Bent pipe machining method and bent pipe

A processing method and pipe bending technology, which is applied in the field of pipe bending processing, can solve the problems of reduced weight and large thickening of the pipe system, and achieve the effect of reasonable structure and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

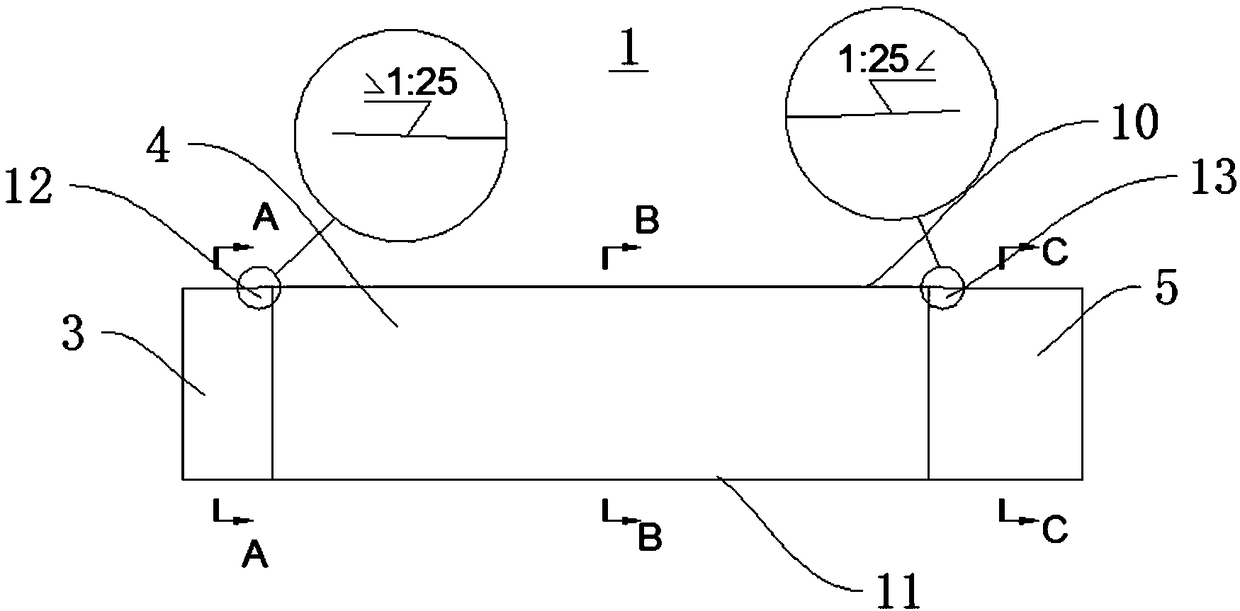

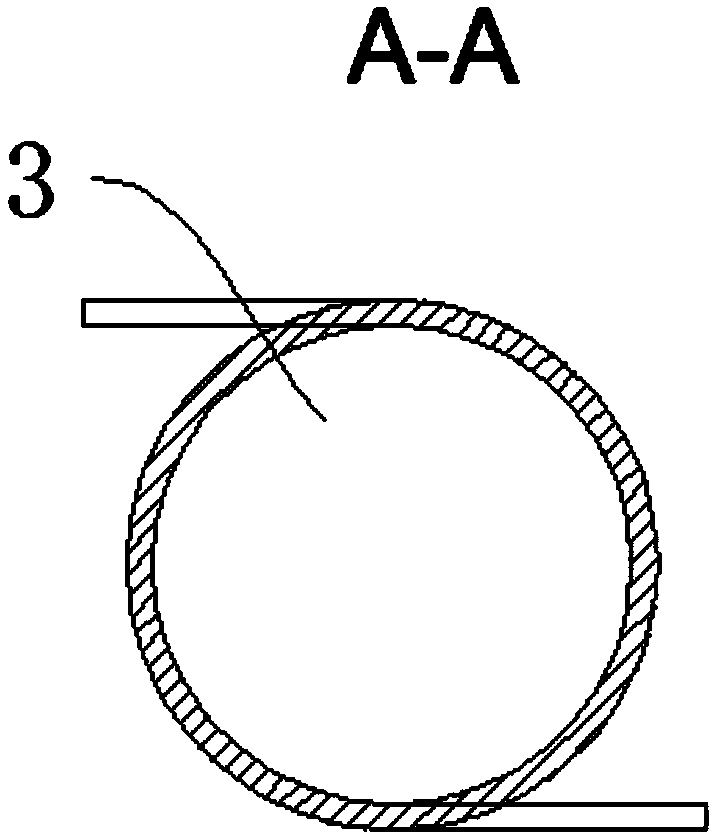

[0038] This embodiment provides an elbow, and the specific structure is described below.

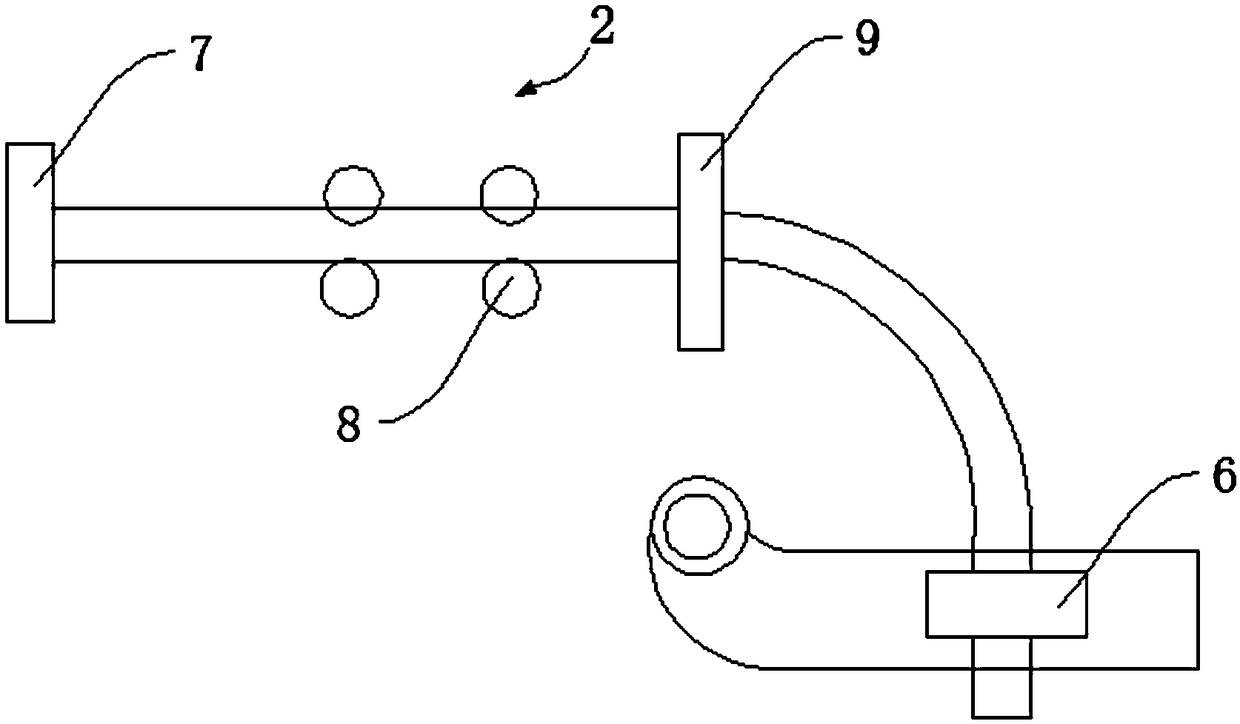

[0039] Please refer to figure 1 , with reference to figure 2 , the specific steps of the processing method of the bent pipe include:

[0040] Step S1: Install the eccentric straight pipe 1 on the support platform, put the intermediate frequency induction heating ring 9 on the section 4 to be bent, install the first pipe section 3 in the guide assembly 8 removably, and clamp it with the front chuck 6 Hold the end of the second pipe section 5, clamp the end of the first pipe section 3 with the push-back bending chuck 7, and push the first pipe section 3 to move along the direction of the processing section 4 to be bent;

[0041] Step S2: Pass an intermediate frequency current into the intermediate frequency induction heating ring 9 to heat the section 4 to be bent, when the temperature of the section 4 to be bent rises to a plastic state, push the first pipe section 3 with mechanical th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com