hydraulic equipment

A hydraulic equipment, hydraulic technology, applied in the direction of brakes, bolts, etc., can solve problems such as the inability to guarantee repeatable quality, and achieve the effect of reducing the risk of assembly errors, small tolerances, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

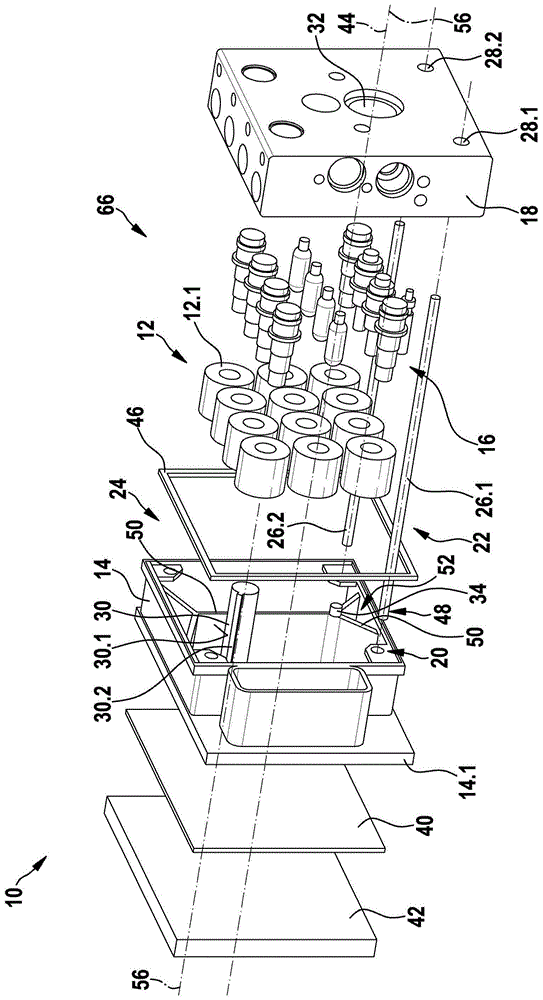

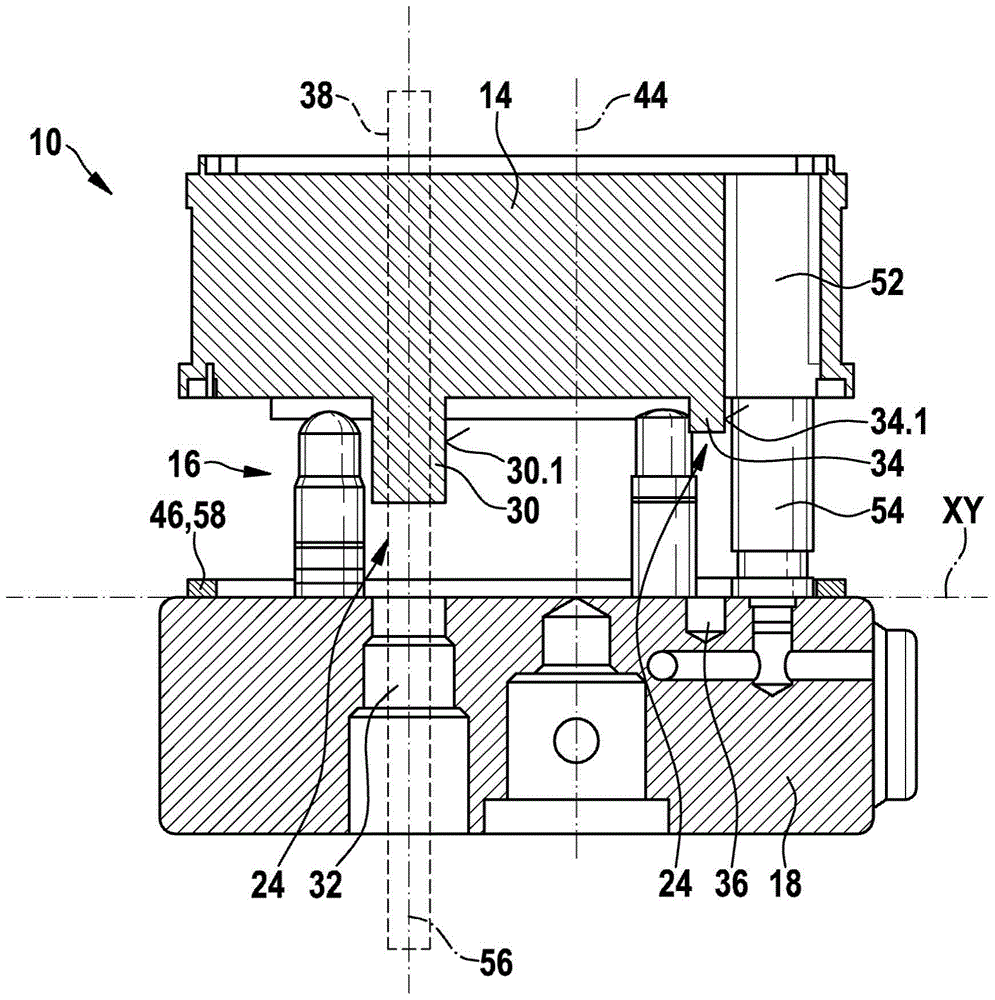

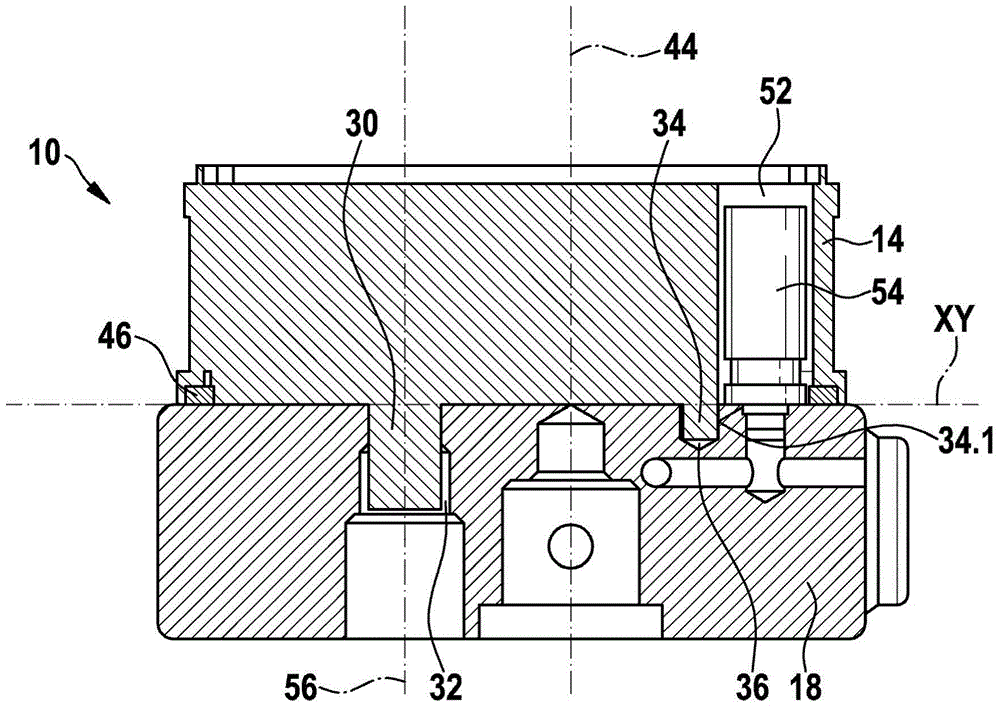

[0022] as available from Figures 1 to 4 As seen in FIG. 1 , the hydraulic system 10 includes a controller housing 14 carrying the electrical valve components 12 and a hydraulic block 18 carrying the hydraulic valve components 16 . In the exemplary embodiment shown, hydraulic system 10 is a component of a hydraulic system of a motor vehicle, for example an anti-lock brake system (ABS) or an anti-skid control system (ASR system) or an electronic stability program system (ESP system). The controller housing 14 is preferably formed as a simple plastic component and the hydraulic block 18 is preferably made of aluminum.

[0023] The hydraulic block 18 has various bores and channels in which in particular the hydraulic valve part 16 of the solenoid valve 66 is at least partially inserted and preferably packed. The electrical valve part 12 in the form of a coil 12 . 1 of the respective solenoid valve 66 is axially pushed onto the hydraulic valve part 16 .

[0024] A cover 42 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com