Novel carrier roller choke plug assembly of belt conveyer

A belt conveyor and idler technology, applied in conveyor objects, transportation and packaging, rollers, etc., can solve the problems of low total stop service life of bulkheads, inconvenient lubricating oil addition, and difficult bearing clearance control, etc. The clearance is easy to control, the service life is long, and the bearing sealing effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

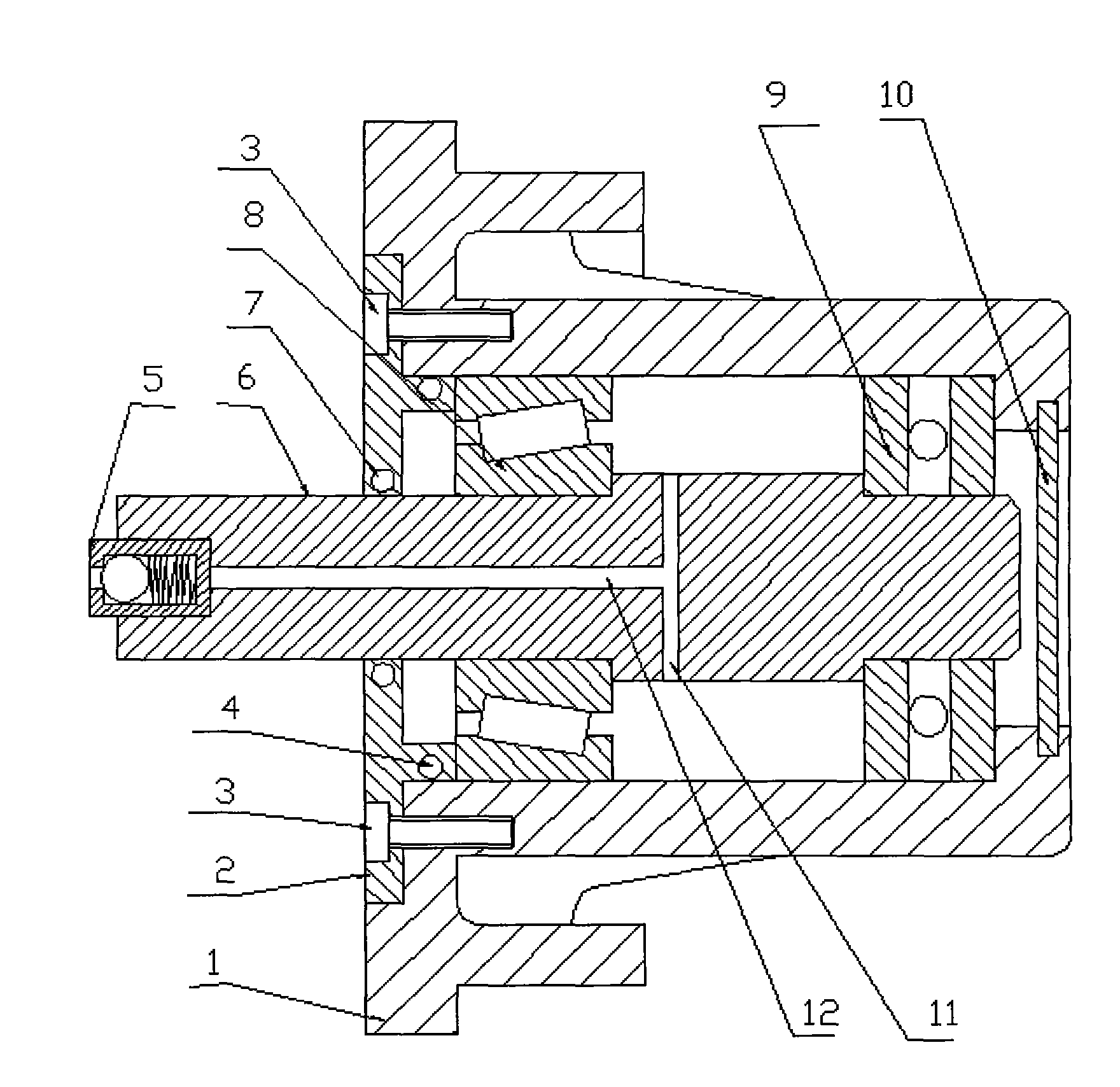

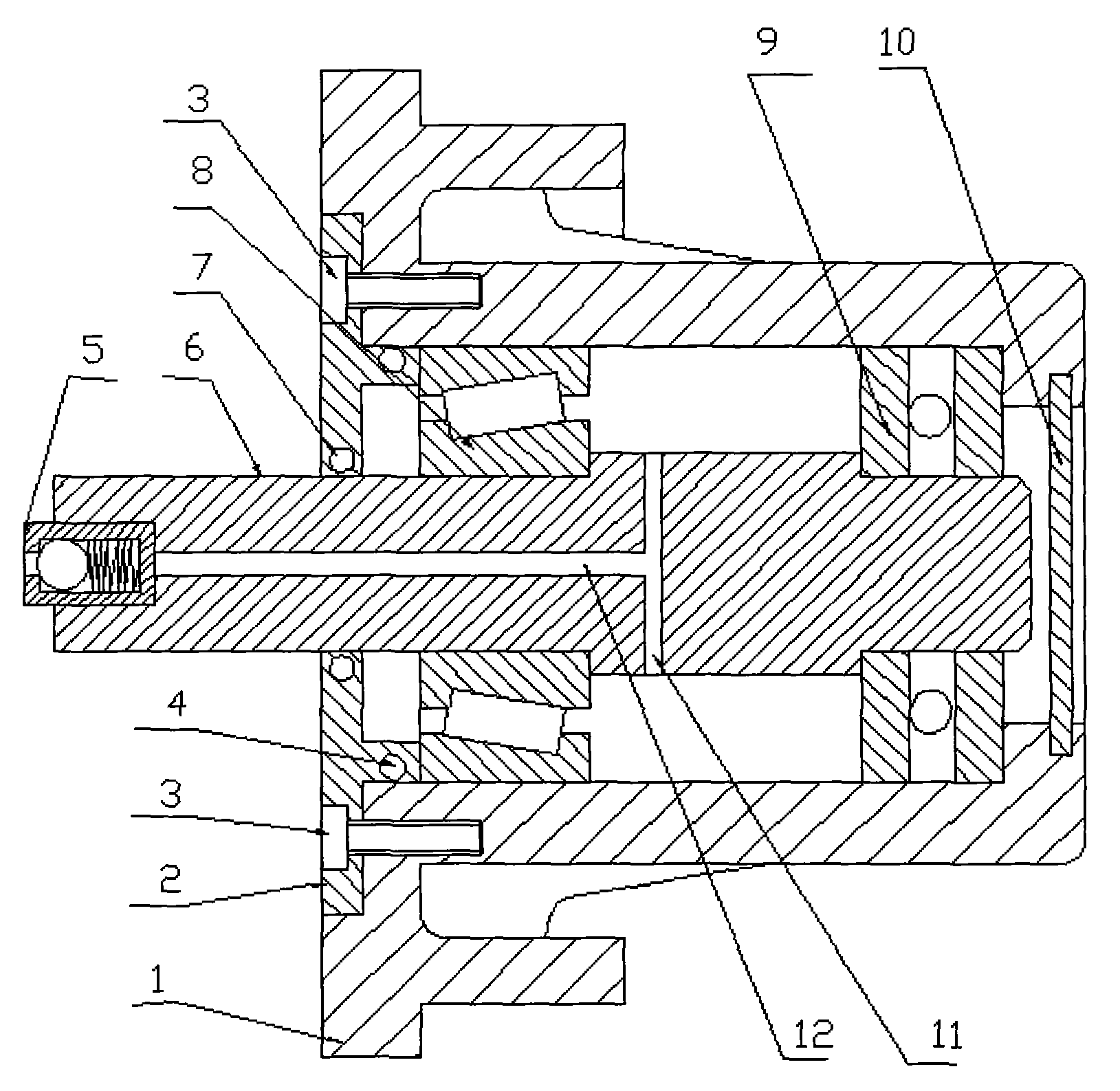

[0008] Install the single-row tapered roller bearing (8) and the thrust bearing (9) on both ends of the steps of the rotating shaft (6) in sequence, and install the rotating shaft (6) on the bearing housing through the single-row tapered roller bearing (8) and the thrust bearing (9) (1) In the through hole in the middle, in order to facilitate the lubrication and oiling of the bearing, an axial oil port (12) is opened at the oil port of the rotating shaft, and another through oil port (11) is opened on the rotating shaft along the vertical direction of the axis , the two oil ports intersect. Install a standard oil nozzle (5) at the oil port at the end of the rotating shaft, in order to facilitate the adjustment and pre-tightening of the bearing clearance, and also to fix the rotating shaft (6) in the bearing seat (1). The port portion of the seat (1) is positioned and installed with the gland fixing bolt (3) to install the bearing gland (2), and the upper part of the bearing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com