Polymer-ceramic hybrid coating composition and method for producing battery separation membrane using the composition

A separation membrane and composition technology, applied in battery pack parts, coatings, circuits, etc., can solve the problems of complex coating steps, reduced ion mobility, increased resistance, etc., to improve mechanical safety and improve heat resistance. performance, safety, and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

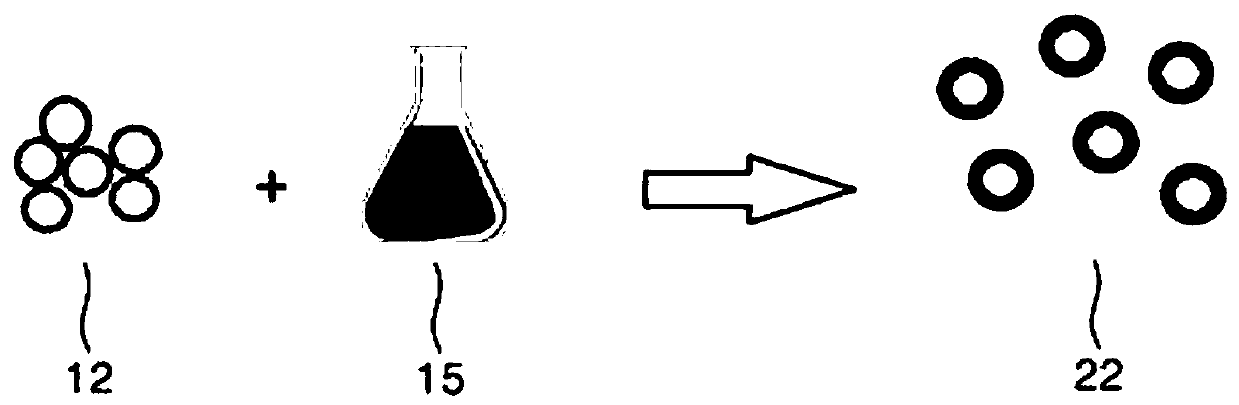

[0093] 96g of alumina (Al 2 o 3 ), 880g of acetone, 4.8g of vinyl triethoxysilane (Triethoxyvinyl Silane, TEVS) as a surface modifier, and 1g of hydrogen chloride were stirred for 4 hours to modify the surface of alumina .

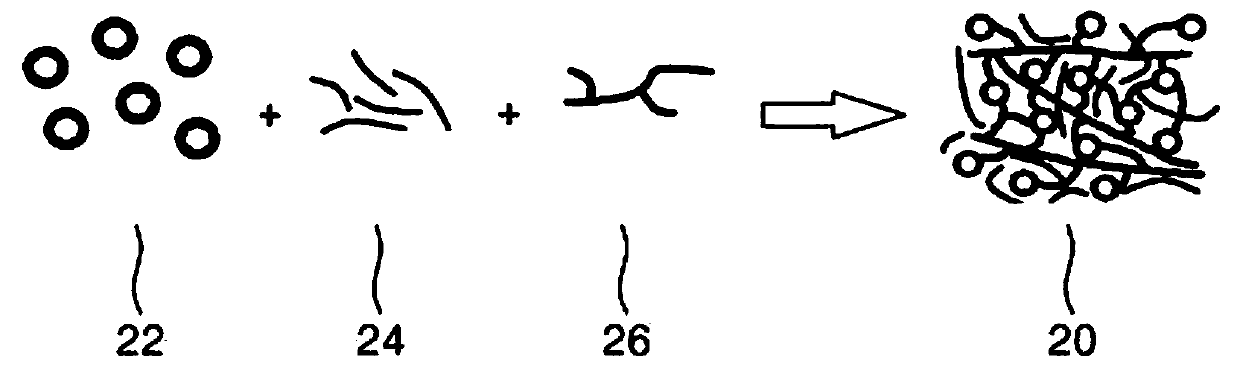

[0094] The aluminum oxide particles after the above-mentioned surface modification, 18 g of polyvinylidene fluoride (PVDF) polymer as a high molecular fluoropolymer, and 3 g of N-vinylpyrrolidone (N- Vinylpyrrolidone) and 3g of 1,4-butanediol dimethacrylate (1,4-Butanediol Dimethacrylate) and 0.01g of benzoyl peroxide (Benzoyl Peroxide, BPO) as a thermal initiator are mixed to produce A composition for coating a separation membrane is disclosed.

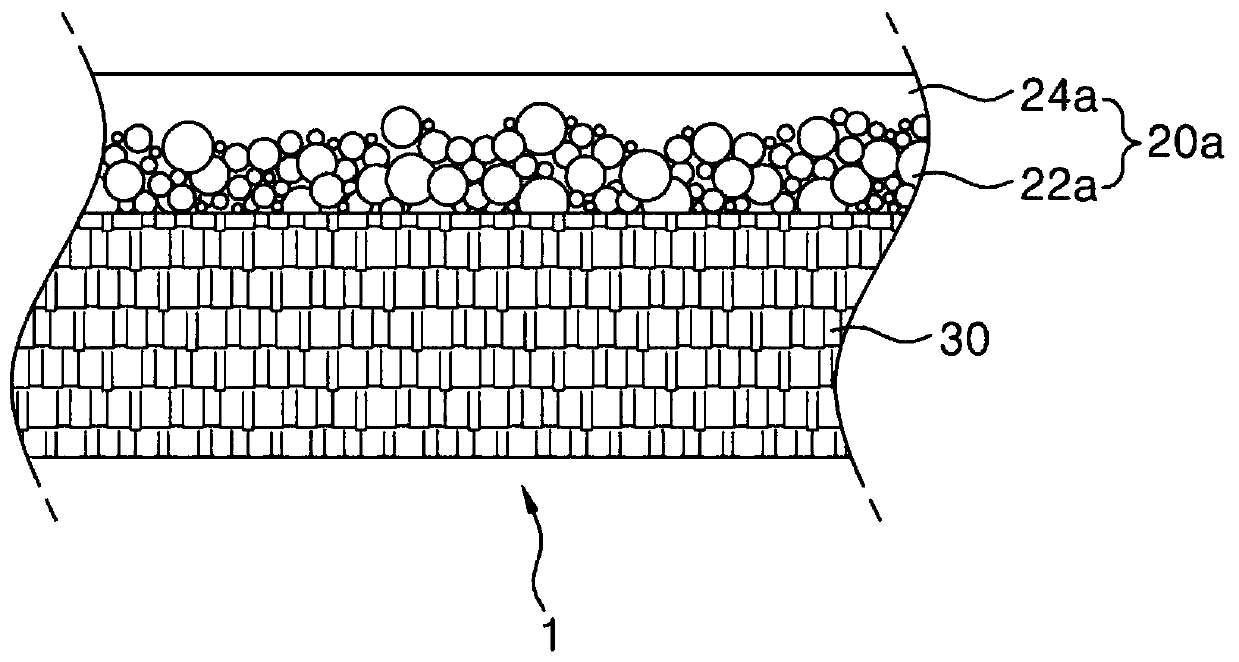

[0095] Next, the above composition for coating a separation membrane was applied to a thickness of 3 μm on one side of a 18 μm polyethylene-based film using a microgravuer. After the coating was completed, a crosslinking reaction was performed at a temperature of 70° C. for 10 minutes. Next, a hardening trea...

Embodiment 2 to 13

[0097] The separation membrane coating composition was produced by the same production method as in Example 1, but components with different conditions were used, and when producing the battery separation membrane, by using the compositions in Examples 2 to 13 respectively Coating was carried out to manufacture a separation membrane. Table 1 shows the comparison data of the separation membrane coating composition obtained in Examples 1 to 13 and the production method of the battery separation membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com