Fully-automatic box assembling equipment

A fully automatic, framing technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as instability, framing angle errors, etc., to improve quality, save time, and improve assembly. Corner quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

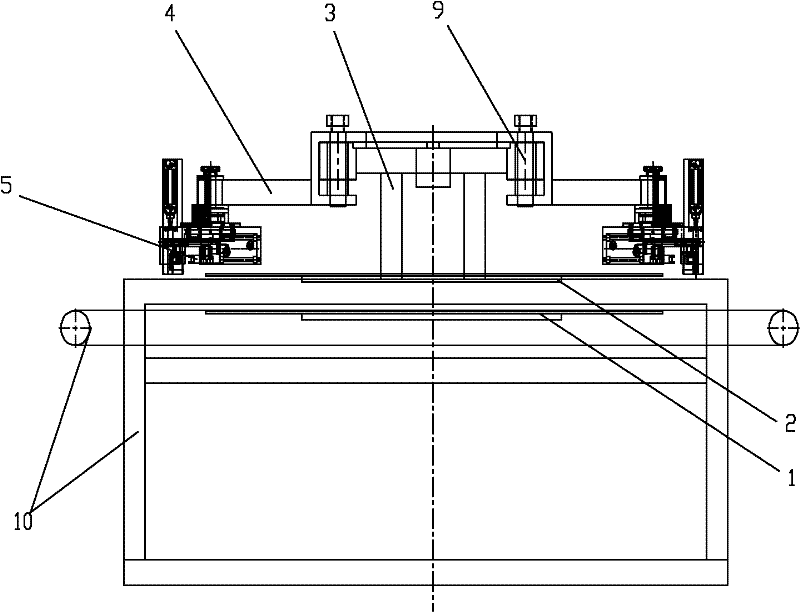

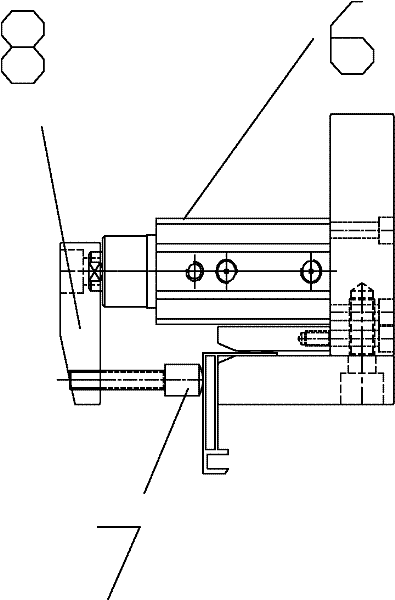

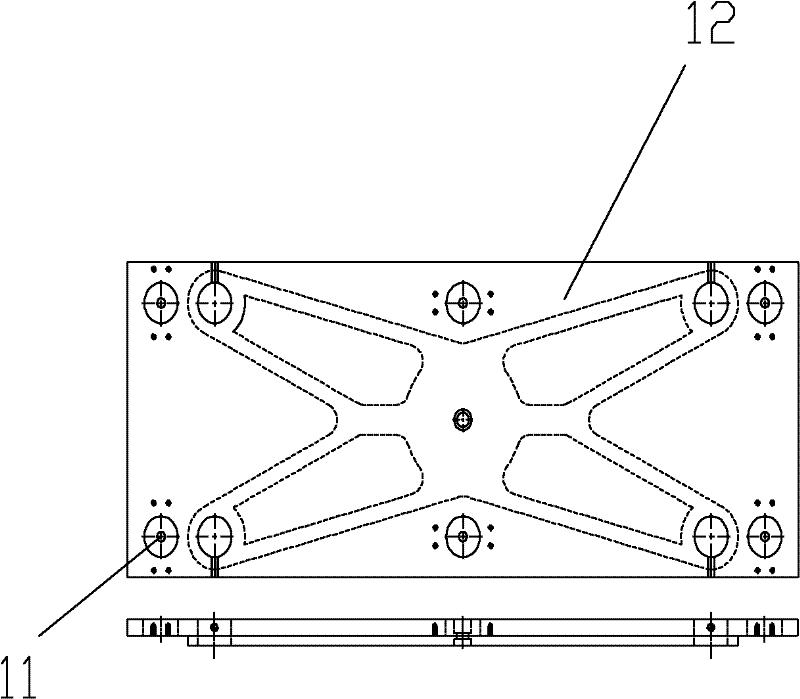

[0014] Such as Figure 1-3 , a fully automatic framing equipment, the equipment includes a frame and a conveyor belt 10, a glass lifting platform 1 and a frame aluminum profile pushing mechanism 2 on the glass lifting platform 1, and a gantry-type group corner floating is provided on the glass lifting platform 1 Claw installation bracket 3, gantry-type group angle floating claw installation bracket 3 is provided with four telescopic mechanical arms 4, and floating claw 5 is installed on the telescopic mechanical arm 4 heads. The group frame aluminum profile pushing mechanism 2 includes a clamping cylinder 6 and a rotating clamping jaw 8, one end of the rotating clamping jaw 8 is movably connected to the clamping cylinder 6, and an elastic pressure head 7 is fixed at the other end. Corner conveying devices are installed on the four corners of the glass lift table 1, which are respectively used to transport the corners with barbs. When working, the corners are facing the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com