Intelligent crushing device for astaxanthin processing

A pulverizing device, astaxanthin technology, applied in the directions of transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low pulverization efficiency, difficult removal of equipment debris, and high powder temperature, and increase the stirring effect. , The effect of convenient cutting, stable and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

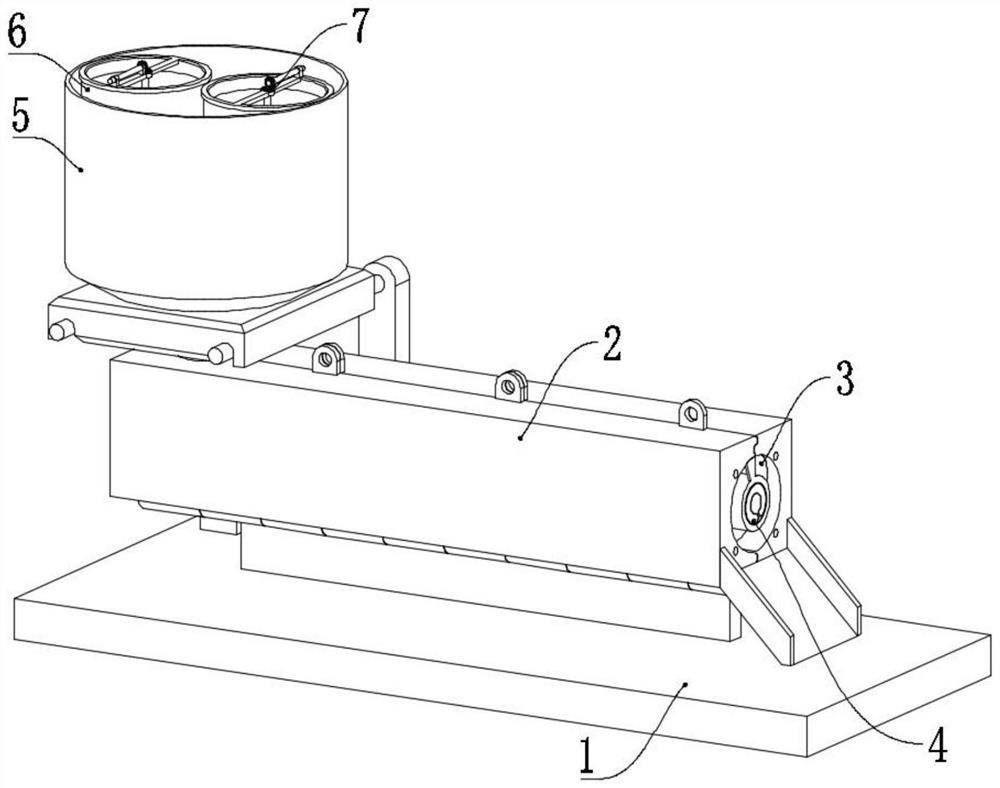

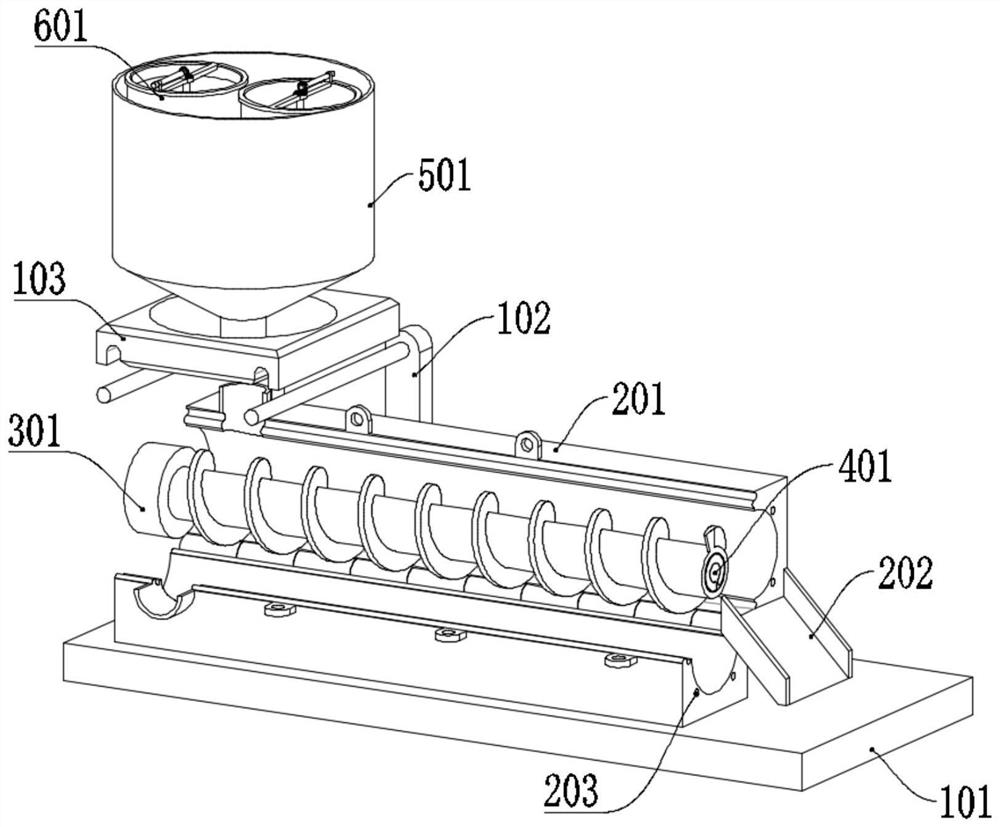

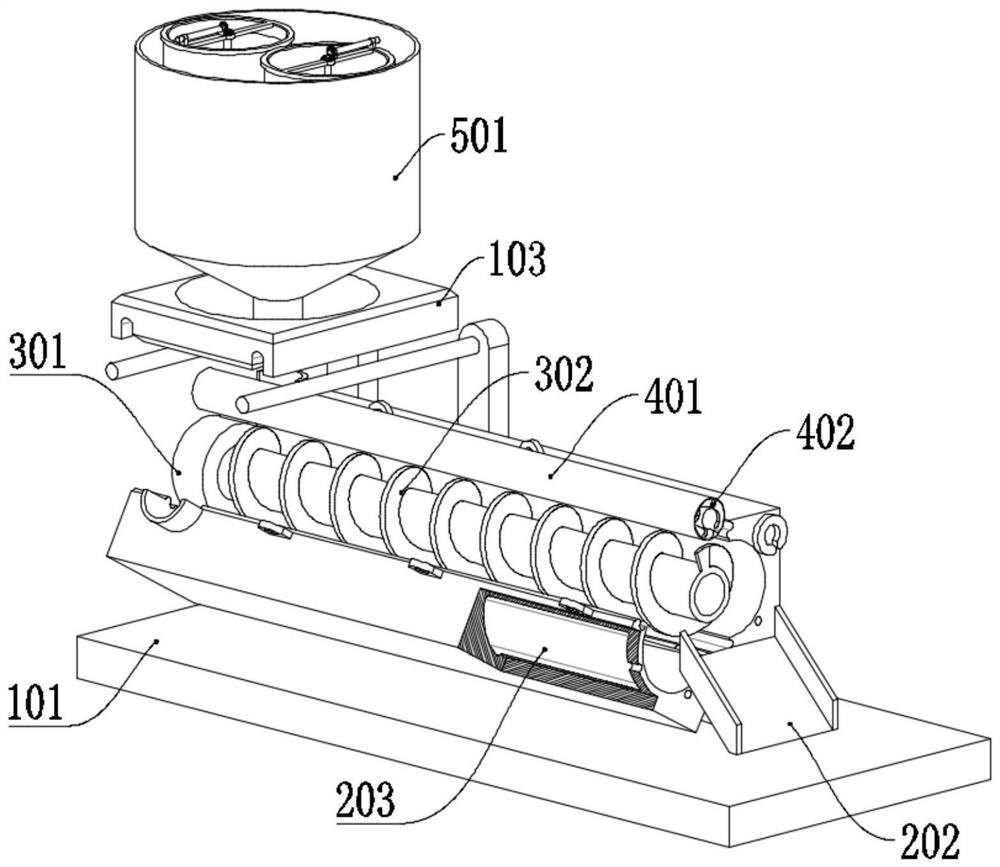

[0034] Example: Please refer to Figure 1 to Figure 9 :

[0035] The present invention proposes an intelligent crushing device for astaxanthin processing, comprising: an installation device 1; a feeding assembly 2 is arranged on the installation device 1, and the feeding assembly 2 includes: a feeding cylinder 201, and the feeding cylinder 201 is arranged It is two groups of front and back symmetrical structures, the rear lower material cylinder 201 is fixed on the installation device 1, and the front lower material cylinder 201 is hingedly installed on the rear side lower material cylinder 201, and the lower material cylinder 201 is set as front and rear symmetrical hinge connection The structure realizes the convenient disassembly of the lower material cylinder 201, and achieves the effect of cleaning the lower material cylinder 201. The symmetrical lower material cylinder 201 is spliced to form a cylindrical structure, and the middle position of the spliced complete low...

Embodiment 2

[0040] Embodiment 2: including: the internal rotation of the blanking assembly 2 is equipped with a blanking structure 3, the inside of the blanking structure 3 is provided with a cooling assembly 4, the upper left side of the installation device 1 is provided with a mixing device 5, and the bottom of the mixing device 5 In contact with the blanking assembly 2, a bearing assembly 6 is arranged on the upper end of the mixing device 5, a rotating assembly 7 is arranged inside the carrying assembly 6, a crushing assembly 8 is arranged on the rotating assembly 7, and a cleaning assembly is arranged at the outer end of the rotating assembly 7. Component 9.

[0041] Furthermore, according to an embodiment of the present invention, as Figure 5 As shown, the mixing device 5 includes: a mixing bucket 501, the mixing bucket 501 is installed on the fixed plate 103 of the installation device 1, the bottom of the mixing bucket 501 is set as a conical structure, and the bottom surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com