Multi-flow-channel type efficient heat dissipation water cooling row

A multi-channel, high-efficiency technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problem of ineffective cooling and heat dissipation with water, and achieve the effect of good heat dissipation and extended flow stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

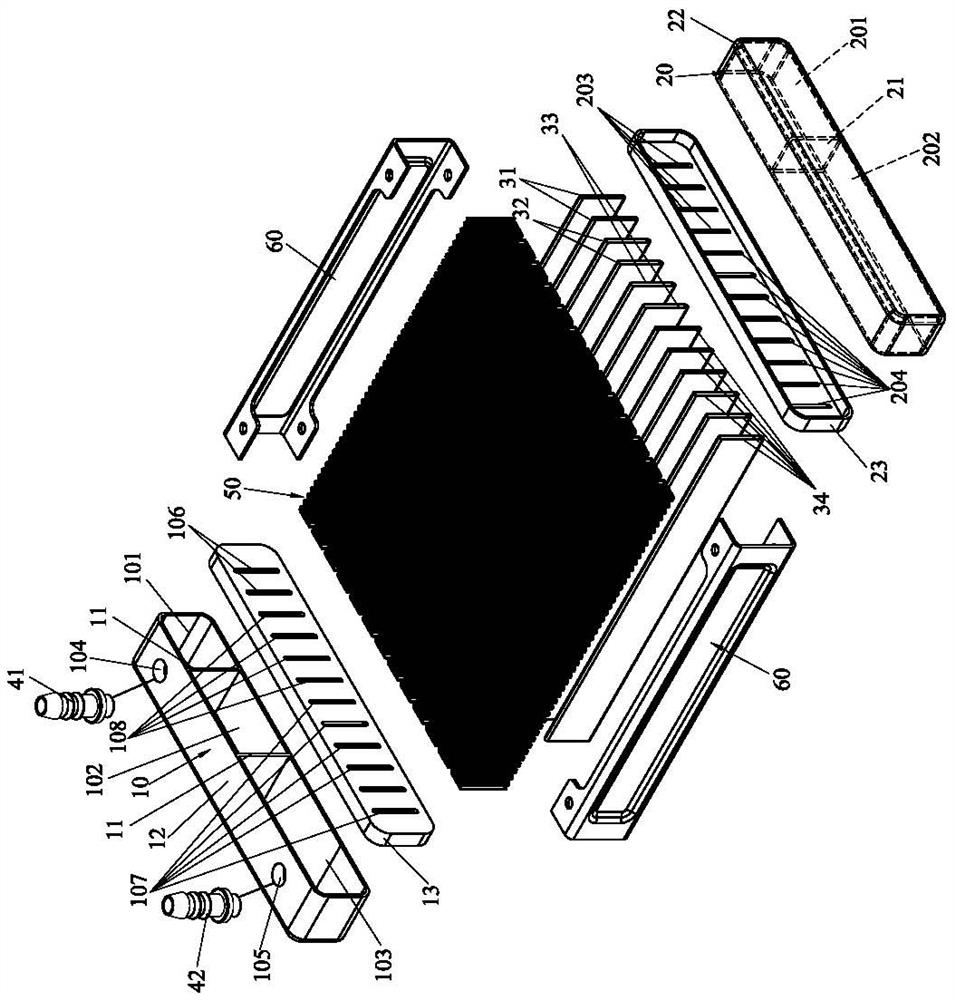

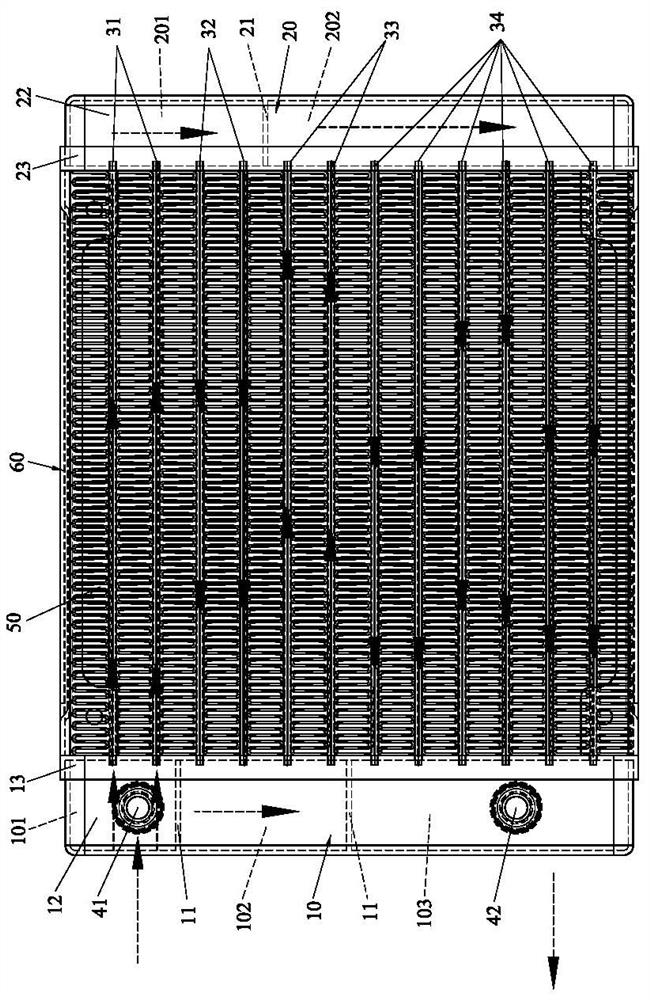

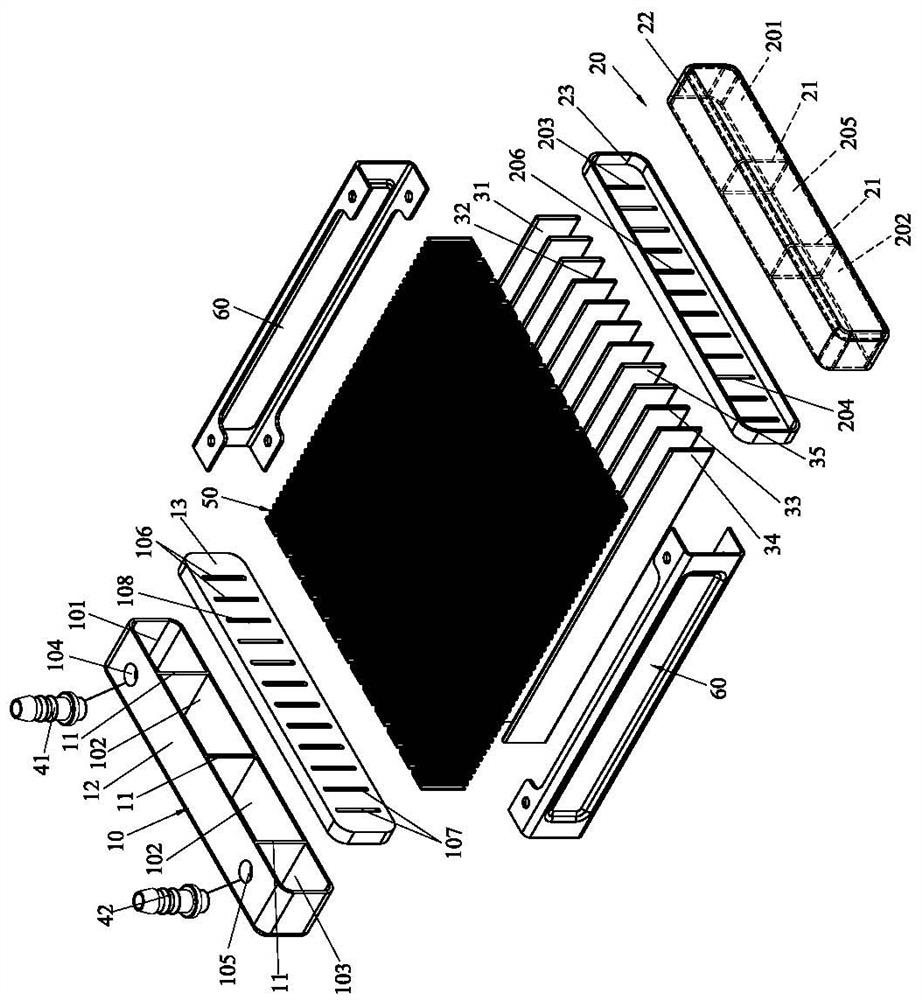

[0044] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including the distribution tank 10, the sump 20, the first row pipe 31, the second row pipe 32, the third row pipe 33 and the fourth row pipe Exhaust pipe 34.

[0045] The shunt tank 10 is made of heat-dissipating metal material, and a plurality of first shunt water baffles 11 are arranged in the shunt tank 10 to form a water inlet chamber 101, a transition chamber 102, and a water outlet chamber 103 to separate the inside of the shunt tank 10, A water inlet 104, a water outlet 105, a first installation groove 106, a second installation groove 107, and a third installation groove 108 are provided on the distribution tank 10, and the water inlet 104 and the first installation groove 106 are connected to the water inlet chamber. The chamber 101 , the water outlet hole 105 and the second installation groove 107 are all connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com