Air filtering unit, railway vehicle and air filter thereof

An air filter and filter unit technology, which is applied in vehicle parts, railway vehicle heating/cooling, brakes, etc., can solve the problems of braking system and wind system influence, short flow stroke, etc., and achieve obvious condensation effect and reduce Moisture, the effect of improving the filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

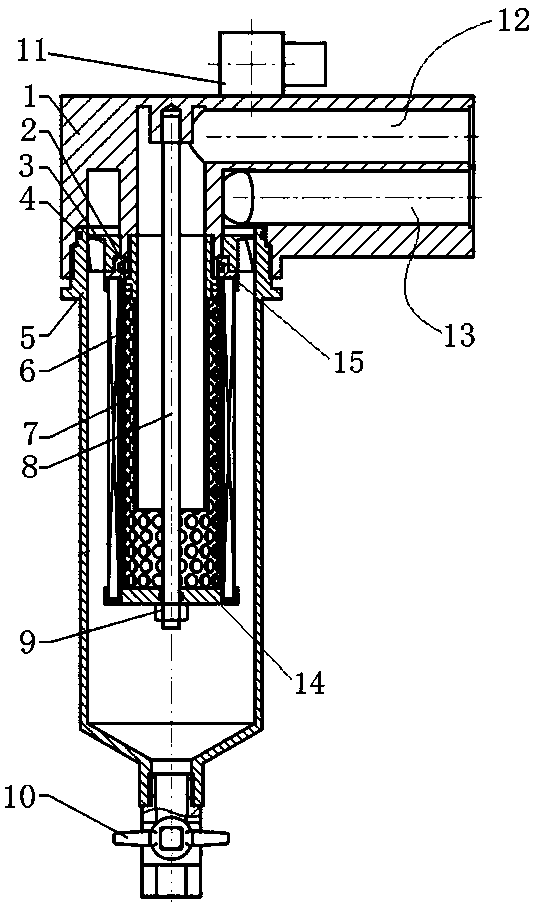

[0037] The air filter in the present embodiment is the air filter that rail vehicle is used, as figure 1 and figure 2 As shown, the air filter includes an upper casing 1, and the upper casing 1 is provided with an air inlet passage 13 and an air outlet passage 12 isolated from each other. In this embodiment, the inlet of the air inlet passage 13 and the outlet of the air outlet passage 12 are located on the upper The same side of the shell is very convenient for docking installation with valves and other structures. Depend on figure 1 It can be seen that the inlet is located below the outlet. Both the air inlet channel 13 and the air outlet channel 12 include a transverse section and a vertical section, and the transverse section of the air inlet channel is located below the transverse section of the air outlet channel. The vertical section of the air intake channel is an annular channel, and the vertical section of the air intake channel and the vertical section of the ai...

specific Embodiment 2

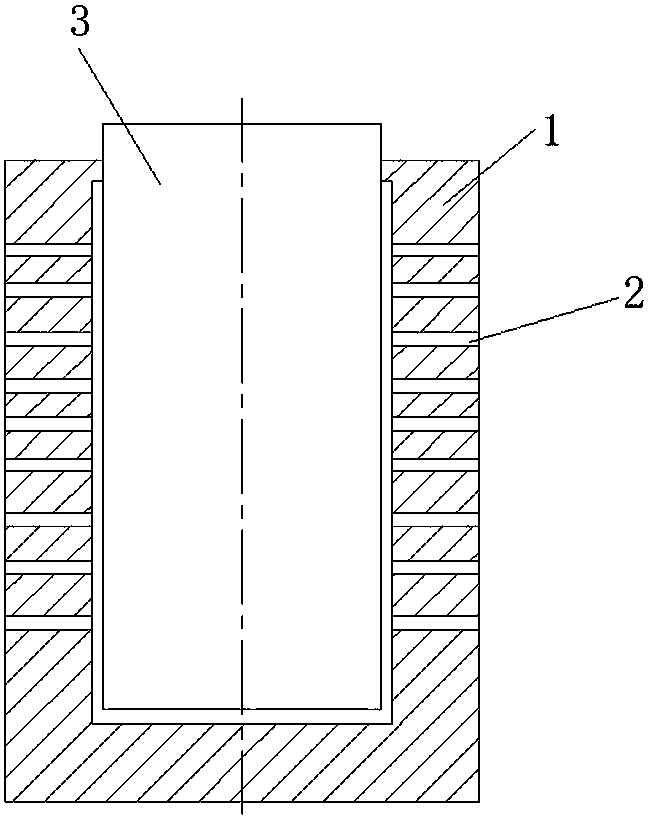

[0045] Such as image 3 As shown, the main difference from the above embodiment is that in this embodiment, the filter hole is not provided at the bottom of the barrel of the filter element 1, and only the filter hole 2 is opened on the barrel wall of the filter element 1, and there is an exhaust pipe cavity in the filter element 1. , a condensation guide pipe 3 is arranged in the exhaust pipe cavity, the air enters the lower end inlet of the condensation guide pipe 3 after passing through the filter hole 2, and then is discharged from the upper end outlet of the condensation guide pipe 3.

[0046] The outer peripheral surface of the condensation guide pipe is used to guide the air at the wall of the filter element barrel into the lower opening of the condensation guide pipe to form a guide outer peripheral surface. The lower end opening of the condensation guide pipe forms an air inlet, and the upper end opening forms an exhaust port. .

[0047] In this embodiment, "up" and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com