A high-efficiency continuous vacuum stripping system for removing dioxane

A technology of vacuum stripping and dioxane, applied in vacuum distillation, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of low efficiency, reduce energy consumption, increase residence time, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

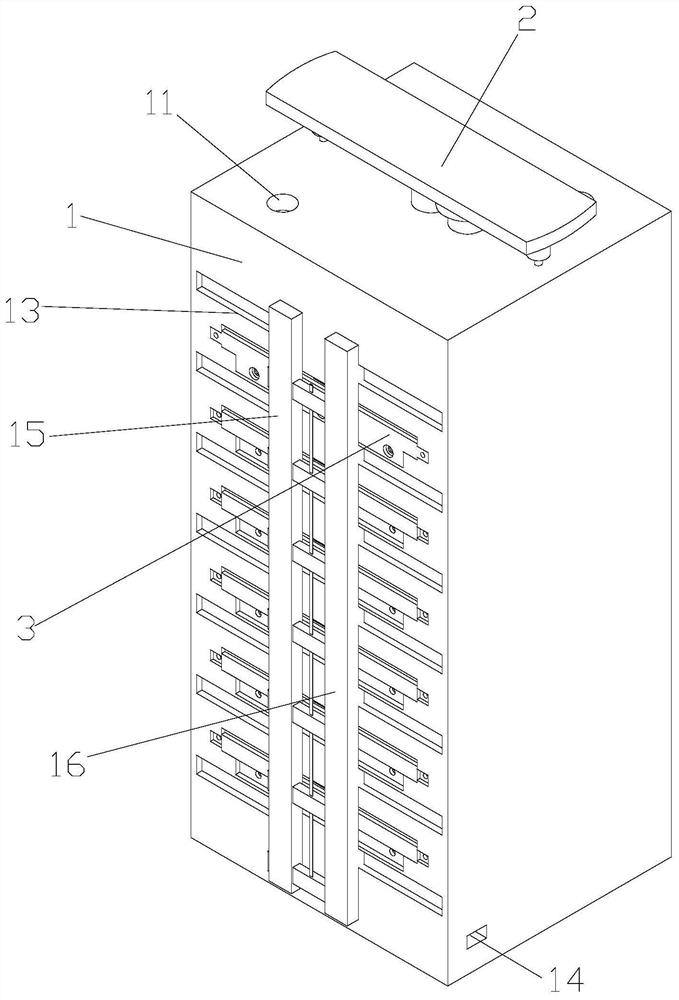

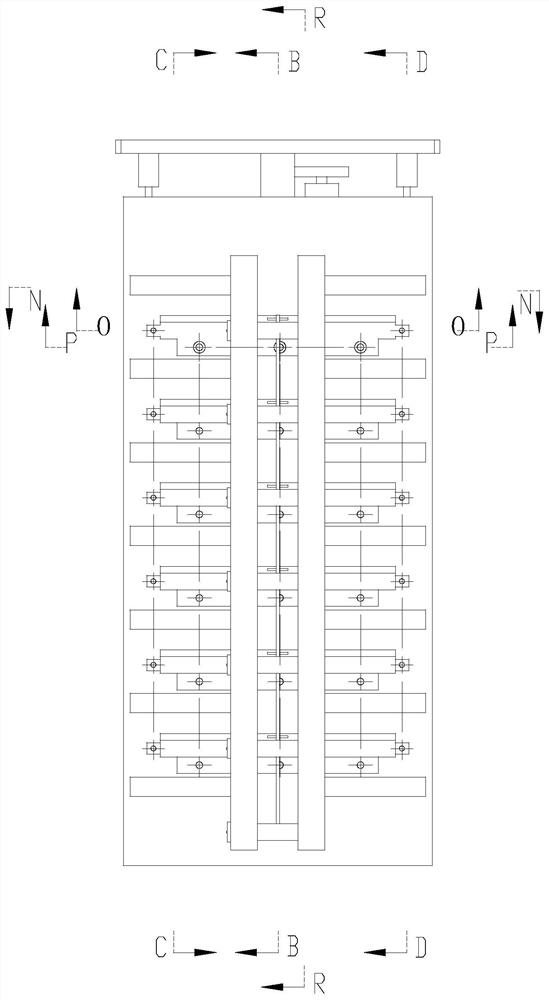

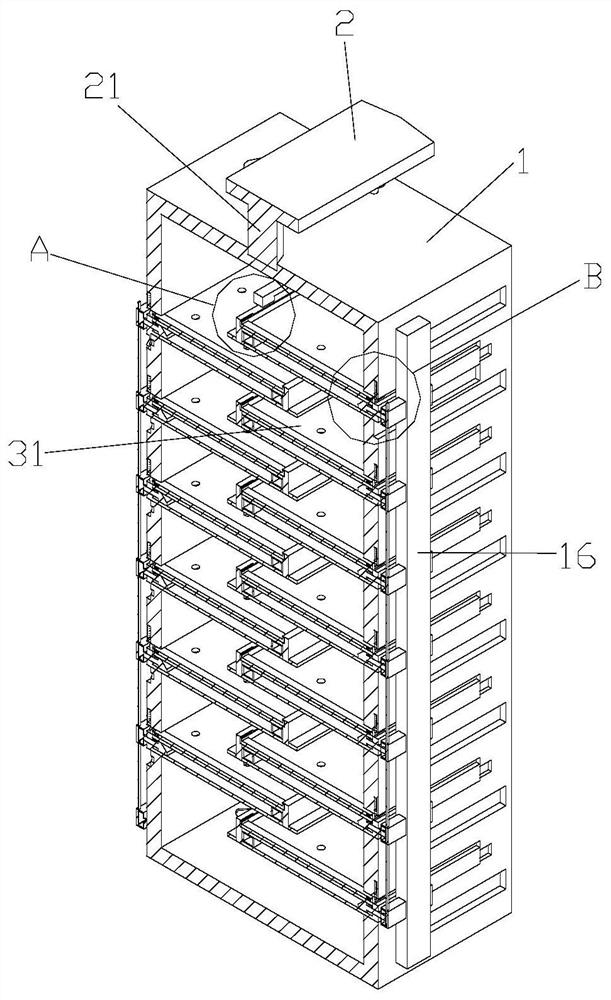

[0044] Such as Figure 1-30 As shown, a high-efficiency continuous vacuum stripping system for removing dioxane includes a stripping tower 1 and a tray 3 located in the stripping tower 1, and a heating module is arranged in the stripping tower, so The heating module described above has the same structure as the heating mechanism in the prior art, so it will not be repeated here; when the heat of the product is not enough, the product can be heated through the heating module, so as to provide heat supply for the dedioxane treatment of the product; The top of the stripper 1 is provided with a liquid inlet 11 and a gas outlet 12, the bottom of the stripper 1 is provided with a liquid outlet 14, and the side wall of the stripper 1 is provided with a plurality of plates 3 The matching first installation groove, the column plate 3 is penetrated in the first installation groove, and the stripper 1 is provided with a mounting bracket for fixing the column plate 3 in the first installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com