A kind of molding and drilling integrated molding method and automatic molding machine realizing the above method

An automatic molding machine and molding technology, which is applied in wood stamping, wood compression, wood processing equipment, etc., can solve the problems of personnel injury, cost increase, safety hazards, etc., and achieve avoidance of direct contact, mechanical safety and product quality improvement , the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

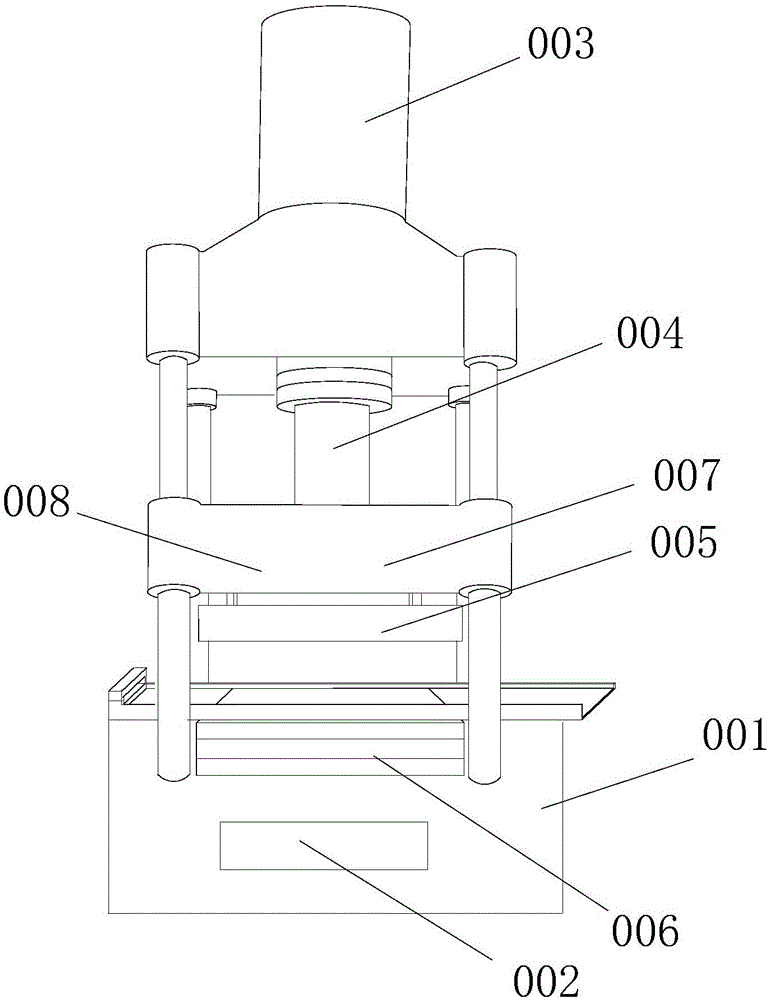

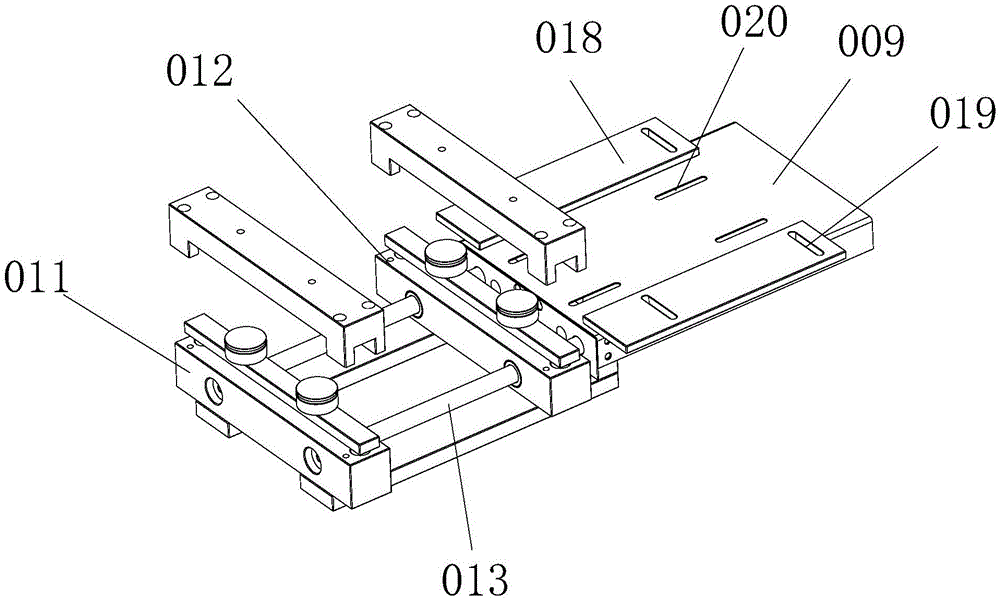

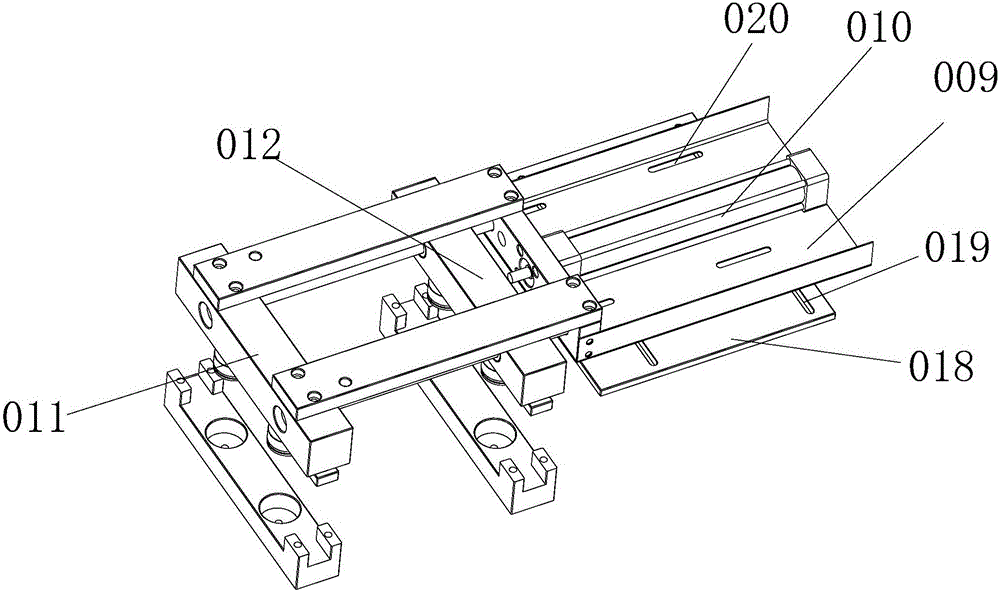

[0024] Figure 1 to Figure 3 A novel automatic molding machine according to the present invention is schematically shown.

[0025] According to one aspect of the present invention, there is provided a molding and drilling integral molding method, comprising the following steps:

[0026] (1), an automatic molding machine is set, and the automatic molding machine is composed of a control device and a regulating and controlling executive mechanism;

[0027] (2), described executive mechanism comprises the molding mechanism that realizes automatic molding, the automatic feeder that realizes automatic feeding and the punching mechanism that realizes punching are formed;

[0028] (3) Place the wooden raw material on the automatic feeder, and the wooden raw material can be continuously transported to the processing position through the automatic feeder, and the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com