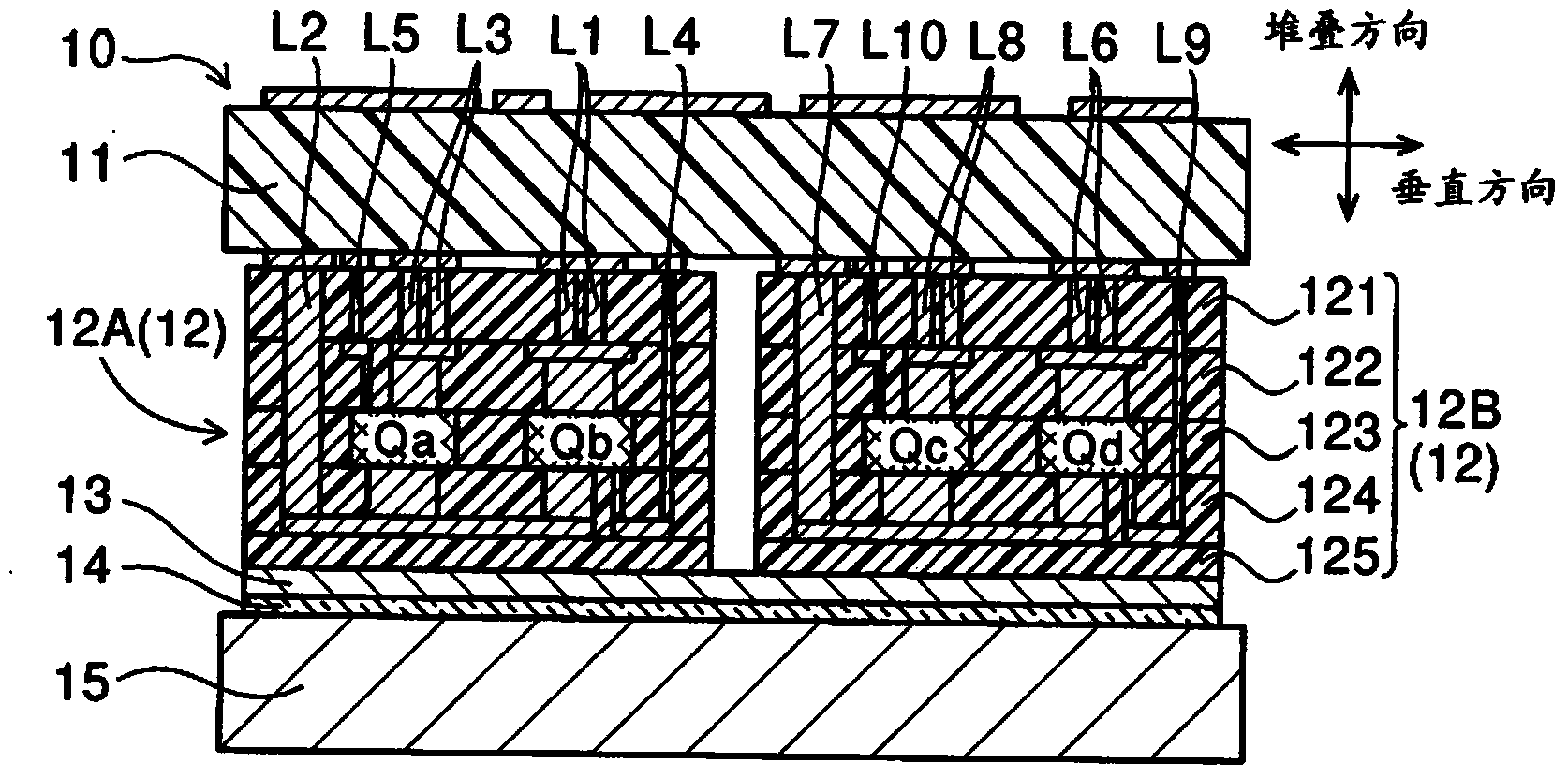

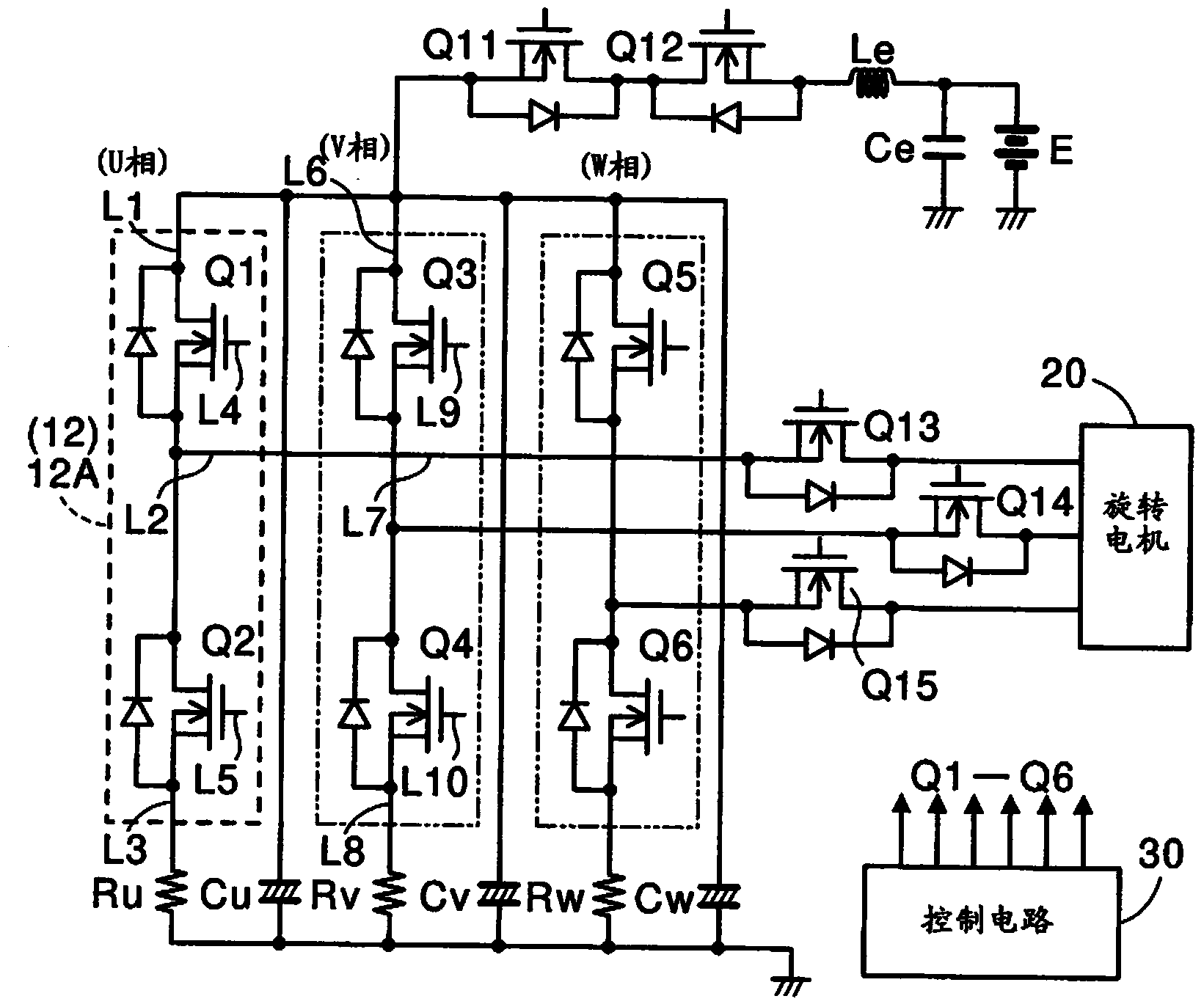

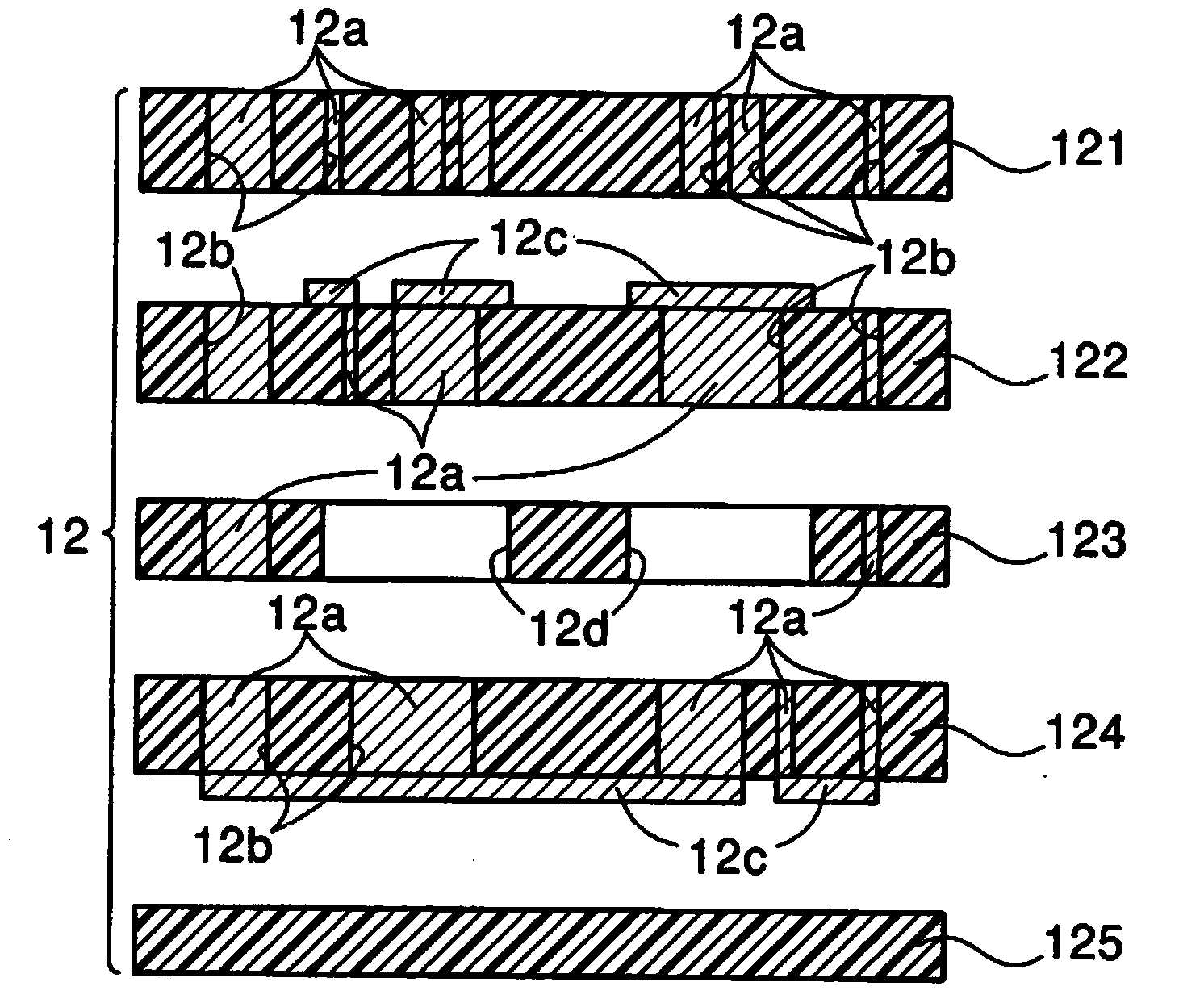

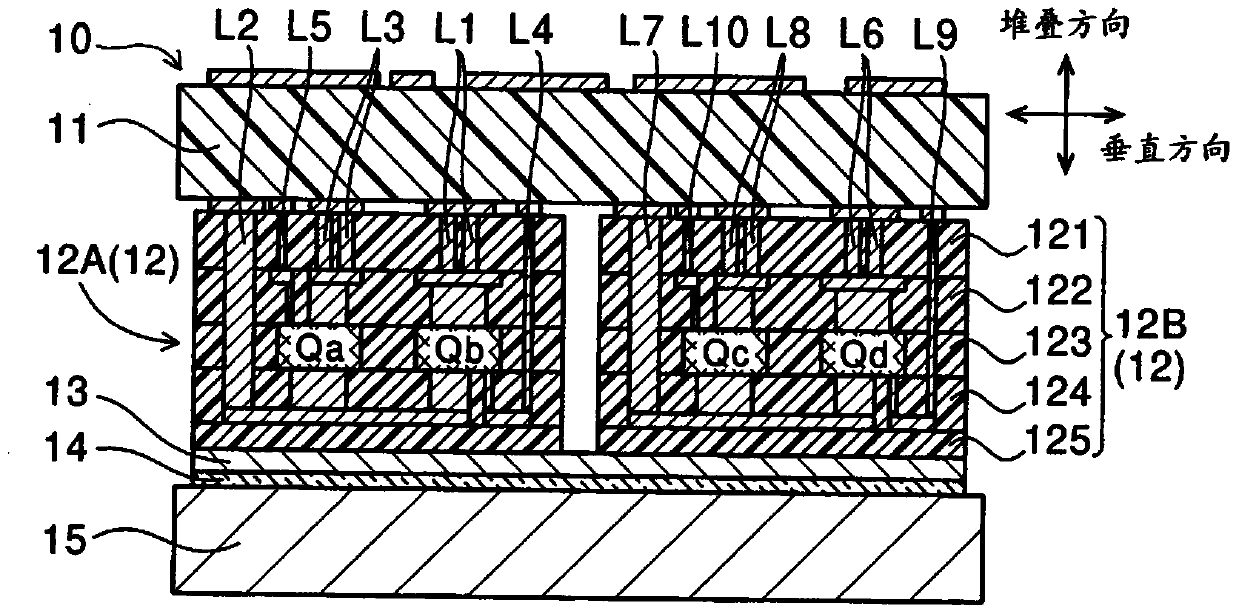

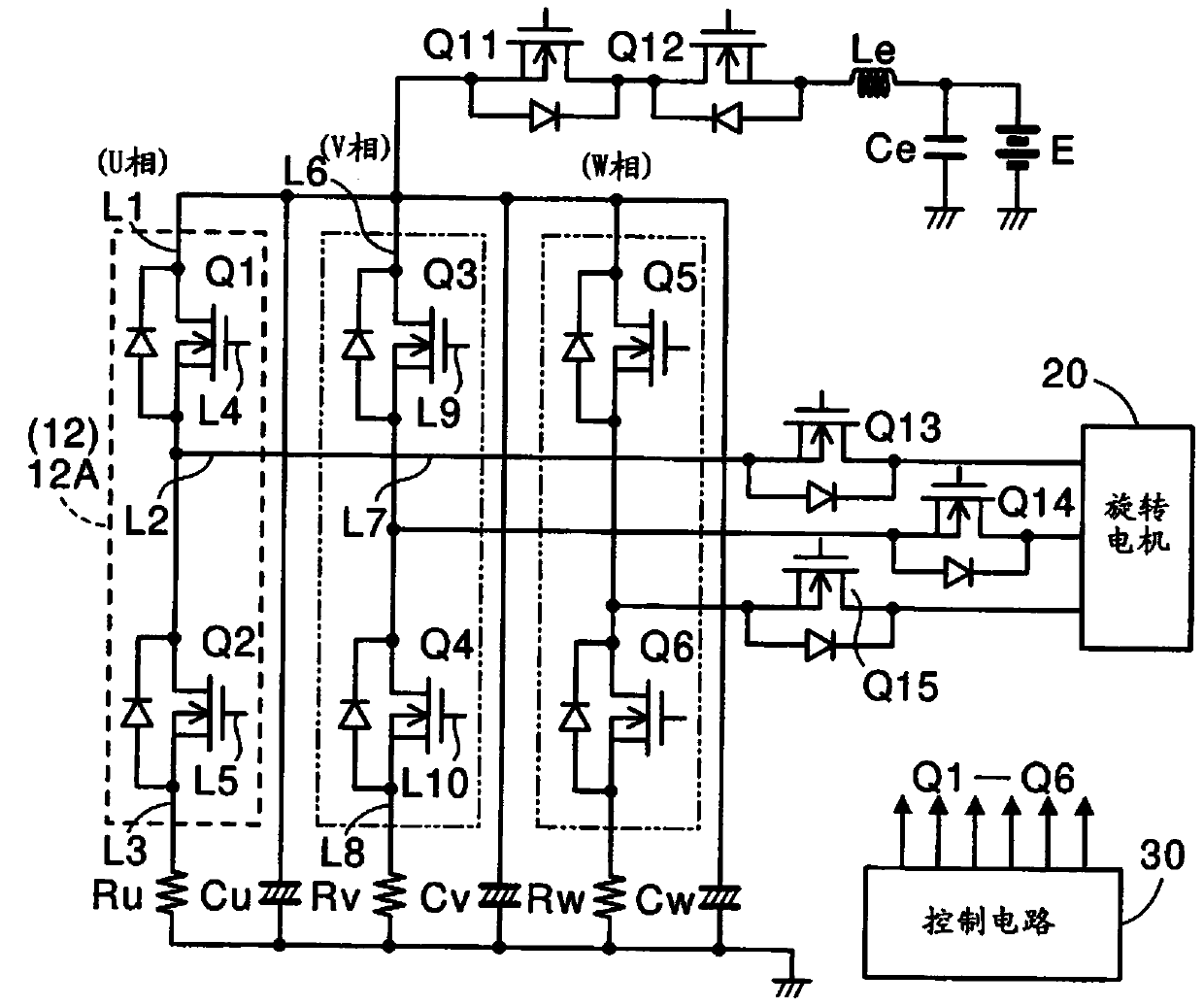

Heat radiation structure of electric device and method for manufacturing the same

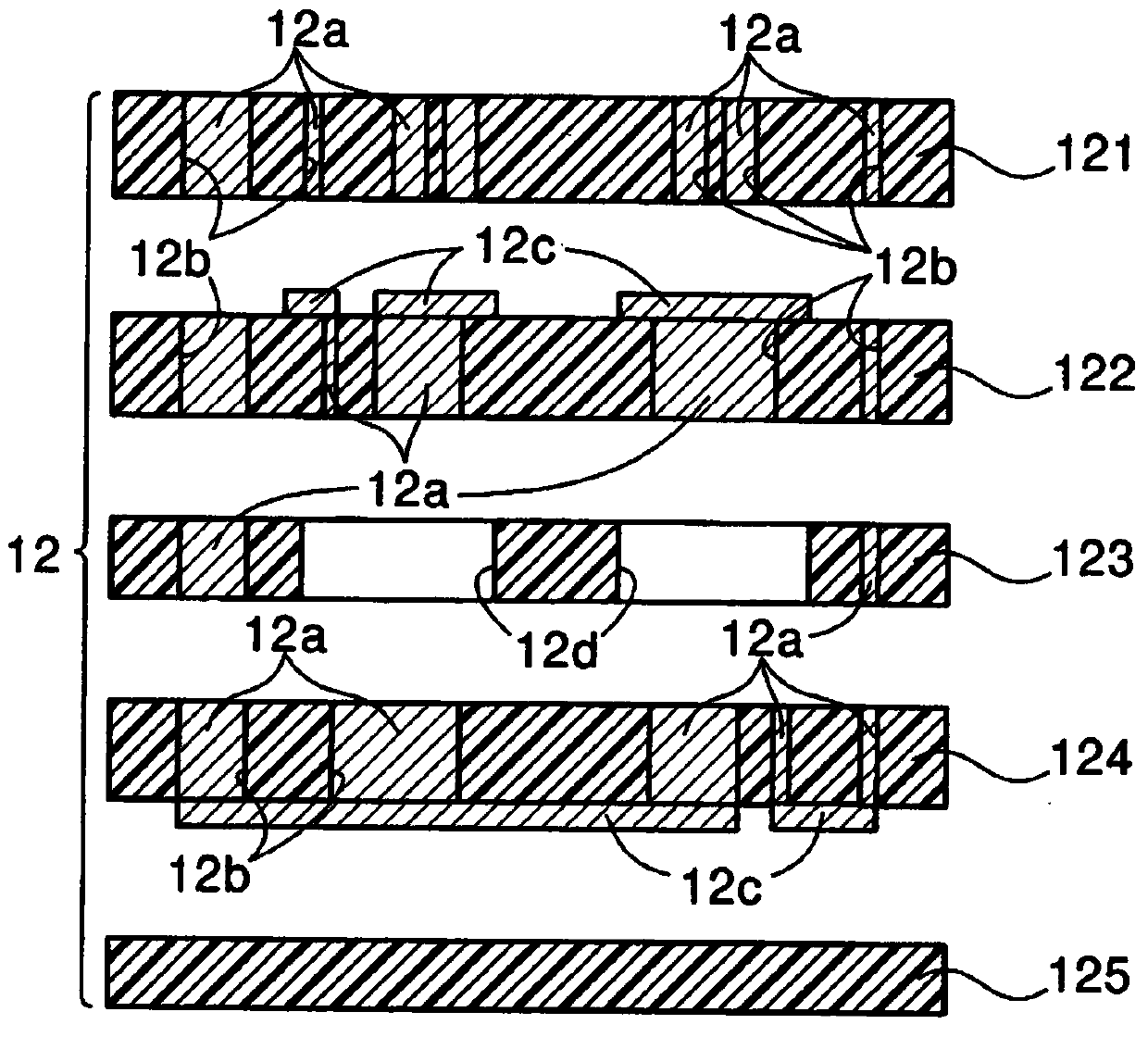

ActiveCN103974601AImprove cooling effectClearance is easy to controlSemiconductor/solid-state device detailsConversion constructional detailsEngineeringRadiation

A heat radiation structure for an electric device (Qa-Qd,16) includes: at least one multi-layer substrate (12,12A,12B) including a plurality of base parts (121-125) made of insulation material and a conductor pattern (12c), which are stacked in a multi-layer structure so that the conductor pattern is electrically coupled with an interlayer connection portion (L1-L10) in the base parts; the electric device having at least one of a first electric element (Qa-Qd) built in the at least one multi-layer substrate and a second electric element (16), which is not built in the multi-layer substrate; and a low heat resistance element (13) opposed to the electric device. The low heat resistance element has a heat resistance lower than the insulation material.

Owner:DENSO CORP

Expansion screen pipe

InactiveCN103967456APrecise control of particle sizeReduce resistanceFluid removalEngineeringCrude oil

The invention provides an expansion screen pipe which comprises an inner layer pipe, a middle layer pipe and an outer layer pipe, wherein the inner layer pipe, the middle layer pipe and the outer layer pipe are fixed and mounted in a sleeved mode in sequence from inside to outside. Multiple kerfs are distributed in the pipe wall of the inner layer pipe, the middle layer pipe is formed by coiling filaments spirally, and multiple holes are also distributed in the pipe wall of the outer layer pipe. The expansion screen pipe has the advantages that the granulometric class of filtered gravel can be controlled accurately, an oil drainage area is enlarged through expansion hole enlargement, oil flow resistance is reduced at the same time, and crude oil produced by a single well daily can be improved by 30-50 percent.

Owner:TIANJIN TOP CLOUD EAST ENERGY TECH

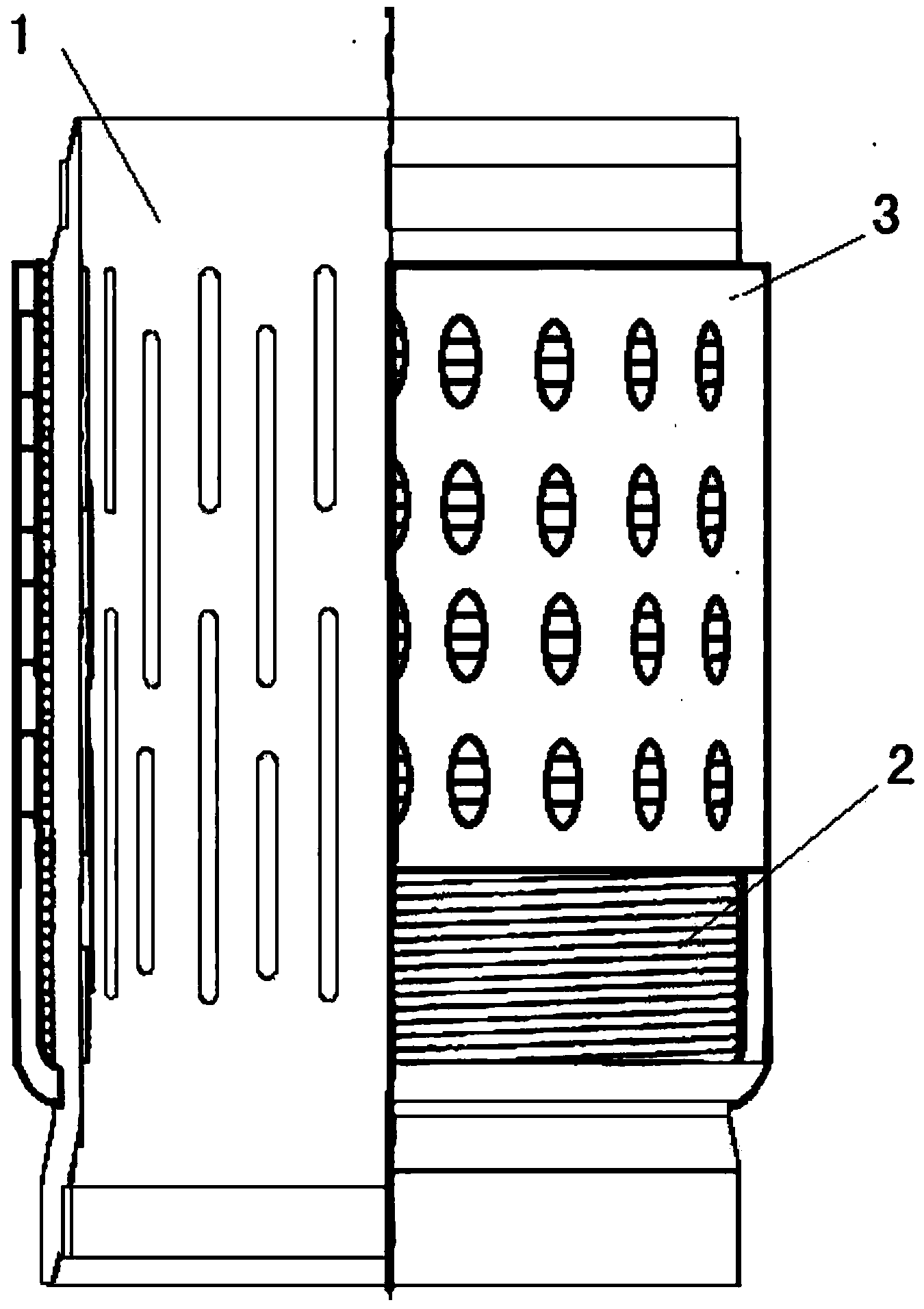

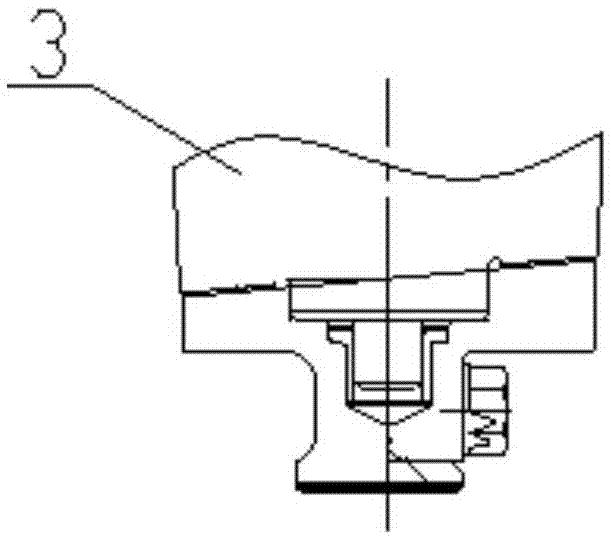

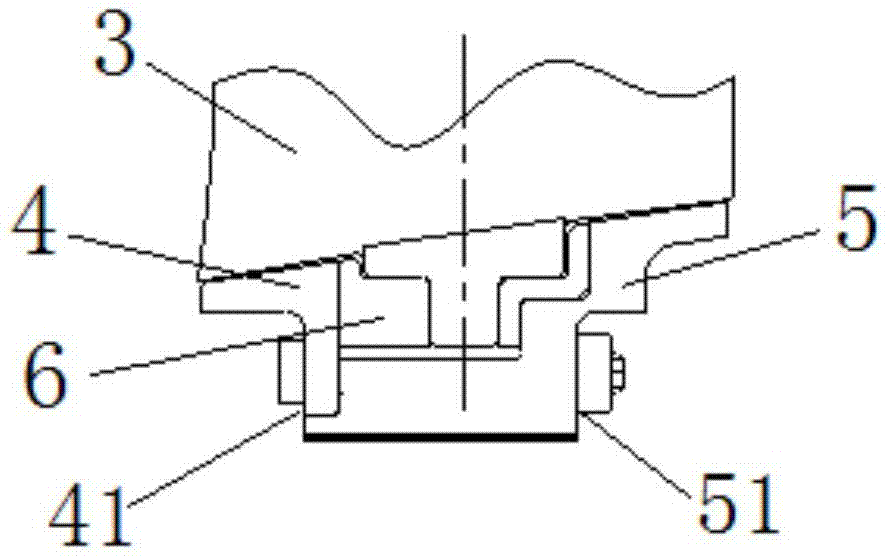

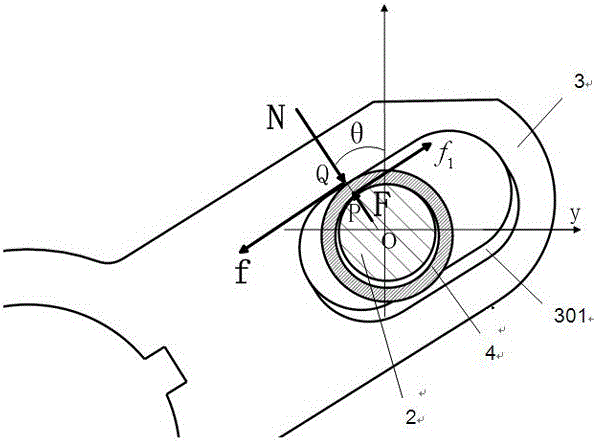

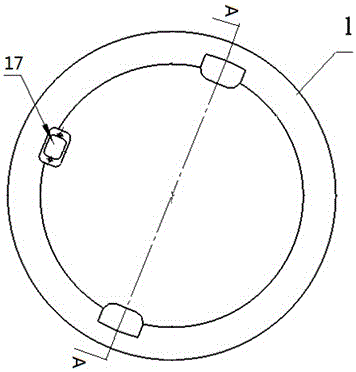

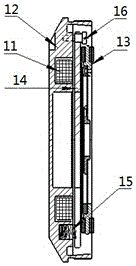

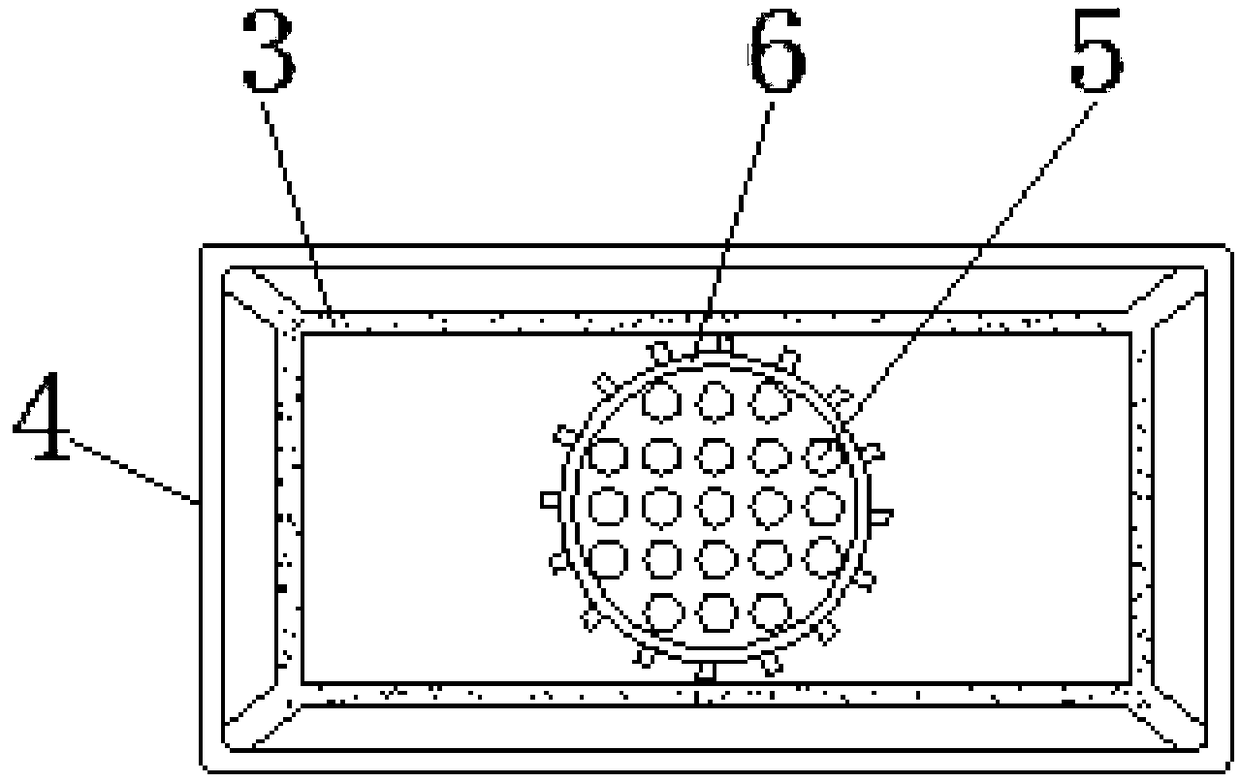

Inner ring structure of adjustable stator blade of engine fan

ActiveCN105443444AEasy to installImprove work efficiencyPump componentsPumpsGas compressorEngineering

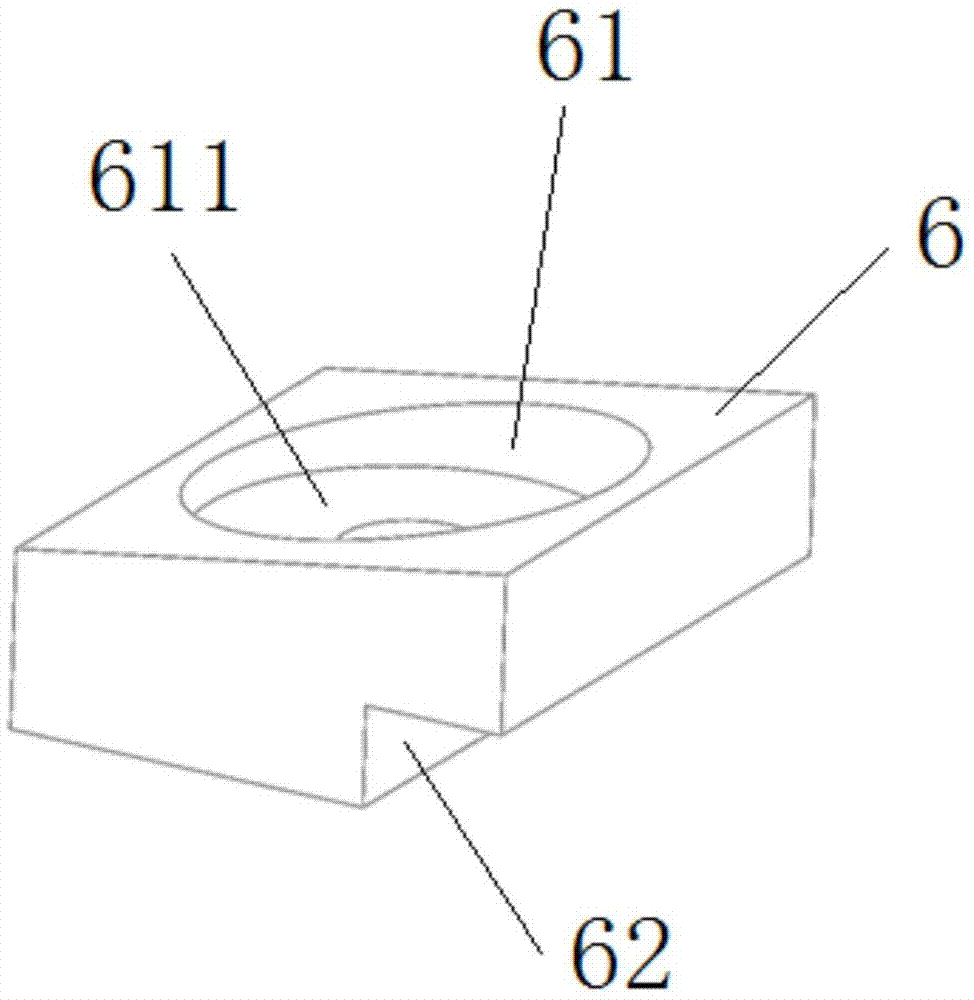

The invention discloses an inner ring structure of an adjustable stator blade of an engine fan, and relates to the technical field of gas compressors. The inner ring structure of the adjustable stator blade of the engine fan is used for positioning the adjustable stator blade (3); the inner ring structure of the adjustable stator blade of the engine fan comprises inner ring front sections (4), an inner ring rear section (5) and a positioning block (6), wherein the positioning block (6) is provided with a positioning hole (61); the positioning hole (61) is used for mounting a rotary shaft of the adjustable stator blade (3); a plurality of clamping slots (51) are uniformly distributed at the circumference of the inner ring rear section (5); the clamping slots (51) are used for mounting the positioning block (6); and the plurality of inner ring front sections (4) are fixedly connected to the inner ring rear section (5) for fixing the positioning block (6). The inner ring structure has the beneficial effects that: the inner ring front sections can be directly mounted without the needs of rotating the adjustable stator blade, so that the mounting is simple and convenient, and the working efficiency is improved.

Owner:AECC SHENYANG ENGINE RES INST

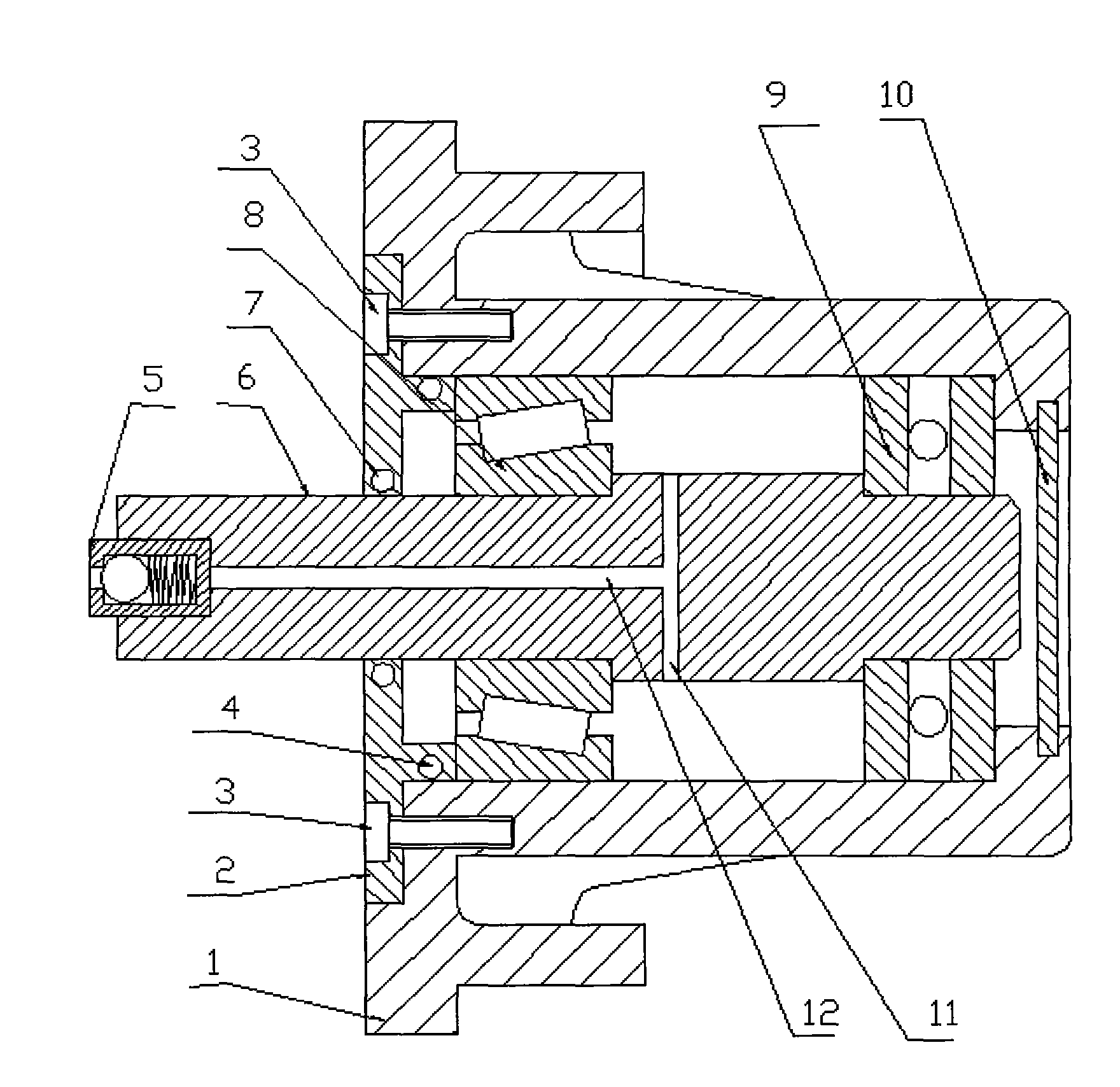

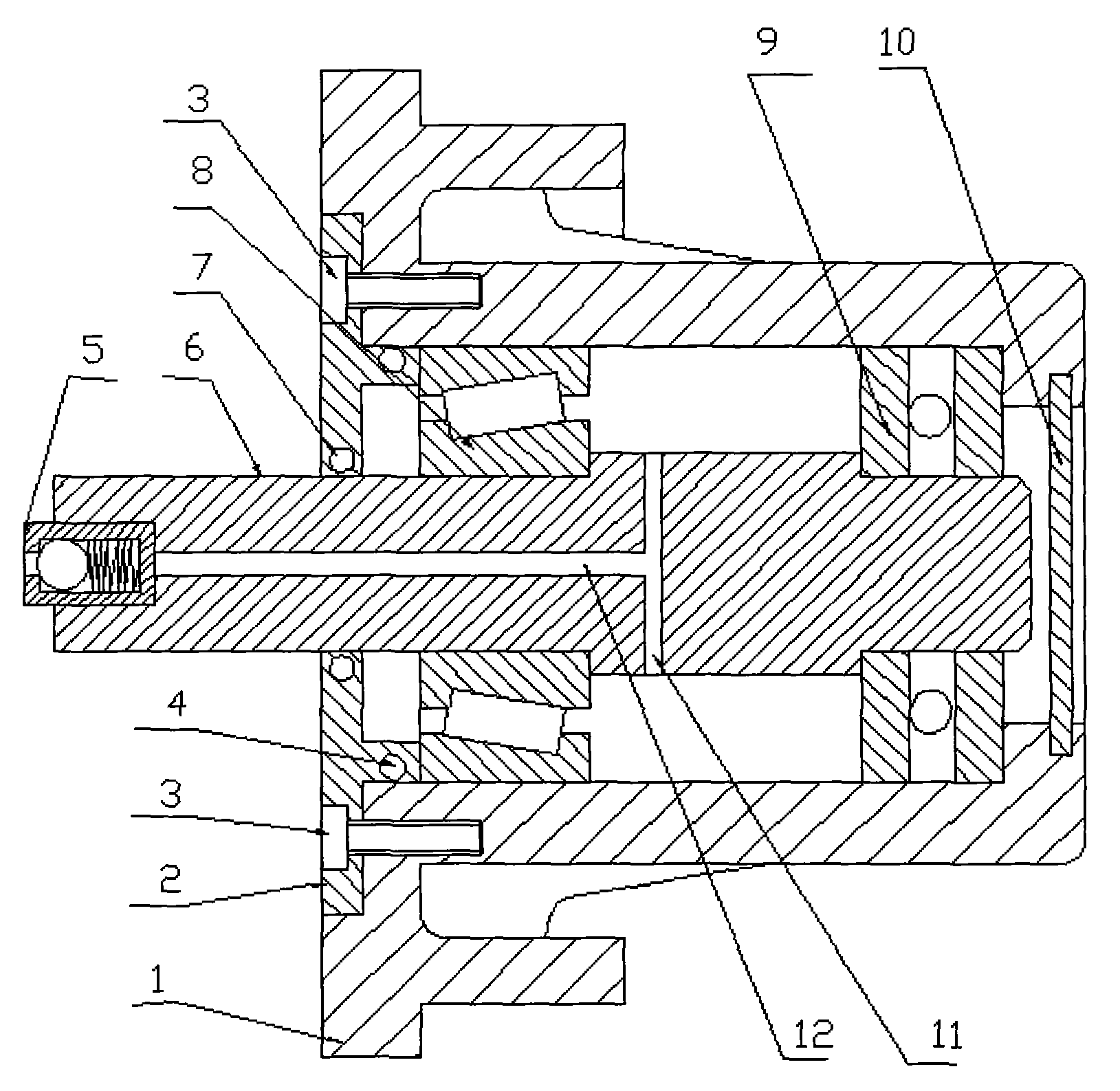

Adjustable electromagnetic power supply switch

InactiveCN102426988AImprove magnetic permeabilityLow costElectromagnetic relay detailsPull in voltagePower switching

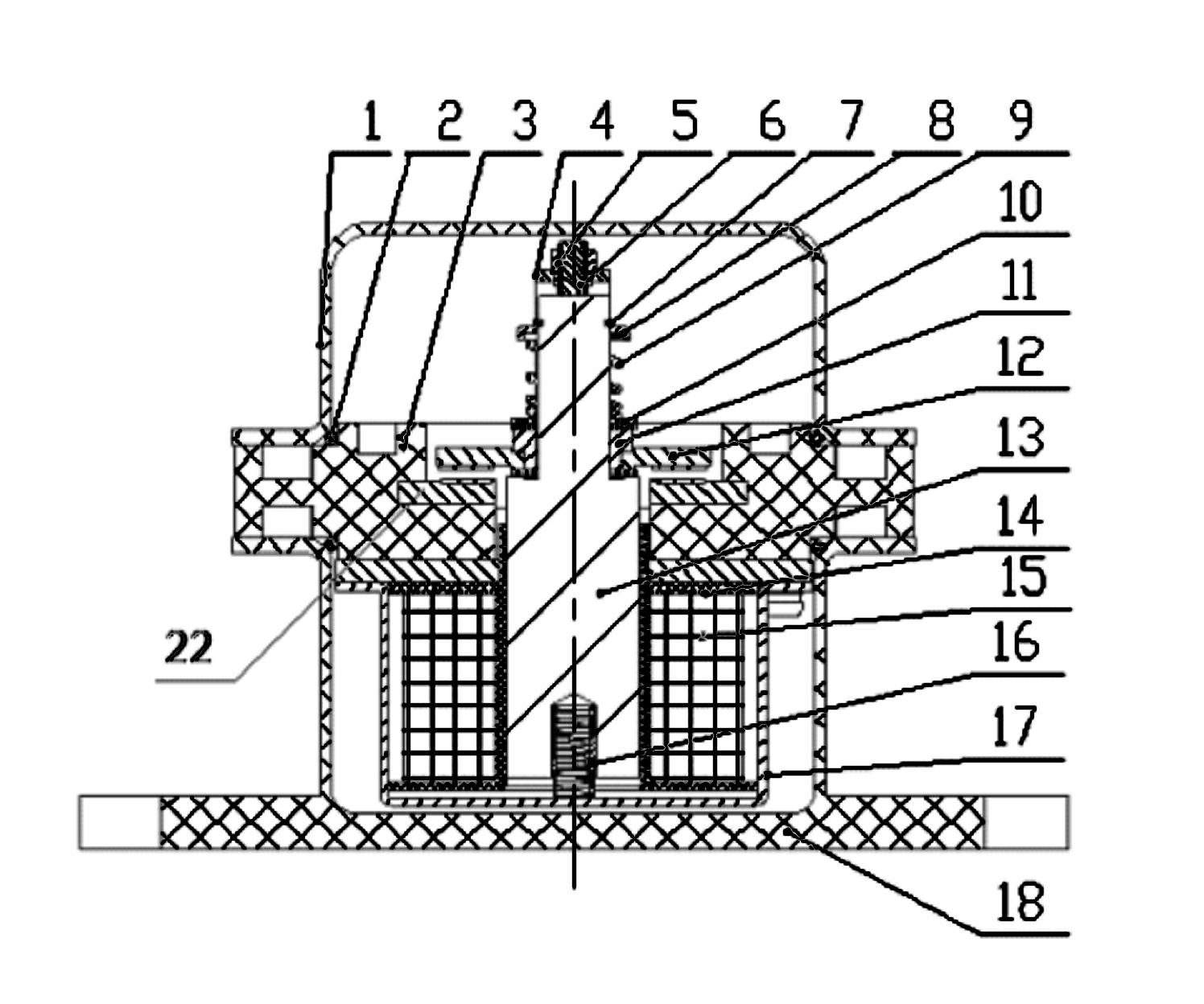

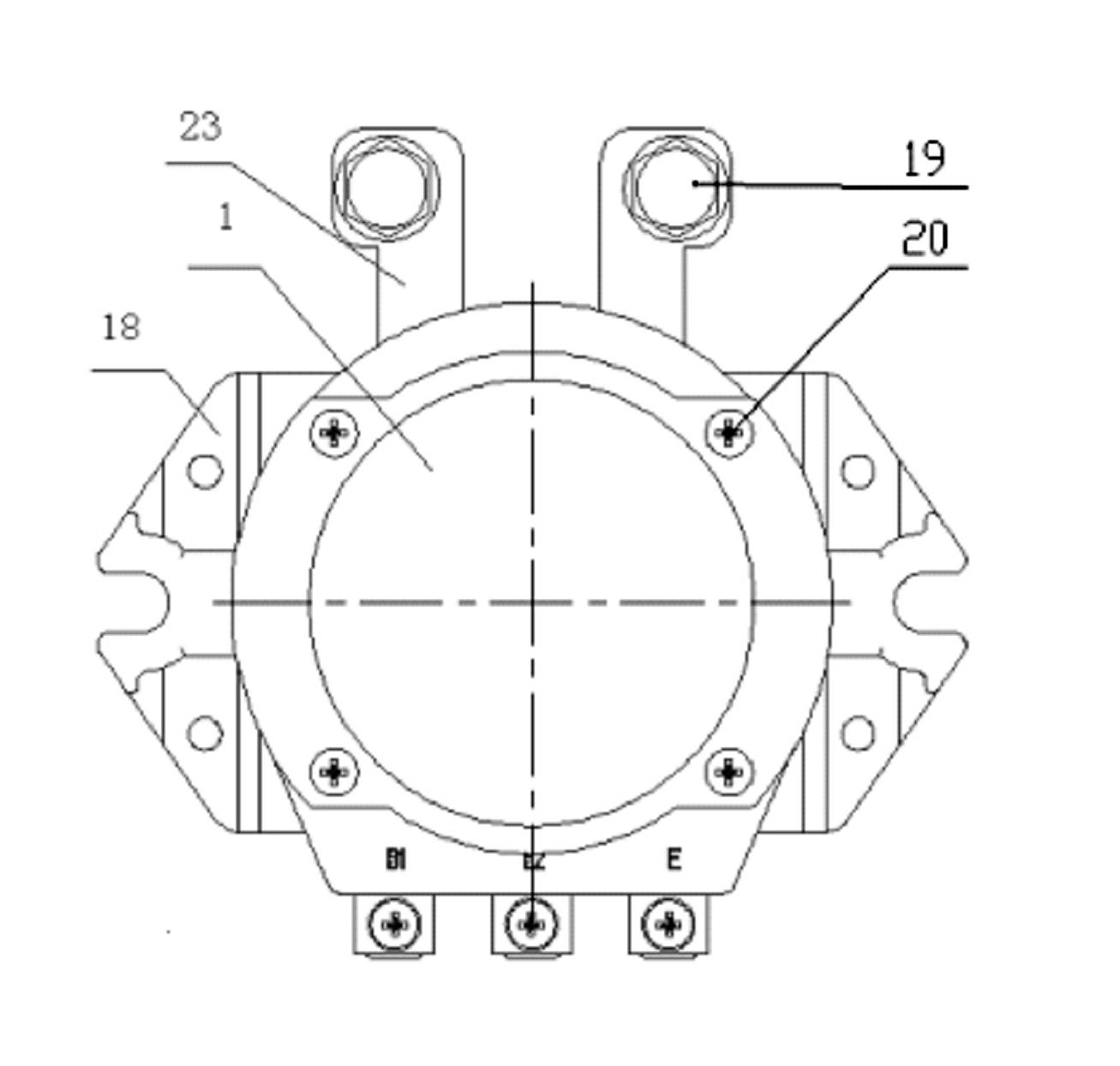

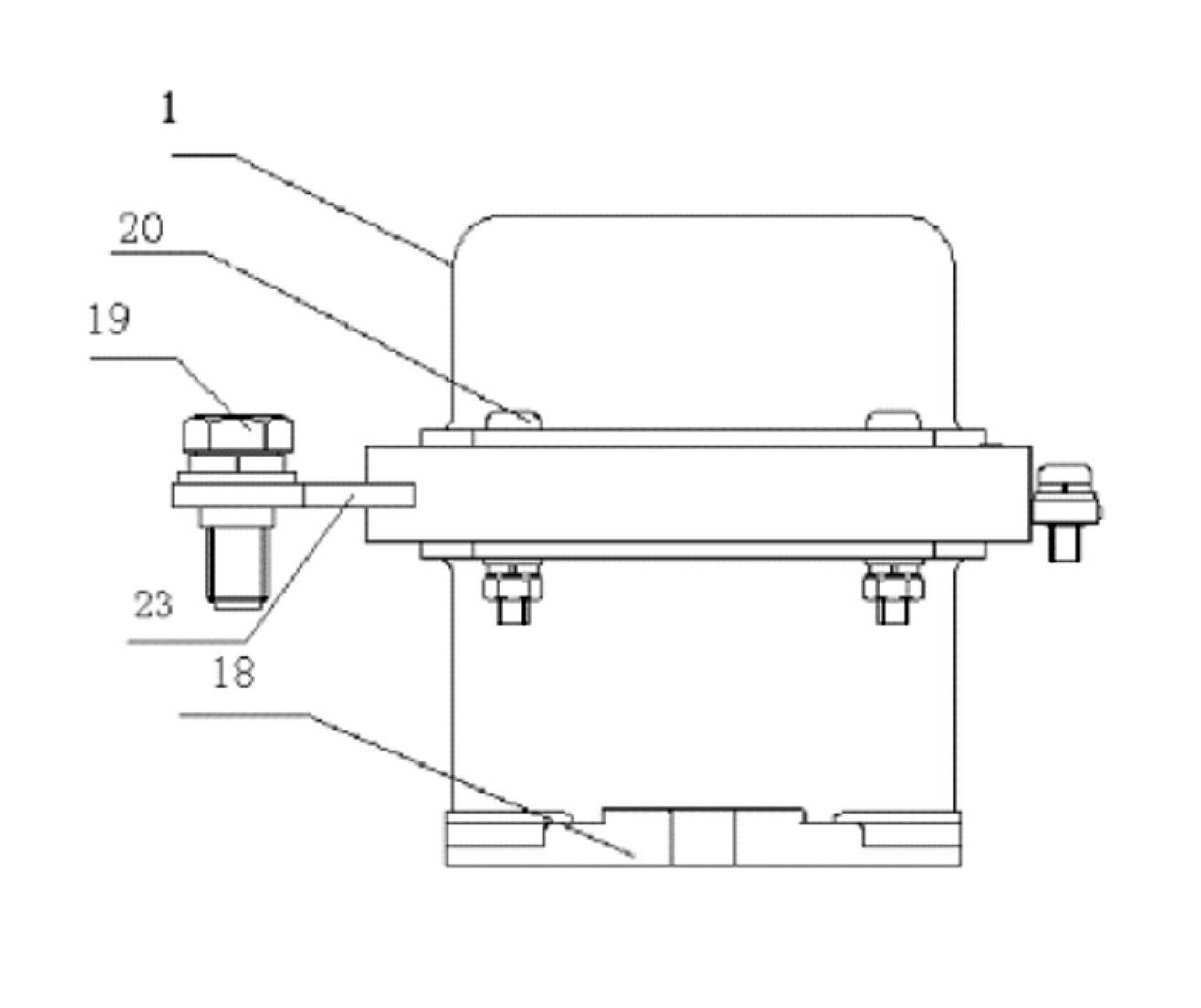

The invention relates to the technical field of automobile power supply switches, disclosing an adjustable electromagnetic power supply switch. The adjustable electromagnetic power supply switch comprises an upper casing (1), a lower casing (18), an iron core (13), a movable contact spring assembly (12), a static contact spring assembly (22), a coil rack assembly (14), an enamelled wire (15) and the like, wherein magnetic conduction inner casings (17) are additionally arranged on the outer sides of the iron core (13), the coil rack assembly (14) and the enamelled wire (15); the inside diameters of the magnetic conduction inner casings (17) are the same as the excircle diameter of the coil rack assembly (14); the upper casing (1) and the lower casing (18) are made of plastic; main contacts are respectively made of composite silver material; and adjusting screws (6) are additionally arranged at the top of the iron core. According to the adjustable electromagnetic power supply switch disclosed by the invention, the problem of overlow or overhigh pull-in voltage is solved; and the phenomenon that the switch is burnt down due to short circuit caused by contact of a spanner and the upper casing when the switch is replaced, can be also avoided. The adjustable electromagnetic power supply switch disclosed by the invention has the advantages of adjustable stroke, controllable clearance, cost saving, convenience for operation, safety and reliability.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

Integrated type side outer plate

InactiveCN103085884AReduce processDirect fixed implementationSuperstructure subunitsEngineeringBreathing

The invention relates to the field of automobile body parts, in particular to an integrated type side outer plate. A plate body on a back protective mounting face on the side outer plate extends towards the automobile bottom direction to form a mounting part. The mounting part is provided with a ventilation frame mounting hole and a skylight back water guide pipe mounting hole. Threaded mounting holes are formed in the back protective mounting face. a plurality of threaded mounting holes are arranged at intervals evenly along the automobile length direction. The side outer plate and the mounting part are in an integrated structure. Processes of connecting plate welding are reduced, and meanwhile errors of welding are avoided. A back protective part is directly fixed on the threaded mounting hole through a nut. Direct fixing of the back protective part and the side outer plate is achieved. The gap and the flatness between the back protective part and the side outer plate are convenient to control. Mounting accuracy is high.

Owner:CHERY AUTOMOBILE CO LTD

Novel carrier roller choke plug assembly of belt conveyer

The invention relates to a novel carrier roller choke plug assembly of a belt conveyer. Single-row tapered roller bearings and thrush bearings are sequentially arranged at both ends of a step of a rotating shaft; the rotating shaft is arranged in a through hole in the middle of a bearing block through the single-row tapered roller bearings and the thrush bearings; a standard oil injection nozzle is arranged at the oil opening position on the end part of the rotating shaft; a circular hole is formed in the center of a bearing gland; an annular seal ring groove in an appropriate shape is formed at the position of the circular hole; a rotating shaft seal ring is arranged in the annular seal ring groove; through the rotating shaft seal ring, a seal is formed between the bearing gland and the rotating shaft; an annular seal ring groove in an appropriate shape is formed on the excircle of an upper opening of the bearing gland; a bearing cavity seal ring is arranged in the annular seal ring groove; and through the bearing cavity seal ring, a seal is formed between the bearing gland and an inner cavity of the bearing block. In order to prevent dust and the leakage of lubricating oil, a bearing block plug cap is arranged at the position of the through hole at the inner end of the bearing block.

Owner:田后征

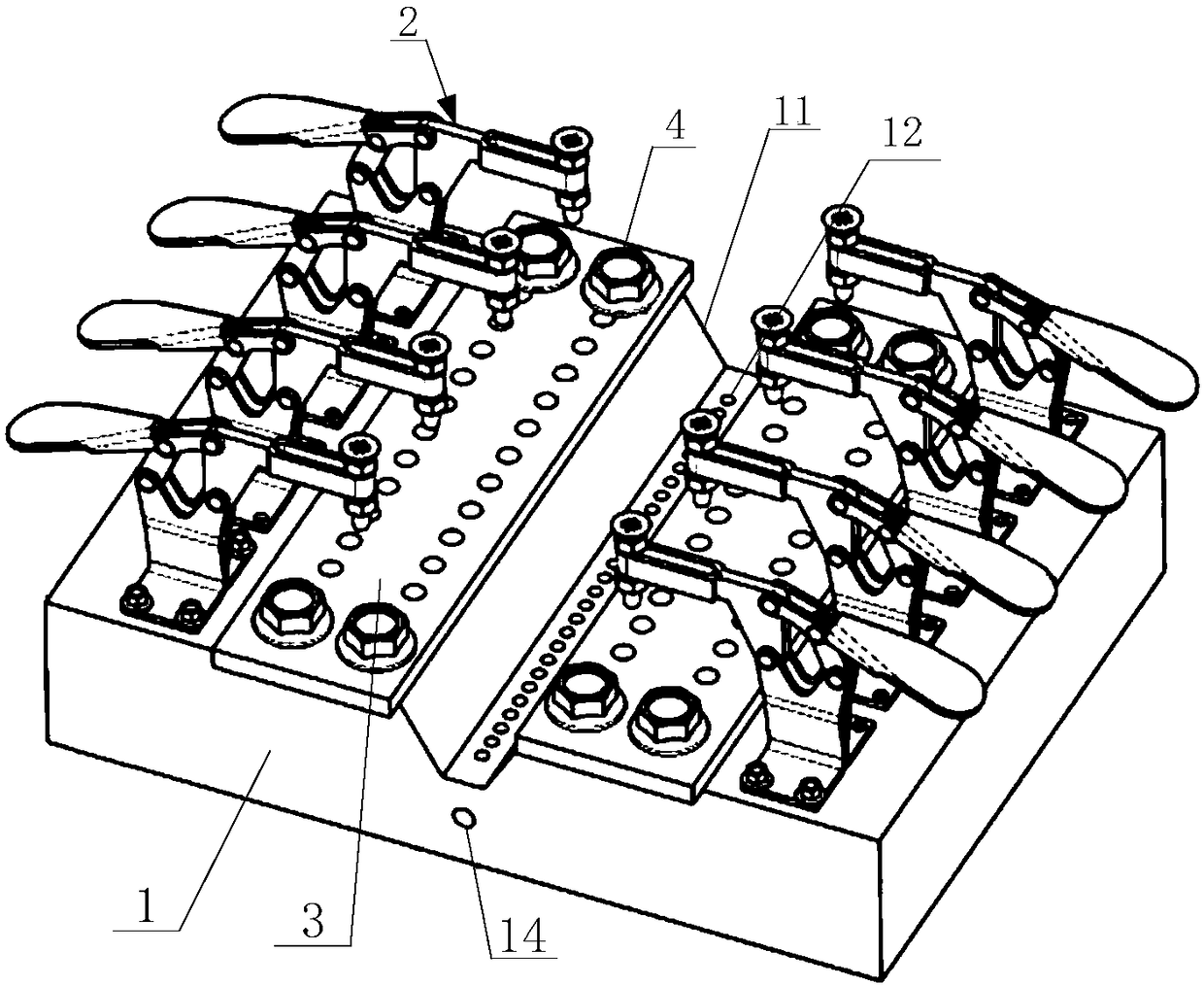

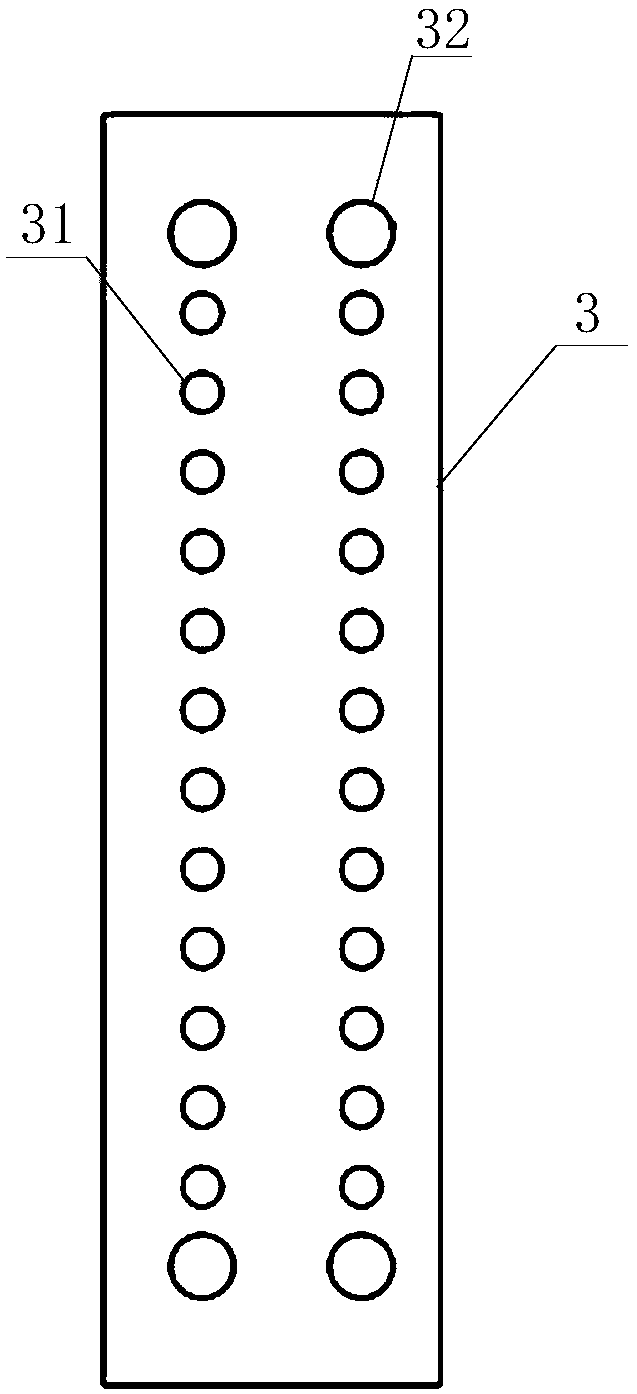

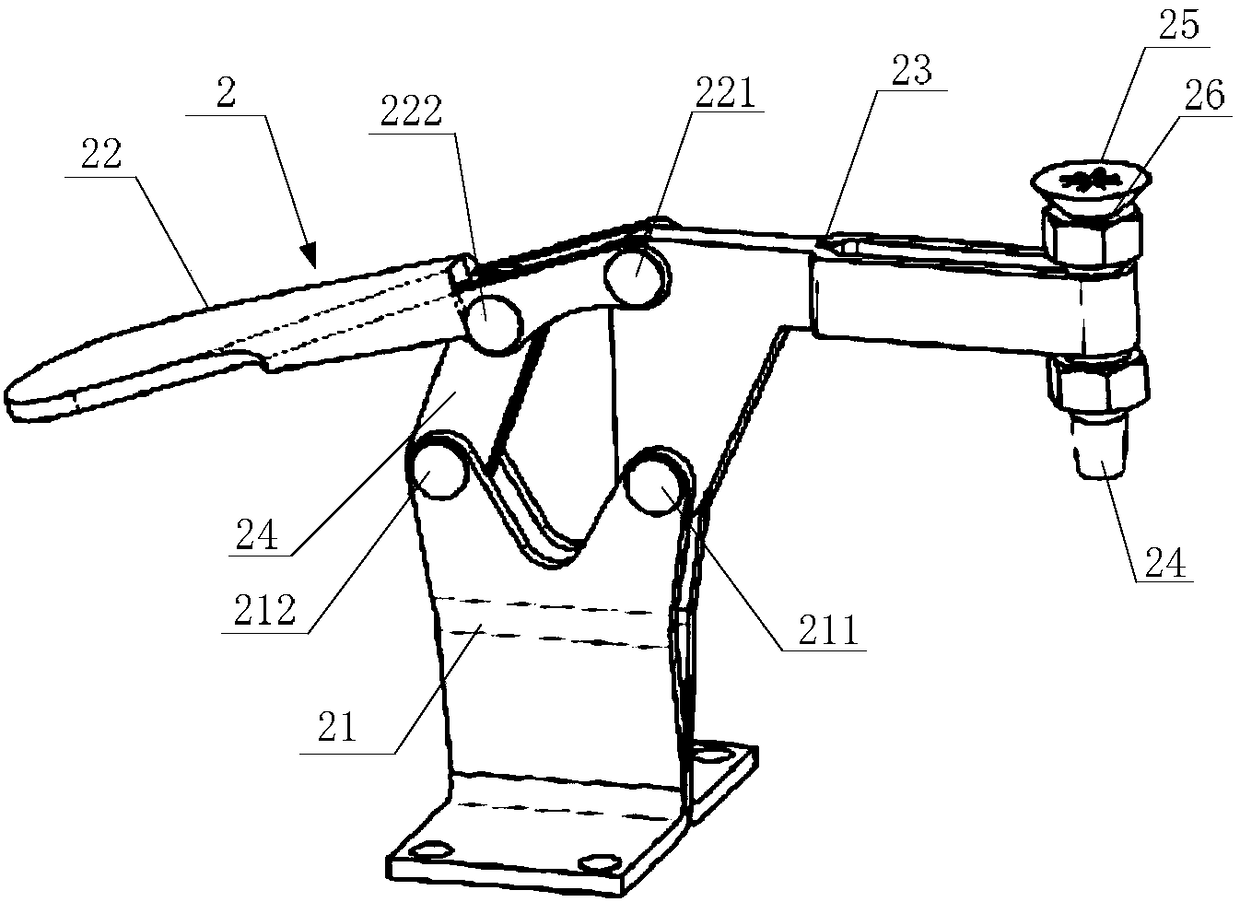

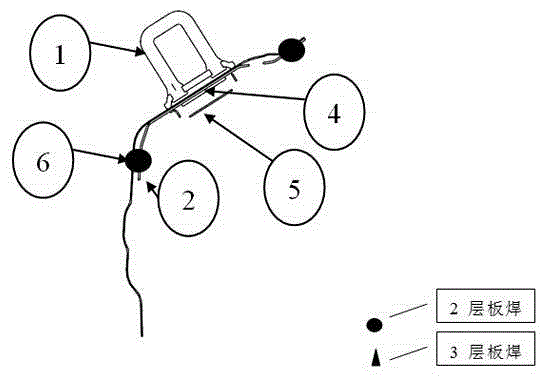

Tool device capable of controlling sheet welding gap

InactiveCN108340111ARealize the supplyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFailure causes

The invention provides a tool device capable of controlling a sheet welding gap. The device comprises a fixing base, quick pressing heads, first bolts and second bolts; a groove is formed in the middle of the fixing base, and a plurality of gas spraying holes are uniformly formed in the bottom of the groove in the extending direction of the groove; first fastening screw holes and first connectingscrew holes are formed in the two sides of the groove, and the bolts are in screw joint in the first connecting screw holes; the quick pressing heads are oppositely arranged and fixed on the two sidesof the groove in the extending direction of the groove correspondingly, each fast pressing head comprises a support, a pressing arm assembly and a pressing head, the pressing arm assemblies are pivoted to the tops of the supports, the supports are fixed to the fixing base, the pressing heads are fixed at the ends, adjacent to the groove, of the pressing arm assemblies, the second bolts are in screw joint in the first fastening screw holes, and the pressing heads can be inserted into the first fastening screw holes. According to the tool device capable of controlling the sheet welding gap, theconsistency of gaps in the welding process can be simply and effectively controlled, and the problems of gap change and clamping failure caused by the fact that a sheet is deformed are prevented.

Owner:SHANGHAI UNIV OF ENG SCI

Fully-automatic box assembling equipment

InactiveCN102683471AImprove machinery safetySame distanceFinal product manufactureSemiconductor devicesFully automaticGlass sheet

The invention discloses box assembling equipment which comprises a machine frame and a conveying belt (10), a glass lifting table (1) and a box assembling aluminum profile pushing mechanism (2) on the glass lifting table (1) and is characterized in that a gantry type assembly angle floating jaw mounting bracket (3) is arranged on the glass lifting table (1); four telescopic mechanical arms (4) are arranged on the gantry type assembly angle floating jaw mounting bracket (3); and floating jaws (5) are installed on the heads of the telescopic mechanical arms (4). The fully-automatic box assembling equipment has the beneficial effects that when a box is assembled, the distances between a glass plate and the peripheries of a side plate are ensured to be consistent, so that the mechanical safety of components is improved; by adopting floating clamping heads, the box assembly angle error is effectively controlled, and the assembly angle quality is improved; and as a gap between the side frame and the glass plate is controllable, the overflow of glue on the surface of the glass plate is reduced, and the effects of avoiding glue scraping and removal and improving the appearance quality of the components are achieved.

Owner:无锡洁尔娇生物科技有限公司

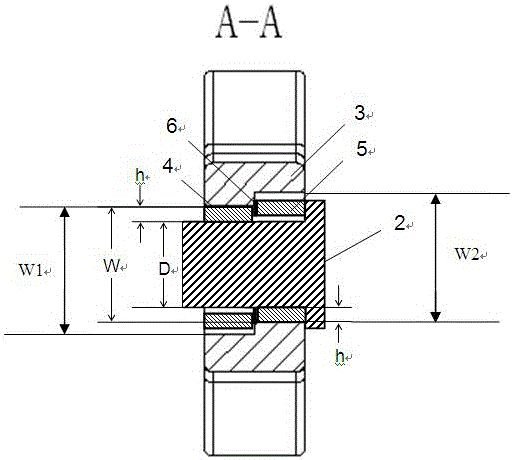

Mechanical drive structure

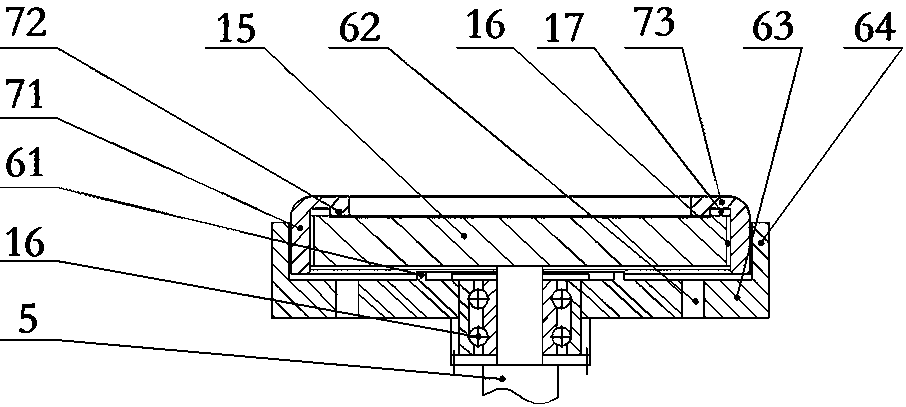

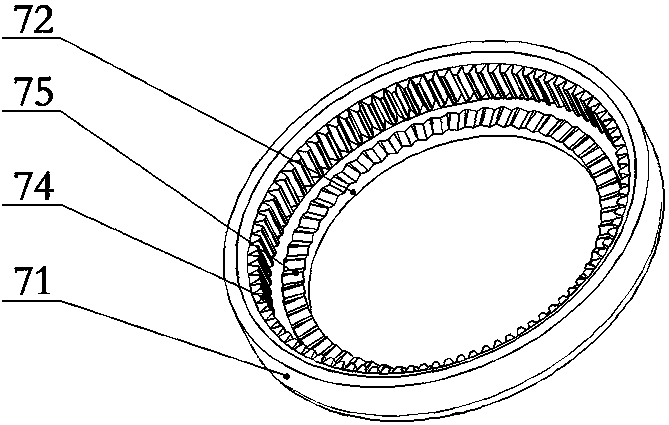

ActiveCN106838179AClearance is easy to controlReduce frictionGearingPortable liftingBall screwEngineering

A mechanical drive structure comprises a swing arm and an anti-backlash ring component, the swing arm is connected with a ball screw nut and a rudder shaft, the anti-backlash ring component sleeves a poking rod of the ball screw nut and is positioned in the swing arm, a first offset rail and a second offset rail are adjacently arranged in a through hole of the swing arm, a horizontal symmetric center line of the first offset rail and a horizontal symmetric center line of the second offset rail are not on the same horizontal plane, the anti-backlash ring component comprises a first anti-backlash ring and a second anti-backlash ring which sleeve on the poking rod, the first anti-backlash ring is positioned in the first offset rail, the second anti-backlash ring is positioned in the second offset rail, and the perpendicular distance between the horizontal symmetric center line of the first offset rail and the horizontal symmetric center line of the second offset rail is H. According to the mechanical drive structure, rolling motion between the poking rod of the screw nut and the swing arm is achieved, and matched gap between the poking rod of the screw nut and the swing arm can be adjusted based on decrease of frictional force.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

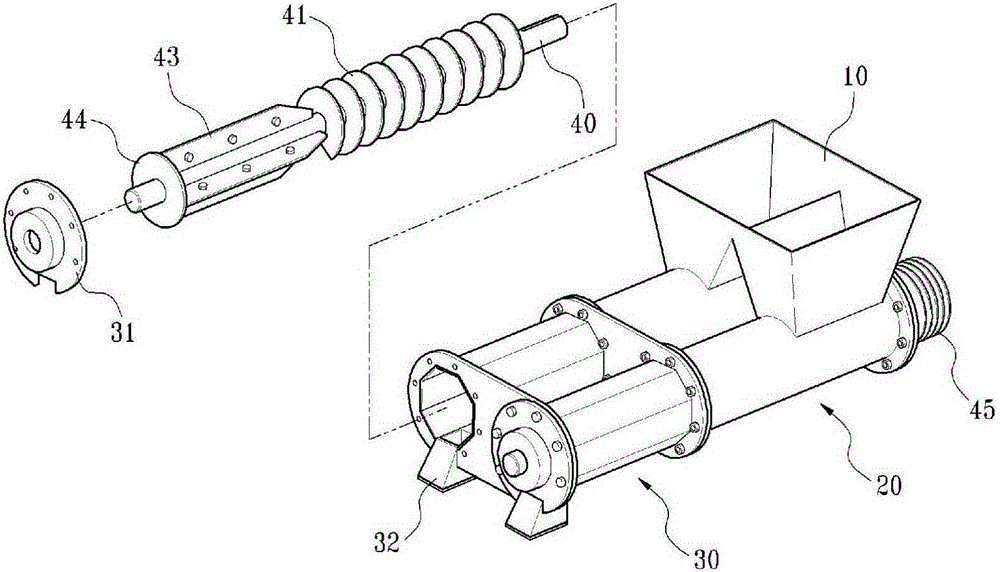

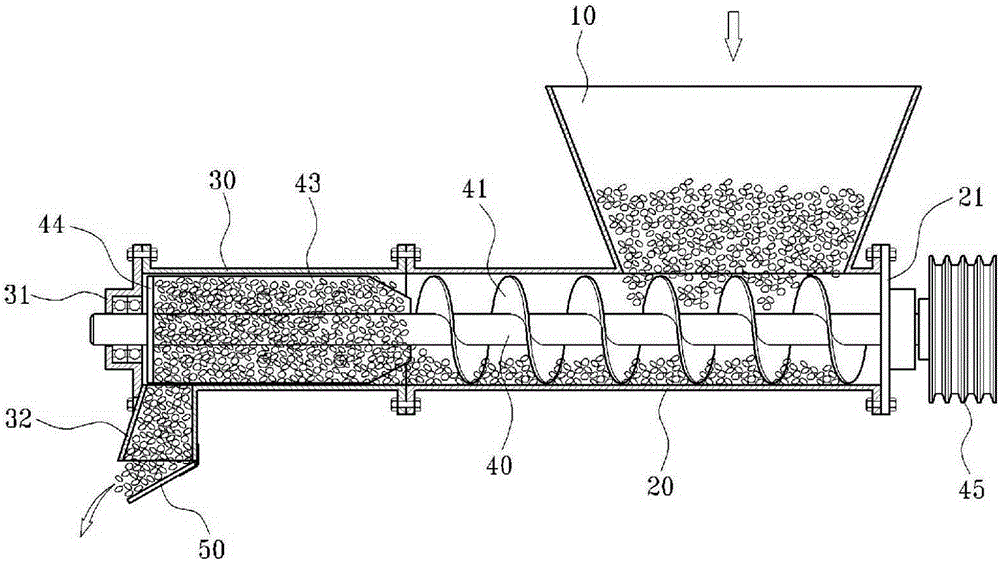

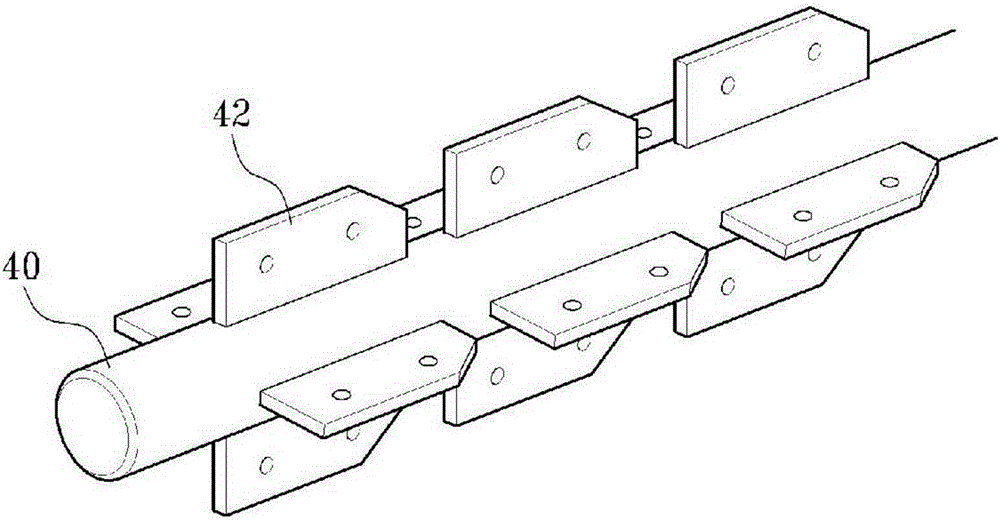

Glass crusher

InactiveCN105233946APush each otherAchieving a shattering effectGlass recyclingGrain treatmentsGlass chipCrusher

The invention discloses a glass producing device and particularly relates to a glass crusher. The glass crusher comprises a shell and a rotating shaft rotationally connected into the shell. The rotating shaft is provided with spiral auger knifes and stirring blades. The shell comprises first cavities for containing the spiral auger knifes and second cavities for containing the stirring blades. The first cavities are provided with feeding hoppers. The second cavities are provided with discharging hoppers. The inner section of the second cavities is a regular hexagon and the second cavities correspond to the stirring blades in number. By means of the glass crusher, the technical defect that in the prior art, strip-shaped glass sheets exist and block follow-up conveying is overcome, glass can be broken completely, and strip-shaped glass sheets are prevented.

Owner:深圳市光华中空玻璃工程有限公司

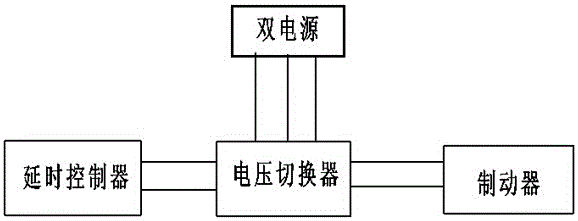

Dual-power supply electromagnetic brake

InactiveCN105715709AReduce power consumptionImprove protectionBrake actuating mechanismsActuatorsElectricityTime delays

The invention discloses a dual-power supply electromagnetic brake, which comprises a brake body and a power supply module for supplying power for the brake body; the brake body comprises a yoke in which coils are arranged, a braking part, an armature and an elastic part, wherein the armature is located between the braking part and the yoke, and the elastic part is arranged on one face, opposite to the armature, of the yoke; the power supply module comprises a dual-power supply module, a voltage switcher and a time delay controller, wherein the dual-power supply module is capable of supplying two different voltages, the voltage switcher is electrically connected with the dual-power supply module, and the time delay controller is electrically connected with the voltage switcher; the dual-power supply module is used for supplying a high power supply to the brake body when the brake body is powered up so as to power up the coils in the brake body to pull in the armature; the time delay controller is used for sending out a switching signal to the voltage switcher after being powered up and delayed for a preset time; and the voltage switcher is used for performing switching according to the switching signal of the time delay controller to supply power for the brake body after the high power supply of the dual-power supply module is switched into a low power supply.

Owner:CHONGQING HUAYU ELECTRIC GRP

Transport plane roller choke plug device

InactiveCN102976054AExtended service lifeImprove sealingRollersHydraulic fluidMechanical engineering

The invention provides a transport plane roller choke plug device. A roller bearing and a double-acting bearing are arranged on an axial rotary shaft, the axial rotary shaft, the double-acting bearing and the roller bearing are arranged on a bearing seat in a combined mode, the end portion of the bearing seat is provided with an upper bearing cover through a bolt, a sliding block is connected with the axial rotary shaft, and an hydraulic fluid port is arranged inside the axial rotary shaft. Seal rings respectively arranged on two sides of the axial rotary shaft are arranged on small bearing seats, bearing traction bars arranged on two sides of the sliding block are connected with the bearing seat, and the rear end of the bearing seat is provided with a double-acting bearing cover which is arranged on the inner side of the bearing seat.

Owner:杨梅

Oil pressure buffer

InactiveCN108996359ARealize fully sealed structureNo pollution in the processElevatorsPore diameterCylinder block

The invention discloses an oil pressure buffer, and relates to the technical field of elevator safety components. The oil pressure buffer comprises a cylinder body, a piston, a piston rod, a throttlering and a throttle cone rod, wherein the throttle ring is positioned in the center of the piston; the throttle cone rod is installed in the cylinder body below the piston; the inner diameter of the throttle ring is larger than the outer diameter of the throttle cone rod and the throttle ring and the throttle cone rod are coaxially arranged; a first communication hole is formed in the bottom of the piston rod; a second communication hole positioned above the throttle ring is formed in the center of the top of the piston; a third communication hole positioned below the throttle ring is formed in the center of the bottom of the piston; and the first communication hole, the second communication hole and the throttle ring communicate with the third communication hole in sequence. According tothe oil pressure buffer, a gap between the throttle ring and the throttle cone rod is increased, and communication holes with different pore diameters are formed in the upper portion and the lower portion of the throttle ring, so that the oil feeding rate and the oil feeding amount are increased, the oil feeding speed is obviously improved, and the problem that the oil pressure buffer takes too long to fill hydraulic oil is solved.

Owner:镇江朝阳机电科技有限公司

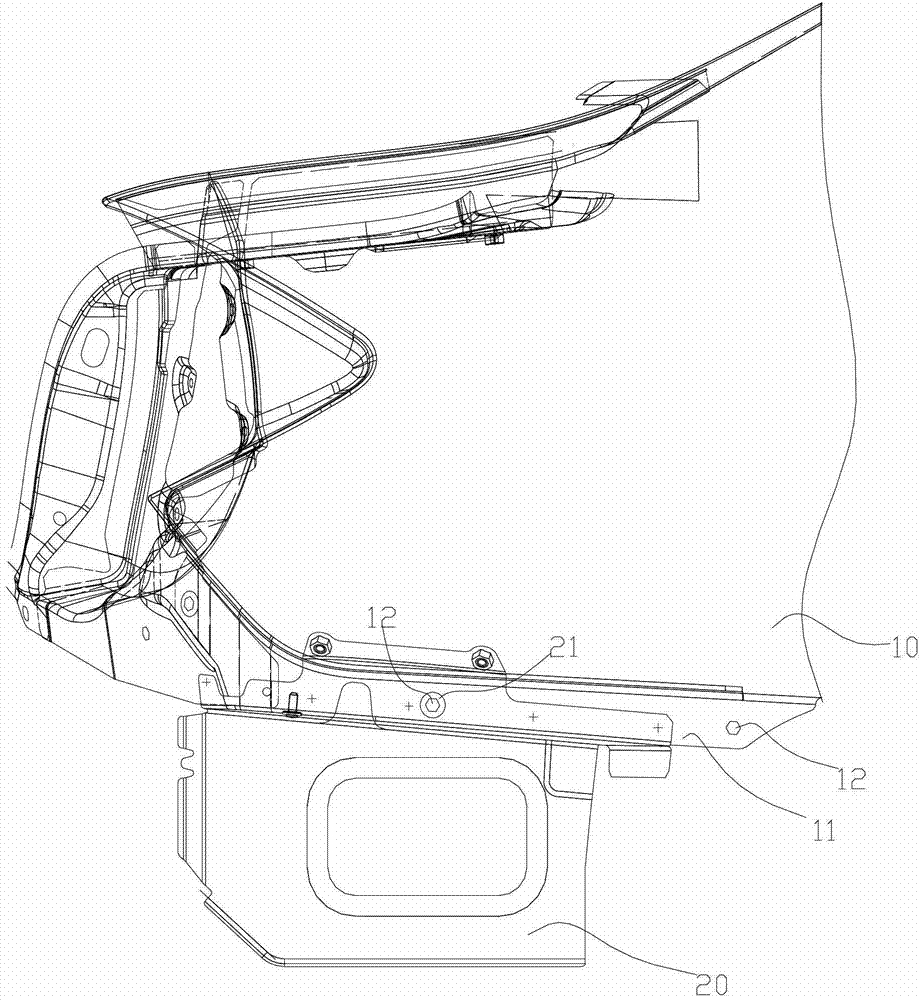

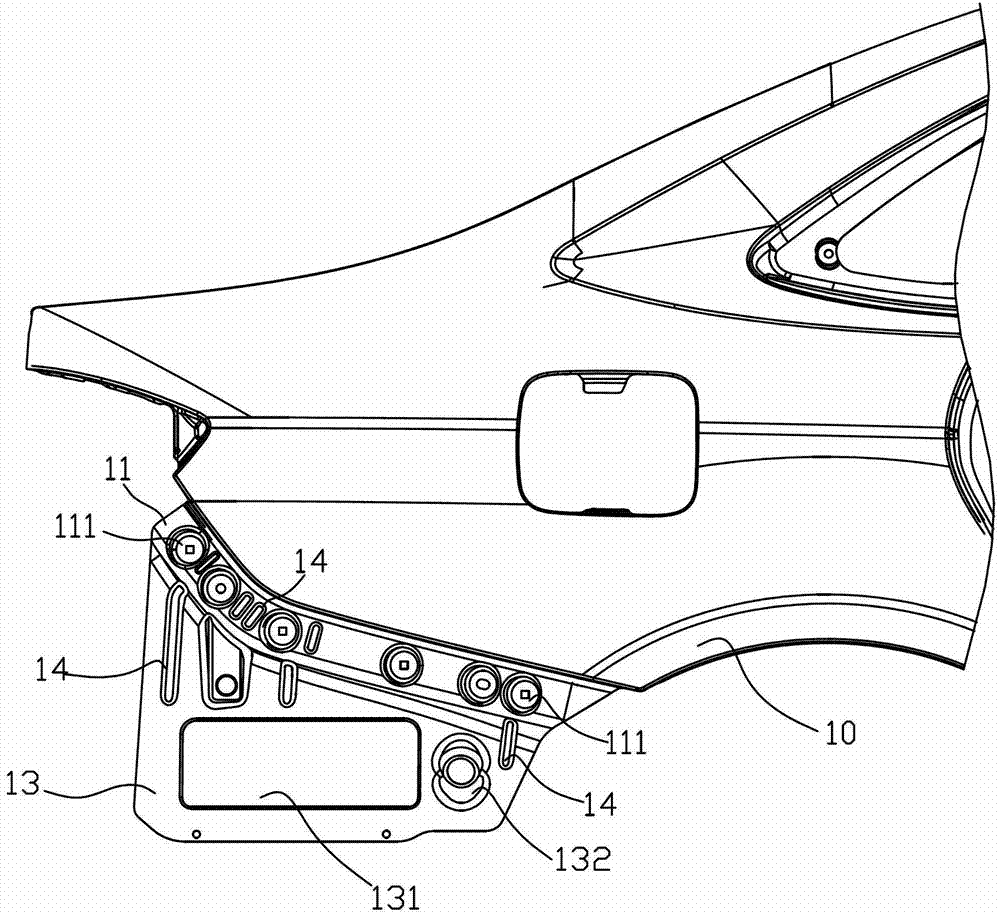

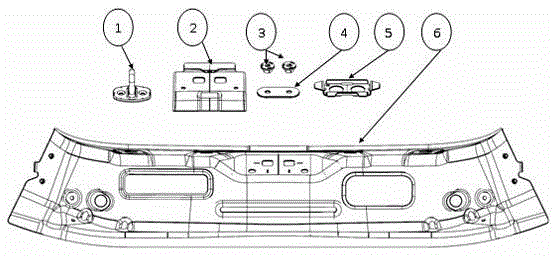

Tail gate lock catch installation structure

InactiveCN104670340AClearance is easy to controlSuperstructure subunitsEngineeringMechanical engineering

The invention provides a tail gate lock catch installation structure comprising bolts, a tail gate lock catch, a tail gate lock catch reinforcing plate, lock catch installation nuts, a tail gate lock catch installation plate and a nut bracket. The nut bracket is connected with the outer side face of the tail gate lock catch reinforcing plate, a hollow cavity is arranged between the nut bracket and the outer side face of the tail gate lock catch reinforcing plate, the tail gate lock catch installation plate is arranged in the hollow cavity, the tail gate lock catch is matched with the lock catch installation nuts through the bolts and is closely attached to the inner side face of the tail gate lock catch reinforcing plate, installation holes are arranged in the tail gate lock catch installation plate, and the bolts penetrate the installation holes in the tail gate lock catch installation plate to be matched with the lock catch installation nuts. The tail gate lock catch installation structure has the advantages that the tail gate lock catch installation plate can move freely in the hollow cavity, so that the installation position of the tail gate lock catch can be adjusted by adjusting the tail gate lock catch installation plate in position, and tail gate clearance is beneficially controlled.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

A carton packing machine with multiple strapping straps

The invention discloses a packing machine capable of packing a carton box through multiple binding tapes. The packing machine comprises a tape binding machine, a conveying belt and a carton box limiting device; the tape binding machine is composed of a supporting platform at the lower part and a frame body at the upper part; the conveying belt is arranged on the supporting platform and penetratesthrough the frame body; the carton box limiting device comprises a pair of horizontal supporting plates; and a pair of upper supporting plates which are symmetrical front and back are formed in the upper end surface of the frame body, the pair of horizontal supporting plates are arranged on the opposite end surfaces of the pair of upper supporting plates in a left-and-right sliding mode correspondingly, a pair of central supporting rods are arranged between the left parts of the pair of horizontal supporting plates in a synchronous rotating mode correspondingly, telescopic supporting rods arearranged at the two ends of the central supporting rods in a telescopic mode correspondingly, and a limiting roller is connected between the pair of telescopic supporting rods on the same side in a pivoting mode. According to the packing machine, the carton box can be bound with the multiple binding tapes, the packing machine can be adapted to the carton boxes with different sizes, and the gaps between the multiple binding tapes can be controlled.

Owner:厦门市欣捷龙包装有限公司

Carton strapping machine with inclined ejection type resistance function

ActiveCN108860824AClearance is easy to controlWrapper twisting/gatheringBinding material applicationCartonEngineering

The invention discloses a carton strapping machine with an inclined ejection type resistance function. The carton strapping machine comprises a strapping machine, a conveying belt and a carton limiting device. The strapping machine comprises a supporting platform on the lower portion and a frame on the upper portion. The conveying belt is arranged on the supporting platform and penetrates throughthe frame. The carton limiting device comprises a pair of horizontal supporting plates and an upper supporting plate, wherein the horizontal supporting plates are symmetrically arranged in a front-and-rear mode. The horizontal supporting plates are fixed to the upper end face of the frame, and rectangular sleeve bodies are connected to the end faces, close to each other, of the right portions of the horizontal supporting plates in a pivot joint mode. Sliding rods are inserted into the sleeve bodies, the upper ends of the sliding rods are hinged to the front end face and the rear end face of the upper supporting plate, and a limiting roller is connected between the lower ends of the sliding rods in a pivotal mode. A telescopic rod is arranged at the lower end of the upper supporting plate and arranged in a left-and-right horizontal movement mode. An angle adjusting device is arranged on the horizontal supporting plate on the front side, and used for adjusting the inclination angle of the cover body on the front side. By the adoption of the carton strapping machine, a carbon can be strapped with a plurality of strapping strips, the carton strapping machine adapts to cartons with different sizes, and the gap between every two adjacent strapping strips is controllable.

Owner:江西客家彩印包装有限责任公司

Heat conduction comb tooth device of electric heating hair straightening comb

ActiveCN112401438AImprove hair straightening efficiencyImprove installation efficiencyCurling devicesHair combsHair straighteningEngineering

The invention provides a heat conduction comb tooth device of an electric heating hair straightening comb. The device comprises a comb tooth unit and a comb tooth base, the comb tooth unit comprises aplurality of comb teeth which are inserted side by side, each comb tooth is sheet-shaped and has a bent cross section, and the cross section in a comb tooth main body part comprises a first arc located at the central part and two second arcs located at two sides of the first arc. The bending direction of the second arc is opposite to that of the first arc, and the curvature radius of the second arc is smaller than that of the first arc; first installation structures for fixedly installing the comb teeth and the comb tooth base are arranged on the two sides of the roots of the comb teeth respectively, second installation structures matched with the first installation structures are correspondingly arranged on the comb tooth base, and the first installation structures are inserted into thesecond installation structures in a sliding mode in the length direction of the comb tooth base. By the adoption of the specific comb tooth shape, the inserting structure between the comb teeth and the detachable structure of the comb tooth unit and the comb tooth base, hair straightening efficiency is improved, accurate positioning can be achieved, installation is convenient, and installation efficiency is improved.

Owner:上海飞美丝网络科技有限公司 +1

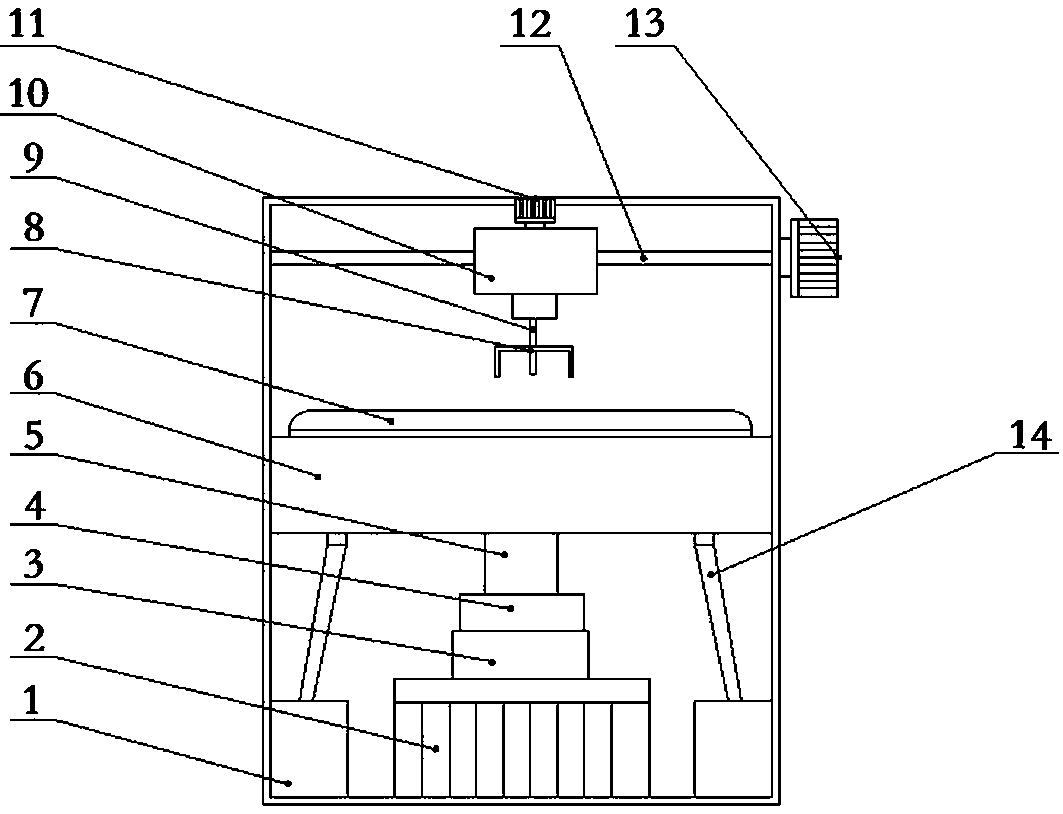

Grinding and polishing machine

The invention discloses a grinding and polishing machine. The grinding and polishing machine comprises a rack, a work table installed on the middle part of the rack in the up-and-down direction, a polishing disk rotatably installed on the work table, a first drive assembly used for driving the polishing disk to rotate around the own axis, polishing cloth attached to the upper surface of the polishing disk, a locking piece coaxial with the polishing disk and a clamp installed on the rack, located above the work table and used for clamping workpieces; a clamping part is outwards reserved on theperiphery of the polishing disk through the polishing cloth; and the locking piece comprises a pressing ring part, a sleeve part and a connecting part for connecting the pressing ring part and the sleeve part, the pressing ring part presses the periphery of the part, located on the upper surface of the polishing disk, of the polishing cloth, the sleeve part is installed on the polishing disc in asleeving manner and used for clamping the clamping portion between the sleeve part and the side face of the polishing disk, the pressure ring part is provided with a first flow guide groove in the radial direction, and the sleeve part is internally provided with a second flow guide groove. By means of the grinding and polishing machine, the polishing cloth is easily fixed, and the fixing reliability is relatively good.

Owner:UNIV OF JINAN

Mixer door adjustment device

Owner:WUXI HUAZHONG TECH

Paper box packing machine driven by swing rods

The invention discloses a paper box packing machine driven by swing rods. The paper box packing machine comprises a belt bundling machine, a conveying belt and a paper box limiting device, wherein thebelt machine is composed of a lower supporting platform and an upper frame body; the conveying belt is arranged on the supporting platform and penetrates through the frame body, the paper box limiting device comprises a pair of L-shaped horizontal supporting plates which are symmetrically arranged in a front-back symmetry mode, and a plurality of lifting supporting blocks are movably arranged between horizontal parts of the horizontal supporting plates in a left and right mode; limiting plates are arranged on the lifting supporting blocks from top to bottom in an inserted mode, the lengths ofthe limiting plates arranged from the left to the right are sequentially shortened, and an upper supporting plate is fixed at the upper ends of the limiting plates; and cylindrical driving rods are formed on the front end face and the rear end face of the upper supporting plate, the swing rods are hinged to the end faces, close to vertical portions, of the pair of the horizontal supporting plates, and the swing rods are provided with long-hole-shaped guide grooves which penetrate back and forth. According to the machine, a carton can be bundled with multiple nylon cable ties, the machine is adaptive to the paper boxes with different sizes, and the gaps between the multiple bundling nylon cable ties are controllable.

Owner:SHANGHAI ZIQI IND

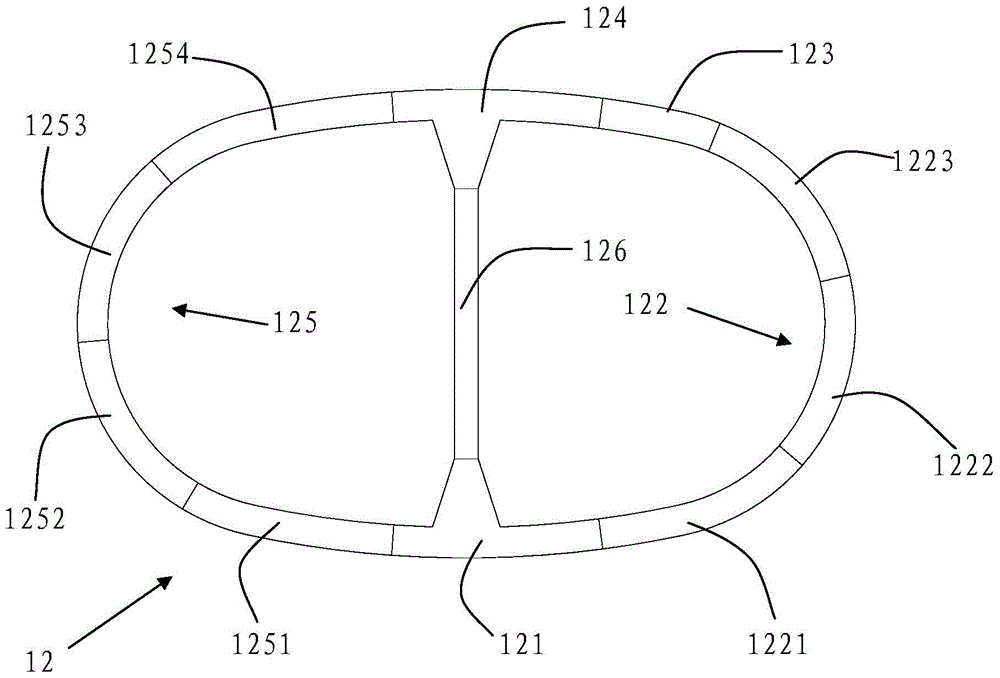

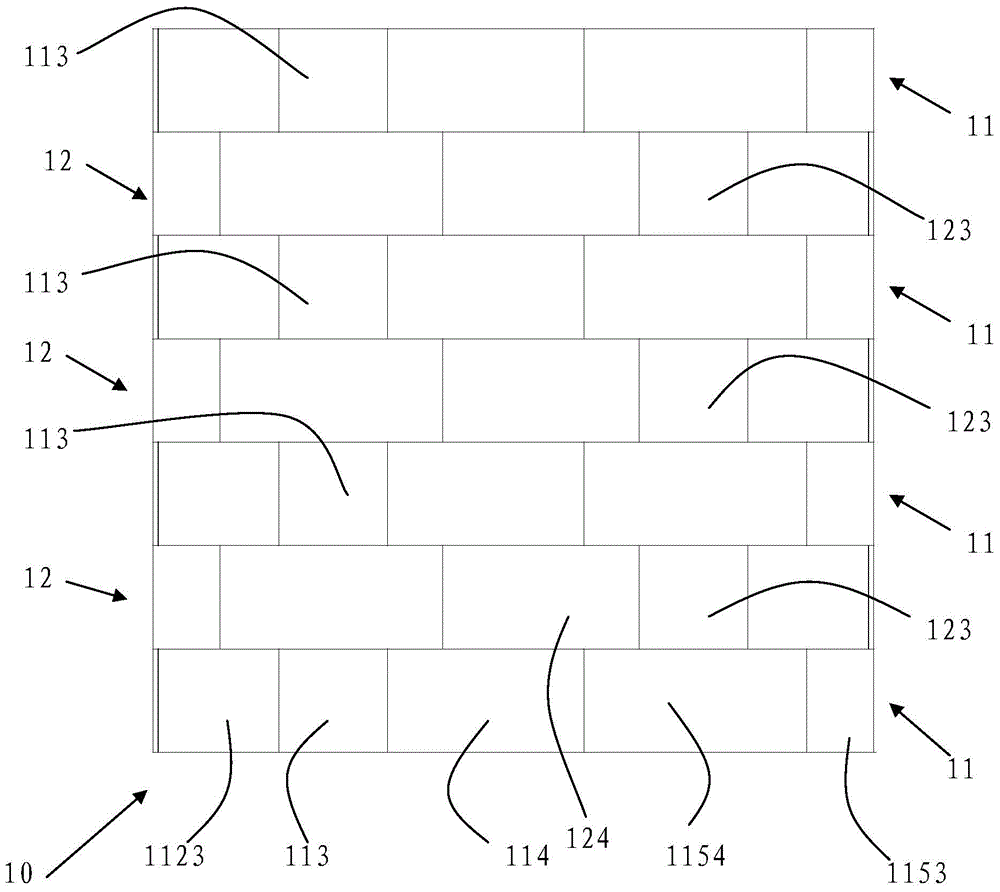

Heat dissipation structure of electric device and manufacturing method thereof

ActiveCN103974601BImprove cooling effectClearance is easy to controlConversion constructional detailsSemiconductor/solid-state device detailsElectrical conductorHeat resistance

A heat dissipation structure for an electrical device (Qa‑Qd, 16), comprising: at least one multilayer substrate (12, 12A, 12B) comprising a conductor pattern (12c) and made of an insulating material A plurality of base parts (121‑125) formed, the conductor pattern and the plurality of base parts are stacked into a multi-layer structure to electrically connect the conductor pattern and the interlayer connection (L1‑L10) in the base part; the electrical device has At least one of a first electrical component (Qa-Qd) built into at least one multilayer substrate and a second electrical component (16) not built into the multilayer substrate; and a low thermal resistance component opposite to the electrical device ( 13). Low thermal resistance components have lower thermal resistance than insulating materials.

Owner:DENSO CORP

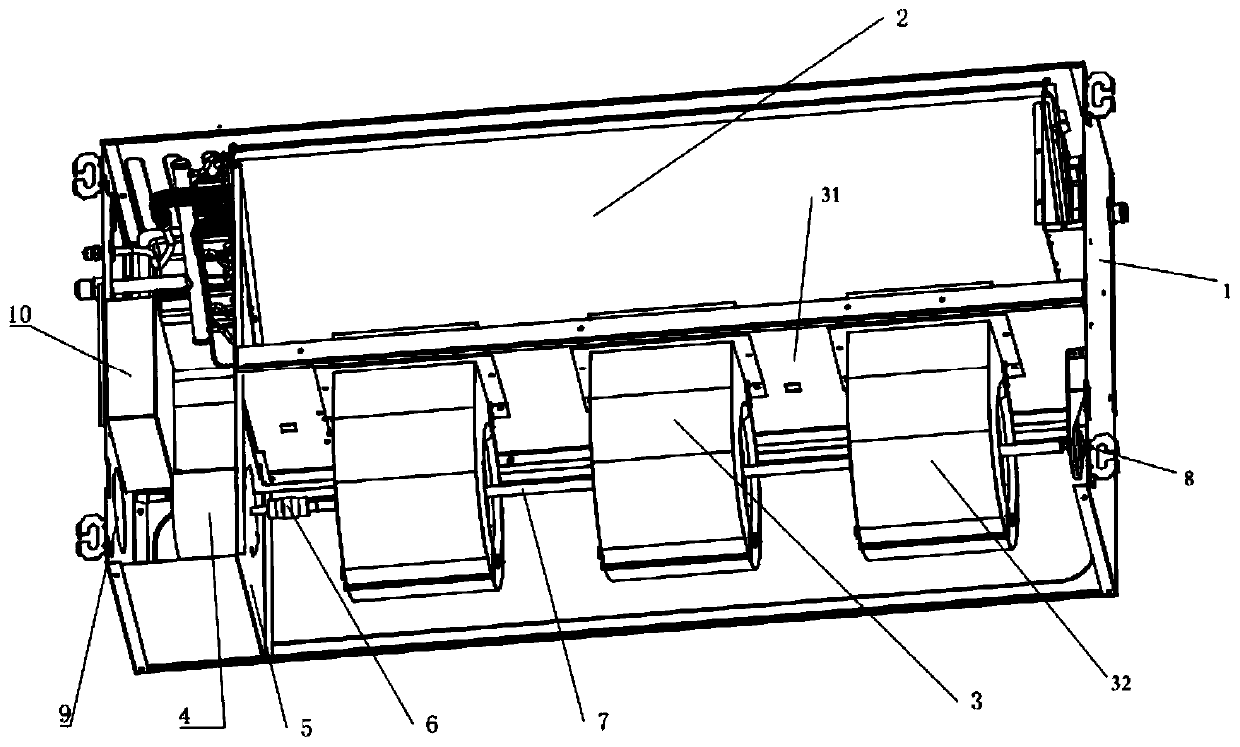

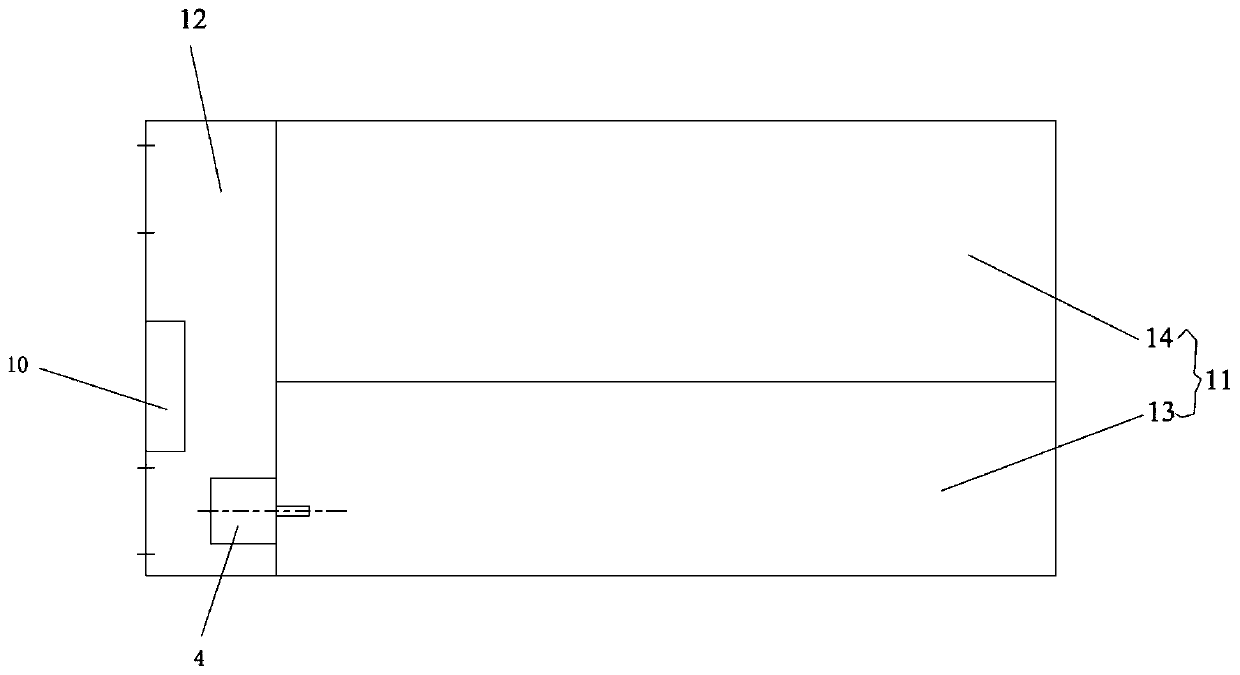

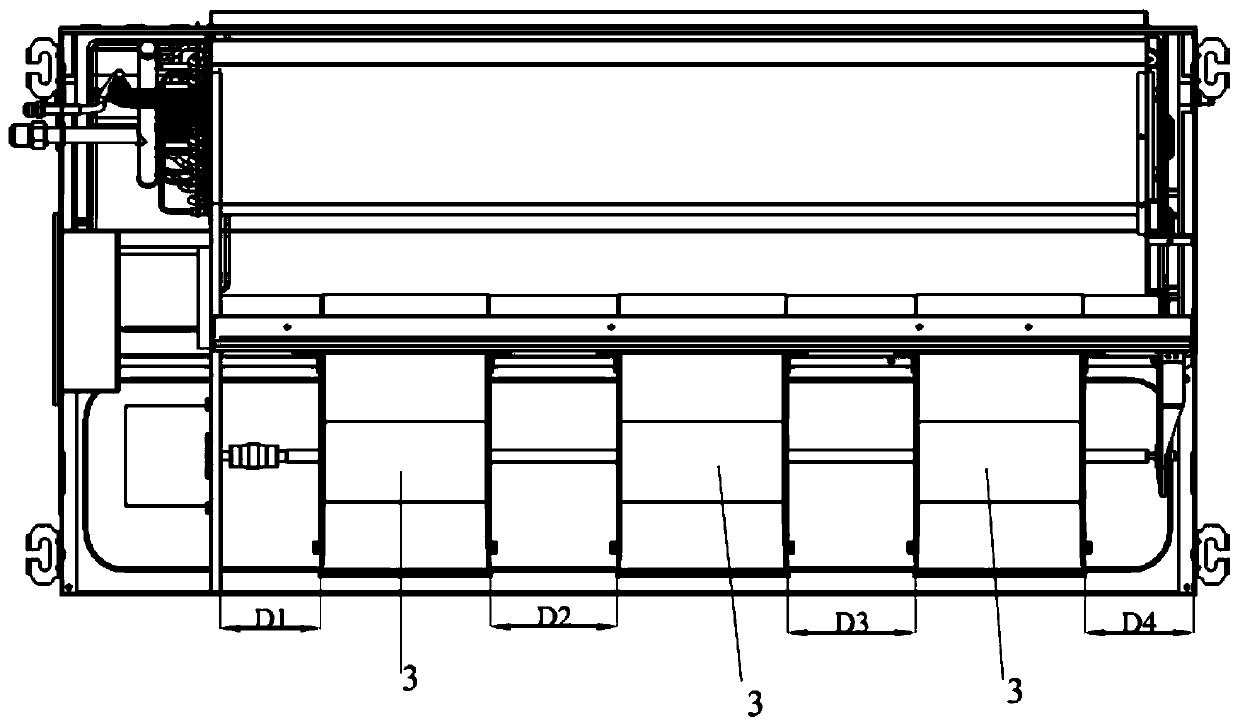

Air duct type air conditioner

PendingCN110207262AAvoid air flowAvoid noiseLighting and heating apparatusNoise suppressionInterior spaceAir volume

The invention provides an air duct type air conditioner. The air conditioner comprises a shell, an evaporator, a plurality of fans and a driving device, and further comprises a sealing plate. The sealing plate is located in an internal space of the shell and partitions the internal space of the shell into a first space and a second space. The multiple fans are located in the first space, and the driving device is located in the second space. According to the air duct type air conditioner, the driving device is isolated from a fan system, and influences of the driving device on the overall blast capacity and noise in the fan running process are avoided.

Owner:NINGBO AUX ELECTRIC

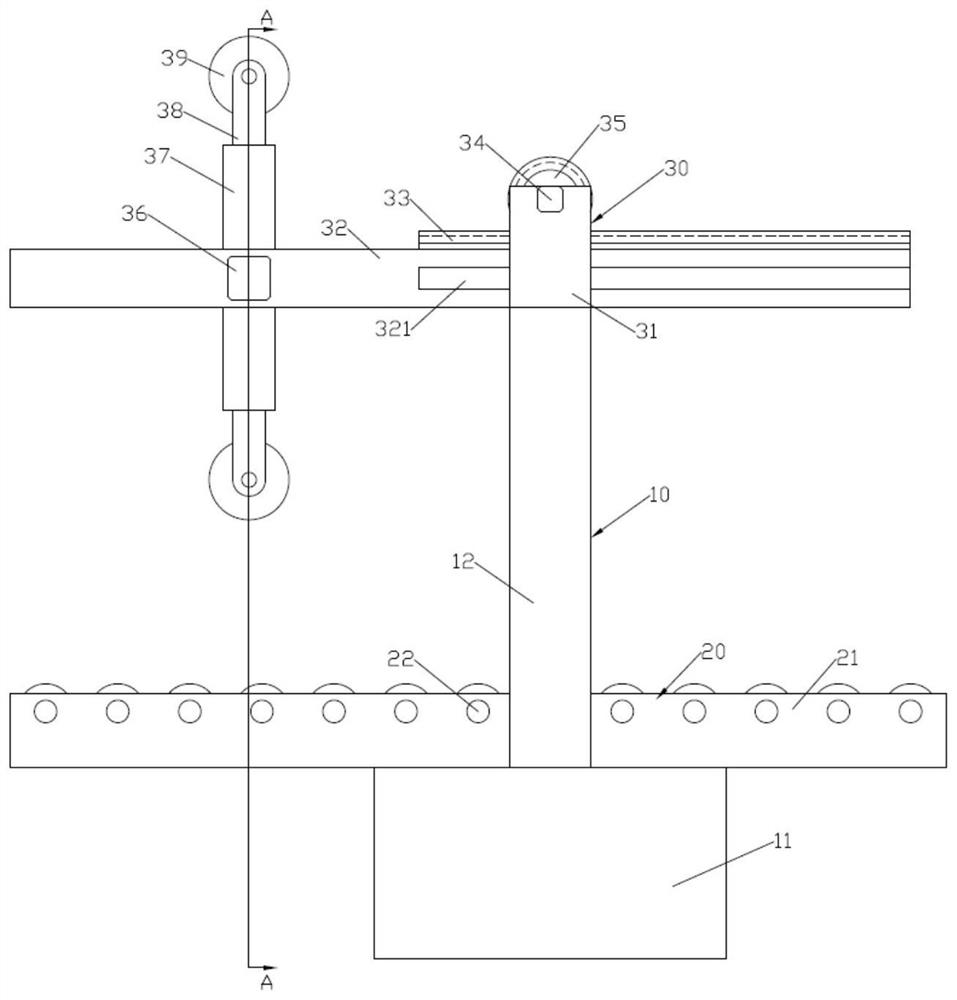

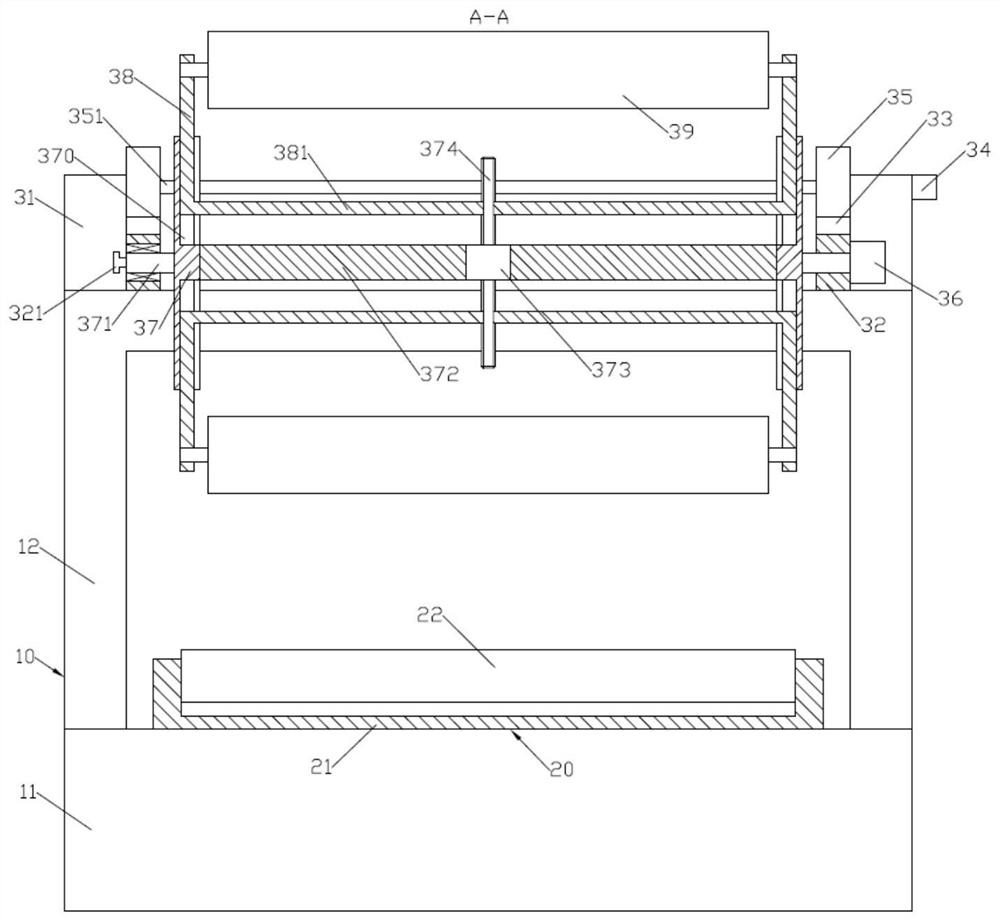

Mixing cylinder door adjusting device

The invention relates to a mixing cylinder door adjusting device. A guide rail is fixed at the bottom end part of a mixing cylinder, channel steel is fixed on a mixing cylinder door, a steel angle is fixed on the channel steel, a pulley is rotationally arranged on a pulley shaft and is matched with the guide rail, an adjusting hole which is waist-shaped is formed in the steel angle, the length direction of the adjusting hole is distributed along a height direction of the steel angle, the pulley shaft is fixed in the adjusting hole, an adjusting nut is fixed on the steel angle, an adjusting bolt is screwed in the adjusting nut, and the bottom end part of the adjusting bolt pushes against the pulley shaft. After the mixing cylinder door adjusting device is assembled and used, the adjusting operation is very convenient, a gap between the mixing cylinder and the mixing cylinder door can be controlled conveniently, and the mixing cylinder door adjusting device has the advantages of simple structure, reliability in use and the like.

Owner:WUXI HUAZHONG TECH

Rotary powder scraping device

InactiveCN108625571ACollect scrape wellPrevent fallingDispersed particle filtrationBuilding constructionsHydraulic cylinderEngineering

The invention relates to a rotary powder scraping device. The rotary powder scraping device mainly comprises a bottom plate and an air suction pipe, a hydraulic cylinder is arranged on the left side of the upper part of the bottom plate, and a suction piece is arranged above the hydraulic cylinder. A protective cover is fixed to the right side of the suction piece. The protective cover is internally provided with a scraping block. A fixing plate is mounted on the right side of the scraping block. A motor is fixed to the right side of the fixing plate. A rotating shaft is arranged on the rightside of the motor. A support rod is arranged on the right side of the rotating shaft. The protective cover is fixed to the left side of the air suction pipe. A draught fan is disposed under the air suction pipe. A powder collecting chamber is installed under the draught fan. A horizontal plate is fixed inside the powder collecting chamber. By arranging the protective cover, the protective cover isin a trapezoid shape by a side section view, and the scraped powder can be collected well; and at the same time, the protective cover and a wall are fixedly connected through the suction piece on theouter side of the protective cover, and therefore the powder is prevented from falling.

Owner:广州元坤新材料有限公司

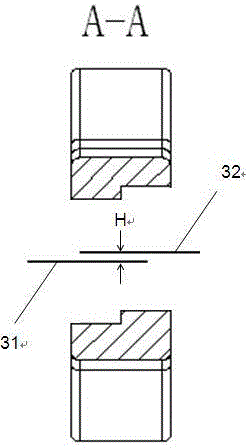

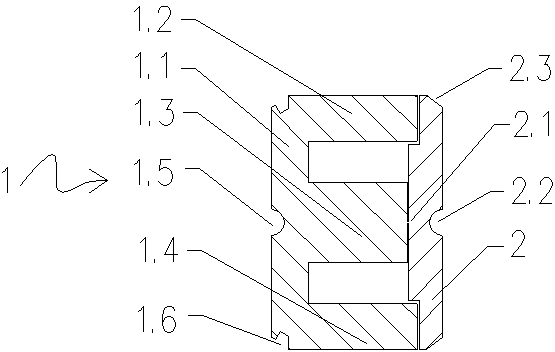

EI-type silicon steel sheet

InactiveCN104252956AClearance is easy to controlSimplify the assembly processTransformers/inductances magnetic coresInductances/transformers/magnets manufactureSilicon

The invention relates to an EI-type silicon steel sheet which comprises an E-type silicon steel sheet (1) and an I-type silicon steel sheet (2) which are arranged left and right. The EI-type silicon steel sheet is characterized in that the E-type silicon steel sheet (1) comprises a vertical section (1.1) as well as a first transverse section (1.2), a second transverse section (1.3) and a third transverse section (1.4) which are respectively connected to the upper part, the middle part and the lower part of the right side of the vertical section (1.1), wherein a raised step (2.1) is arranged in the middle of the left side of the I-type silicon steel sheet (2), and right ends of the first transverse section (1.2) and the third transverse section (1.4) of the E-type silicon steel sheet (1) are just positioned outside the step (2.1) of the I-type silicon steel sheet. When the EI-type silicon steel sheet is mounted, the right ends of the first transverse section and the third transverse section of the E-type silicon steel sheet are just positioned outside the step of the I-type silicon steel sheet, so that a clearance is easy to control, the assembly process is simple, and the efficiency is relatively high.

Owner:JIANGYIN CHUANGJIA ELECTRICAL APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com