Rotary powder scraping device

A rotary and rotating shaft technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, can solve the problems of inability to rotate powder scraping, scratches on the wall, troublesome decoration work, etc., to avoid splashing , avoid scratches, facilitate the effect of speed and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

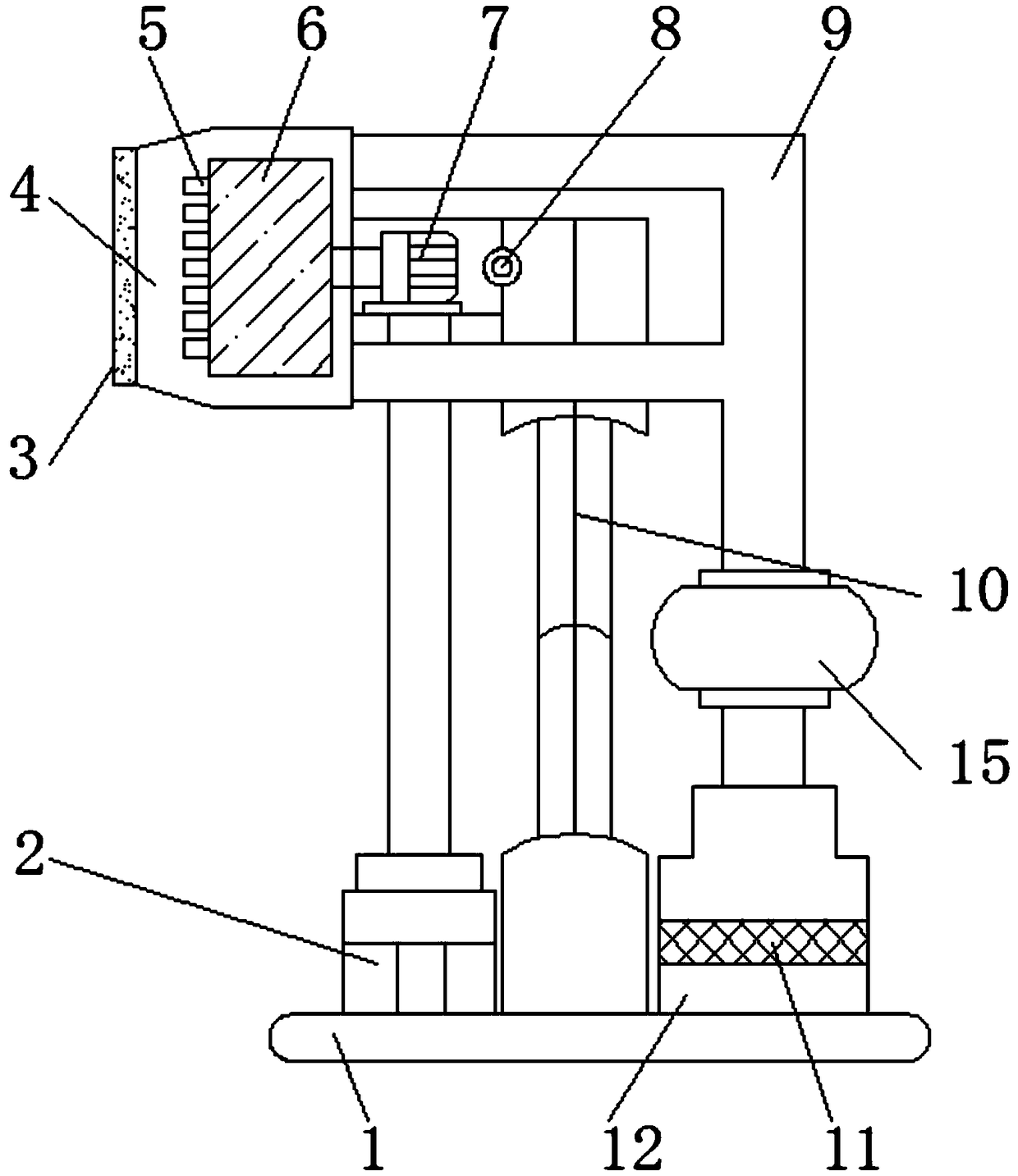

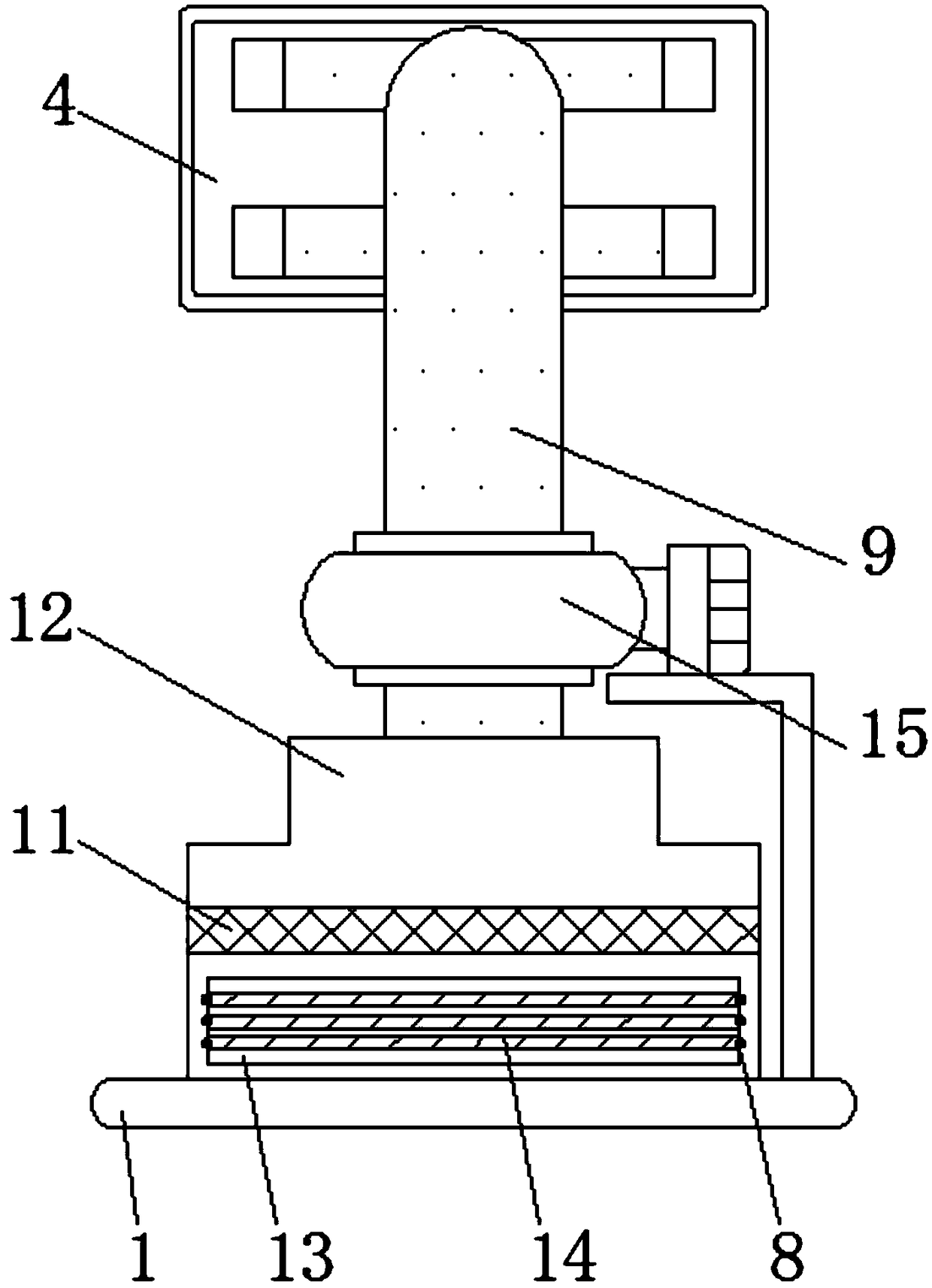

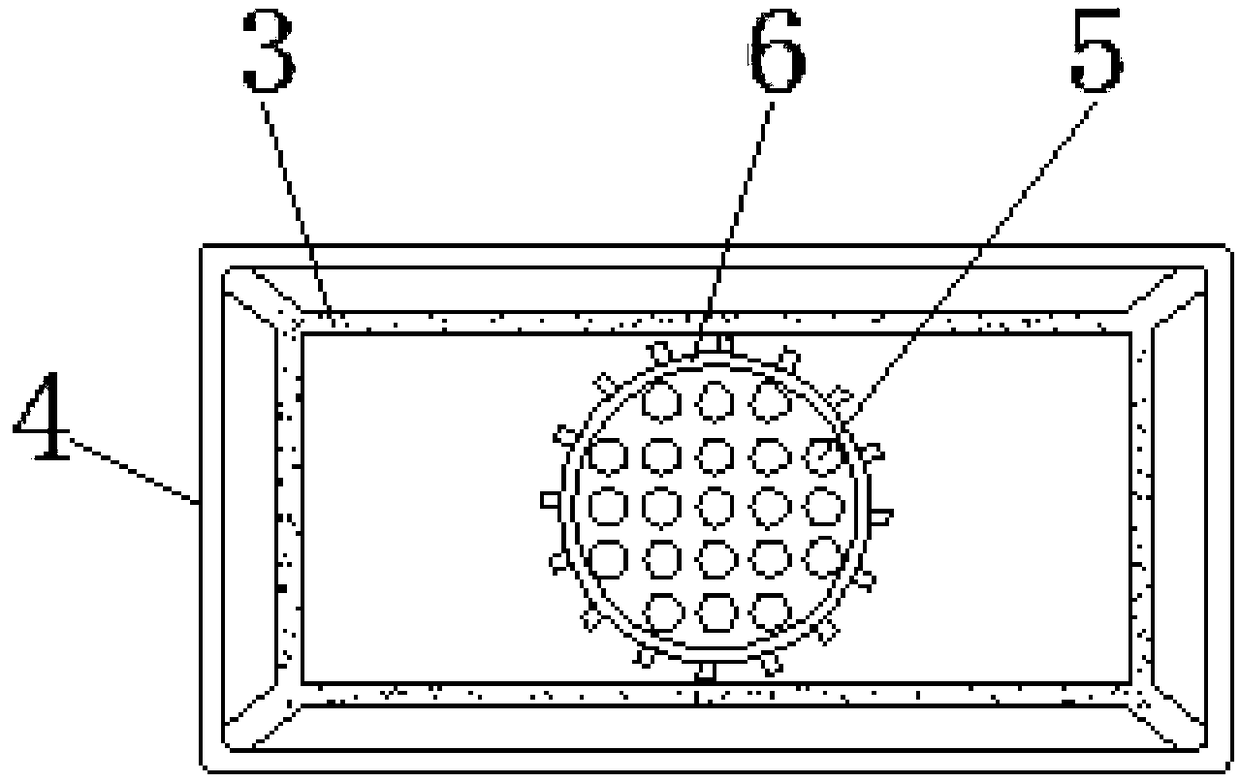

[0016] Such as Figure 1-Figure 3 As shown, a rotary powder scraping device mainly includes a base plate 1, a hydraulic cylinder 2, a suction piece 3, a protective cover 4, a scraper block 5, a fixed plate 6, a motor 7, a rotating shaft 8, a suction pipe 9, and a support rod 10 , Horizontal plate 11, dust collection chamber 12, through groove 13, support plate 14 and blower fan 15.

[0017] A hydraulic cylinder 2 is arranged on the upper left side of the bottom plate 1, and a suction piece 3 is installed above the hydraulic cylinder 2, and a protective cover 4 is fixed on the right side of the suction piece 3, and a scraper 5 is arranged inside the protective cover 4, and the protective cover The side section of 4 is trapezoidal, and the protective cover 4 is a telescopic structure, and the protective cover 4 and the suction piece 3 are integrally structured. The side section of the protective cover 4 is trapezoidal, which can well avoid the splashing of impurities, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com