Transport plane roller choke plug device

A combination installation technology of rollers, which is applied in the direction of transportation and packaging, conveyor objects, rollers, etc., can solve the problems of reduced service life of the boring head assembly, inconvenient addition of lubricating oil, easy damage to the bearing gap, etc., to achieve bearing Clearance is easy to control, long service life, not easy to leak the effect of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

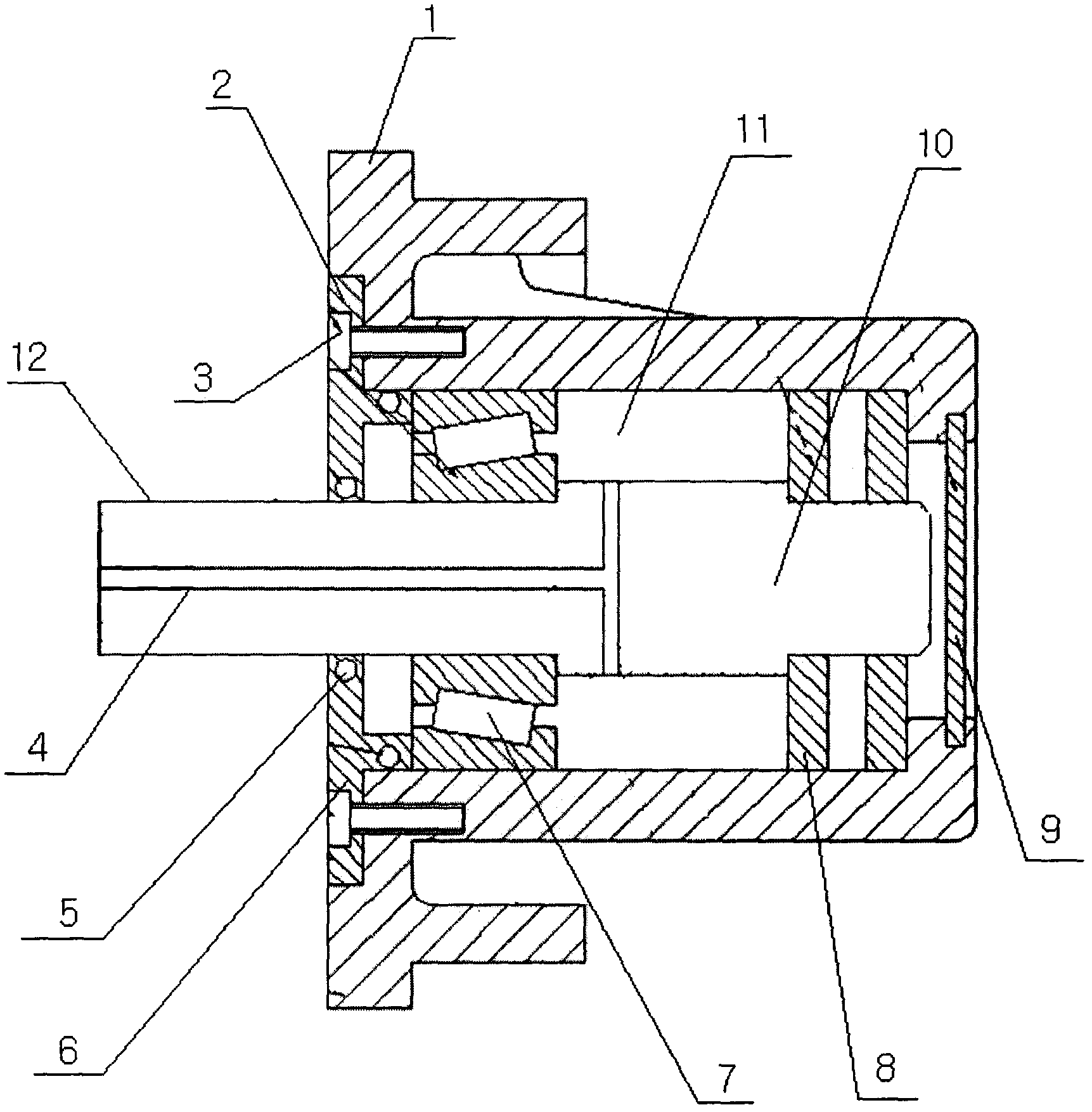

[0008] The idler roller device has a ball bearing (7) and a double-acting bearing (8). The roller bearing (7) and the double-acting bearing (8) are installed on the axial shaft (12), and the axial shaft (12), The double-acting bearing (8) and the roller bearing (7) are installed on the top of the bearing seat (1); at the same time, the upper bearing cover (2) is installed on the end of the bearing seat (1) with bolts (3), and the (10) There is an axial rotating shaft (12) connected to it, and an oil port (4) is installed inside the axial rotating shaft (12), and sealing rings (5) are respectively installed on both sides of the axial rotating shaft (12), and the sealing rings ( 5) Installed on the small bearing seat (6), a bearing thrust rod (11) is installed on both sides of the slider (10), the bearing thrust rod (11) is connected with the bearing seat (1), and on the bearing seat (1) A double-action bearing cap (9) is installed at the rear end, and the double-action bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com