Shaft hole cooling and lubrication system

A cooling lubrication and shaft hole technology, applied in the field of cooling and lubrication, can solve the problems of difficulty in meeting the requirements of the micro power generation system in the aviation field, the limited space of the micro high-speed generator, and the increase of the size and weight of the generator, so as to achieve a simple structure and improve the cooling effect. , The effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

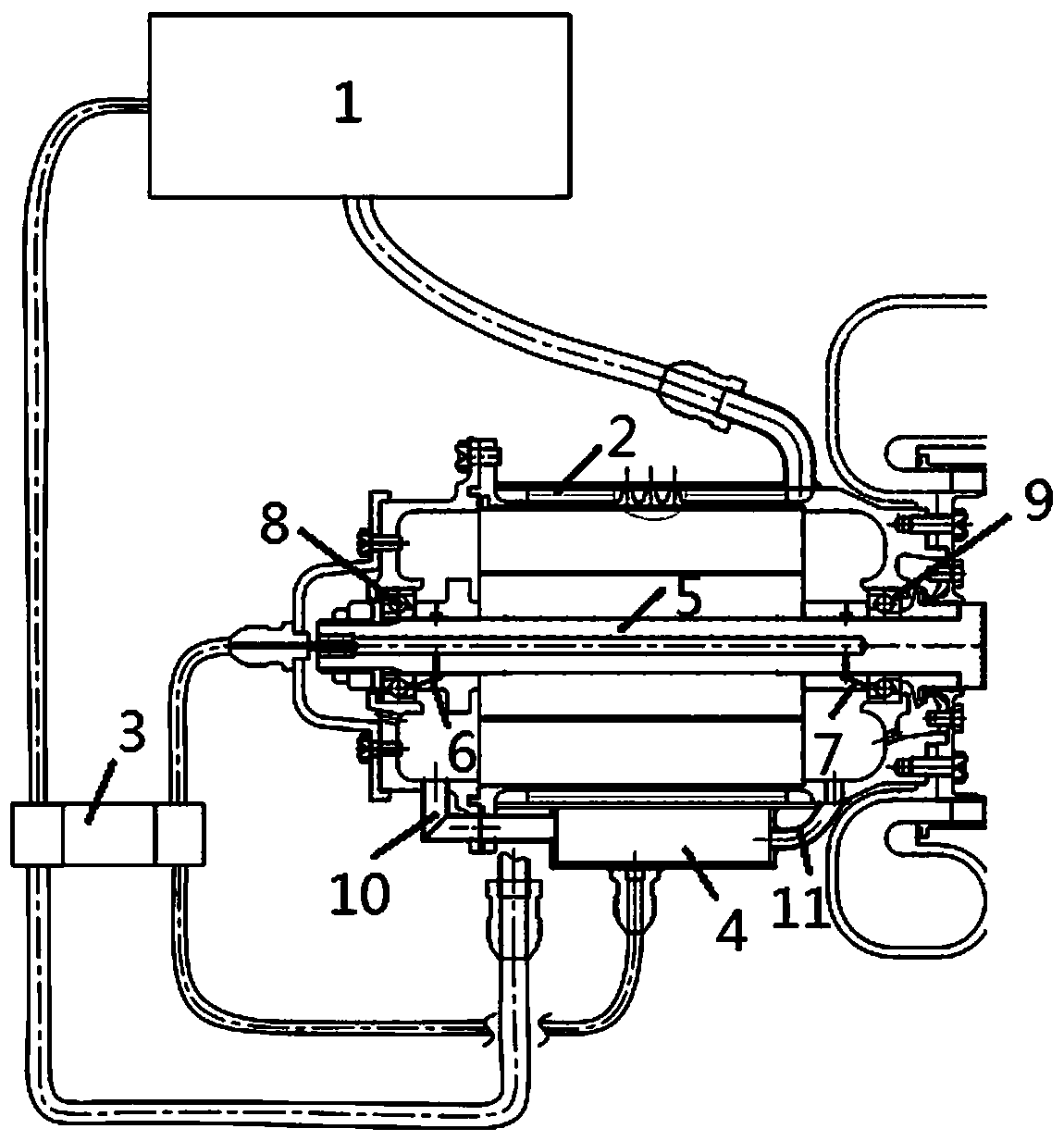

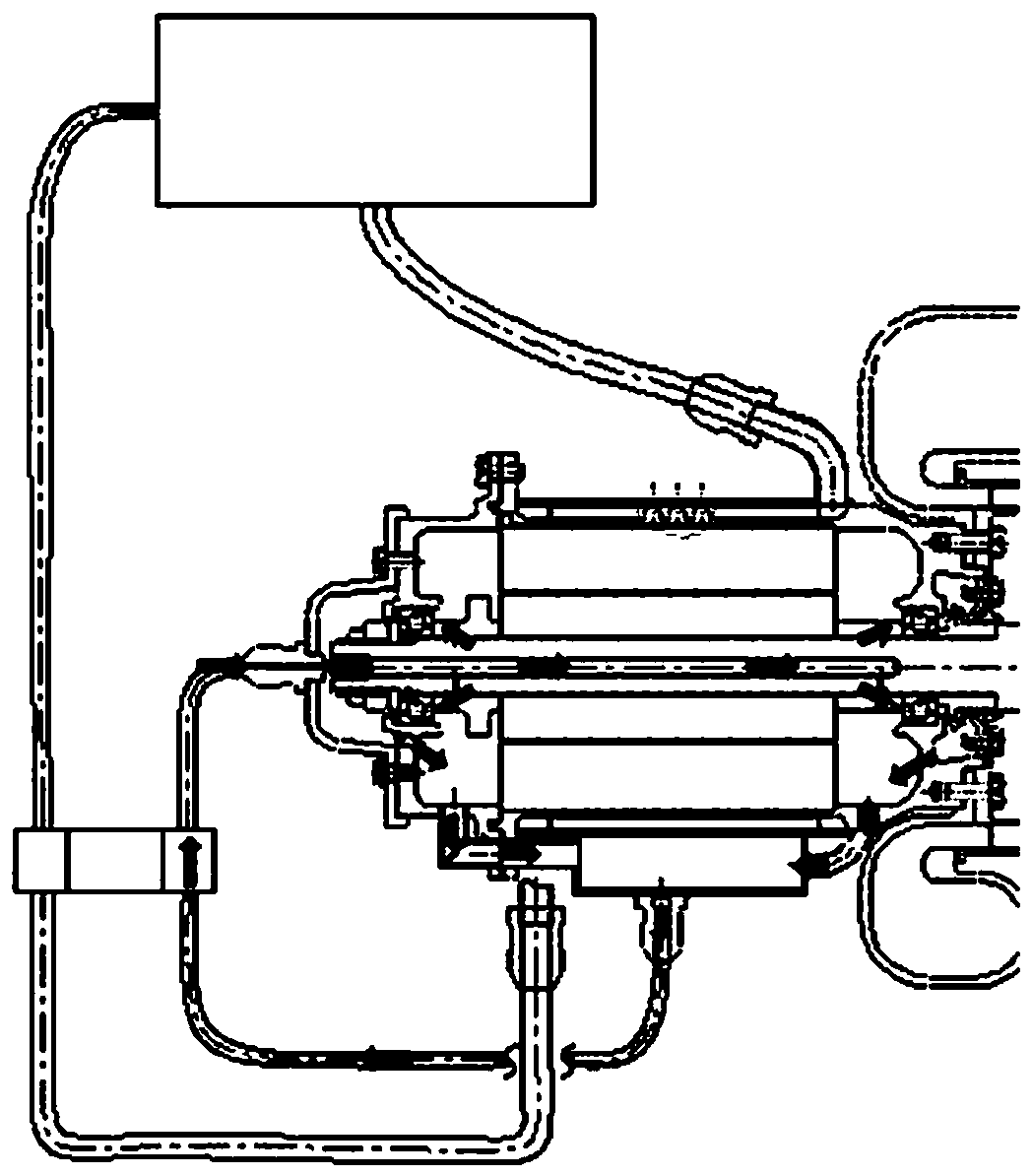

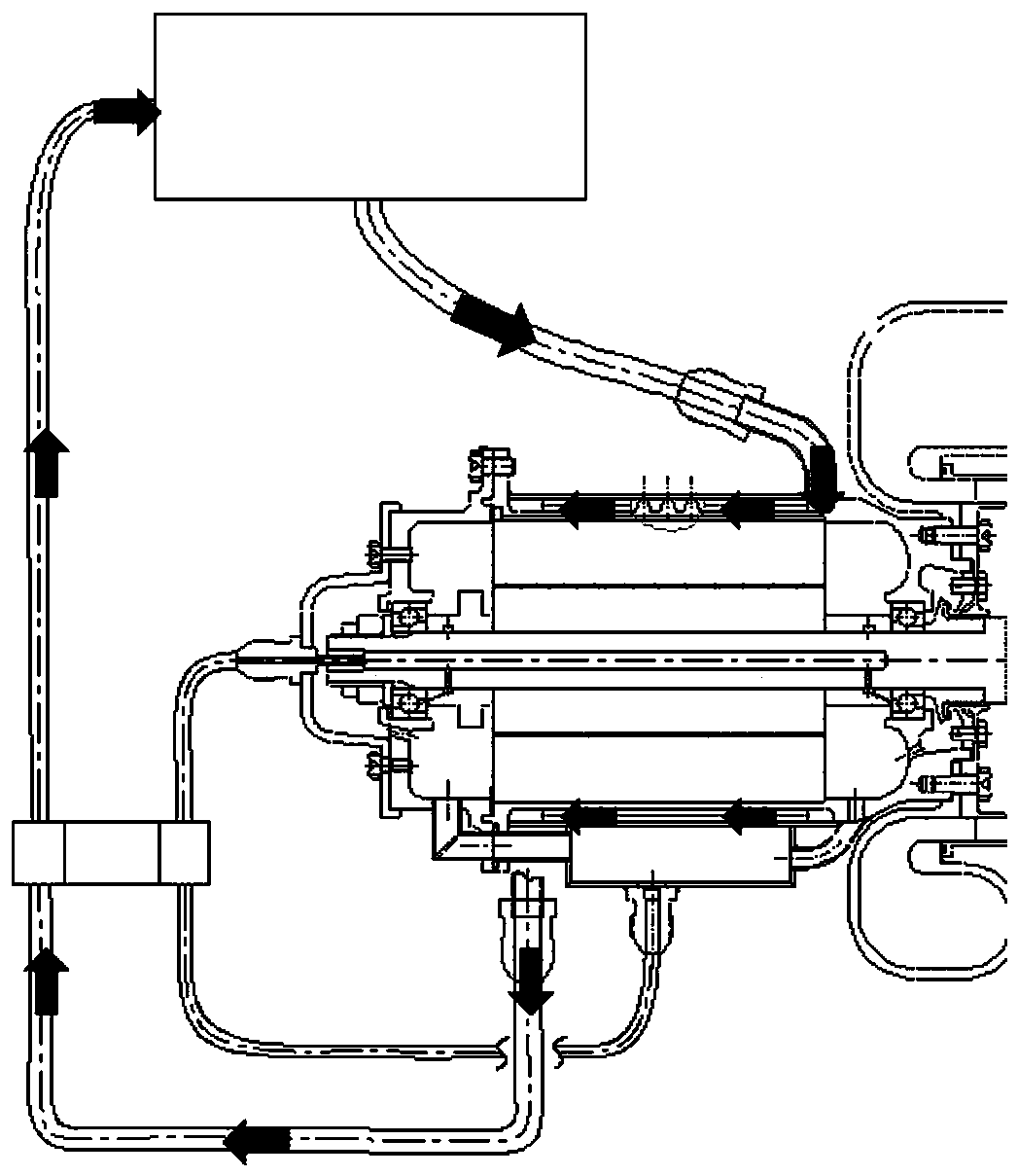

[0029] As shown in the figure, the shaft hole cooling and lubricating system is composed of an internal circulation oil circuit and an external oil circuit. The internal circulation oil circuit includes a double-head oil pump 3, a lubricating oil tank 4, a rotary static joint, and a rotating shaft 5; the double-head oil pump 3 passes through the pipe The oil tank 4 and one end of the rotary static transfer joint are respectively connected to each other, and the other end of the rotary static transfer joint is connected to the rotating shaft 5. The two ends of the rotating shaft 5 are respectively provided with a front pressing plate 6 and a rear pressing plate 7. The front pressing plate, the rear pressing plate and the shaft There is a diversion hole on the top, the diversion hole is connected to the front and rear oil return chambers, and the front and rear oil return chambers are connected to the lubricating oil tank through the front oil return circuit 10 and the rear oil re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com