Sewer pipeline filter having automatic crushing function

A pipeline filter and functional technology, applied in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve the problems of large pieces of debris falling into the pipeline, debris that cannot be crushed, and sewer pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

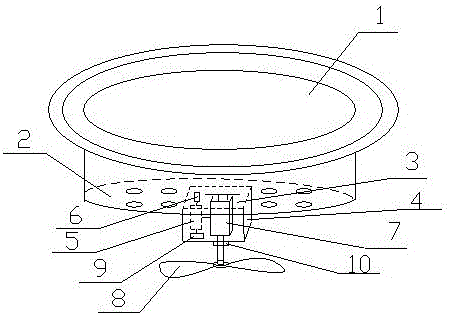

[0021] Such as figure 1 As shown, the present invention designs a sewer pipe filter with automatic crushing function, including a filter cartridge body 1 and a bottom cover 2 provided with filter holes 3, the bottom of the bottom cover 2 is fixed with a waterproof box 4 and is arranged on a waterproof The crushing mechanism in the box 4, the crushing mechanism includes a battery 9, a microcontroller 5, a wireless signal receiver 6, a motor 7 and a rotating blade 8; the battery 9, the wireless signal receiver 6 are connected to the microcontroller 5 respectively The microcontroller 5 is connected with the motor 7; the rotating shaft of the motor 7 stretches out of the waterproof box 4 and is fixedly connected with the center of the rotating blade 8; the signal received by the wireless signal receiver 6 is sent to the microcontroller 5, and the The microcontrolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com